Method of melting alloy containing high-vapor-pressure metal

A vapor pressure and metal technology, which is applied in the melting field of alloys containing high vapor pressure metals, can solve the problems of high manufacturing cost, unsuitable for mass production, and pollution of alloy uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

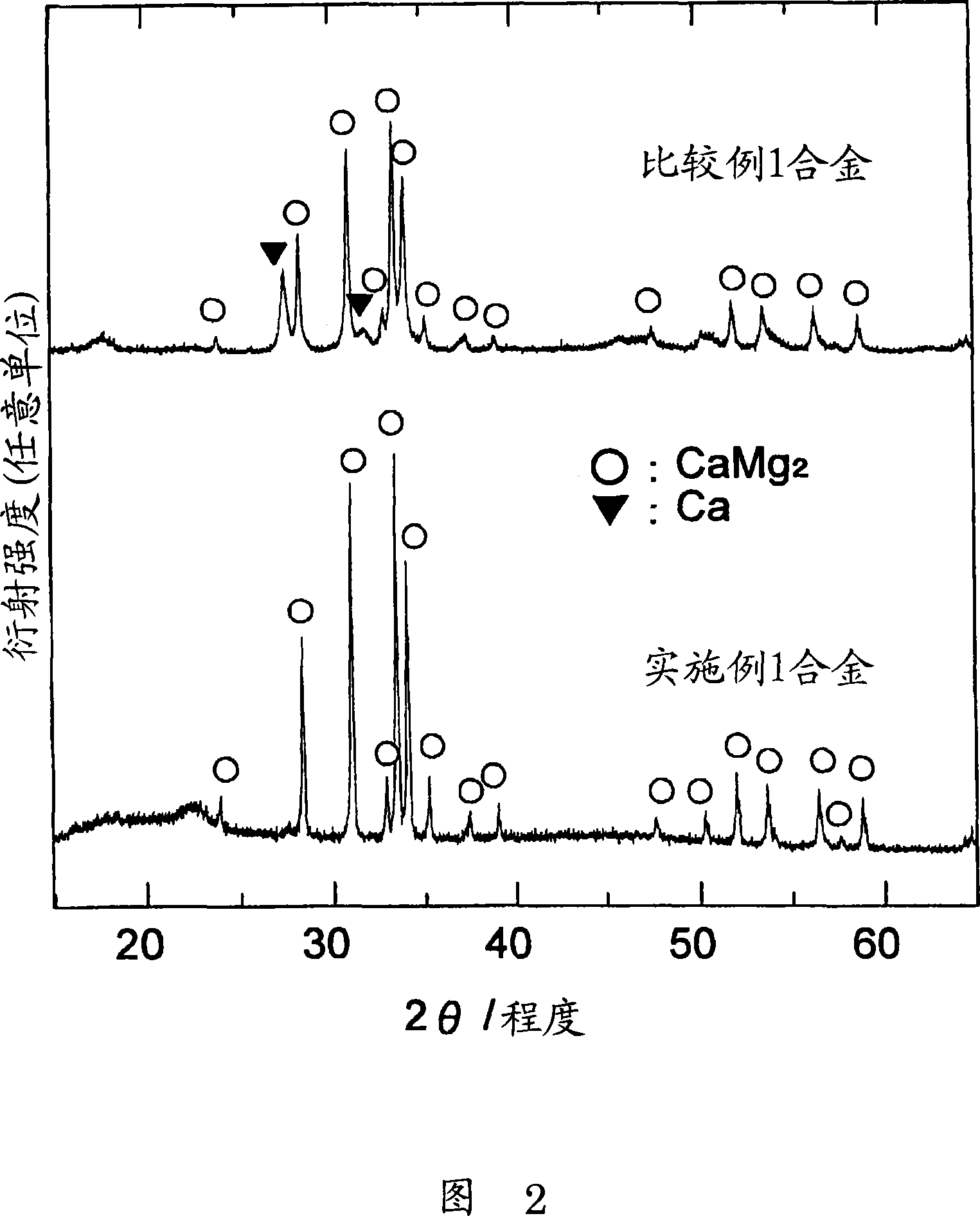

Embodiment 1

[0032] Prepare a total of 1 kg of Mg and Ca metals, so that their molar ratio is 2:1, as the hydrogen-adsorbing alloy CaMg 2 raw materials, put them all into the induction melting type melting furnace, discharge the gas in the furnace to 8×10 -3 Torr, and then, helium gas (concentration 100 vol %) was introduced to 600 Torr as a shielding gas. Thereafter, while filling the furnace with the protective gas, the temperature in the melting furnace was heated to 1100° C. to melt the raw materials, and the molten metal temperature of the alloy was maintained at 1050° C. for 30 minutes. Thereafter, the molten metal of the above alloy is poured onto the water-cooled ingot chassis, and cooled at a cooling rate of 1000°C / sec to solidify the molten metal of the above alloy to produce CaMg 2 alloy. For the CaMg thus obtained 2 For the alloy, the melting yield and chemical composition were measured by the methods (1) and (2) below.

[0033] (1) Determination of melting yield

[0034] ...

