Process for producing frozen water-boiled egg and process for producing frozen processed food containing water-boiled egg

A technology of processing food and boiling in water, which is applied in the field of preparation of frozen processed food and the manufacture of frozen processed food, to achieve the effect of inhibiting freezing denaturation, good taste and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the present invention also includes the step (B) of immersing the peeled boiled egg prepared by the step (A) into a sugary aqueous solution at a specific temperature containing phosphate, trehalose and sorbitol, and then adding B) The step (C) of immersing the prepared dipped and peeled boiled eggs in a sugar-containing heating solution at a specific temperature containing phosphate, trehalose, and sorbitol. However, when neither the process (B) nor the process (C) is performed, the effect of suppressing freezing denaturation is not sufficient especially for normal-temperature type peeled boiled eggs.

[0019] The phosphate used in the step (B) or step (C) is a component that can maintain the water retention capacity of the peeled boiled egg, and suppress and prevent the decrease in the elasticity of the protein part and the excess water in the yolk part caused by freezing denaturation , For example, sodium dihydrogen phosphate, potassium dihyd...

Embodiment 1

[0048] Normal-temperature peeled and boiled quail eggs sold in the market were prepared. A sugar-containing aqueous solution having a sodium tripolyphosphate concentration of 1% by mass, a trehalose concentration of 15% by mass, and a sorbitol concentration of 15% by mass was prepared. The Brix value of this aqueous solution was 31%.

[0049] Next, the prepared sugar-containing aqueous solution was kept at 4°C, and 2Kg of peeled and boiled quail eggs were immersed in the solution for 16 hours. In addition, a slight agitation operation was performed every 4 hours during the maceration process. Moreover, the aqueous solution temperature of 4° C. was also maintained during the dipping process.

[0050] The obtained soaked and shelled boiled quail eggs were transferred to the sugar-containing heating solution obtained by heating the sugar-containing aqueous solution prepared by the same preparation method as above to 85° C., and immersed for 30 minutes. Moreover, the heating so...

