Gasket assembly for plate heat exchanger

A plate heat exchanger, heat exchanger technology, applied in heat exchange equipment, fixed plate conduit components, heat exchanger types, etc., can solve problems such as manufacturing difficulties, eliminate dead zones, reduce the risk of bacterial reproduction, reduce The effect of the risk of bacterial reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

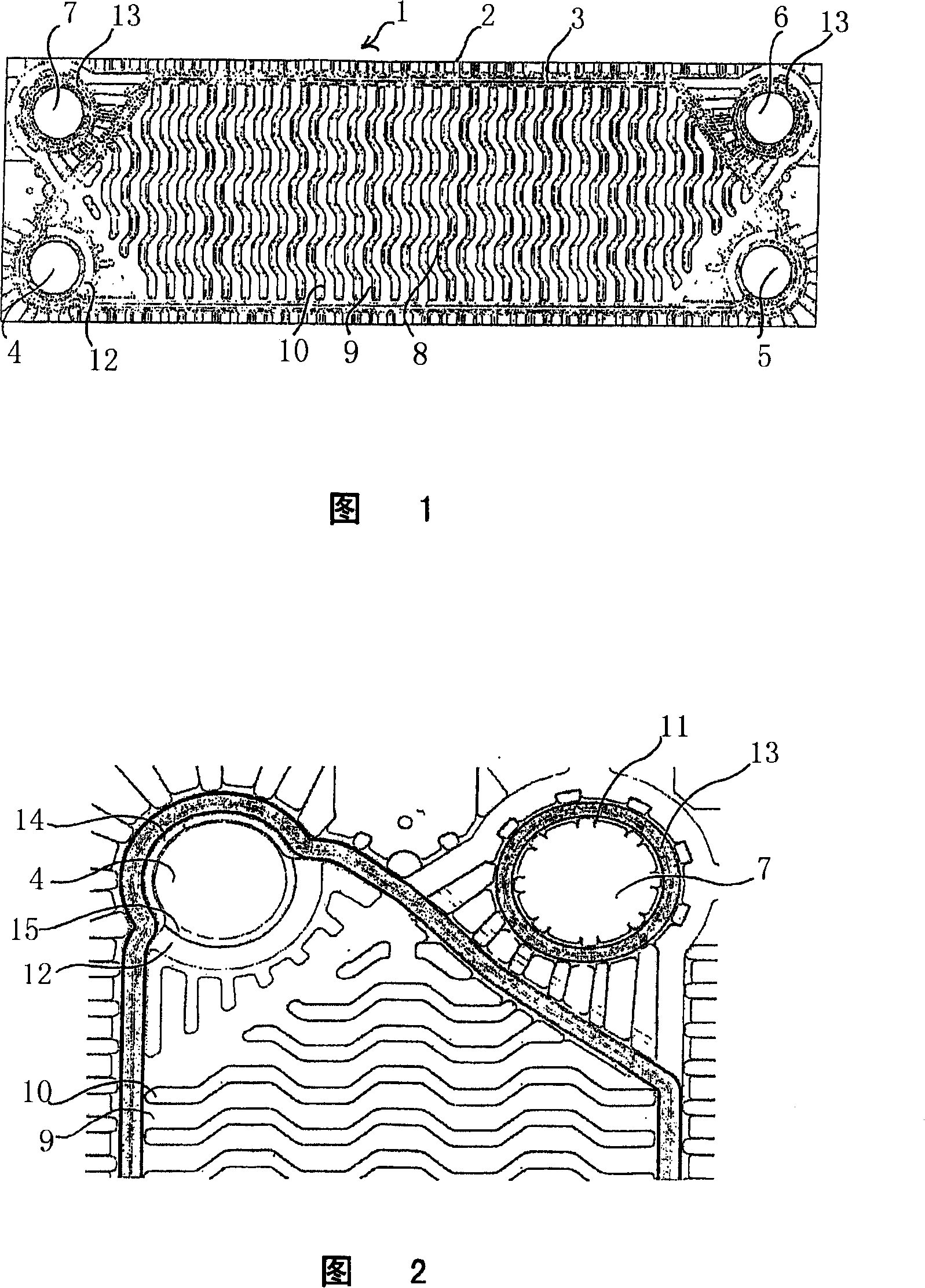

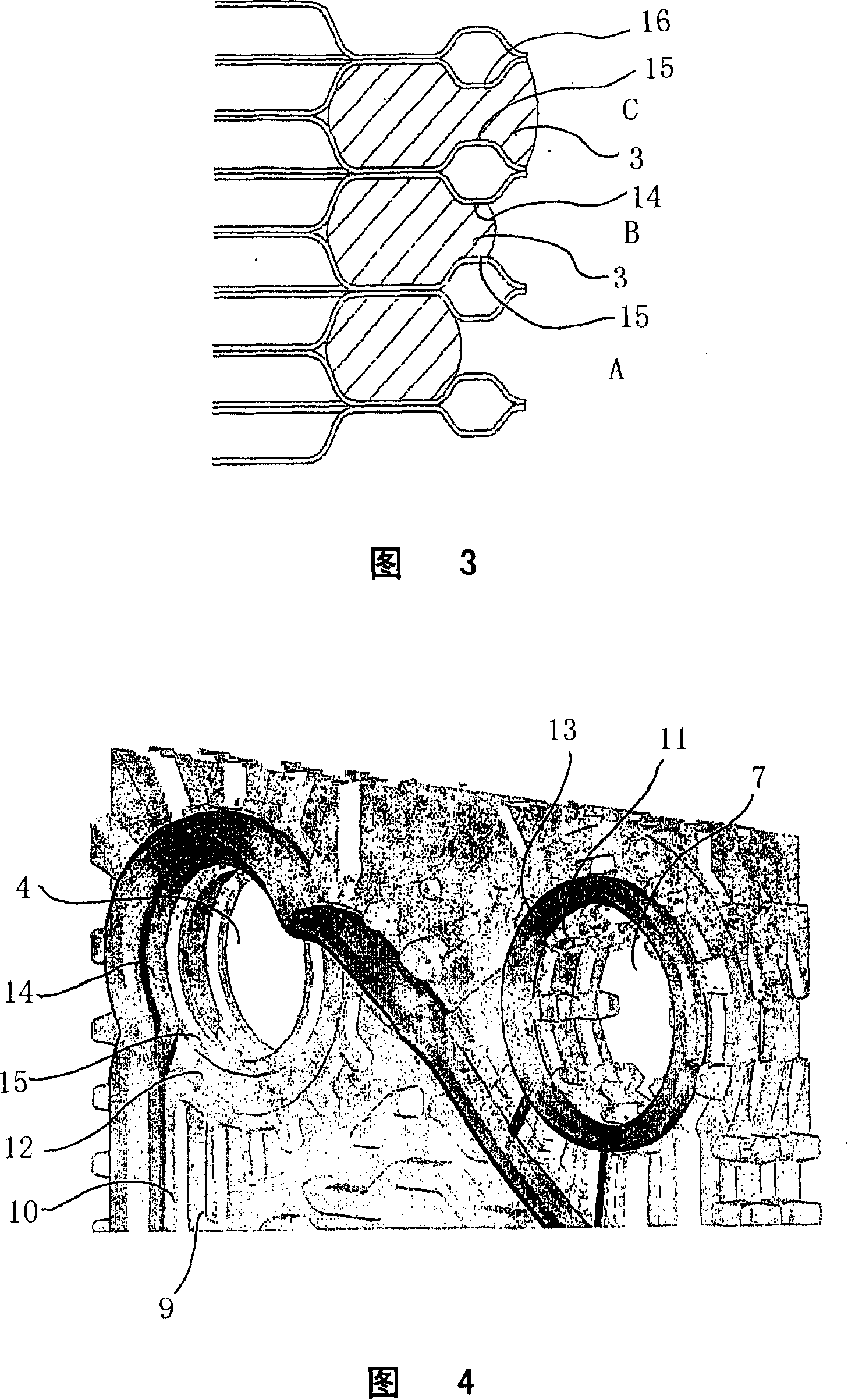

[0022] Figures 1 and 2 show a cassette 1 comprising two heat exchanger plates 2 permanently connected together and a gasket 3 according to the invention. The two heat exchanger plates 2 have at least 4 inlets and outlets forming the inlets and outlets 4, 5, 6, 7 and a heat transfer surface 8 with several ridges 9 and recesses Valley 10. Cassette 1 can be made by welding or brazing, whereby the two heat exchanger plates 2 are permanently joined together along their periphery and around at least two of the inlets 4 , 5 .

[0023] The heat exchanger plates 2 are shaped in such a way that there are as few contact points as possible between two mutually adjoining cassettes, preventing the trapping of fibers and solid material that the fluid may contain in the spaces between the cassettes. According to the invention, the heat exchanger plates are also designed in such a way that the contact points for the necessary mechanical support are mostly produced only on the inner side betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com