Patents

Literature

33results about How to "Eliminate tensile stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

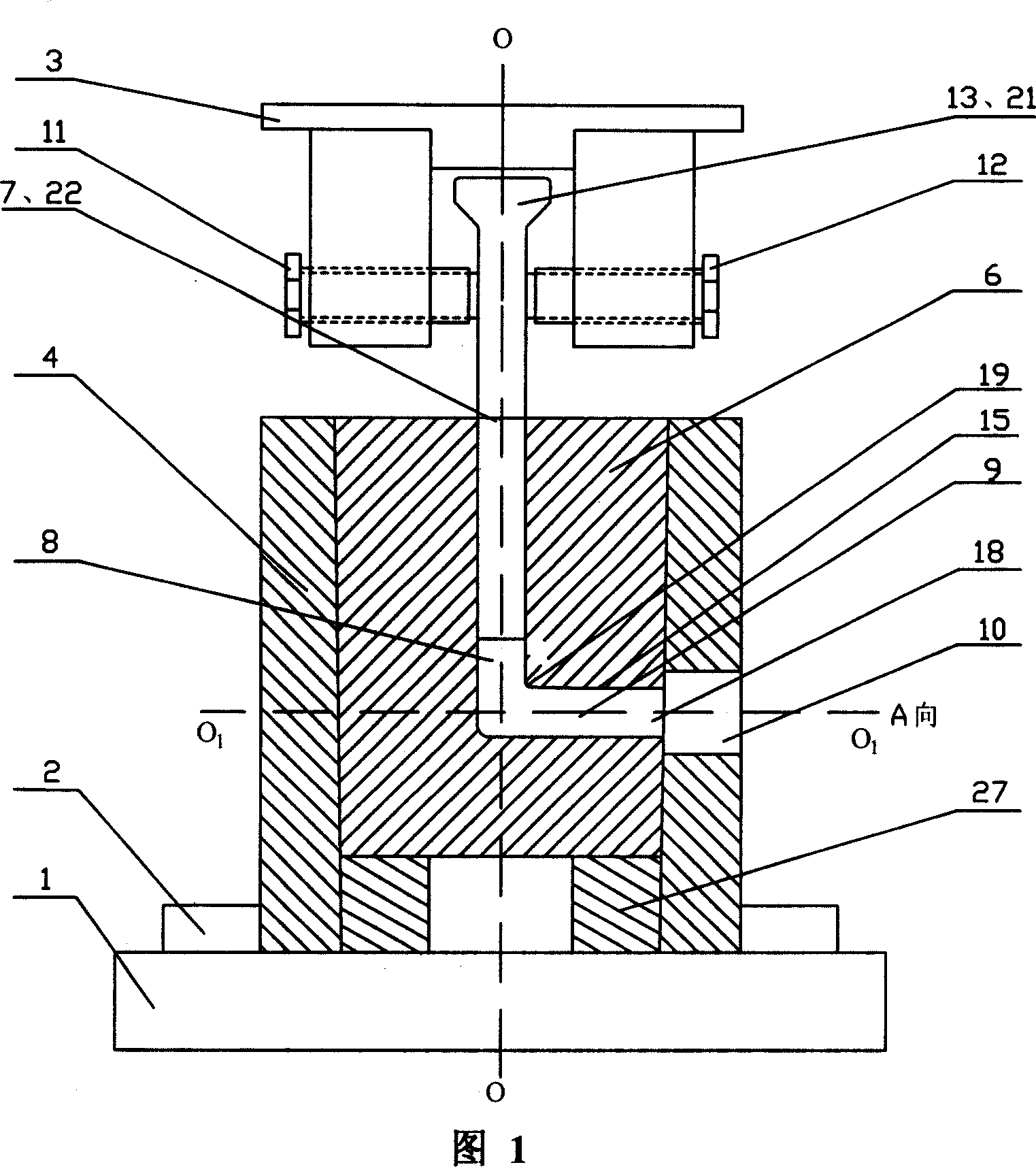

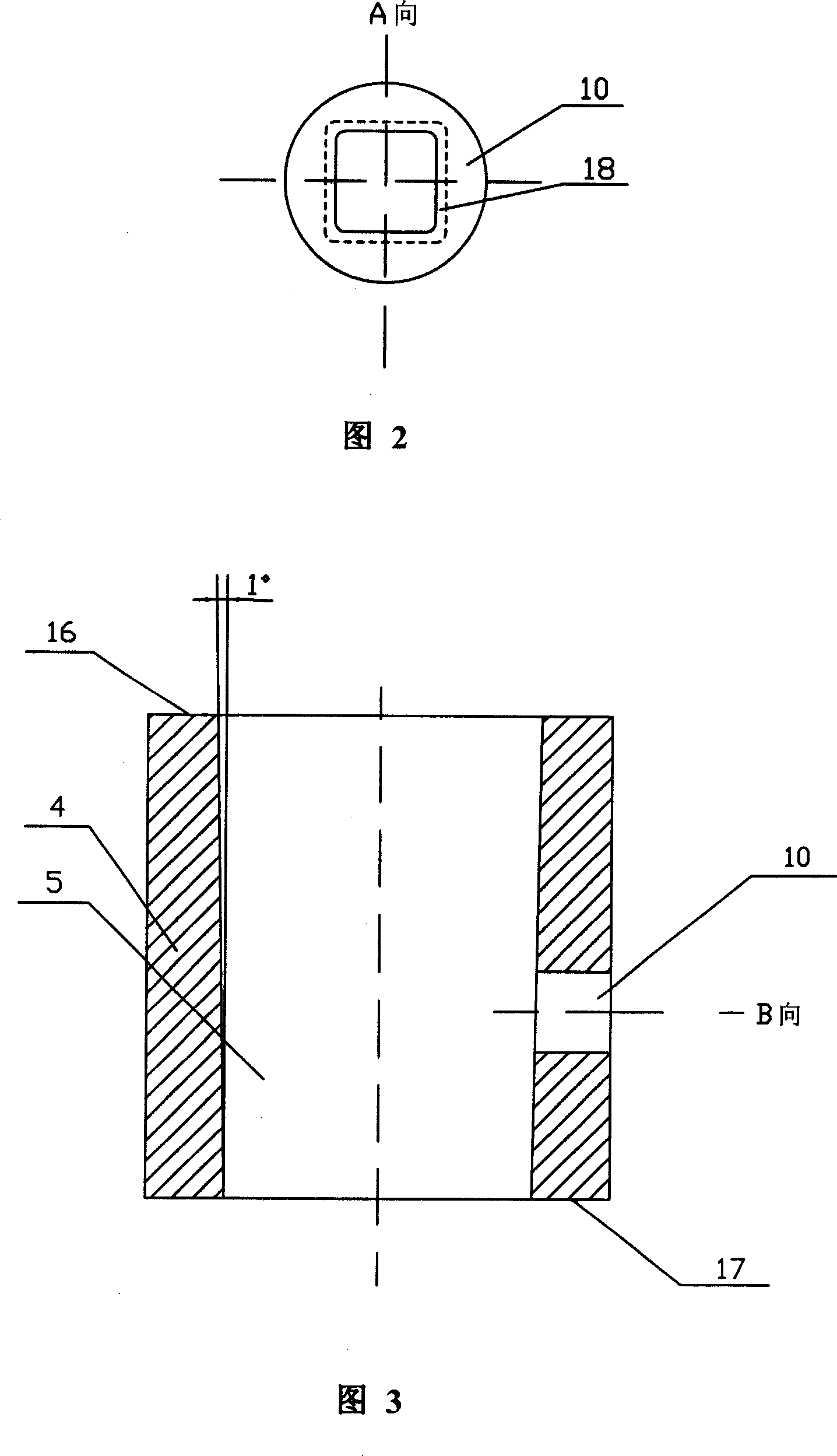

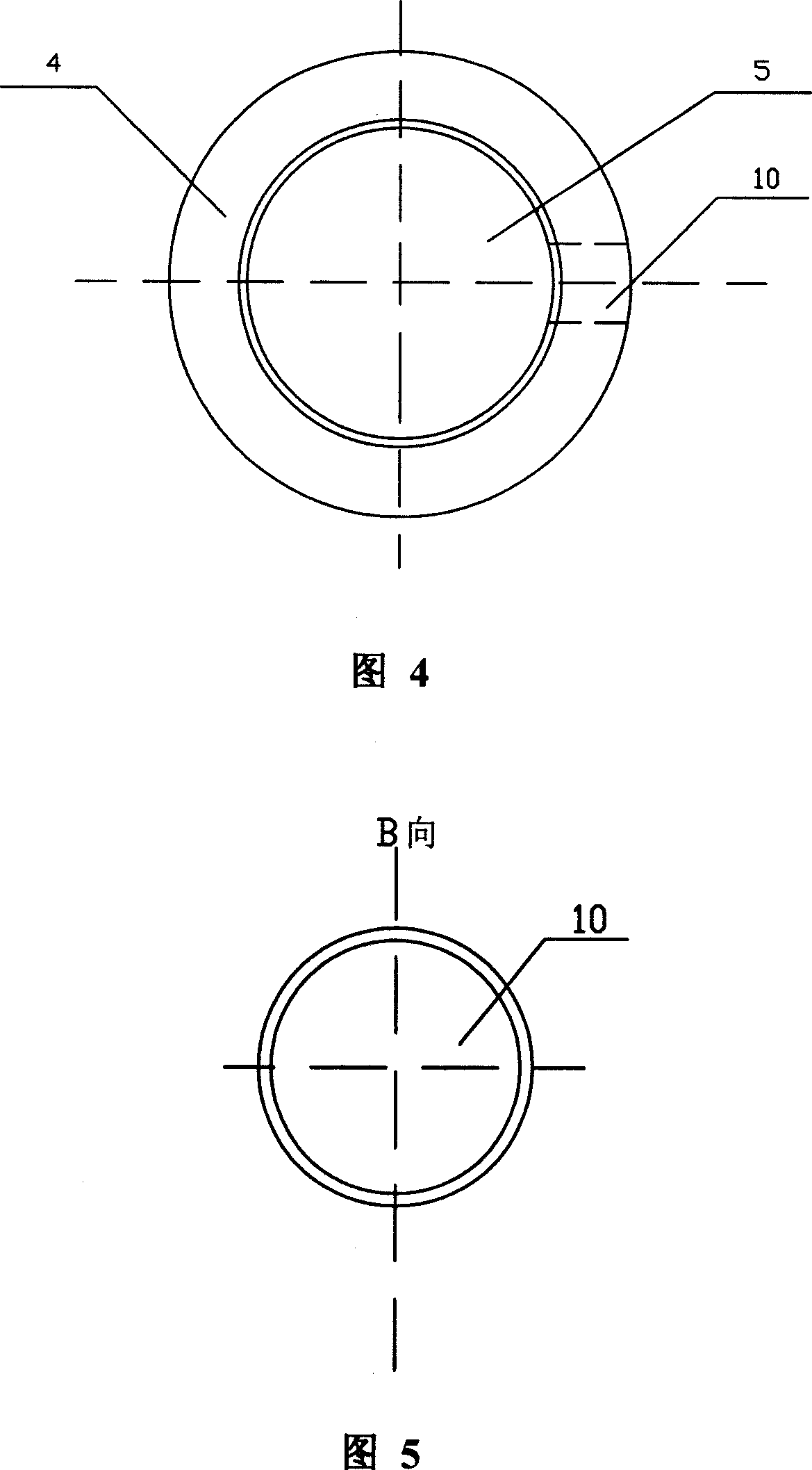

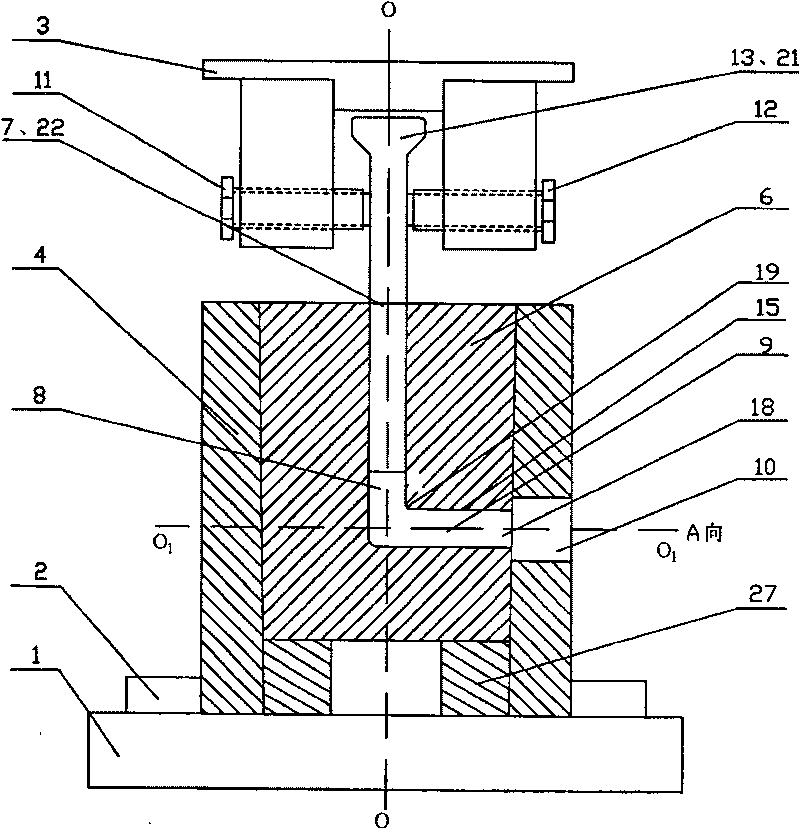

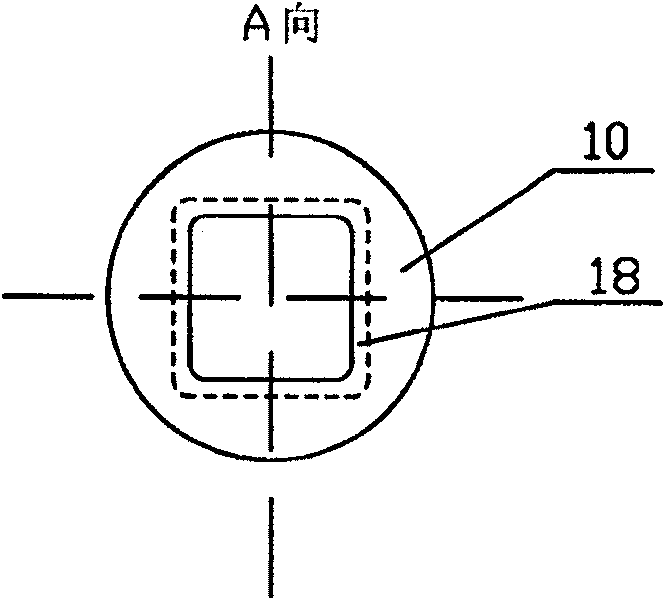

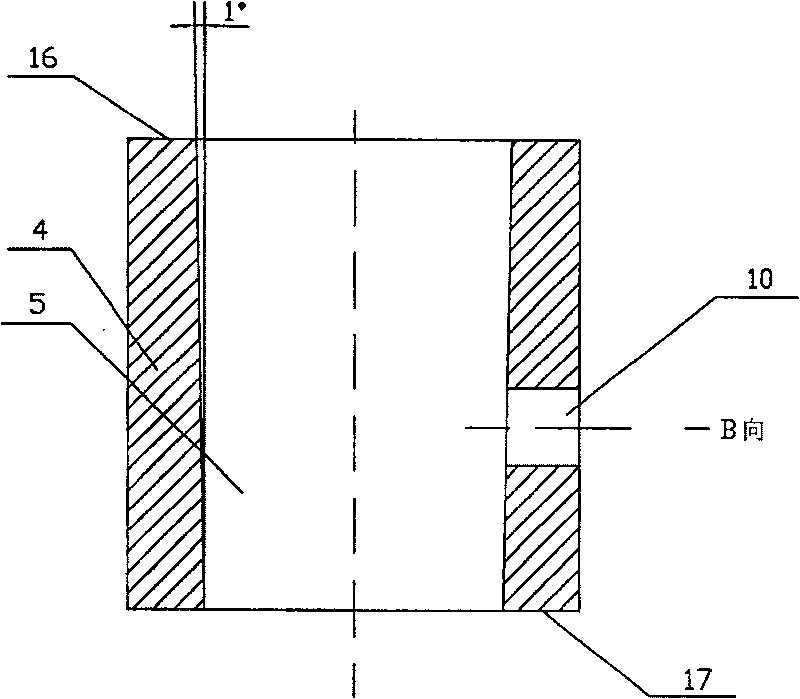

