Winding device for rewinding machine

A technology of coiling device and rewinding machine, which is applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve problems such as difficulties in automatic production, change of coil width, and limitation of relative rotation, etc., to reduce loading Dismantling steps, improving production efficiency, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

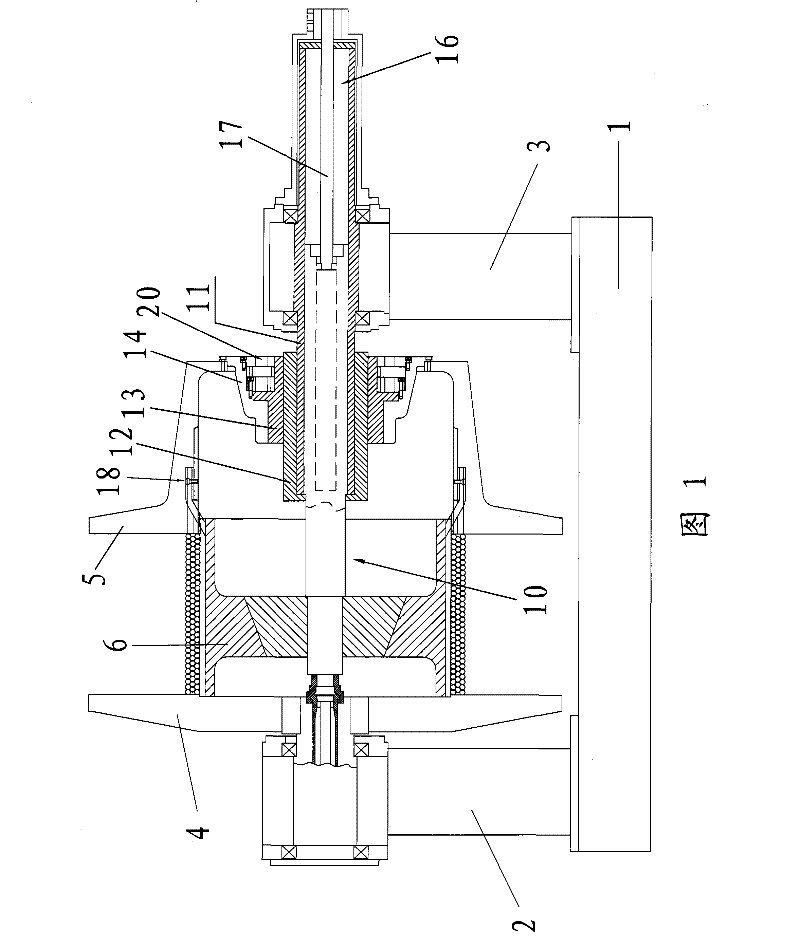

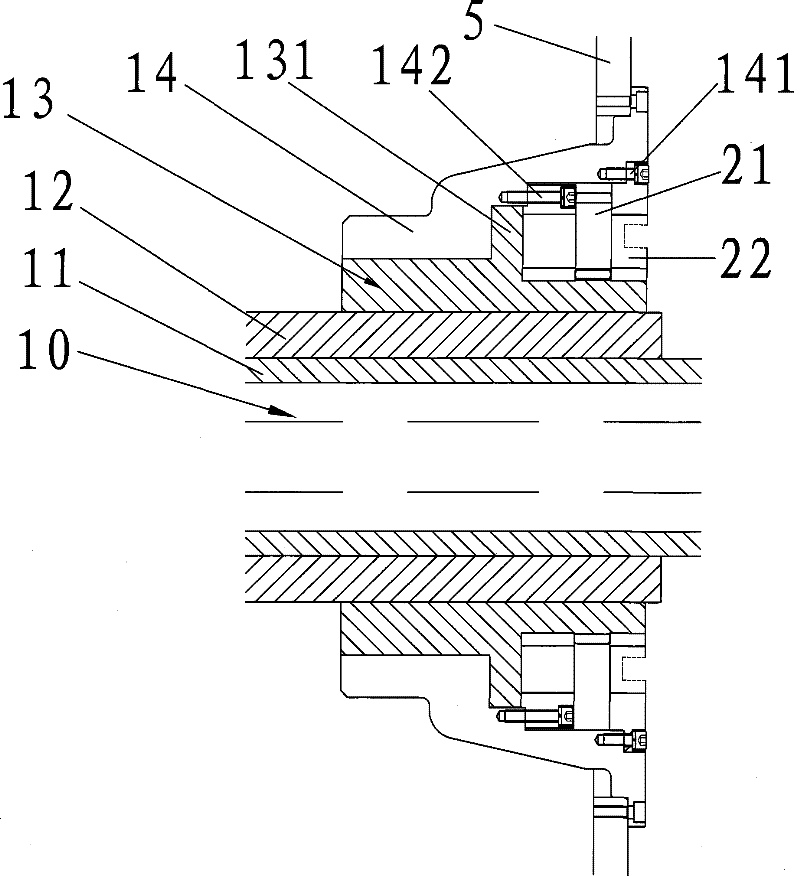

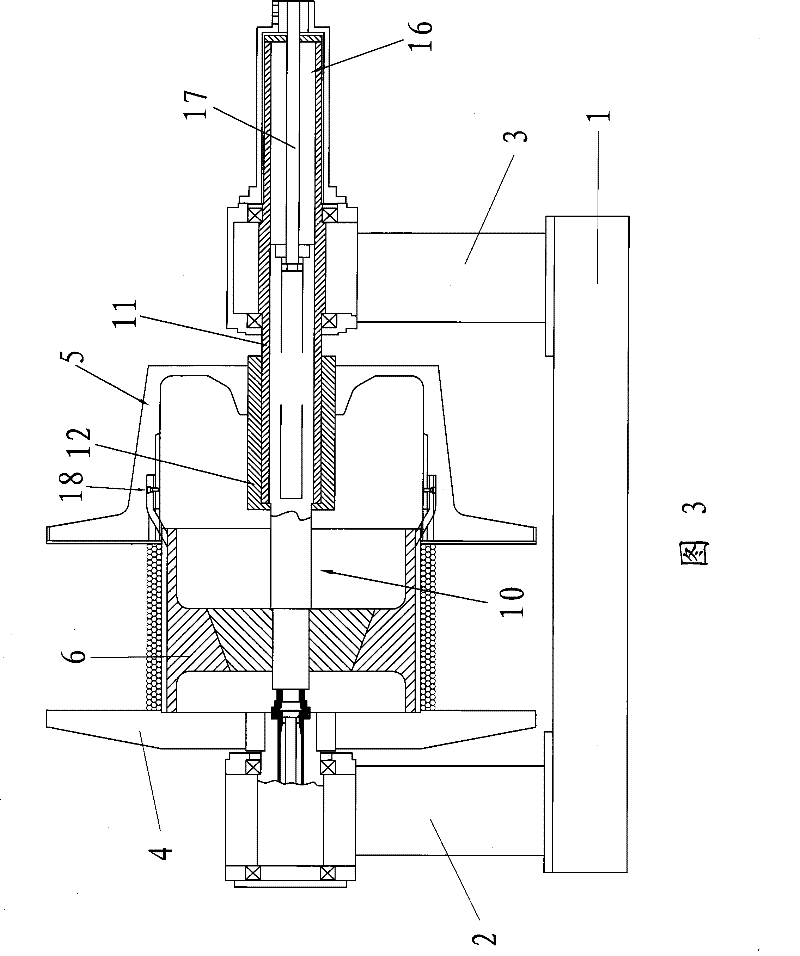

[0024] see figure 1 , a rewinding machine coiling device, which includes a bottom box 1 provided with a driving device, a first vertical arm 2 and a second vertical arm 3 fixedly arranged on the bottom box 1, rotatably arranged on the first vertical arm The first turntable 4 on the 2, the bushing 11 that is rotatably arranged on the second vertical arm 3, the sliding shaft 10 that can slide in the axial direction is housed in the bushing 11, and the sliding shaft 10 that is fixedly arranged on the sliding shaft 10 The core 6 that can be used to take up the copper pipe, the second turntable 5 that can be used to accommodate the core 6 and is detachably connected to the core 6, the sliding shaft 10 is fixed relative to the shaft sleeve 11, wherein the rewinding A roll width adjustment mechanism is also provided on the machine coiling device, and the roll width adjustment mechanism includes a first screw sleeve 12 which is slidably arranged on the outer surface of the shaft slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com