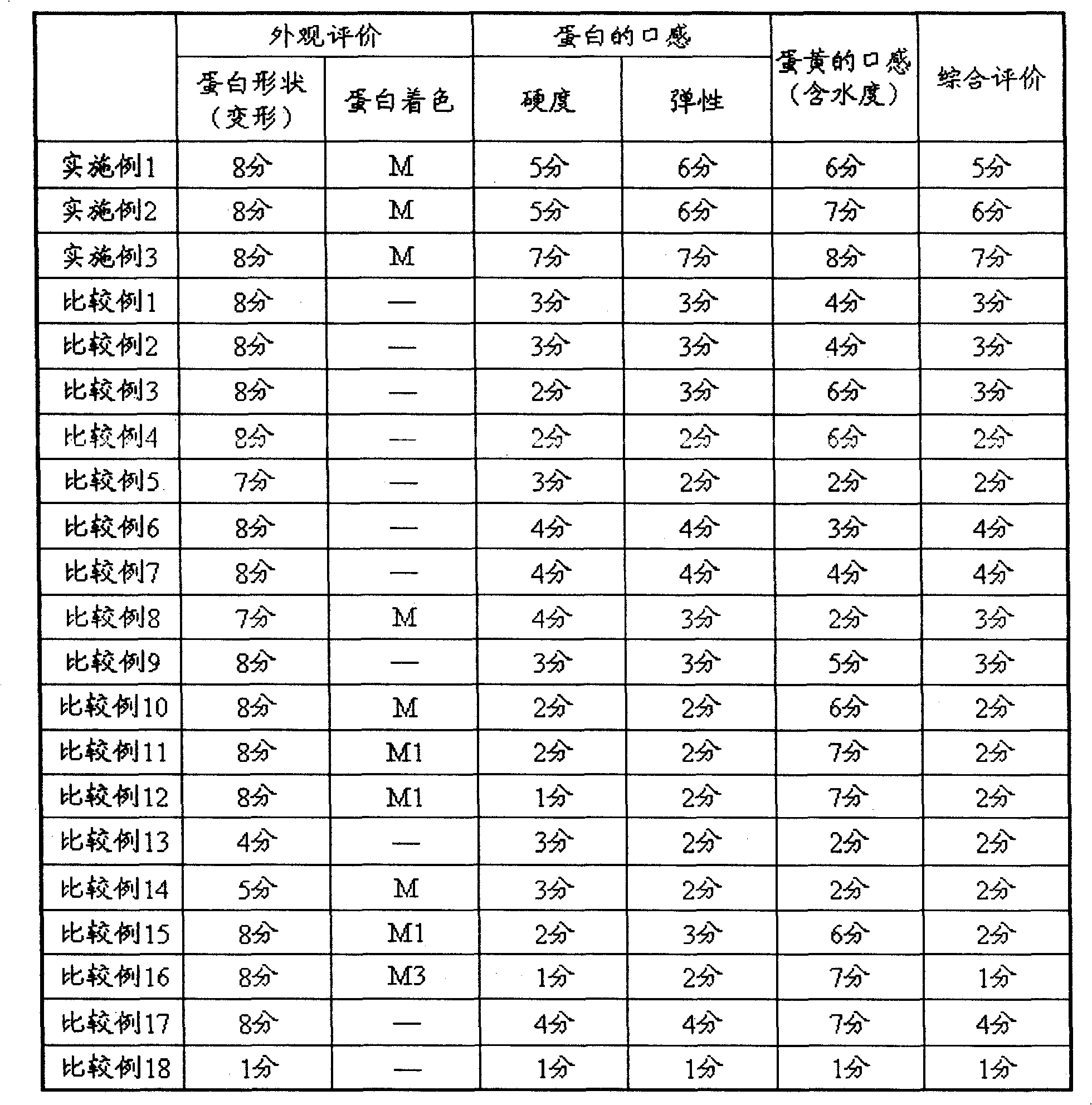

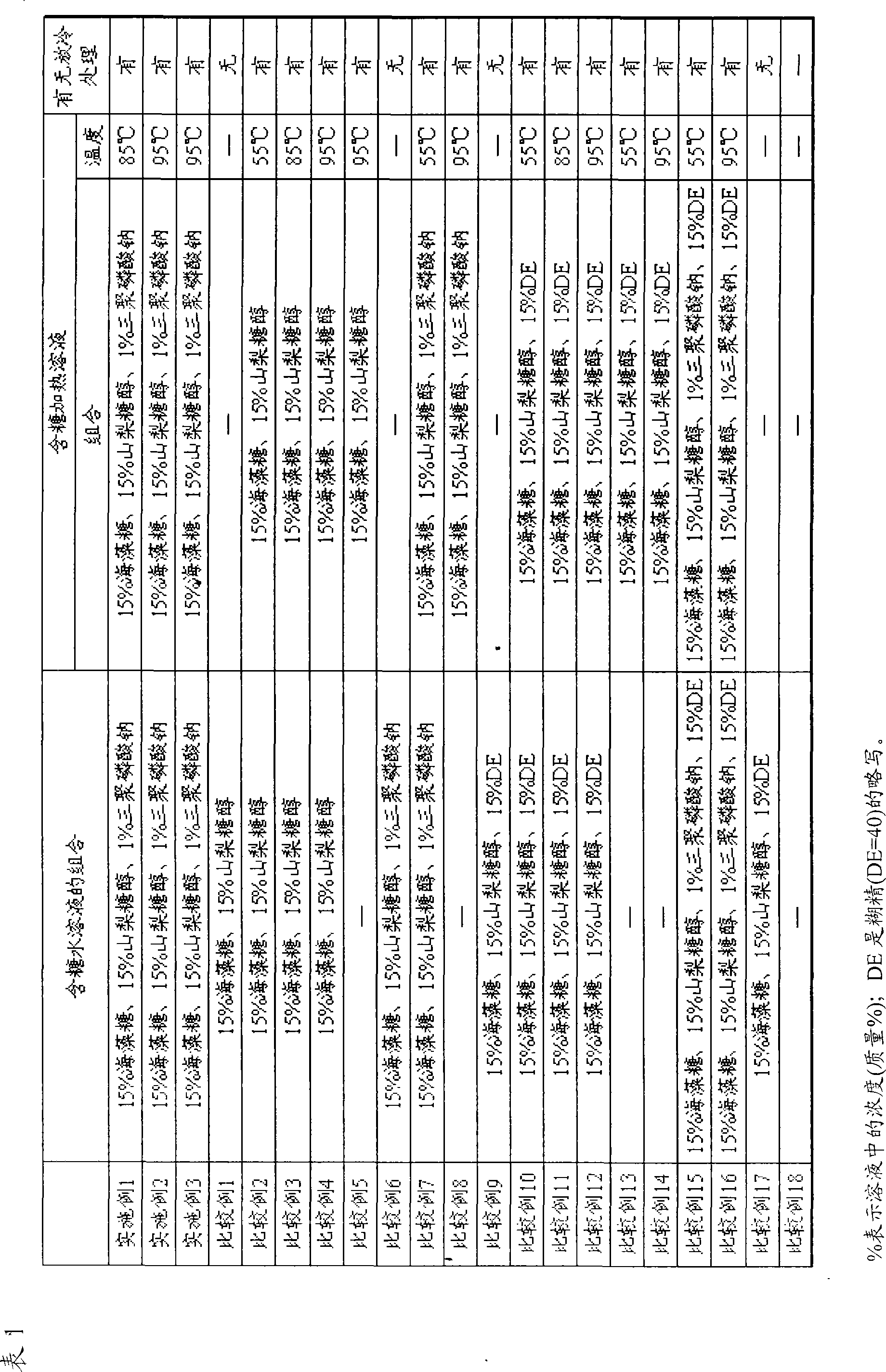

Embodiment 2、3 and comparative example 1~18

[0055] Using the sugar-containing aqueous solution and the sugar-containing heated solution shown in Table 1, frozen peeled boiled quail eggs were prepared in the same manner as in Example 1, and the same evaluation was performed. Evaluation was performed on the same basis as in Example 1. The results are shown in Table 2.

[0056] In addition, the temperature and immersion time of the sugar-containing aqueous solution, the immersion time in the sugar-containing heating solution, the cooling conditions and the freezing conditions are all the same as in Example 1. Moreover, Example 3 and Comparative Example 17 are examples in which commercially available refrigerated quail eggs are used instead of commercially available normal-temperature peeled and boiled quail eggs. In Table 1, sugar-containing aqueous solution or sugar-containing heated "-" in the column of the solution means that it has not been impregnated with these solutions. In addition, Comparative Example 18 is an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com