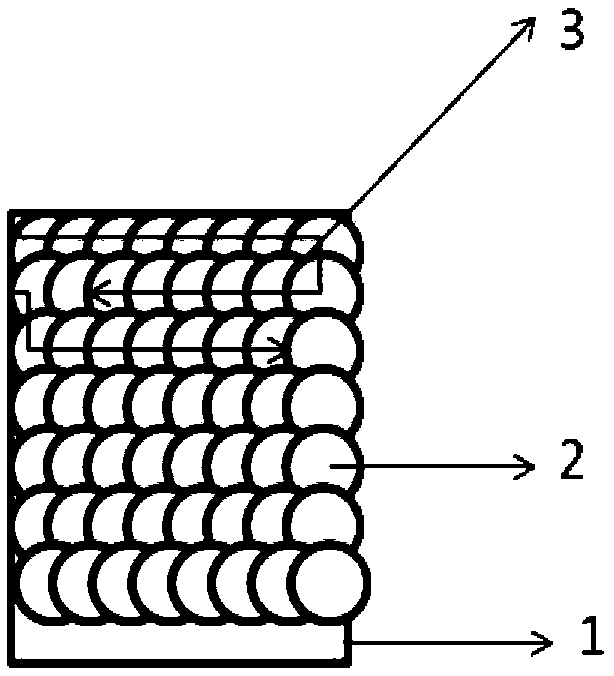

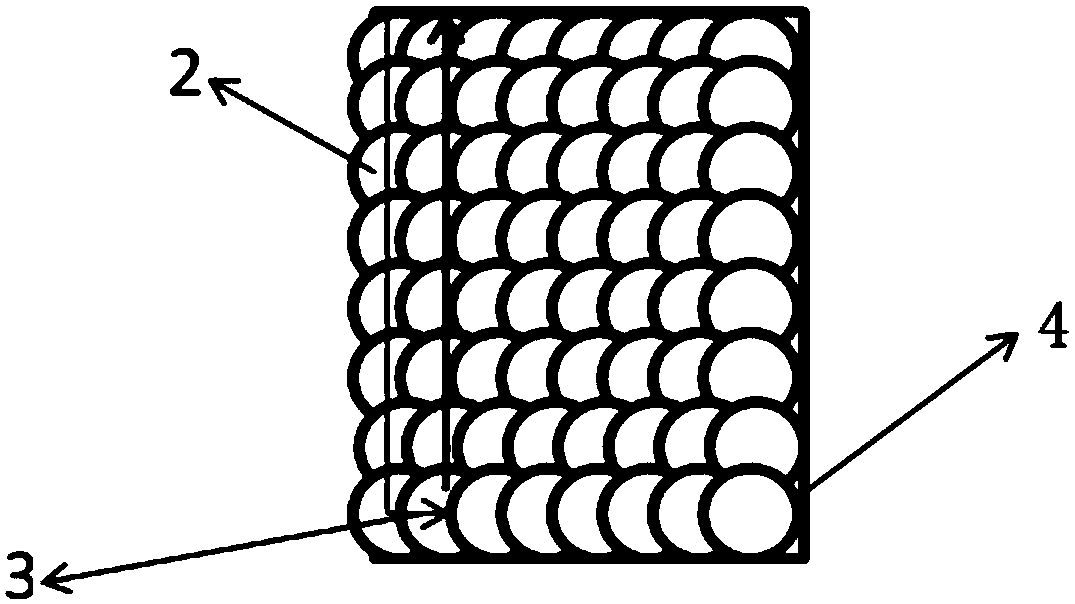

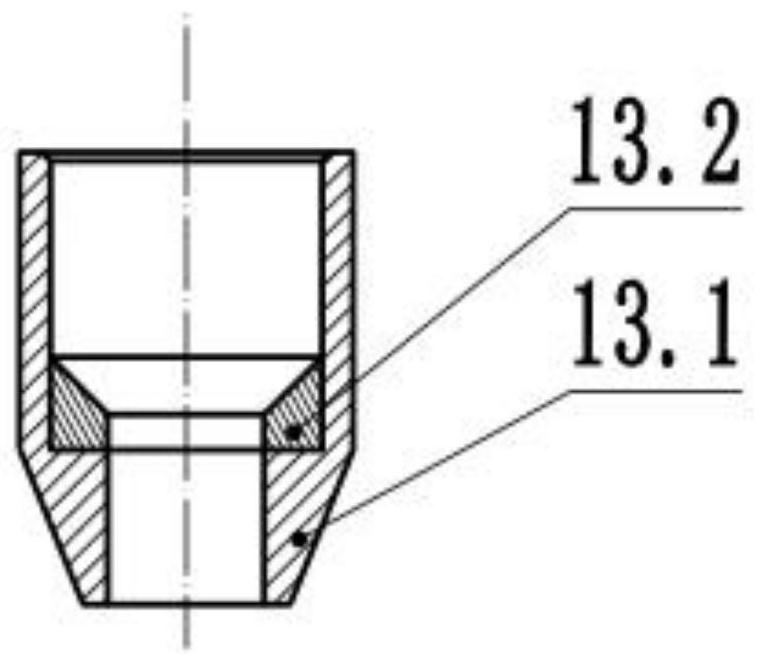

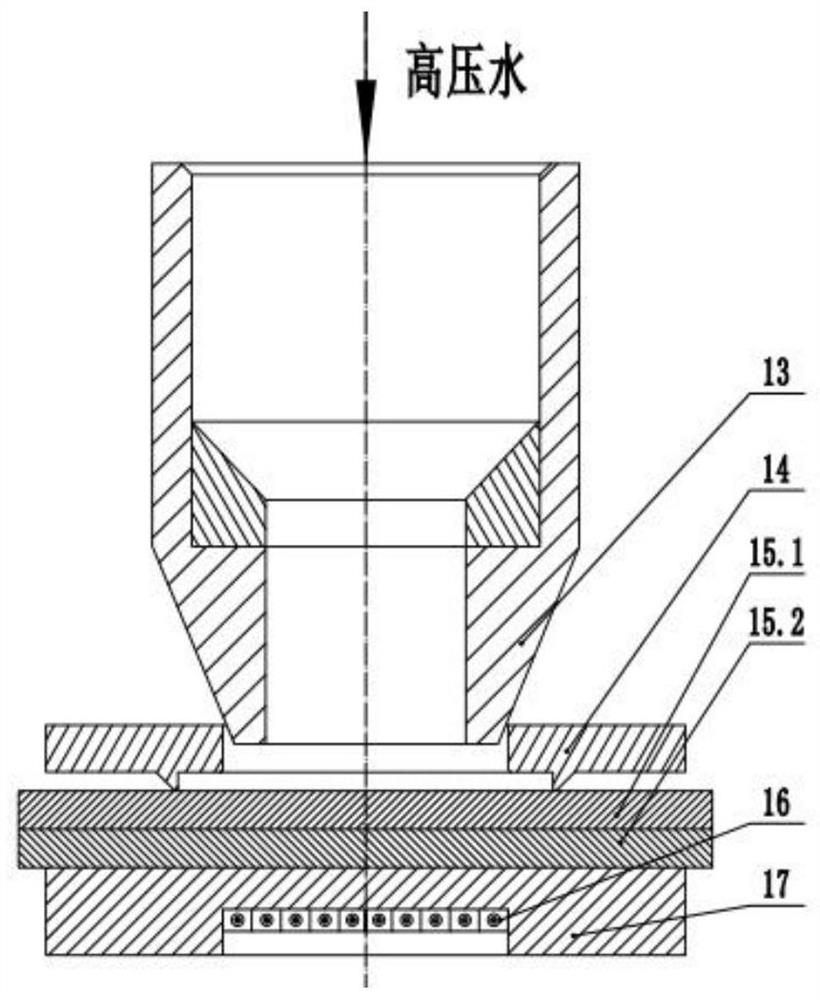

L-shaped extrusion device for producing ultra-fine crystal block body material

The extrusion apparatus for preparing superfine crystal block material has one structure comprising a die holder, a connecting seat, a conic die case, a conic die core, a wedged extruding rod with reduced extrusion force to avoid cracking of the block, a turning unit, a square vertical channel, a square horizontal channel and a product outlet. The product has high crystal grain fining and smooth surface, and the extrusion apparatus has simple structure, excellent mechanical performance, easy installation and use, and no pollution.

