Pipe-extractor of whole-doffing spinning machine

The technology of a tube puller and spinning frame is applied in the direction of conveying filamentous materials, textiles and papermaking, thin material processing, etc., which can solve the problems of increasing doffing times, reducing spinning time, yarn layer and yarn damage, etc. Achieve the effect of reducing doffing times, prolonging spinning time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

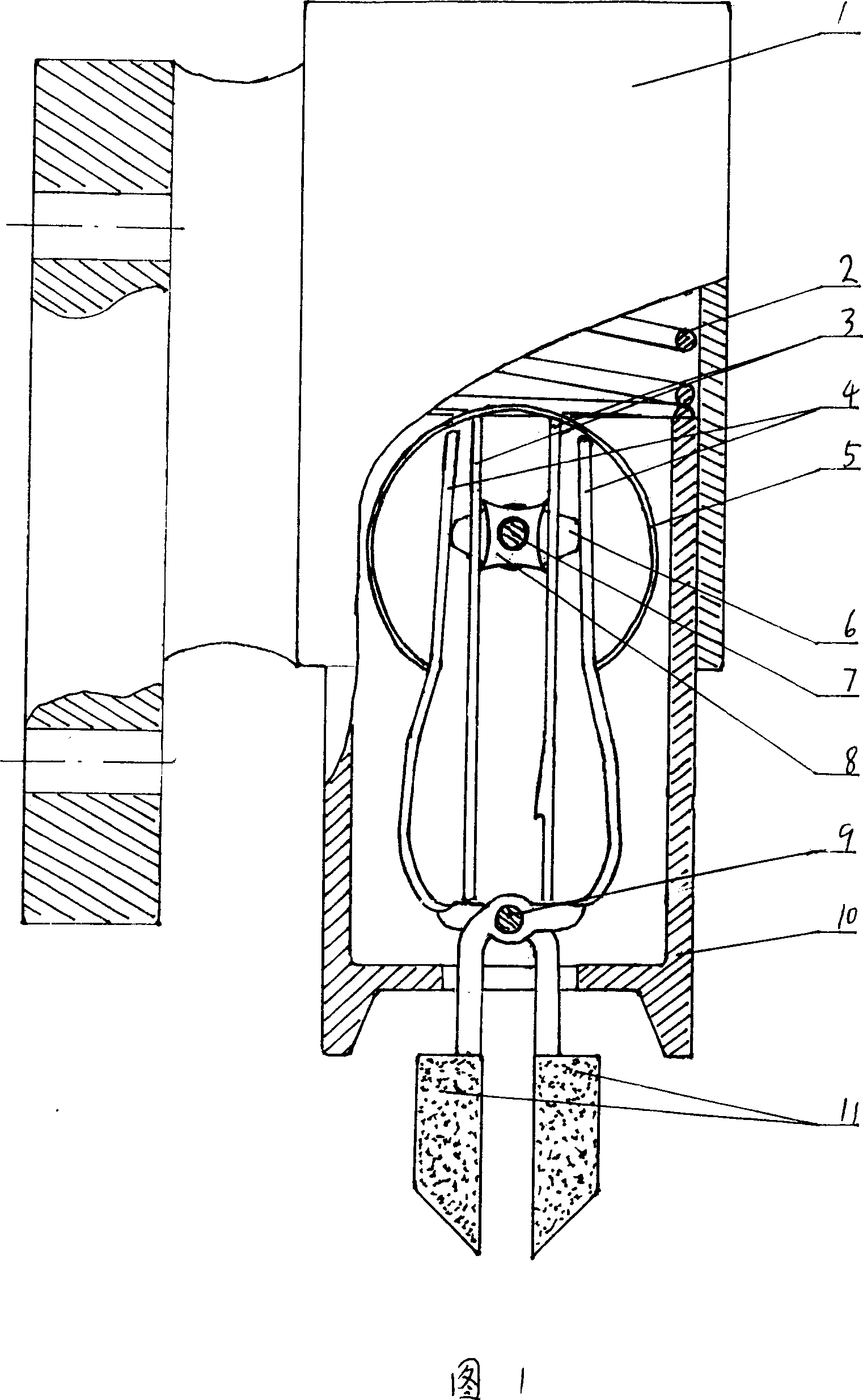

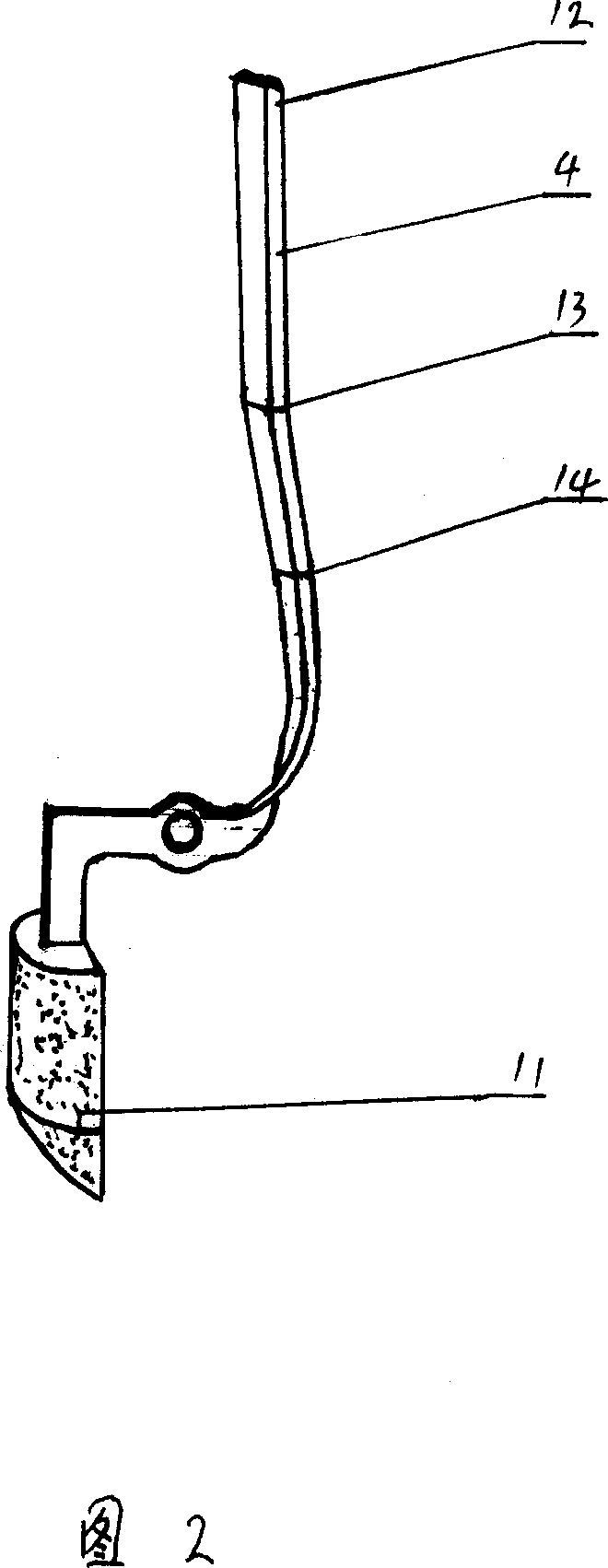

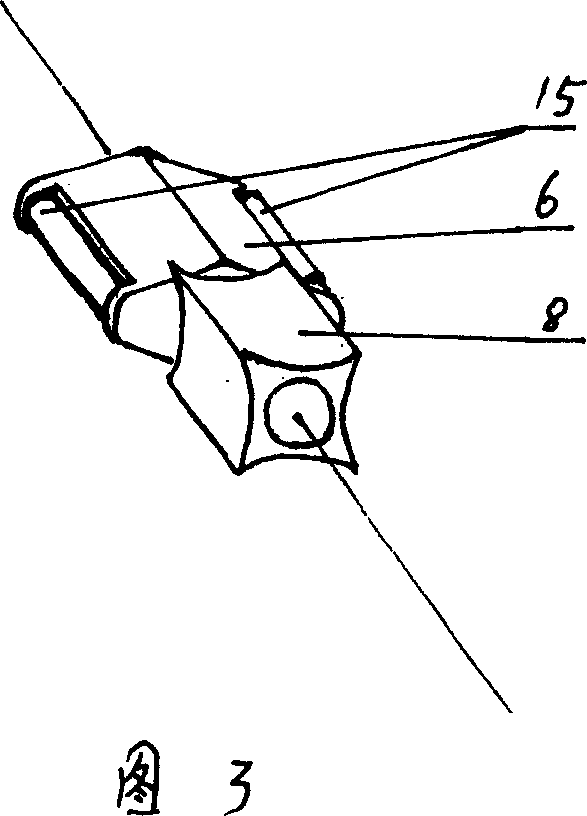

[0012] When the doffing starting arm carries the tube puller of the present invention so that the left and right support pins (11) are inserted into the hole on the top of the bobbin when they are combined, the overcoat (1) will move upward under the action of the starting arm, But because the self weight of inner cover (10) adds the effect of spring (2) again, therefore, inner cover (10) at this moment does not move. When the jacket (1) drives the central shaft (7) and the support block (6) to continue to move up along the central shaft slideway (16), the four-corner steering device (8) touches the barb on the right spring piece (3) Afterwards, support block (6) just makes 90 degree rotations. Because the two spring sheets (3) on the left and right are clamping the four-corner steering device (8), the four-corner steering device (8) and the support block (6) will not easily change the direction position when moving up and down. After the needle roller (15) at the maximum dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com