Dust-free blackboard eraser

The technology of a blackboard eraser and bottom board, which is applied in the field of teaching equipment, can solve the problems of high cost, impossibility of popularization, inconvenient use, etc., and achieve the effect of low cost, simple structure and easy popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

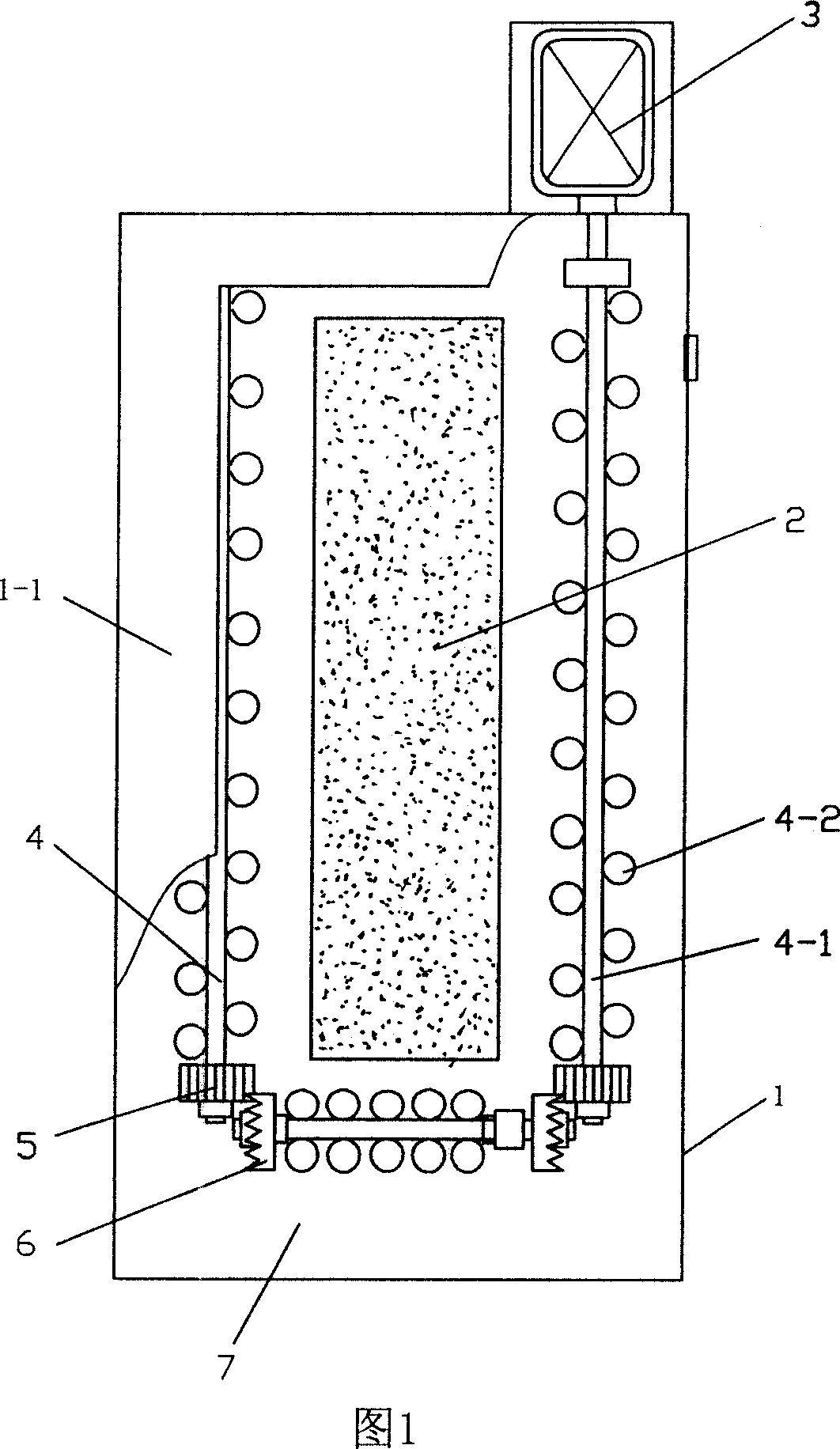

Embodiment 1

[0012] Shell 1 of the present invention can adopt plastics to make, and shell 1 is rectangular box body, and front four periphery is provided with the square frame shape cover plate 1-1 that can disassemble freely, and the lower end of shell 1 is ash chamber 7, and the bottom of shell 1 The end face is set as a push-pull open type movable plate, which can easily pour out the chalk dust stored when wiping the blackboard. The hair wiping block 2 is made up of a wiping block body and a hair wiping body, and the wiping block body is made of a hard material. Installed in the middle of the bottom plate of the inner cavity of the shell 1, the hair wiping body is made of woolen cloth with strong adsorption and good wiping effect, and is glued to the front surface of the wiping block body with glue, the hair wiping block 2 and the wiping block 2 Correspondingly, there is a rectangular battery slot and a battery cover on the bottom plate of the shell 1. The battery slot is connected with...

