Corrosion-resistant magnetic drive centrifugal pump

A magnetic drive, corrosion-resistant technology, used in pumps, pump devices, pump components, etc., can solve the problems of inability to stop at will, incompetence, and inexhaustible discharge of residual liquid, achieving good cooling and lubrication effects, reasonable design and structure, The effect of reducing volume loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

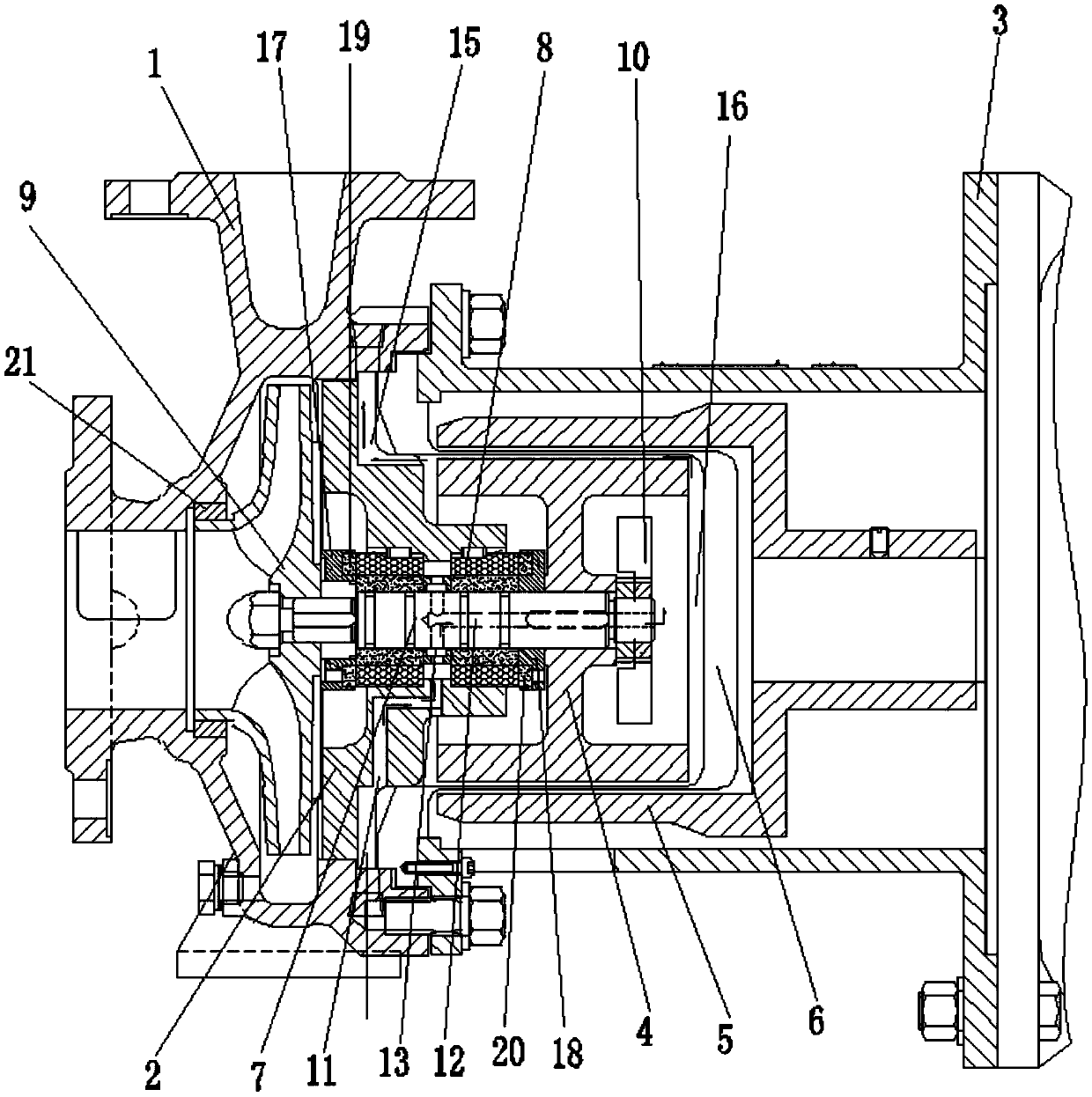

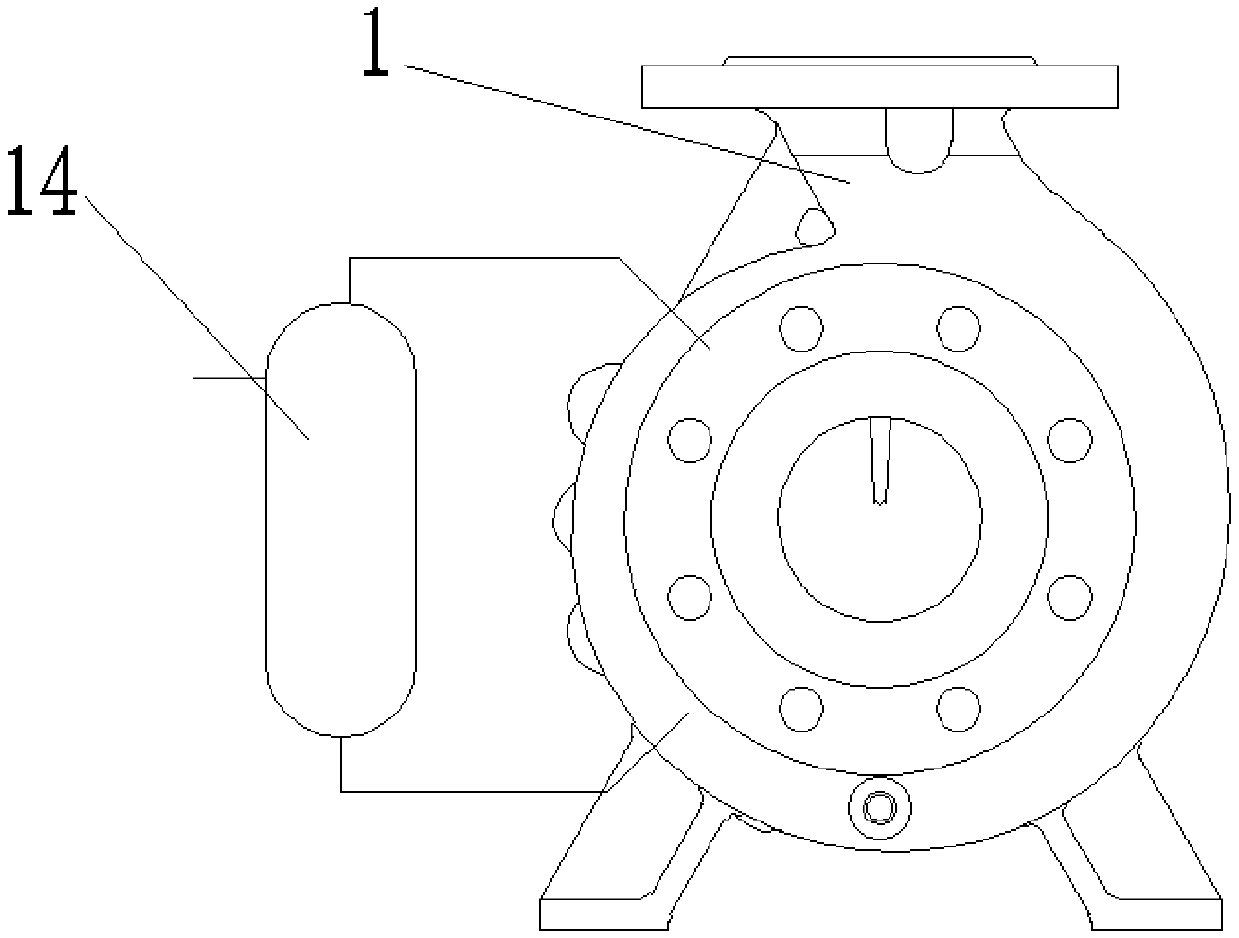