Owner:TAIYUAN UNIV OF TECH

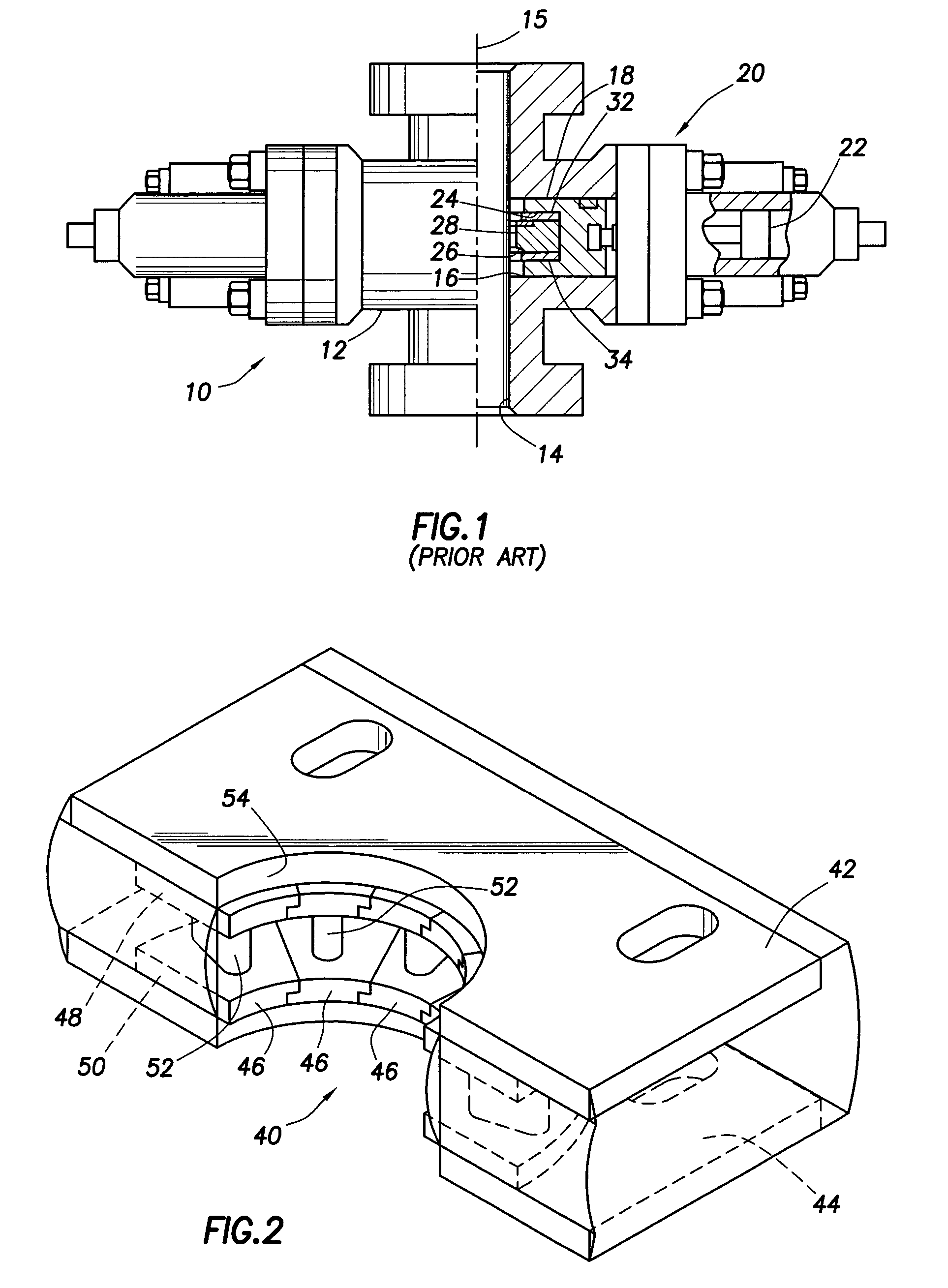

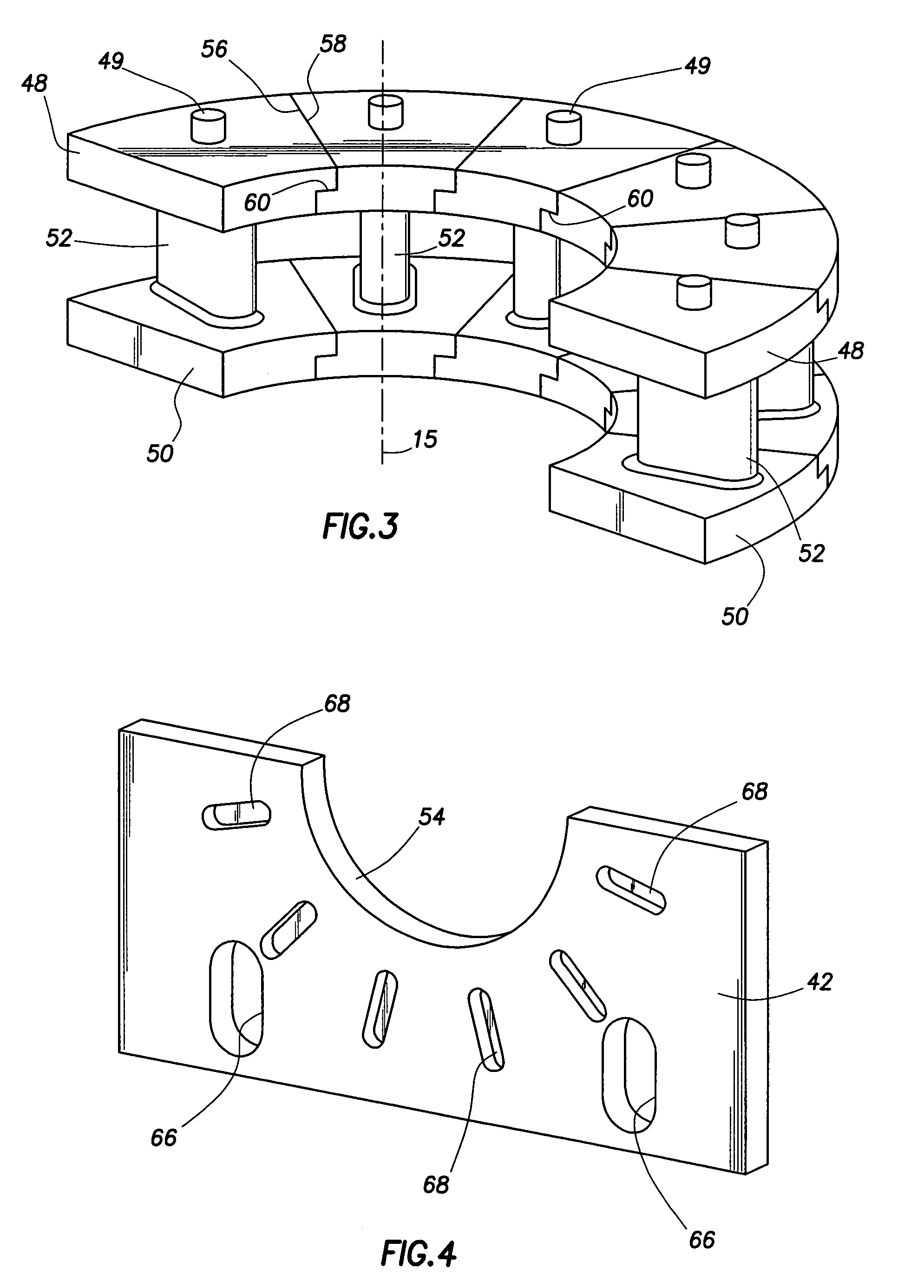

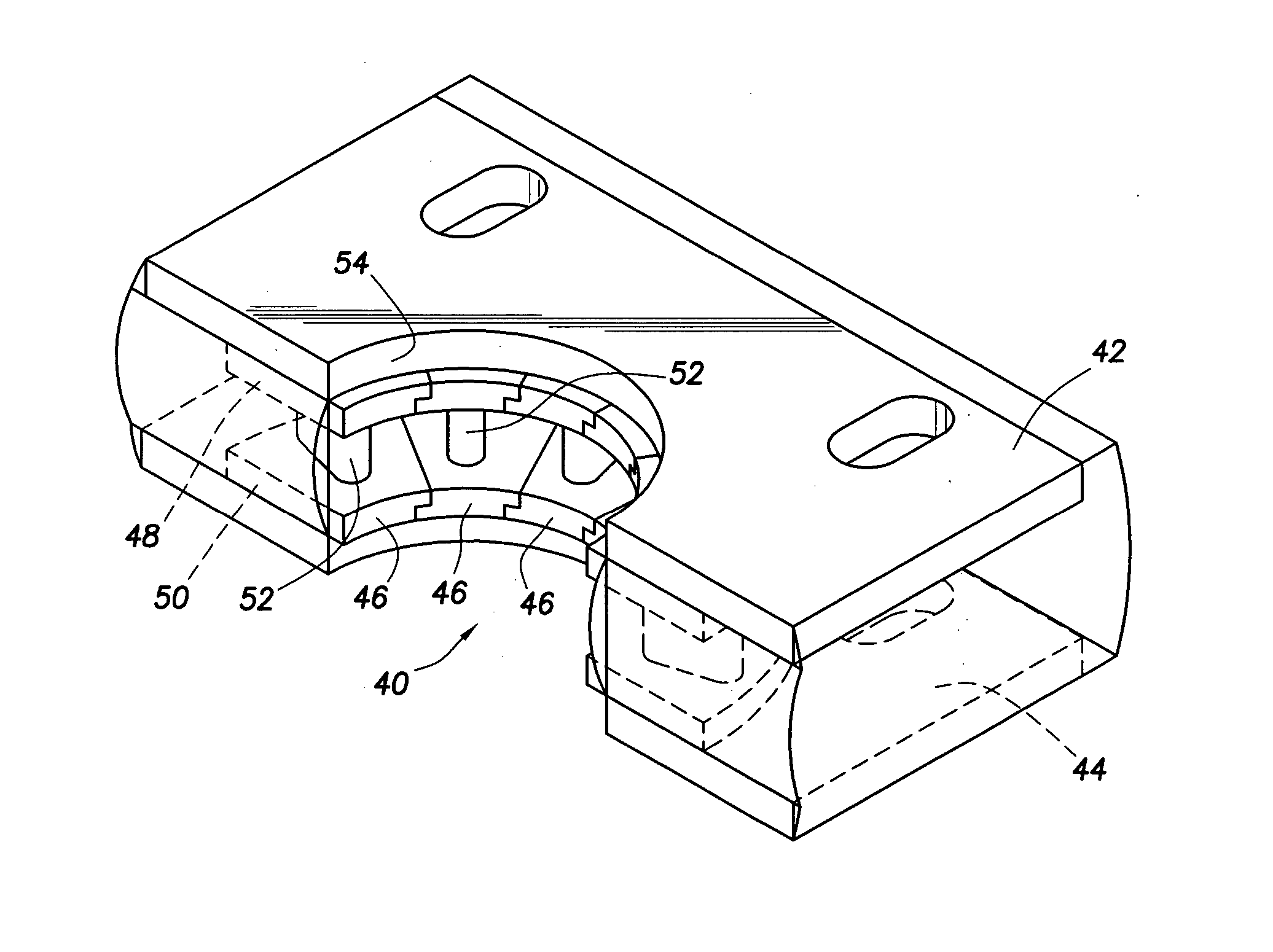

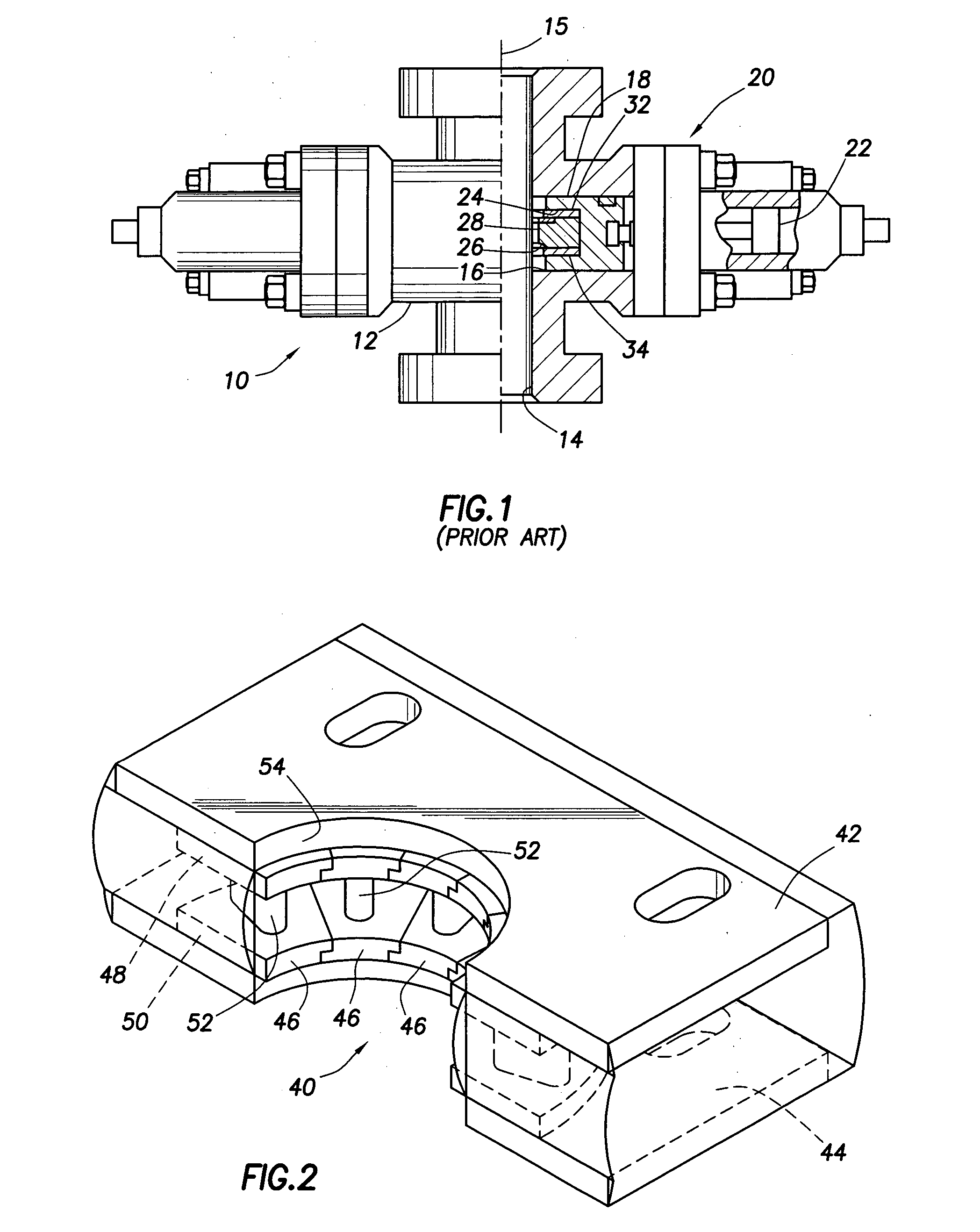

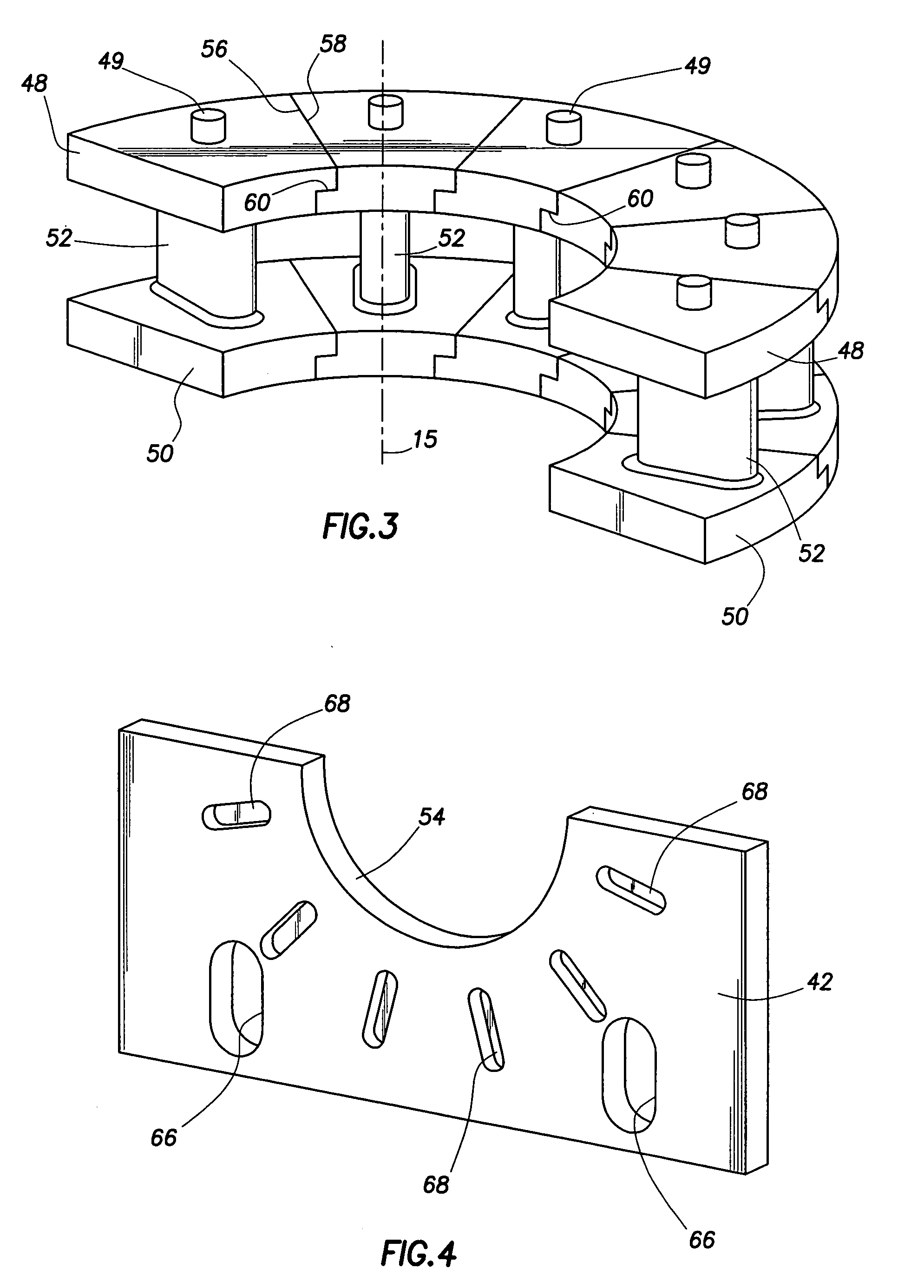

Variable bore ram

