Exhaust valve braking device

A braking device and exhaust valve technology, applied in valve devices, engine components, engine control and other directions, can solve the problems of easy driver fatigue and insufficient braking power of exhaust butterfly valves, reduce driving fatigue, and be suitable for promotion. Application, wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

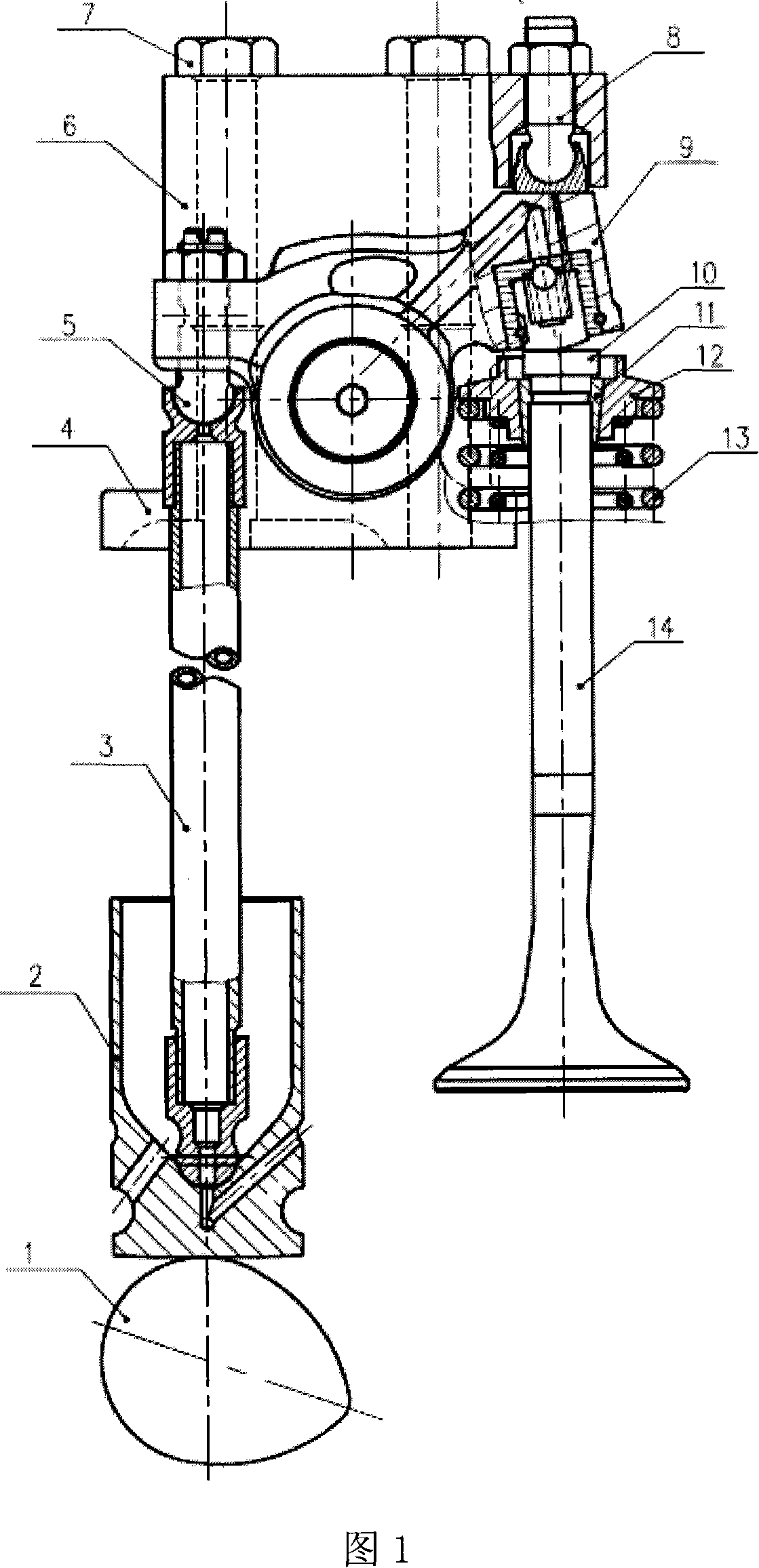

