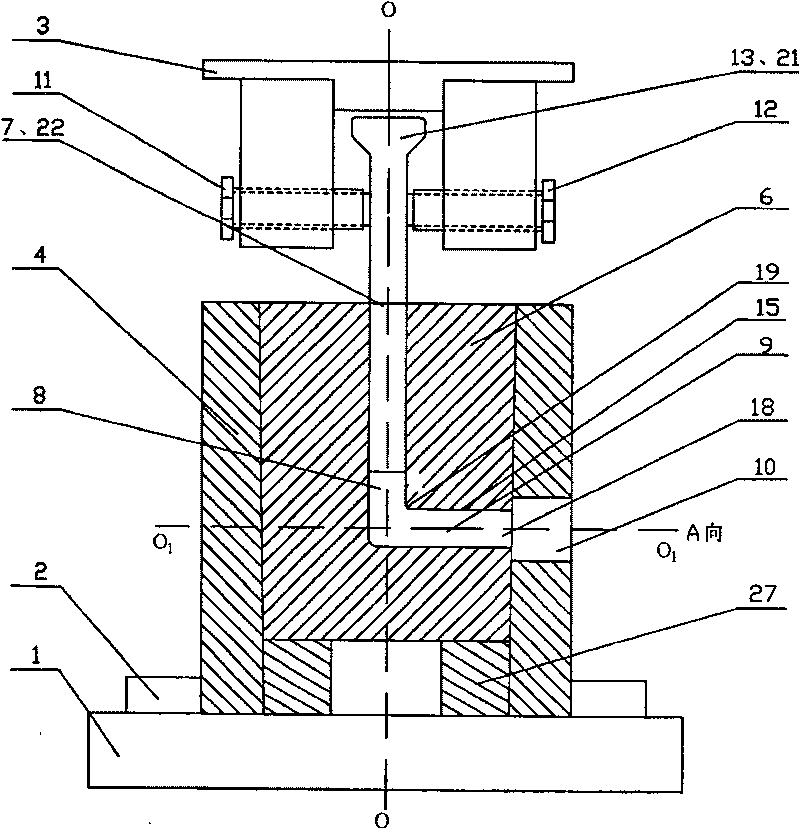

L-shaped extrusion device for producing ultra-fine crystal block body material

A block material and extrusion device technology, applied in the field of L-shaped extrusion device, can solve problems such as block cracking, failure to meet ultra-fine grain requirements, block material cracking, etc., to avoid The effect of block cracking, improving the degree of grain refinement, and eliminating tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Extrusion equipment, mold sleeves, mold cores, extrusion rods, etc. are all in quasi-working condition;

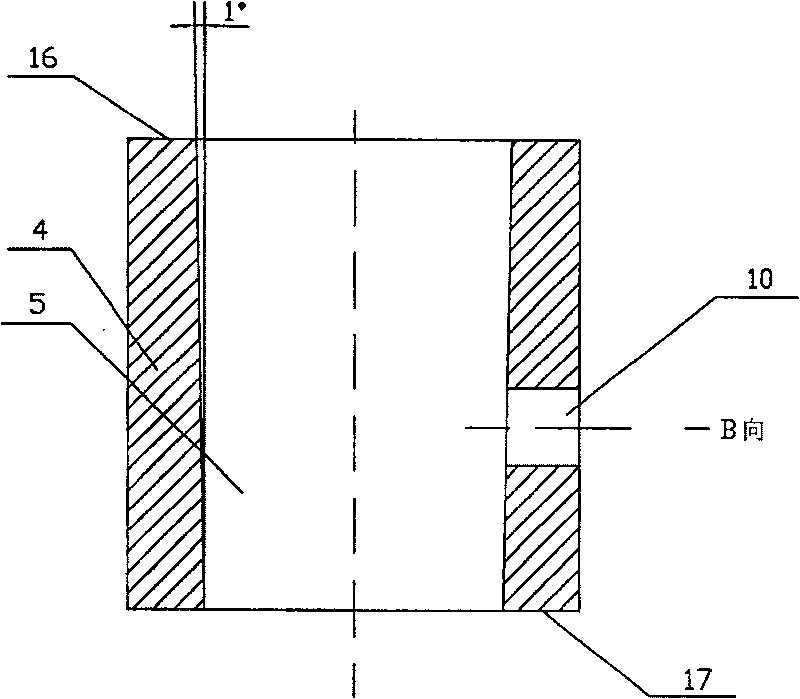

[0053] (1), square extruding rod 7, wedge-shaped extruding rod 22 surfaces evenly smear graphite+Vaseline lubricant;

[0054] (2), put the extruded first material rod into the vertical channel 8, insert the square extrusion rod 7, and extrude with the extrusion speed of 0.04mm / s. When the material rod is squeezed to the corner 19, pull out Out of the square extruded rod 7;

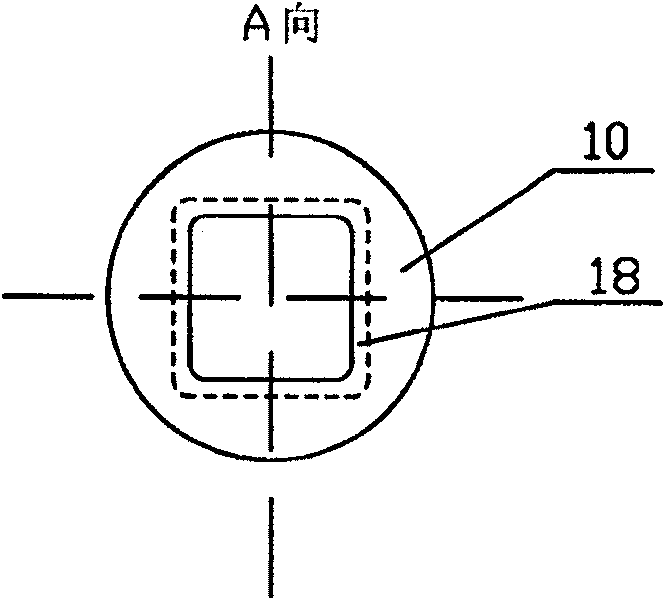

[0055] (3), change into the wedge-shaped extruding rod 22, make the wedge-shaped angle face towards the exit, and extrude until all the block materials enter the horizontal channel 9, and pull out the wedge-shaped extruding rod 22;

[0056] (4) Load the second material rod, extrude according to the above steps, eject the first material rod, and discharge it from product outlets 18 and 10, and complete the first extrusion of the first material rod ;

[0057] (5) Pull out the wedge-shaped extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com