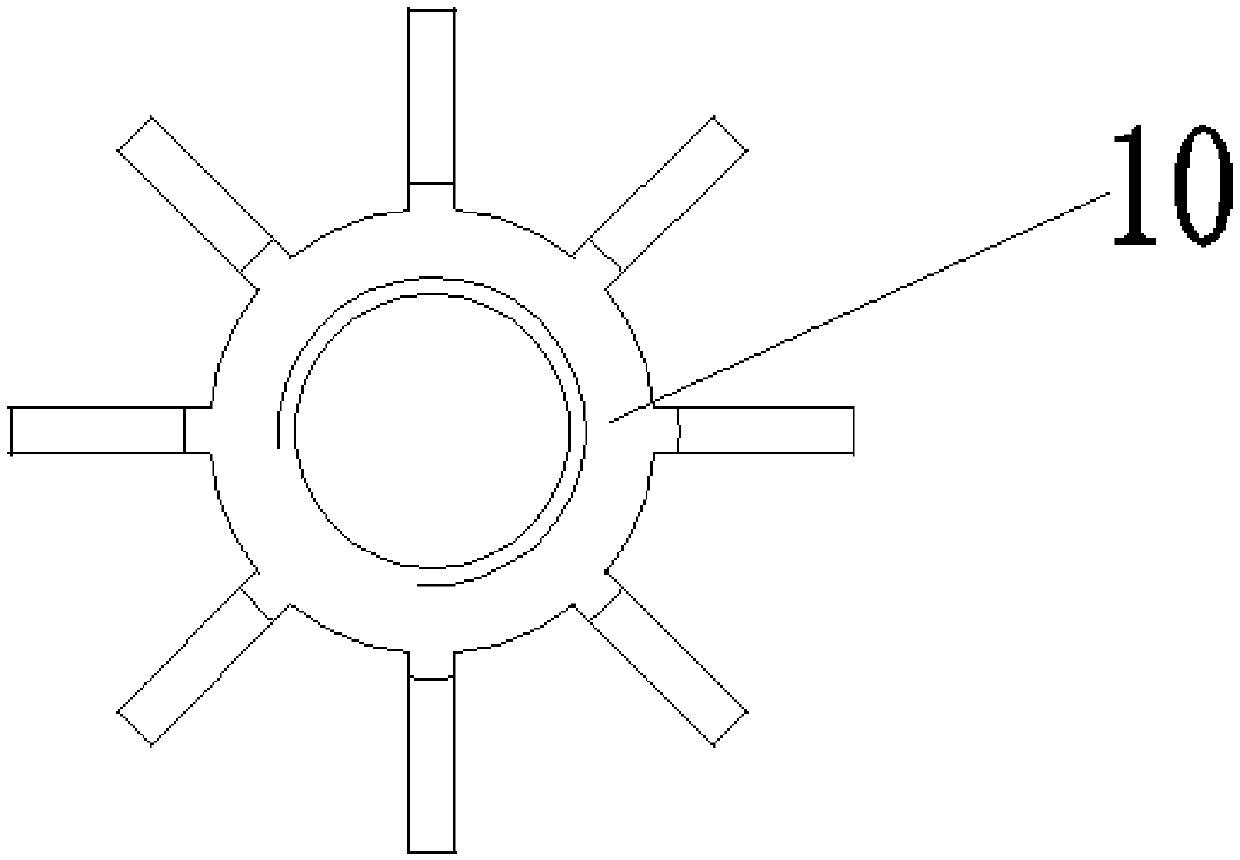

[0016] Such as Figure 1-Figure 3 As shown, a corrosion-resistant magnetic drive centrifugal pump includes a pump body 1, a pump cover 2, a suspension 3, an inner magnetic rotor 4 and an outer magnetic rotor 5, and the outer magnetic rotor 5 is fixed on the suspension 3. A spacer 6 is provided between the outer magnetic rotor 5 and the inner magnetic rotor 4, and the corrosion-resistant magnetic drive centrifugal pump also includes a drive delivery shaft 7, and the drive delivery shaft 7 is fixed on the pump cover 2 through two sliding bearings 8 , the front end of the drive delivery shaft 7 is fixed with an impeller 9, and the rear end of the drive delivery shaft 7 is provided with an agitator 10, the inner magnetic rotor 4 is arranged at the rear portion of the drive delivery shaft 7, and the agitator 10 is provided with In the middle of the inner magnetic rotor 4, the space between the inner magnetic rotor 4 and the isolation sleeve 6;

[0017] The pump cover 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com