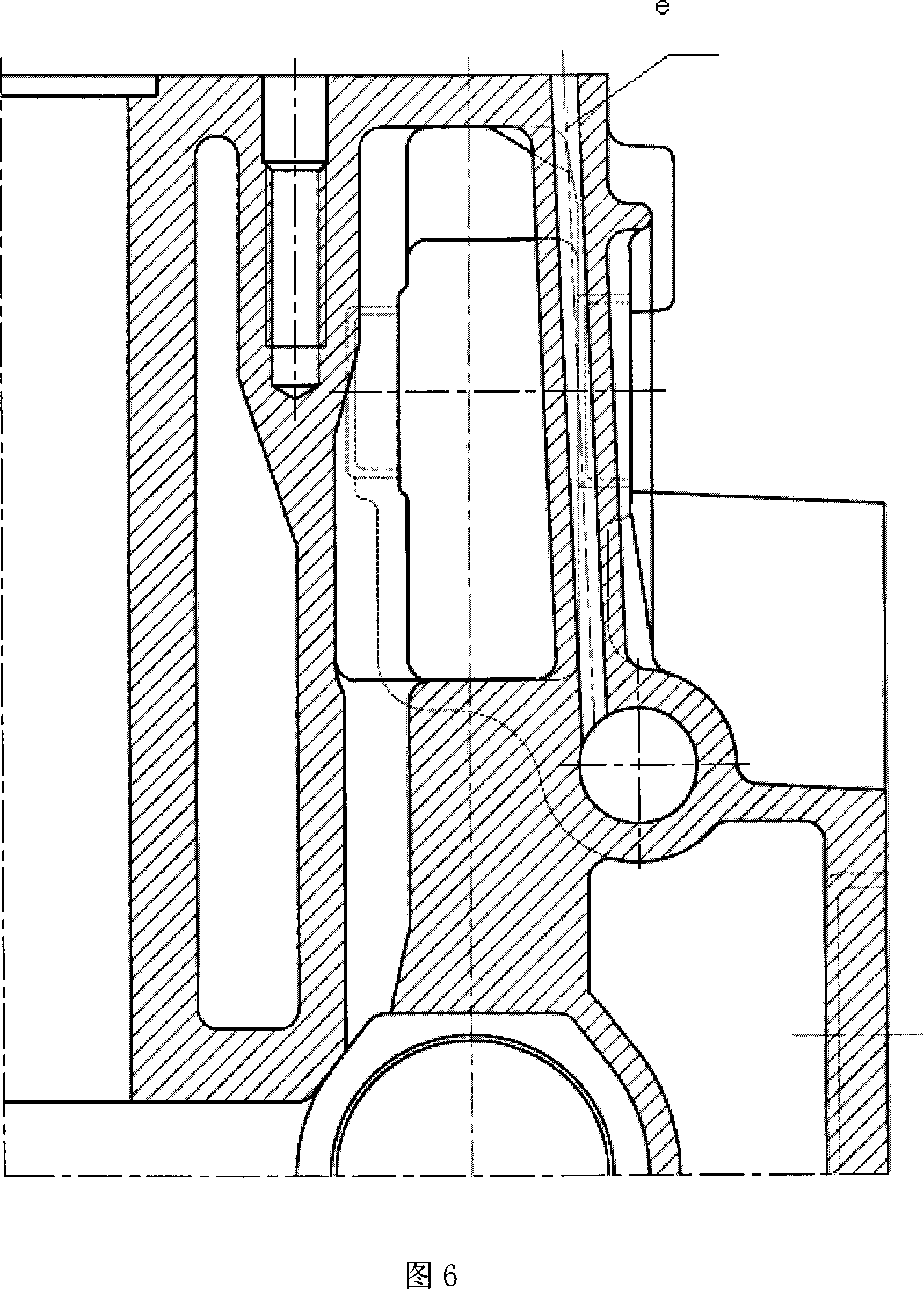

[0028] A kind of exhaust valve brake device as shown in Figure 1, comprises exhaust valve 14, the rocker arm structure that is installed on the cylinder head and is used for opening exhaust valve 14 and is used for driving the power device that rocker arm rotates, so The oil seal pressing block 6 is installed on the rocker arm structure described above.

