Composite scanning filling method for quick forming machine

A technology of composite scanning and filling method, which is applied in the field of composite scanning and filling to achieve the effect of improving the precision of parts and increasing the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

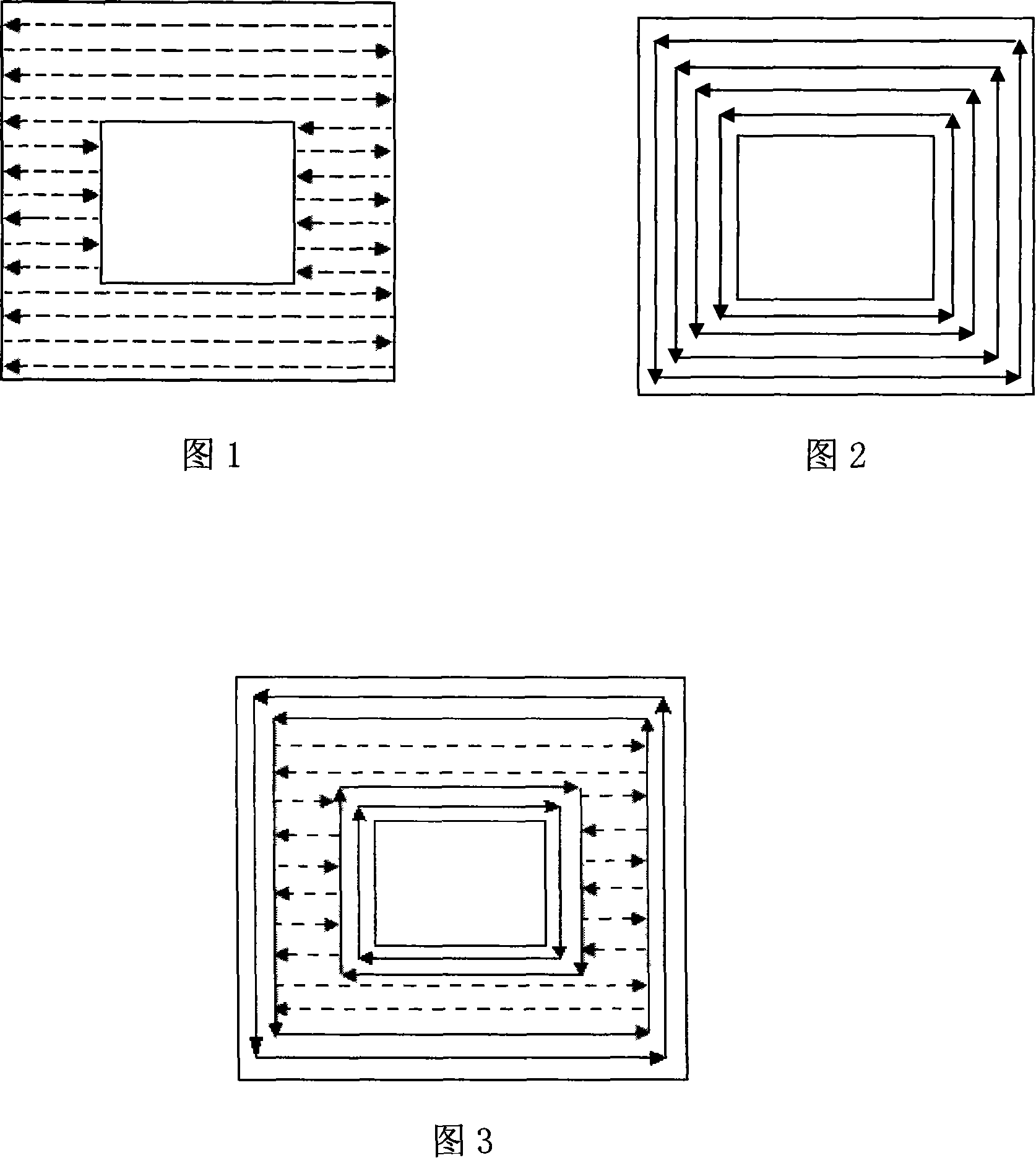

[0010] As shown in the figure, in the rapid prototyping layer process planning, the boundary between the contour offset scanning area and the partition scanning area is firstly determined by computer division, and then the scanning path area is divided for the two scanning areas, and finally the scanning forming is started: The boundary is used as the reference, and the inner and outer contour areas are filled with contour offset, and in other solid areas, partition scanning is used. During scanning, in order to avoid warping and deformation due to the consistent shrinkage stress direction of the scanning lines, an angle of 90° is staggered between the scanning directions of two adjacent sections.

[0011] The area division method adopted in this embodiment is to combine the filling line segments according to the arrangement order of the scanning line intersections, so as to directly form a monotonous filling area. Since we have ensured that the number of intersection points o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com