Circular guide rails of elevator and assembly of connector thereof

A technology of circular guide rails and connecting parts, which is applied in the directions of elevators, transportation and packaging, etc. It can solve the problems of inability to ensure the straightness of guide rails, stainless steel is easy to deform, and affects the appearance, and achieve the effects of shortening assembly time, improving precision, and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

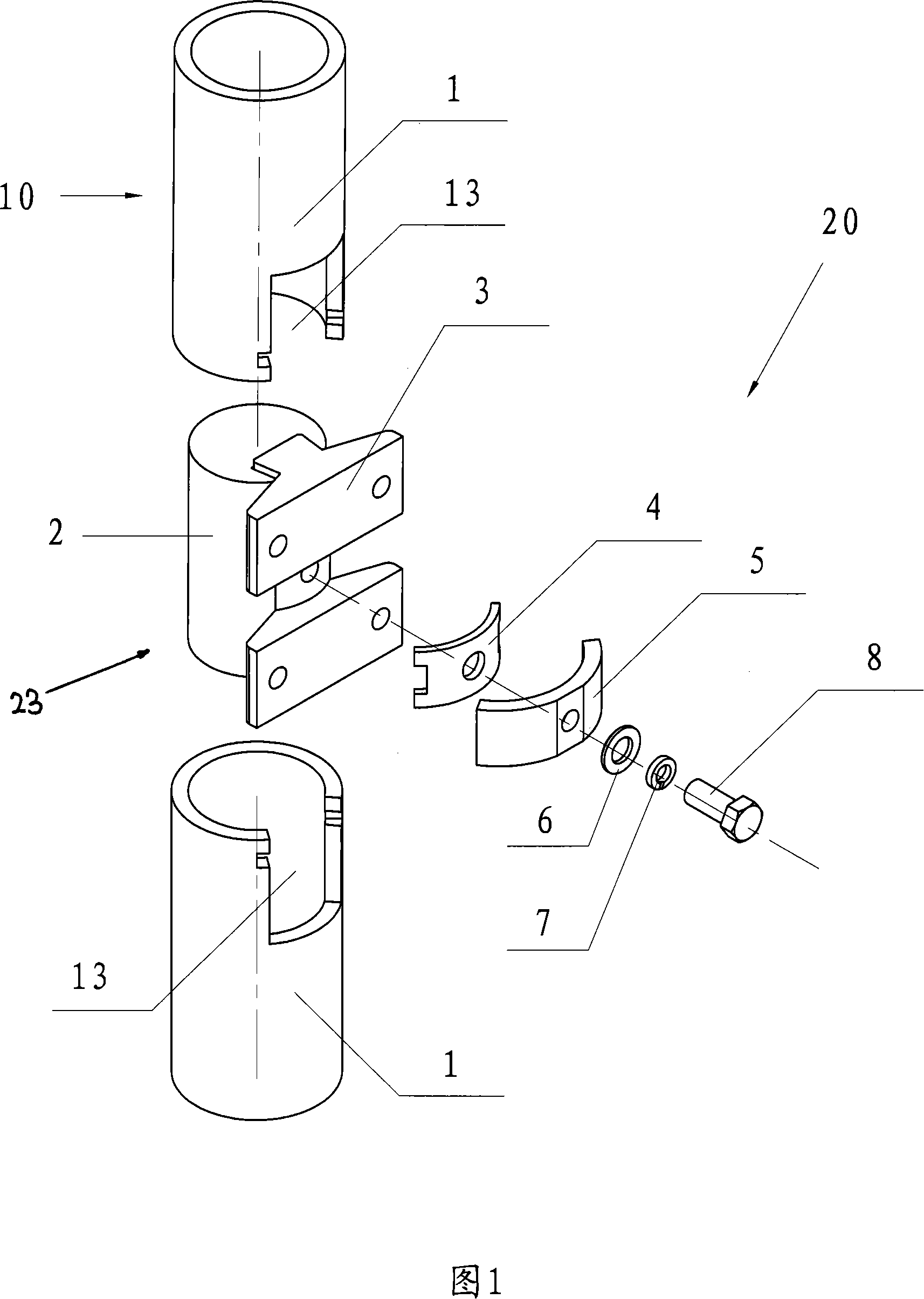

