Speed changing driving device for special four-wheel offroad vehicles

An off-road vehicle, variable-speed drive technology, applied in control devices, vehicle components, transportation and packaging, etc., can solve the problems of difficult assembly and maintenance, complex structure, etc., and achieve the effects of easy maintenance, simple operation and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

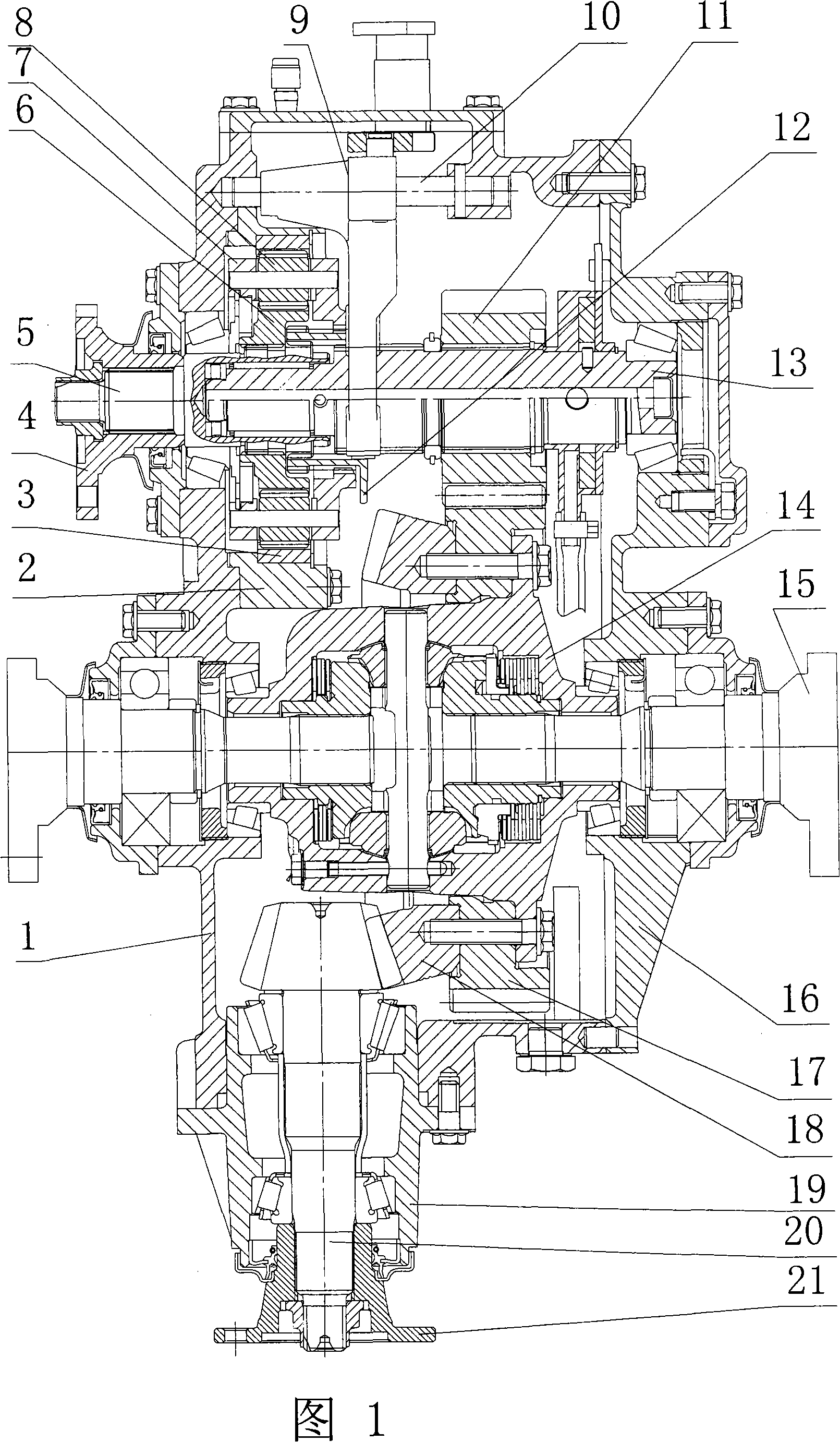

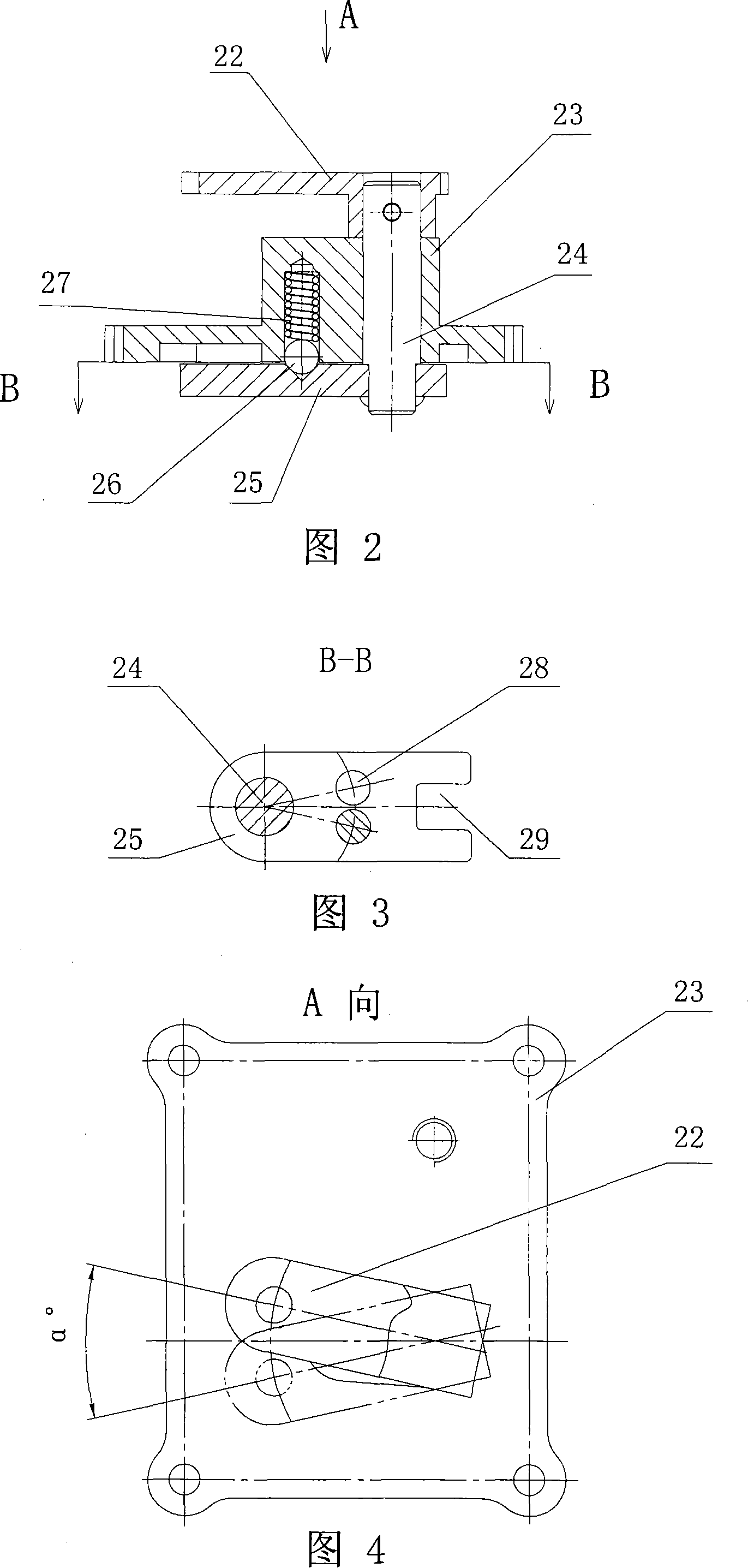

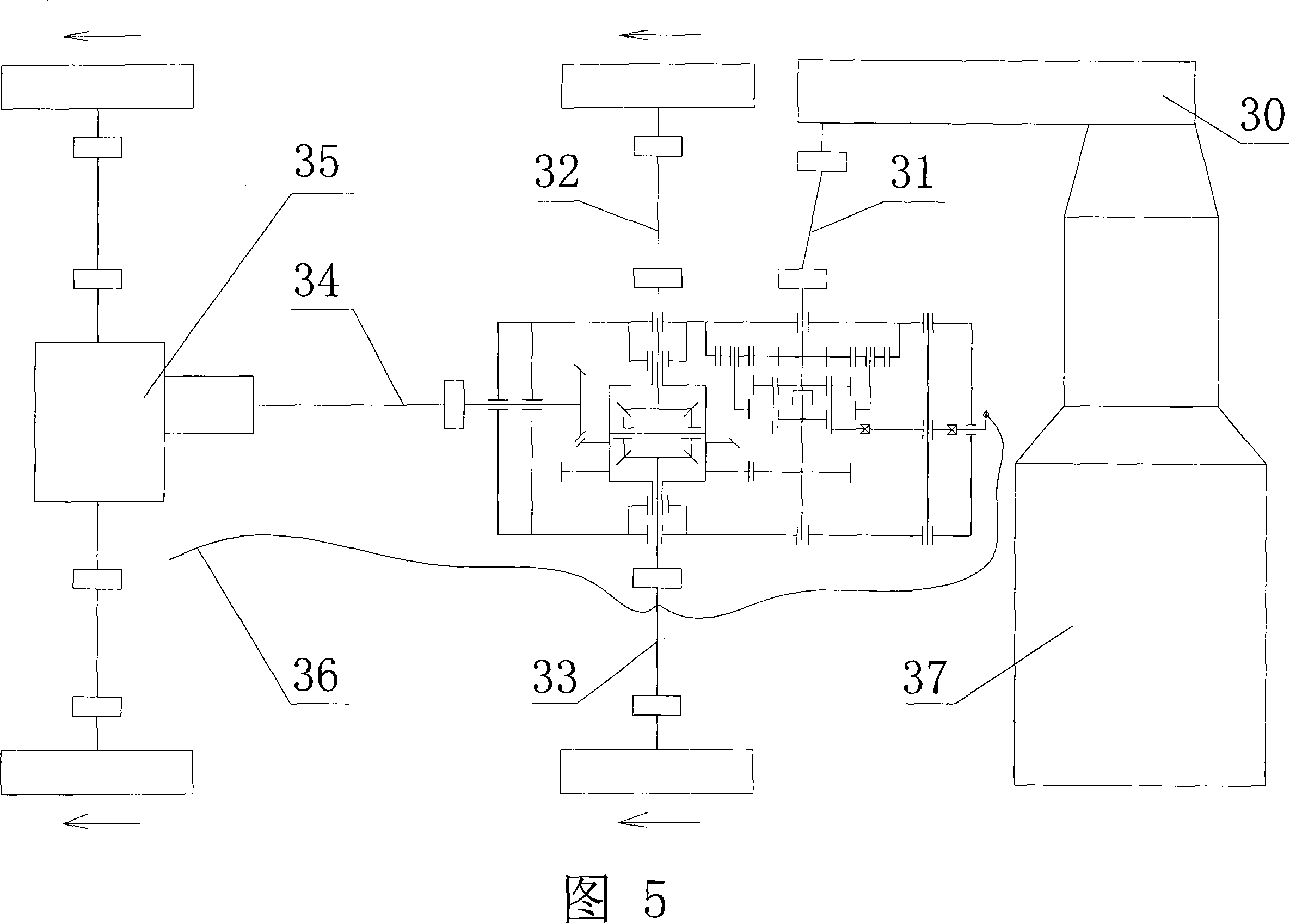

[0013] The specific structure of the present invention will be described in detail according to Figs. 1-5. The variable speed drive of the special four-wheel off-road vehicle includes a rear drive axle with a power input shaft 5 and a front drive axle 35 with an electronic coupler driven by its output shaft-bevel pinion shaft 20 and transmission shaft 34 . The supporting body of the rear drive axle is formed by the housing 1 and the end cover 16 . A planetary reduction mechanism, a shift mechanism, a main drive and a differential are assembled in the housing 1 and the end cover 16 . The input shaft flange 4 is assembled on the external spline of the input shaft 5 through the lock nut; the input shaft 5 is assembled on the housing 1 of the rear drive axle through the bearing, and the input shaft 5 and the second shaft 13 are assembled together through the needle bearing .

[0014] The planetary reduction mechanism includes: a planetary large ring gear seat 2, a planetary larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com