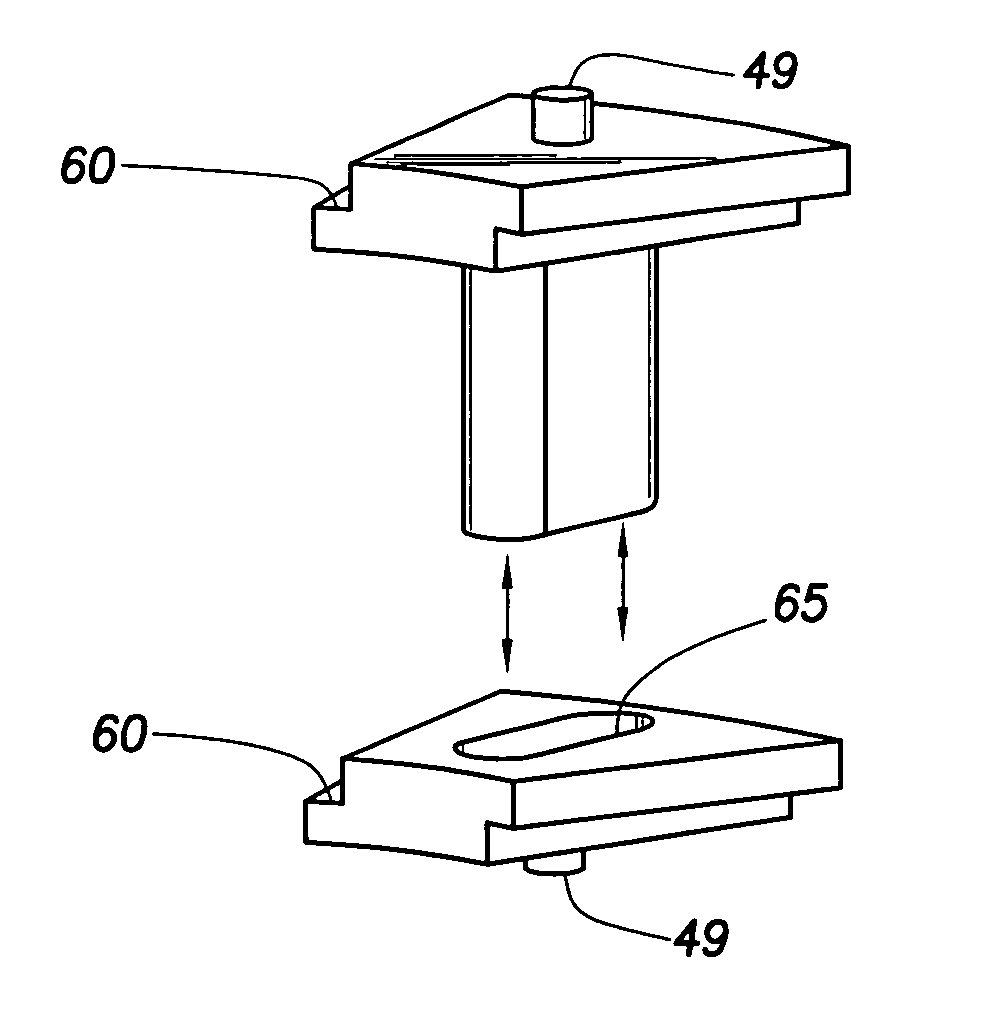

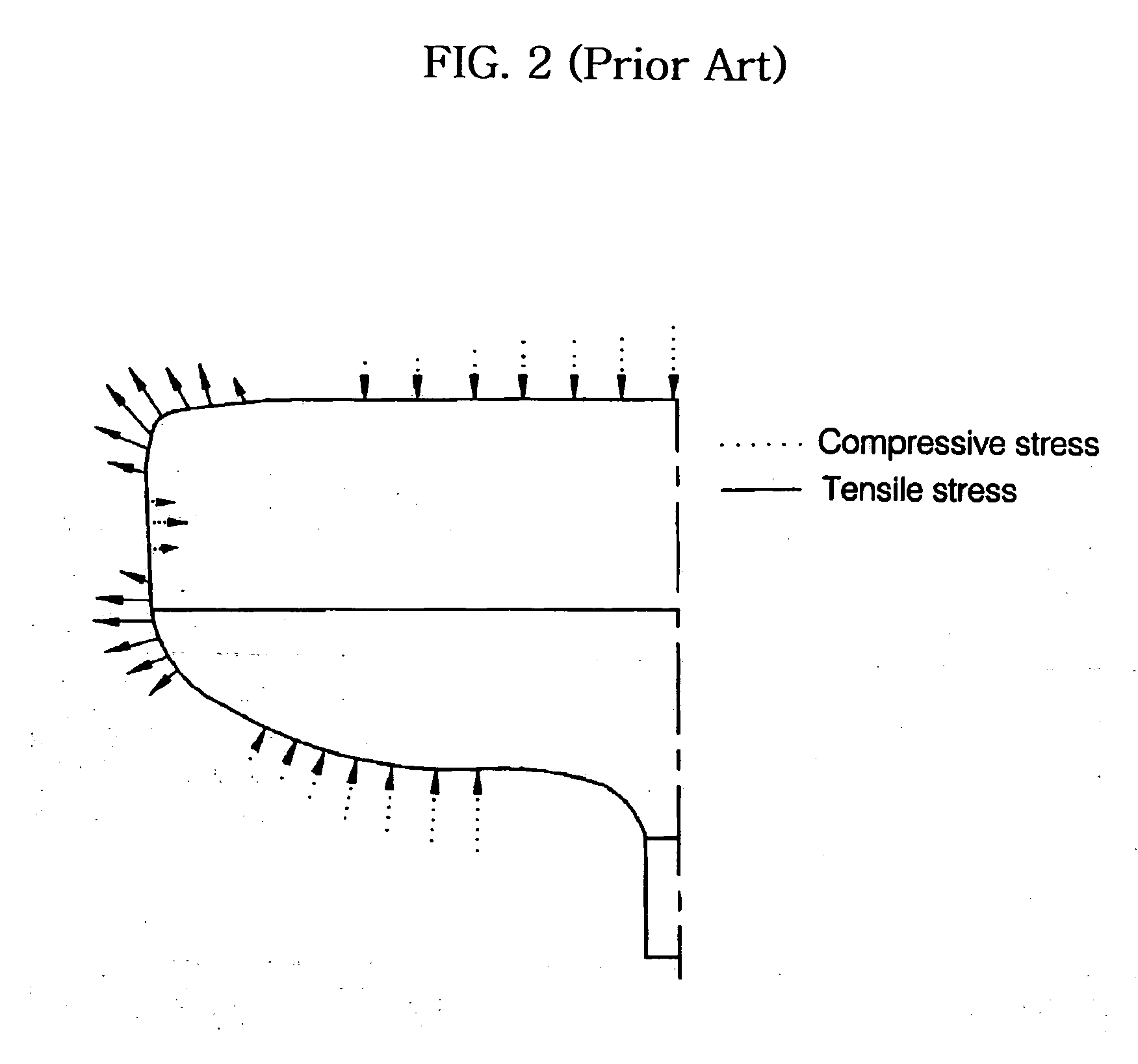

ActiveUS6974135B2Eliminate tensile stressSmall sizeFluid removalSealing/packingEngineeringBlowout preventer

A ram type blowout preventer includes variable ram packers for sealing about tubulars of different outside diameters in the bore of the preventer housing or about a single tubular having a variable outside diameter. Each ram packer includes a body of elastomeric material formed about vertical ribs to conform to tubular having variable OD within a certain range.

