Heating lamp box of blow molding machine

A blow molding machine and light box technology, applied in the field of heating light boxes, can solve the problems that the mouth of the blank cannot be well cooled, the air circulation of the heating light box is uneven, and the energy consumption is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

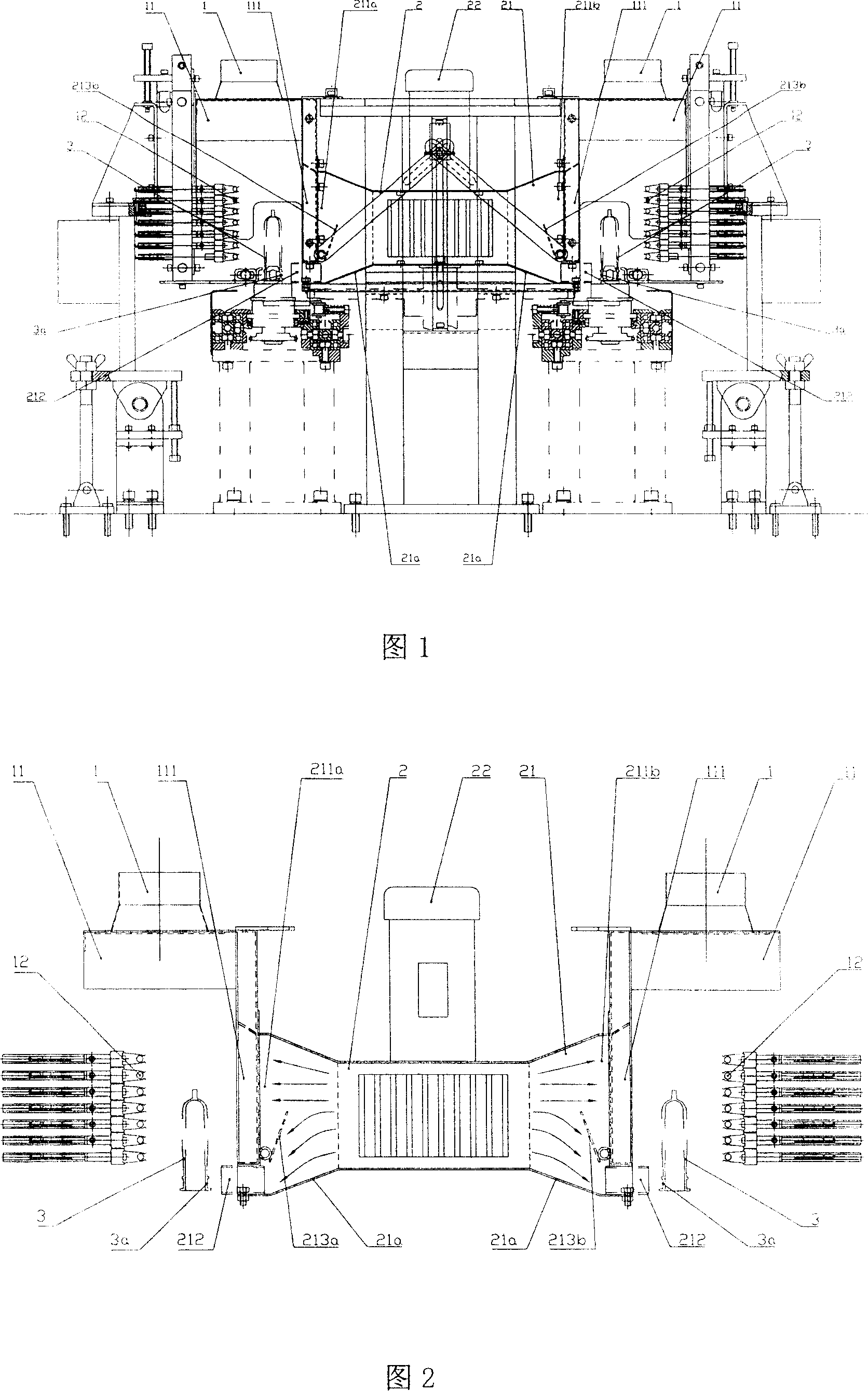

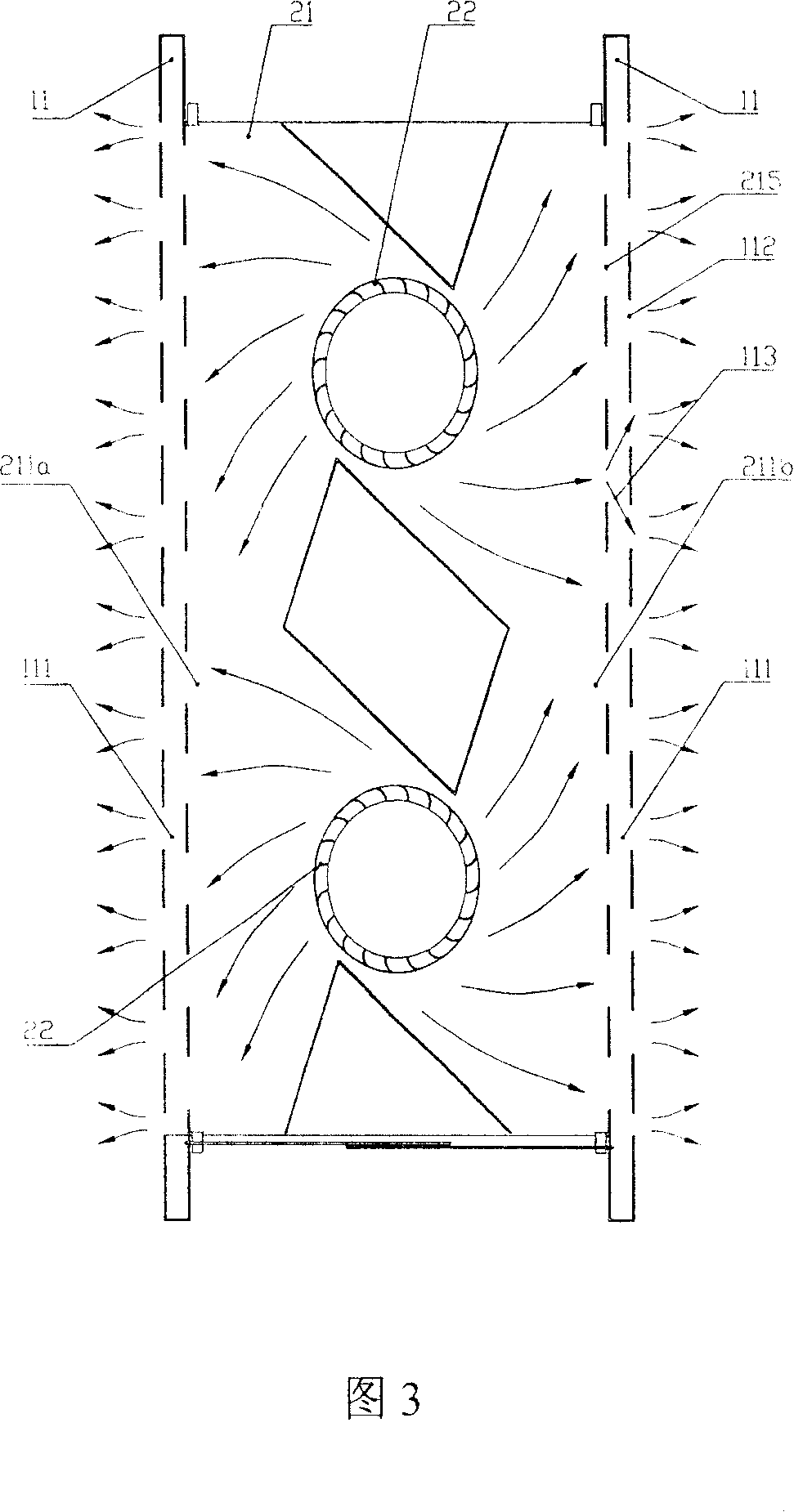

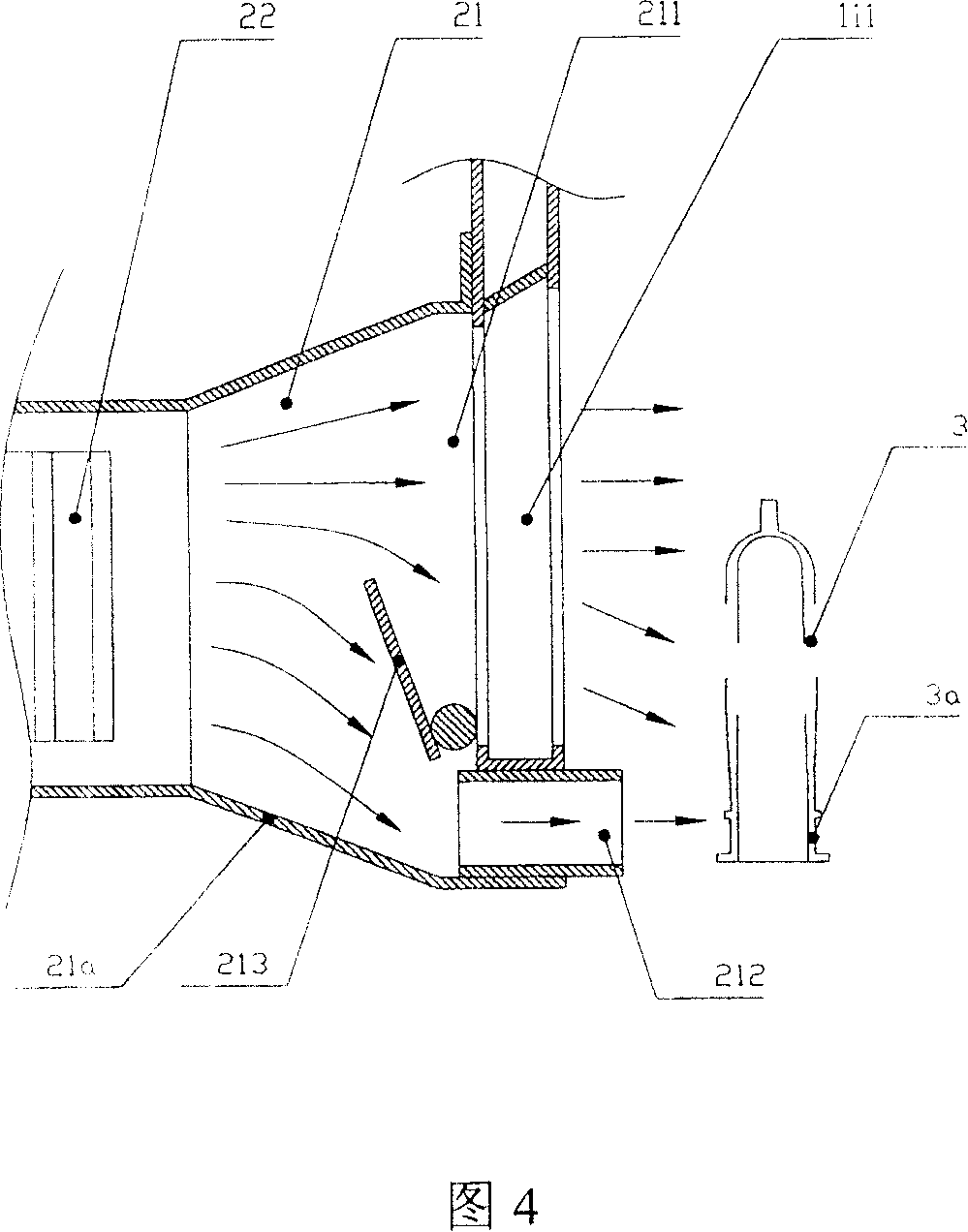

[0020] The heating light box of the blow molding machine is to heat the blanks fed into the heating light box. After heating to a certain degree, it can be sent out for blowing. As shown in FIG. 1 and FIG. 2 , the heating light box of the blow molding machine of the present invention includes a heating device 1 and a cooling device 2 . The heating device 1 is used to heat the blank 3 , and includes several semi-closed first boxes 11 and heating elements 12 arranged in the first boxes 11 . The number of the first boxes 11 can be determined according to the specific needs of the containers blown by the blow molding machine.

[0021] The cooling device 1 blows the heating device 2, so as to blow the heated blank 3 in the heating device 2, so that the temperature of the blank 3 is properly cooled. The cooling device 2 includes several se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com