Ring-shaped sliding rail air operated machine

A circular-shaped, wind-driven technology, applied to wind engines, motors, and wind engines at right angles to the wind direction, etc., can solve the problems of heavy weight, difficult manufacture, and high price of wind blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

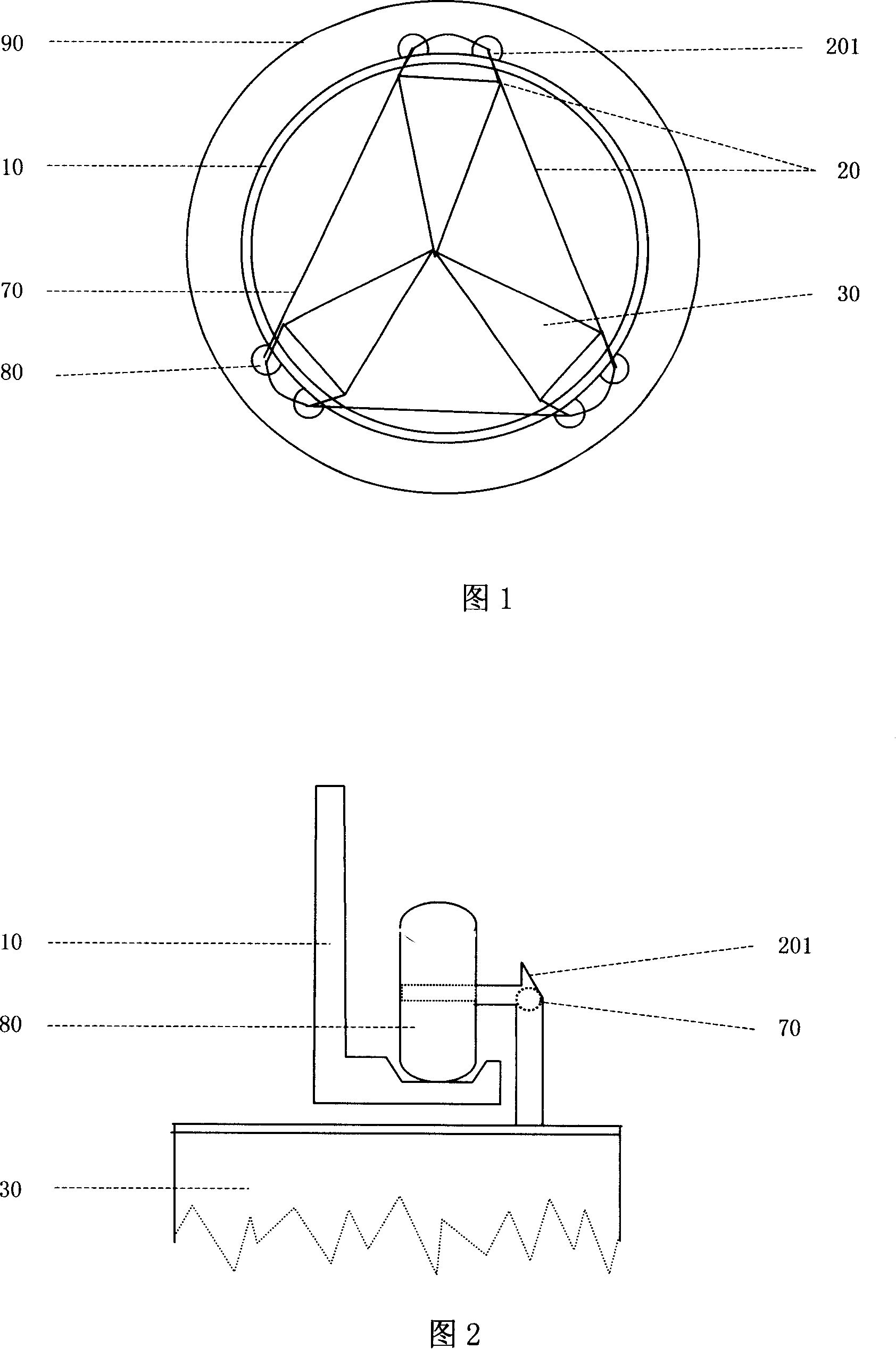

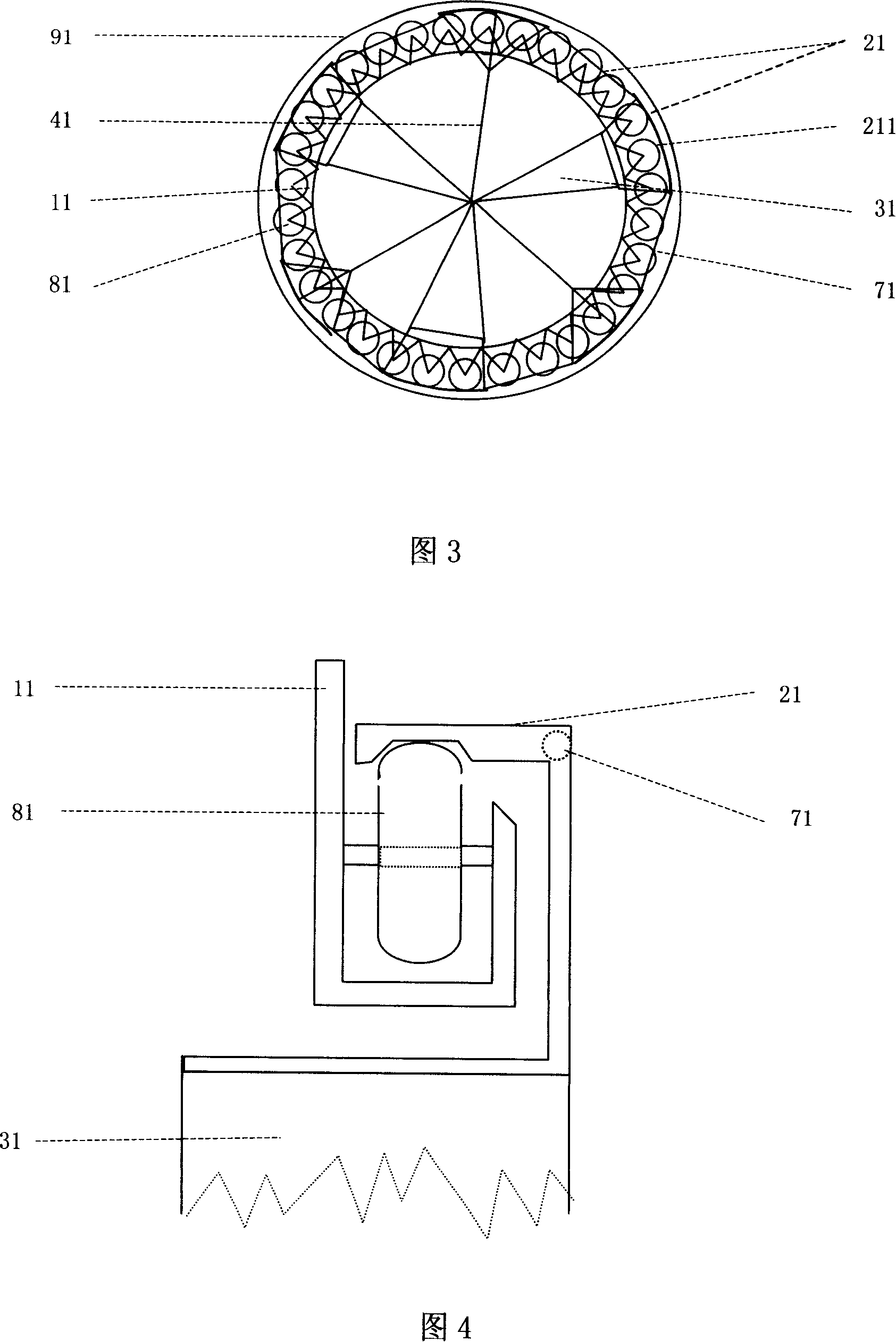

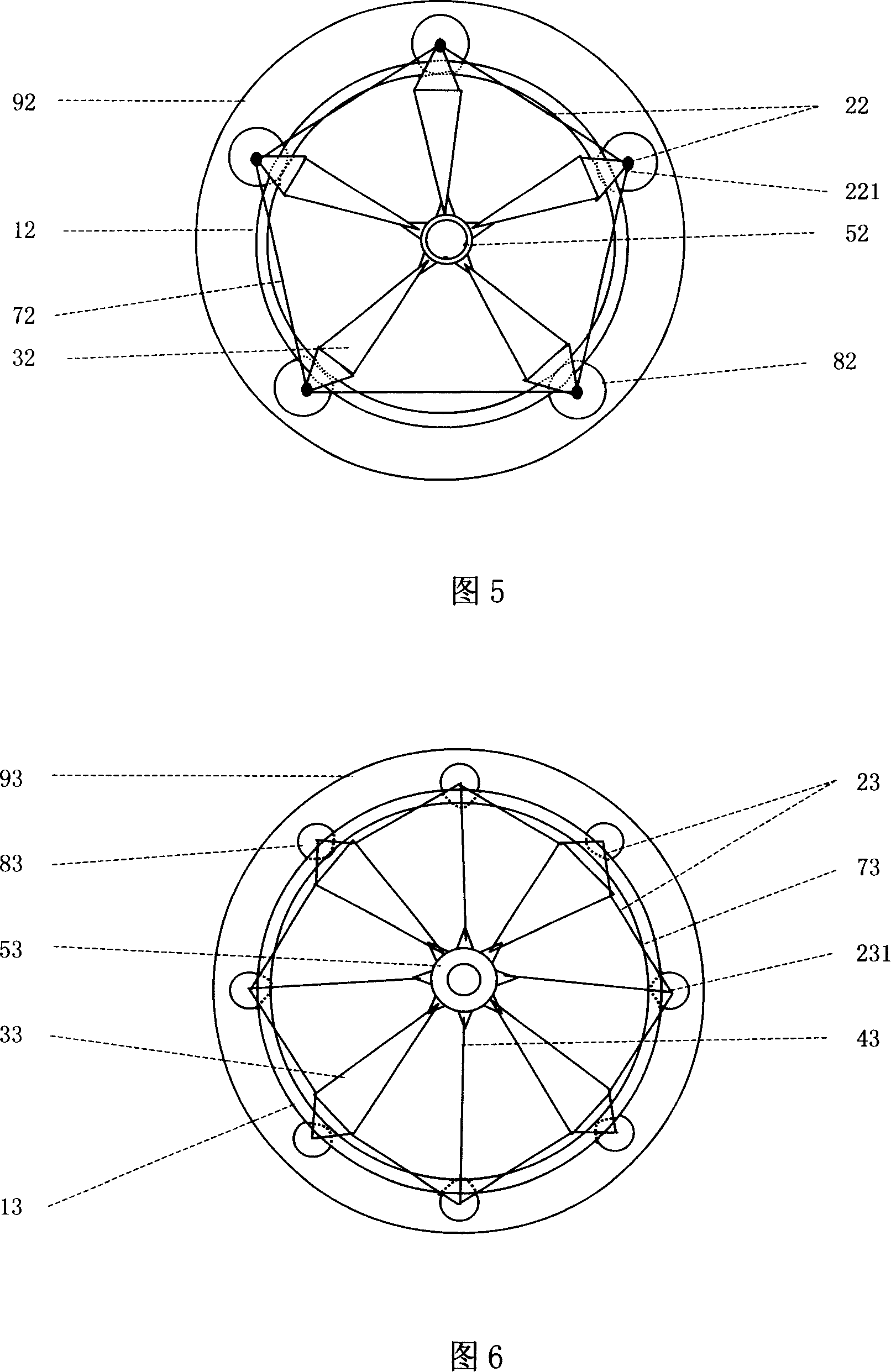

[0063] In this specification, the "circular slide rail" is generally a closed ring, which plays the role of providing support for the slider and the circular slide rail. It can also be fixed in a circular ring at a certain interval. The rollers, rollers, or other known technology rolling devices or friction reducing devices on the circular slide rails or brackets are used as circular slides. The outer side of the ring is the support surface of the slider and the slideway. The part of the slider connected to the fan blades can go around the side of the ring from the outside of the ring to connect with the fan blades on the inner side of the ring, and the other side of the ring The side of the ring is the connecting part of the circular slide rail air motor, the support frame and the support seat. In addition, the inside and part of the outside of the ring can also be used as the connecting parts of the ring-shaped slide rail wind motor, the support frame, and the support seat, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com