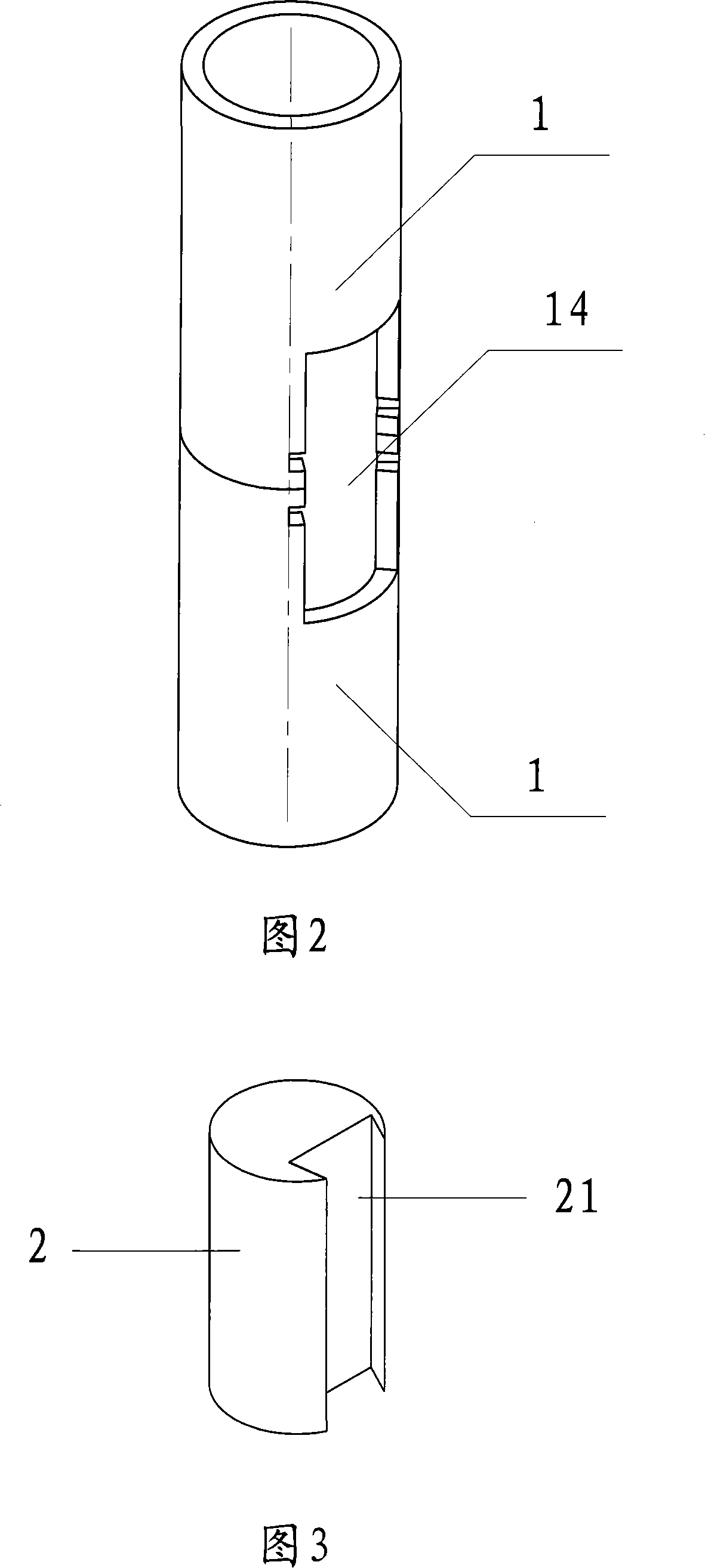

[0021] As shown in accompanying drawings 1 and 2 , the present invention includes at least two guide rails 10 whose upper and lower end surfaces can be bonded and a connecting piece 20 arranged between two adjacent guide rails 10 .

[0022] The guide rail 10 includes a hollow cylindrical guide post 1 and notches 13 formed at both ends of the guide post 1 . When the upper and lower end surfaces of two adjacent guide posts are bonded together, the adjacent notches are connected to form a rectangular connection groove 14 .

