Insulation inspecting apparatus

A technology of insulation inspection and equipment, applied in the direction of instruments, testing dielectric strength, measuring devices, etc., can solve problems such as insufficient methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the insulation inspection apparatus according to the present invention will be described below. The same or corresponding elements have the same reference numerals, and descriptions thereof will not be repeated.

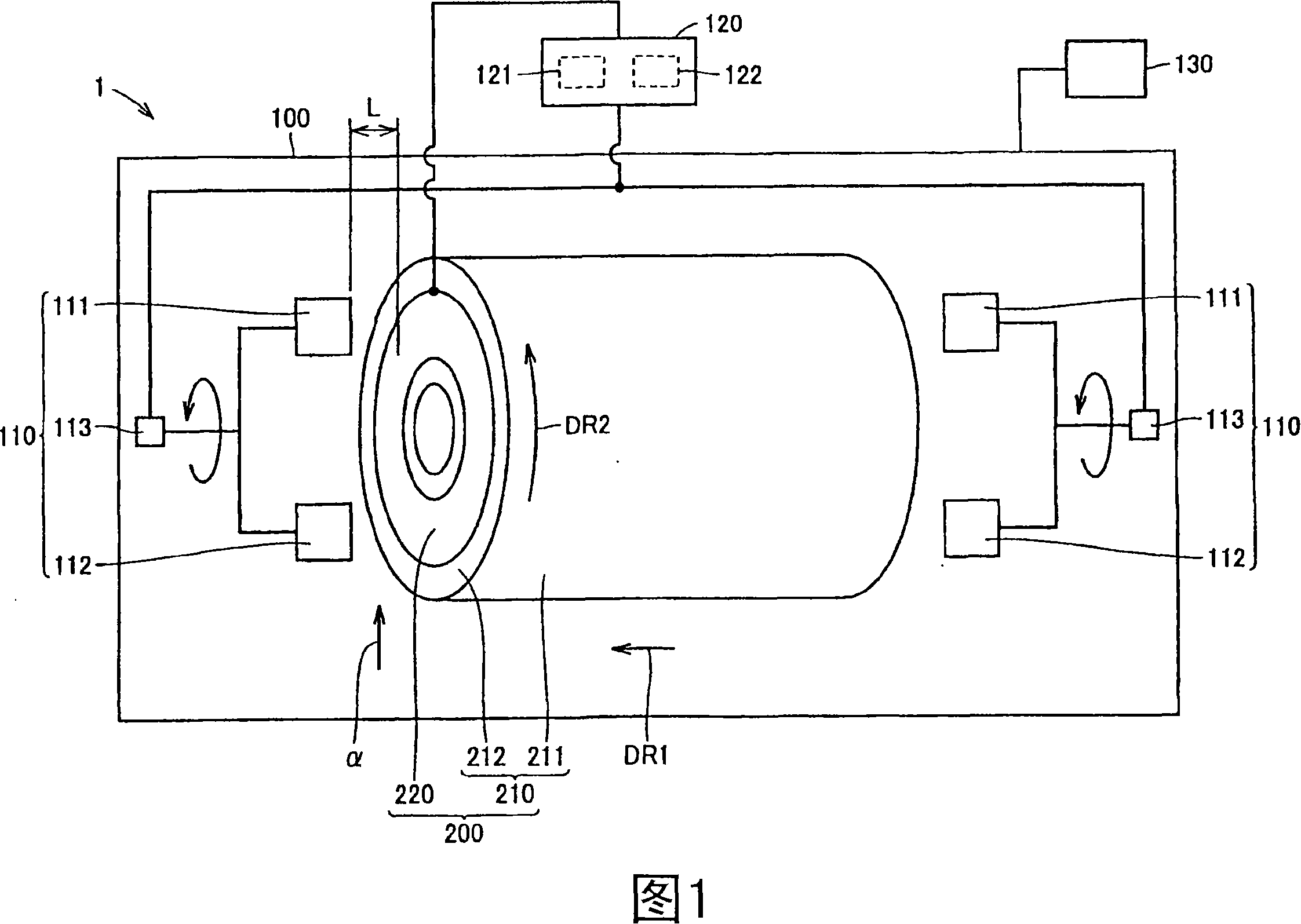

[0024] FIG. 1 shows the configuration of an insulation inspection device according to an embodiment of the present invention. Referring to FIG. 1 , the insulation inspection apparatus 1 of the present embodiment includes a chamber 100 (inspection container).

[0025] The stator 200 is placed in the chamber 100 . The stator 200 includes a stator core 210 and coil ends 220 .

[0026] Plates formed of a magnetic material such as iron, iron alloy, etc. are stacked to constitute the annular stator core 210 . A plurality of tooth portions (not shown) and groove portions (not shown) as recesses between the teeth are formed on the inner peripheral surface of the stator core 210 . The slot portion is formed to open on the inner peripheral side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com