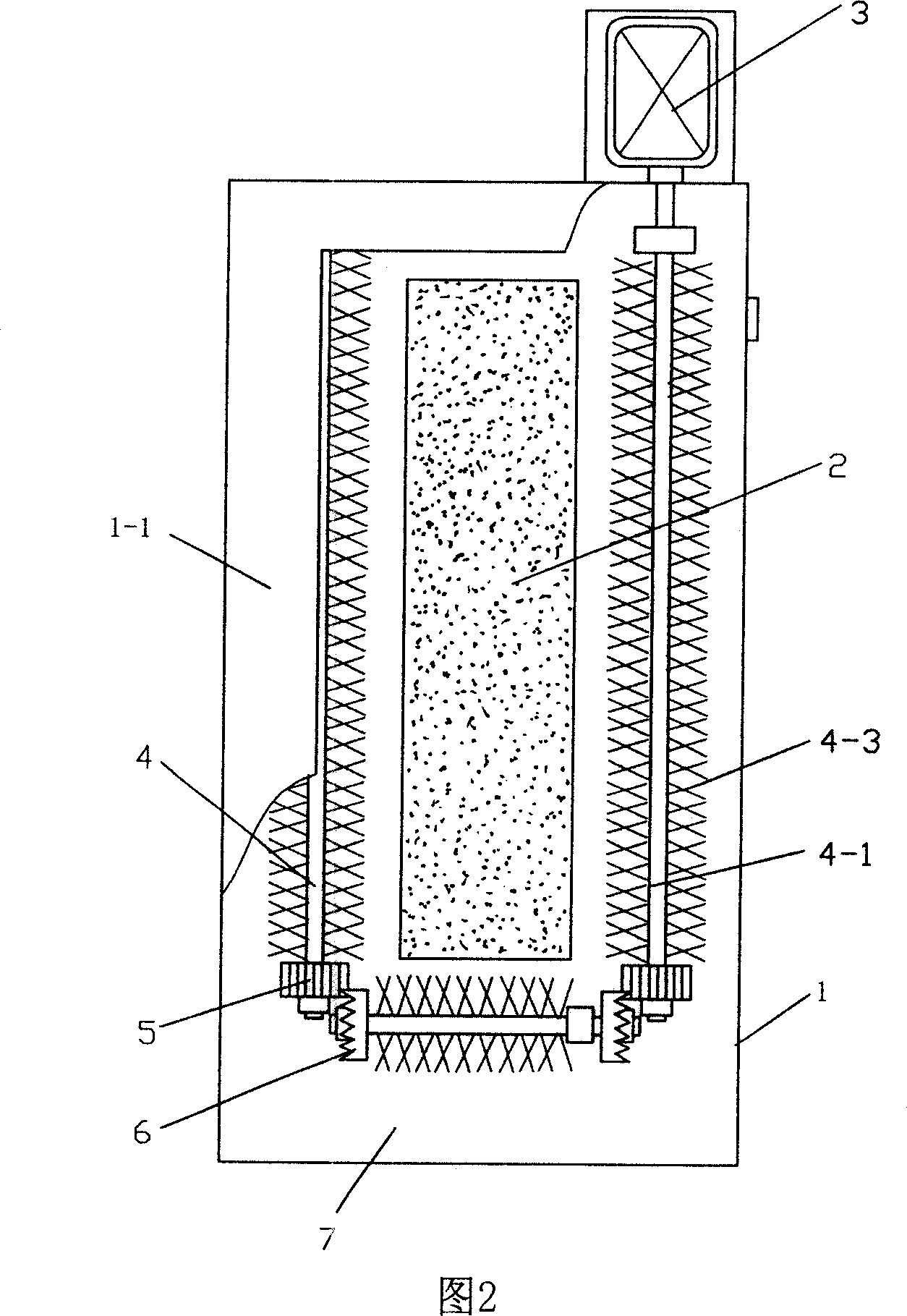

Embodiment 2

[0014] It is basically the same as Example 1, the difference is that the brushing block and the brushing body of the brushing block 2 are pasted together by Velcro, which can be easily removed to clean the dust in the brushing body, and there are four dust-stopping strips 4 , respectively fixed on the left and right sides and the upper and lower inner cavity floor of the housing 1 by the bearing seat 2, the gray bar 4 is composed of the roller 4-1 and the brown hair arranged on the roller 4-1 5-3 composition, the lower end of the left gray bar 4 and the upper and lower ends of the right gray bar 4 are equipped with transmission gears 5 respectively, and the upper gray bar 4 corresponds to the right gray bar 4 One end and the two ends of the gray bar 4 below are equipped with disc gear 6 respectively, and other are with embodiment 1.

Embodiment 3

[0016] It is basically the same as embodiment 1, the difference is that there are two gray-blocking strips 4, and the two gray-blocking strips 4 are respectively fixed on the inner cavity bottom plate of the left and right side shells 1 of the brushing block 2 by bearing seats, The upper and lower ends of the two gray bars 4 are respectively provided with transmission gears 5, and the lower ends of the two gray bars are connected by a transmission shaft. Disc gear 6 is linked with the transmission gear 5 of the left and right side gray bars 4 lower ends, and others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com