Owner:VARCO I P INC

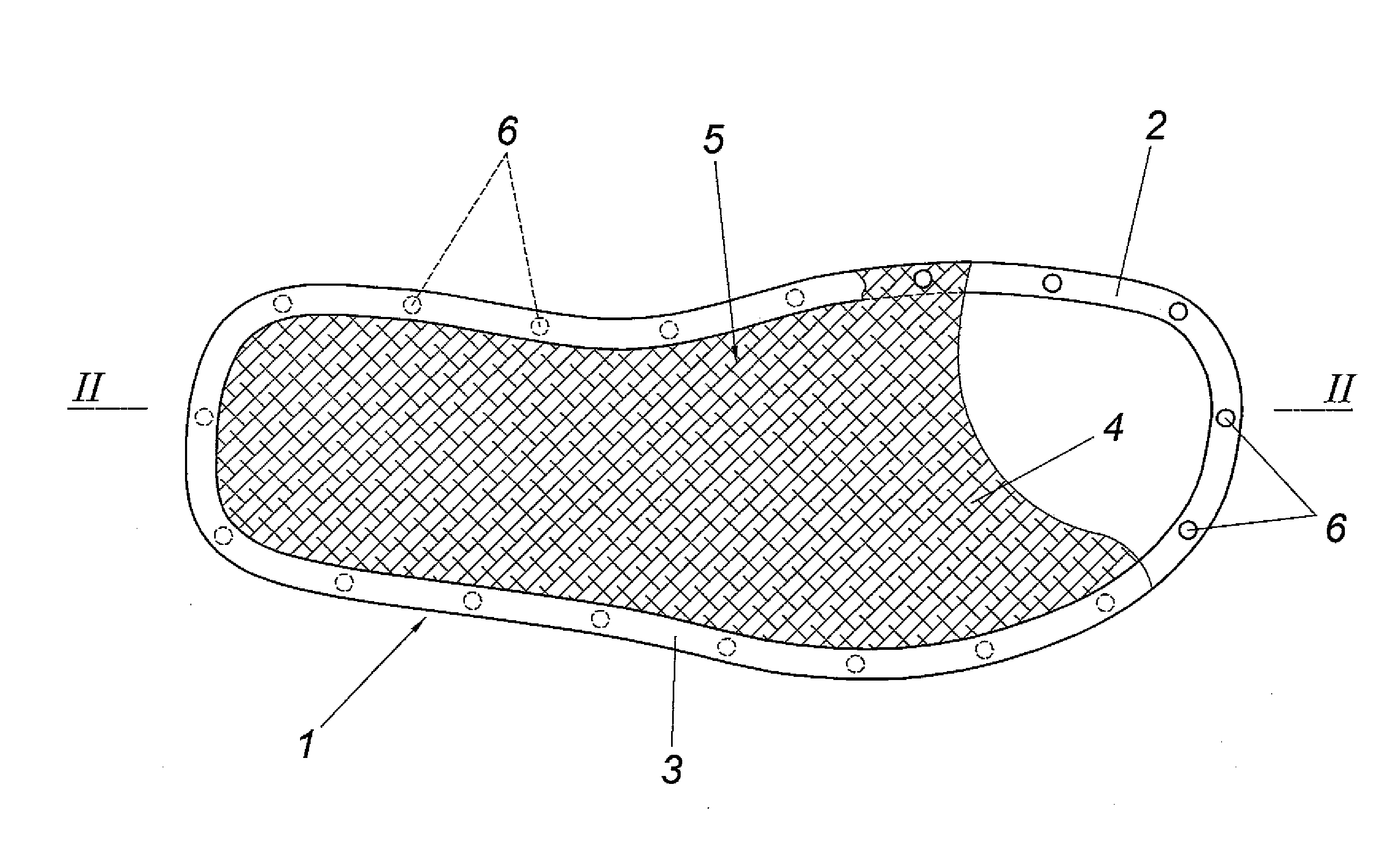

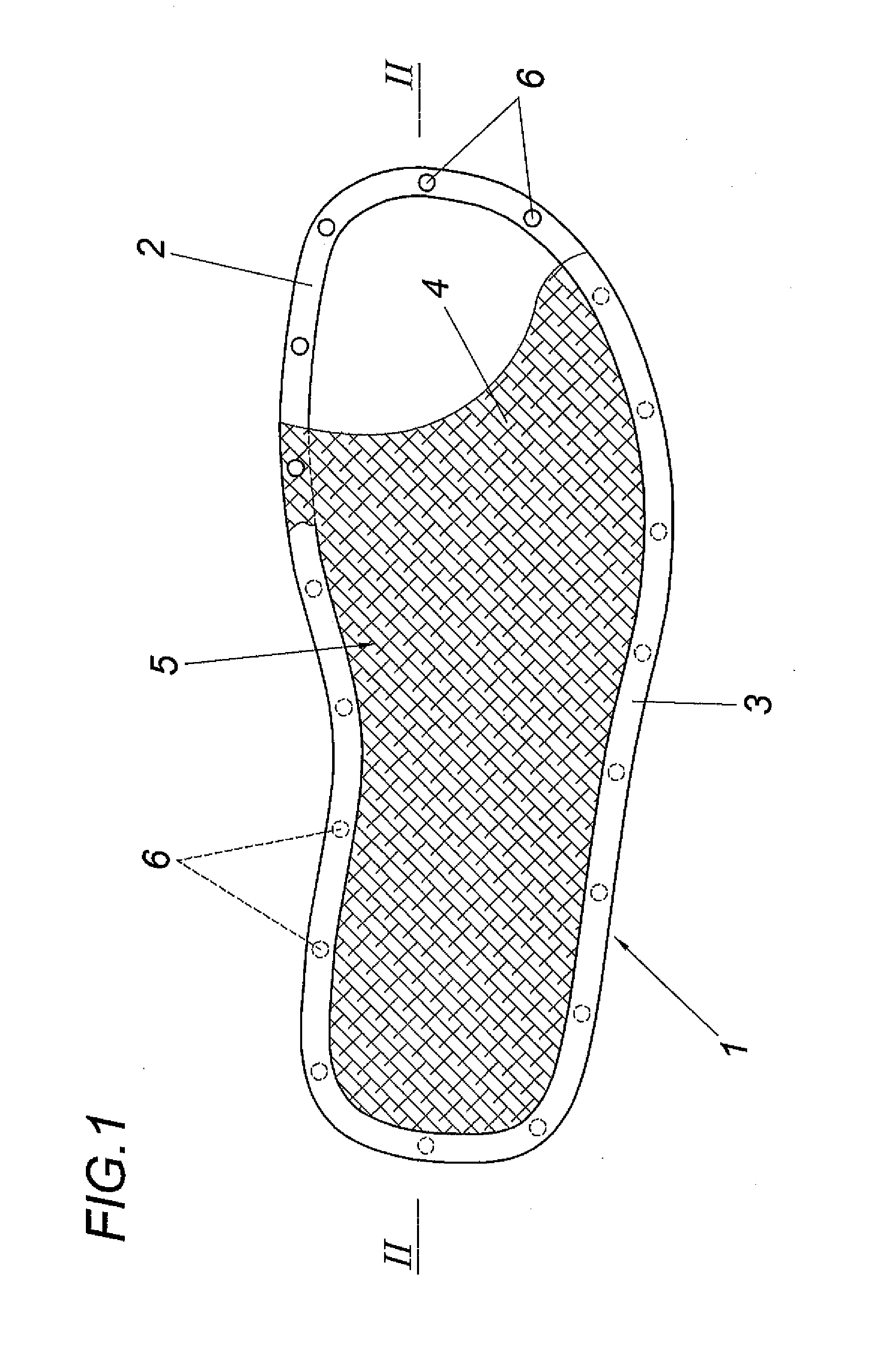

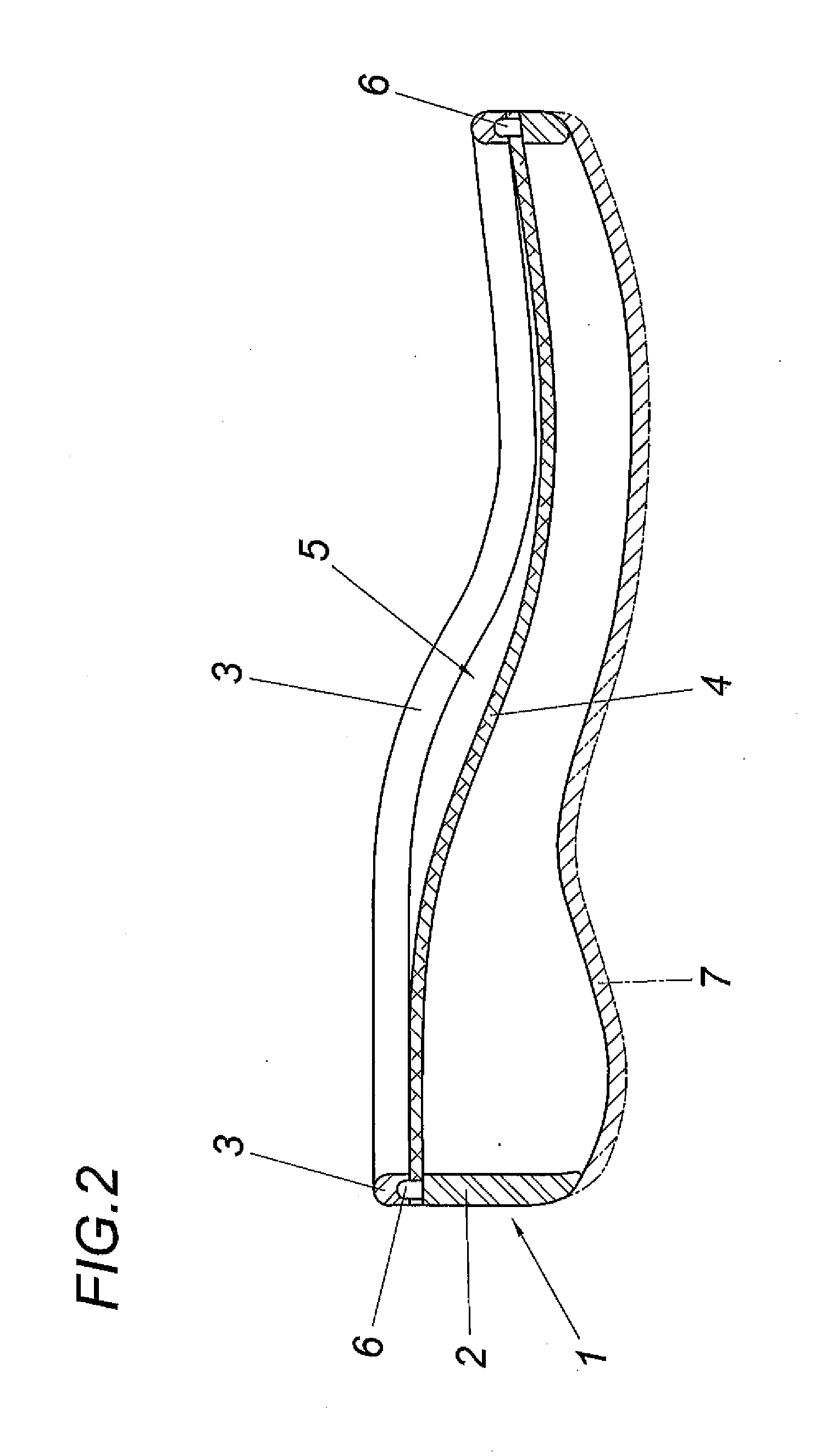

Shoe sole comprising a footbed