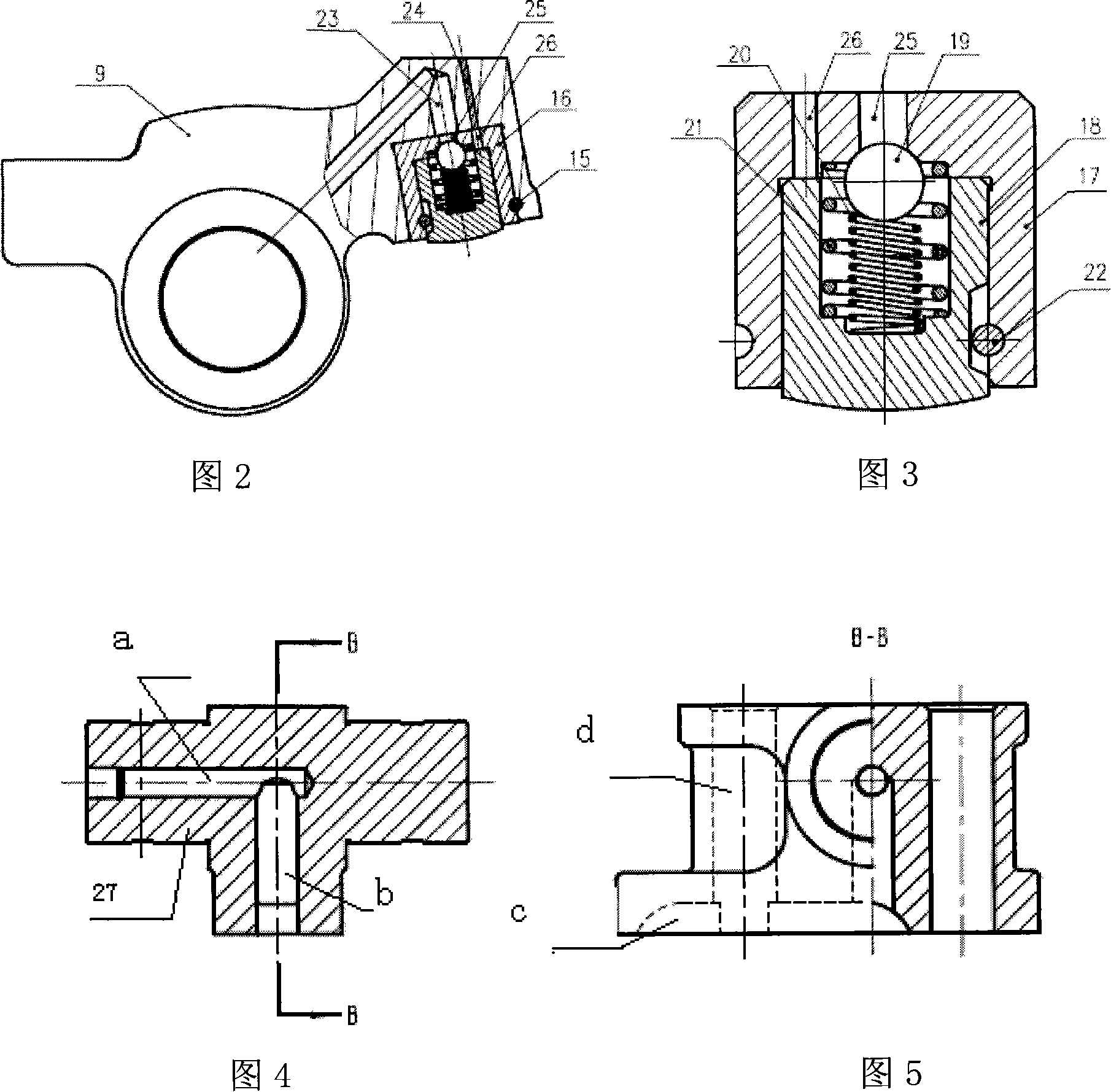

[0029] The rocker arm structure shown in Figure 4.5 includes a rocker arm seat 4, a rocker arm shaft 27, a rocker arm 9 and a piston couple 16. The bottom surface of the rocker arm seat 4 is provided with an oil groove c, and an oil tank c is arranged perpendicular to the bottom surface. hole d, the rocker arm shaft 27 has an axial oil hole a and the same radial oil hole b, the end of the rocker arm 9 is equipped with a piston coupling, and the rocker arm 9 is provided with an oil inlet Holes 23, oil drain holes 24, and oil inlet holes 25 and oil drain holes 26 are also provided at the corresponding positions of the piston co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com