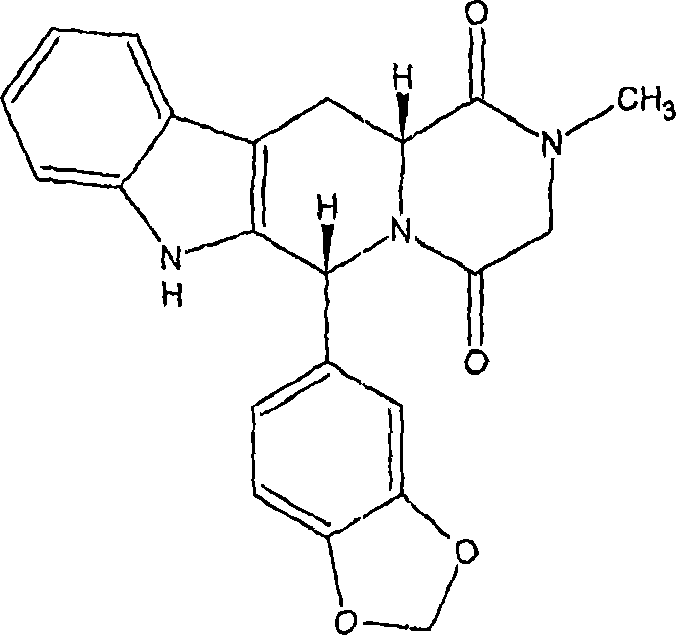

Process of purifying tadalafil

A tadalafil and solution technology, applied in organic chemistry, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve problems such as increasing production costs of tadalafil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Crystallization of Tadalafil in n-Butanol

[0033] In a 3 liter reactor equipped with a mechanical stirrer, condenser and thermometer, crude tadalafil (30 g dry basis) and butanol (2400 mL) were mixed to form a crude tadalafil solution. The solution was heated to 125°C and stirred at 100 rpm for about 1 hour to obtain a clear solution. The solution was cooled to 90°C and seeded. The mixture was stirred at about 90°C for 1 hour and then cooled to 10°C over 12 hours. The mixture was stirred for an additional 3 hours at about 10°C, filtered under vacuum, and washed with butanol (180 mL). Wet tadalamorph crystals were obtained (28.9 g, 99.5% by HPLC).

Embodiment 2

[0034] Example 2: Crystallization of Tadalafil in Acetone / Methanol

[0035]In a 1-liter reactor equipped with a mechanical stirrer, condenser, and thermometer, combine crude tadalafil (20 g of dry base), acetone (600 mL), and methanol (120 mL) to form a crude tadalafil solution . The solution was heated to 50°C and stirred at 100 rpm for about 1 hour to obtain a clear solution. The solution was then filtered and cooled to about 20°C and seeded. The mixture was stirred at about 20°C for 1 hour, then further cooled to 0°C over 3 hours. The mixture was stirred at 0 °C for an additional 1 h, then filtered under vacuum and washed with methanol (120 mL). Wet tadalamorph crystals were obtained (12.4 g, 100% by HPLC).

Embodiment 3

[0036] Example 3: Crystallization of Tadalafil in Acetone / Water

[0037] In a 1-liter reactor equipped with a mechanical stirrer, condenser, and thermometer, combine crude tadalafil (30 g of dry base), acetone (900 mL), and water (90 mL) to form a crude tadalafil solution . The solution was heated to 30°C and stirred at 200 rpm for about 1 hour to obtain a clear solution. The solution was then cooled to about 12°C and seeded. The mixture was stirred at about 12°C for 1 hour, then further cooled to -10°C over 12 hours. The mixture was stirred at -10°C for an additional 6 hours, then filtered under vacuum and washed with methanol (120 mL). Wet tadalamorph crystals were obtained (22.35 g, 99.7% by HPLC). According to the XRD analysis of the obtained substance, what is obtained is type I tadalafil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com