Embodiment 2~4

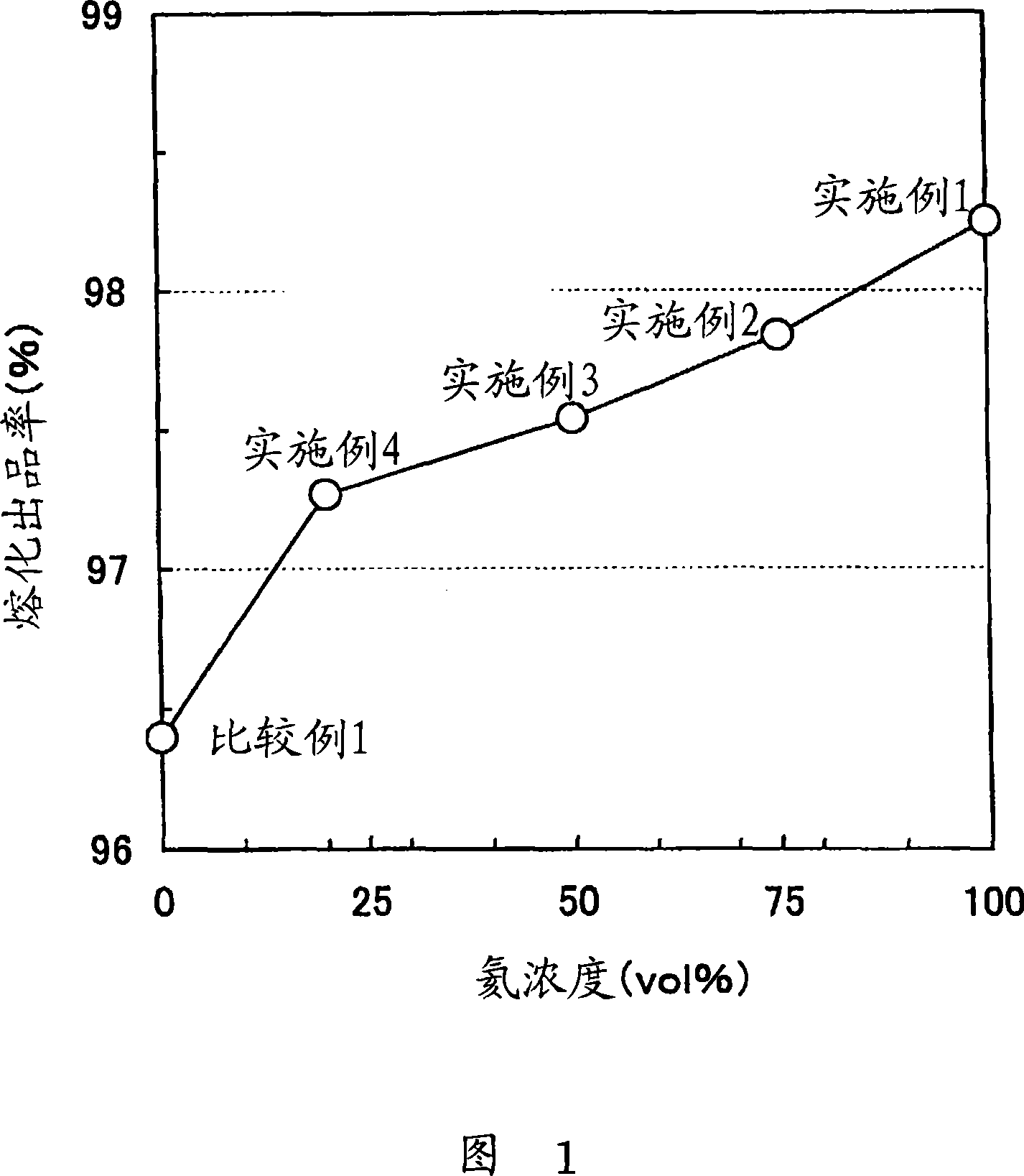

[0044] CaMg was produced in the same manner as in Example 1 above, except that the concentration of helium introduced as a protective gas was changed to 75vol%, 50vol%, and 25vol% (the rest was argon). 2 alloy. Determination of these CaMg by the method of (1) and (2) above 2 The melting yield and chemical composition of the alloy are recorded in Table 1 together with the results. From these results, it can be seen that when the helium concentration exceeds 50 vol% (Examples 2 and 3), the melting yield is as high as about 98%, and the target alloy composition can be obtained with high accuracy. On the other hand, although in the case of a helium concentration of 25vol% (Example 4), the melting yield and alloy composition are worse than those of Examples 1-3, but they are comparable to the case of no helium (Comparative Example 1). Ratio, the melting yield and the accuracy of the alloy composition are improved, and the effect of introducing helium can be confirmed.

[0045] F...

Embodiment 5

[0049] Except adopting Ca and Al as alloy raw materials, all the other manufacture CaAl in the same manner as in Example 1 above. 2 Alloy, with the above (1) and (2) method to measure the obtained CaAl 2 The melting yield and chemical composition of the alloy are recorded in Table 1 together with the results. From the results, it can be seen that in Example 5, a high-precision target alloy with a melt yield as high as about 98% and within ±1% of the target Al composition ratio was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com