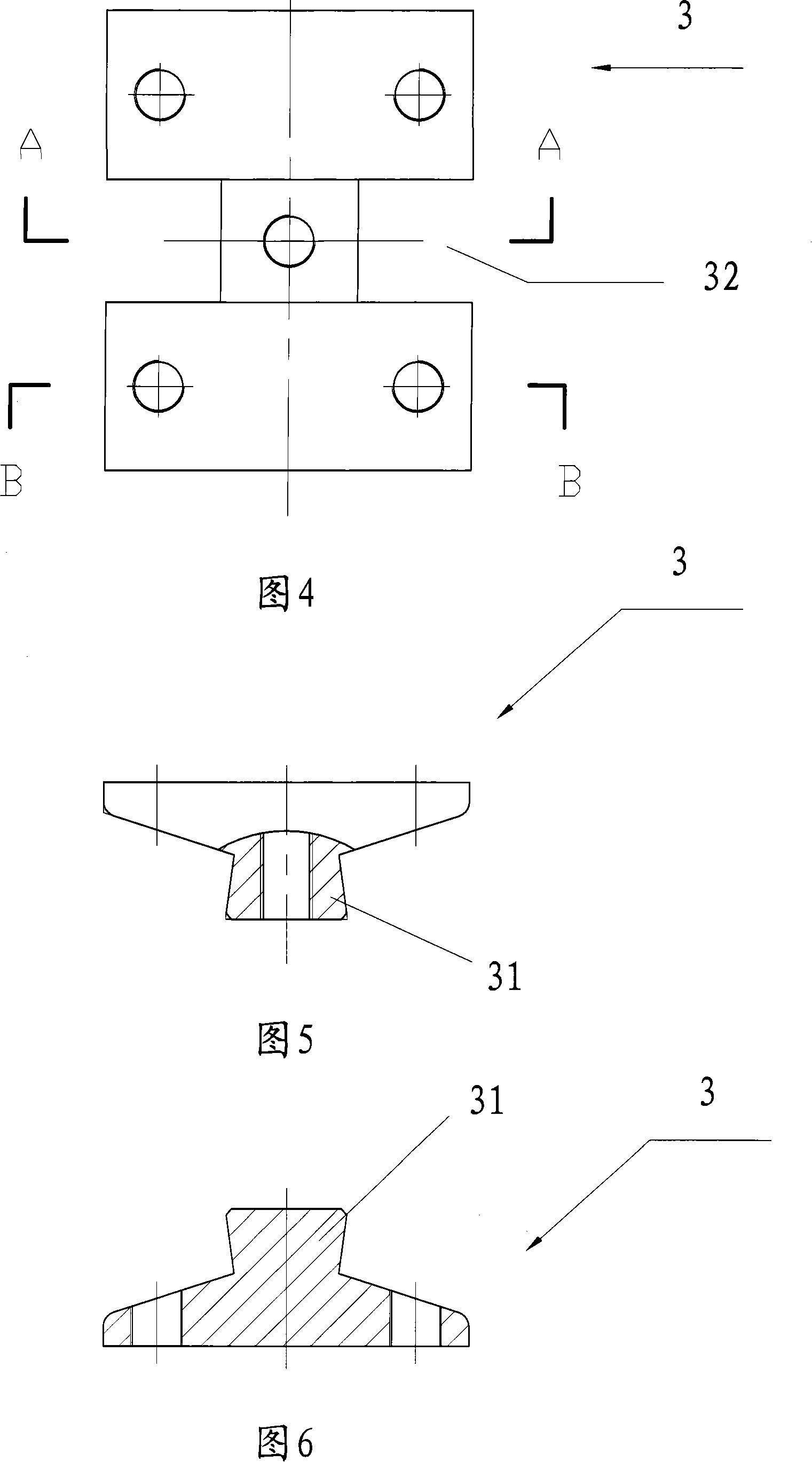

[0023] The connecting piece 20 includes a cylinder 2 , a positioning piece 3 , a fixing plate 4 , an arc pressure plate 5 , a flat washer 6 , a spring washer 7 and a bolt 8 .

[0024] As shown in FIG. 3 , the shape of the outer surface of the cylinder 2 corresponds to the shape of the inner surface of the guide post 1 and can be fitted. A t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com