Owner:STOHR JULIA

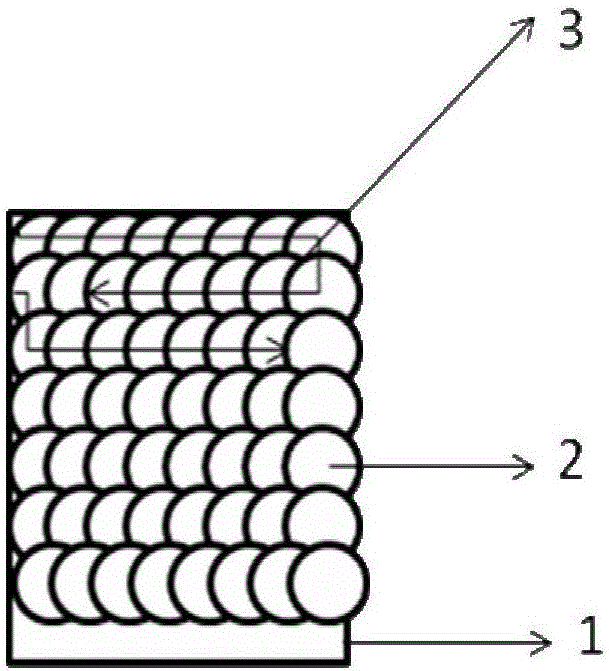

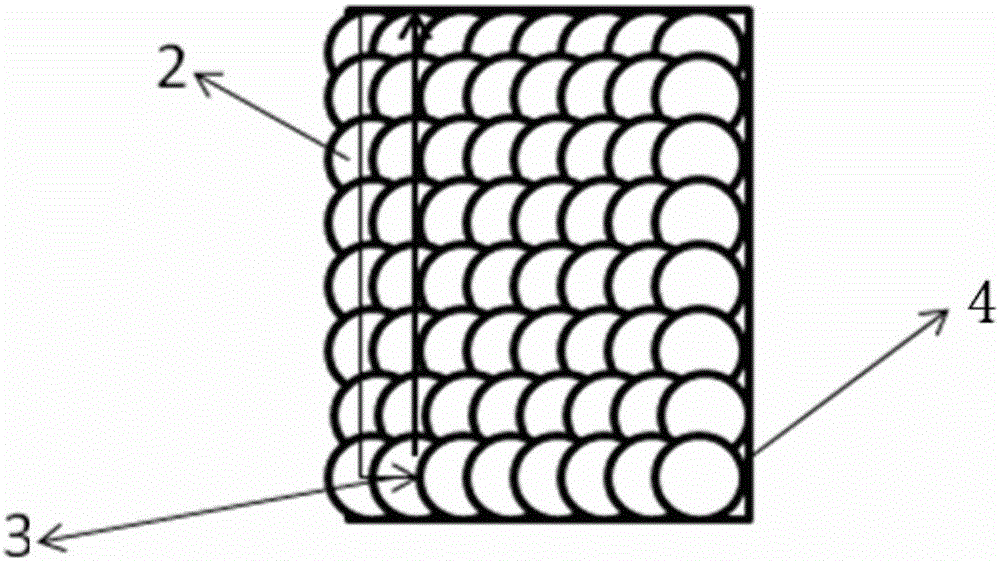

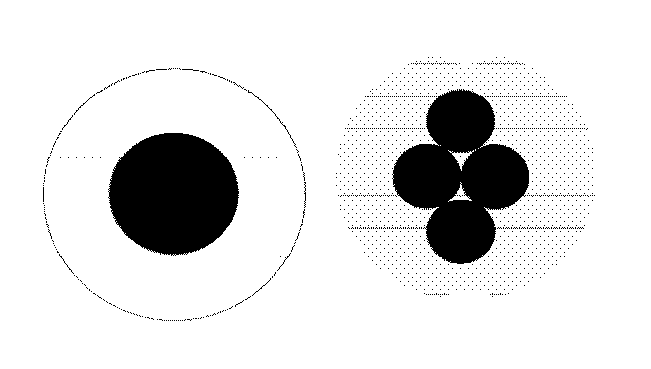

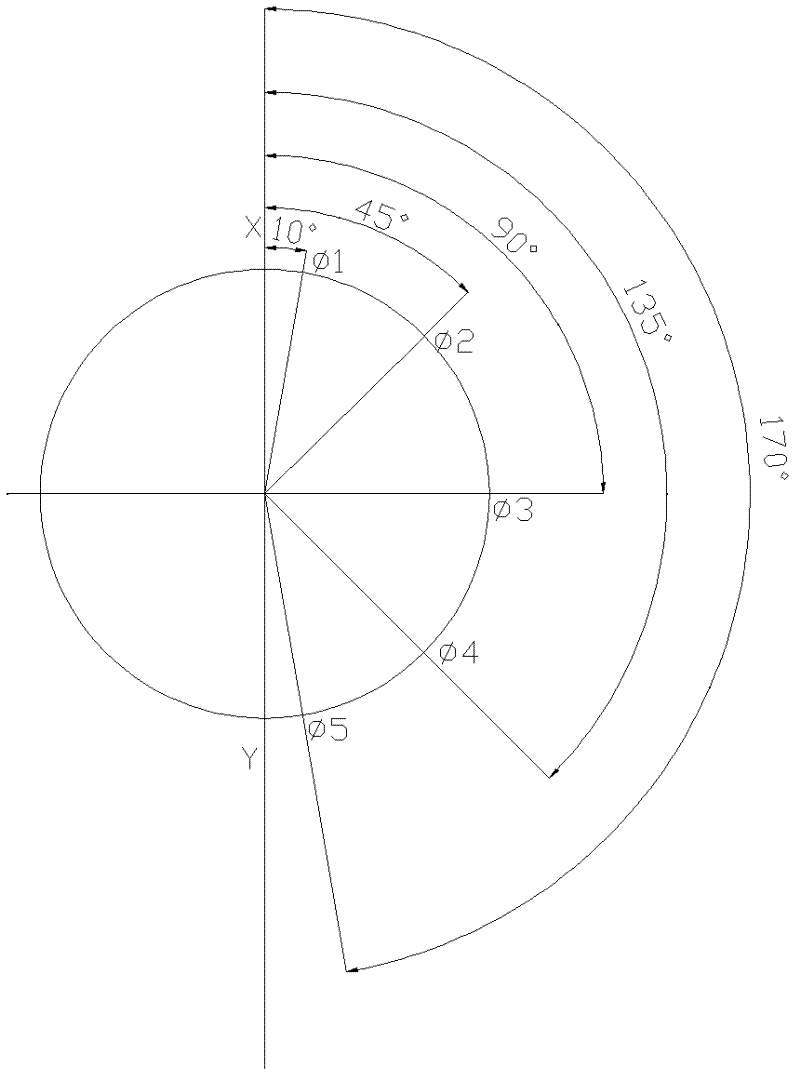

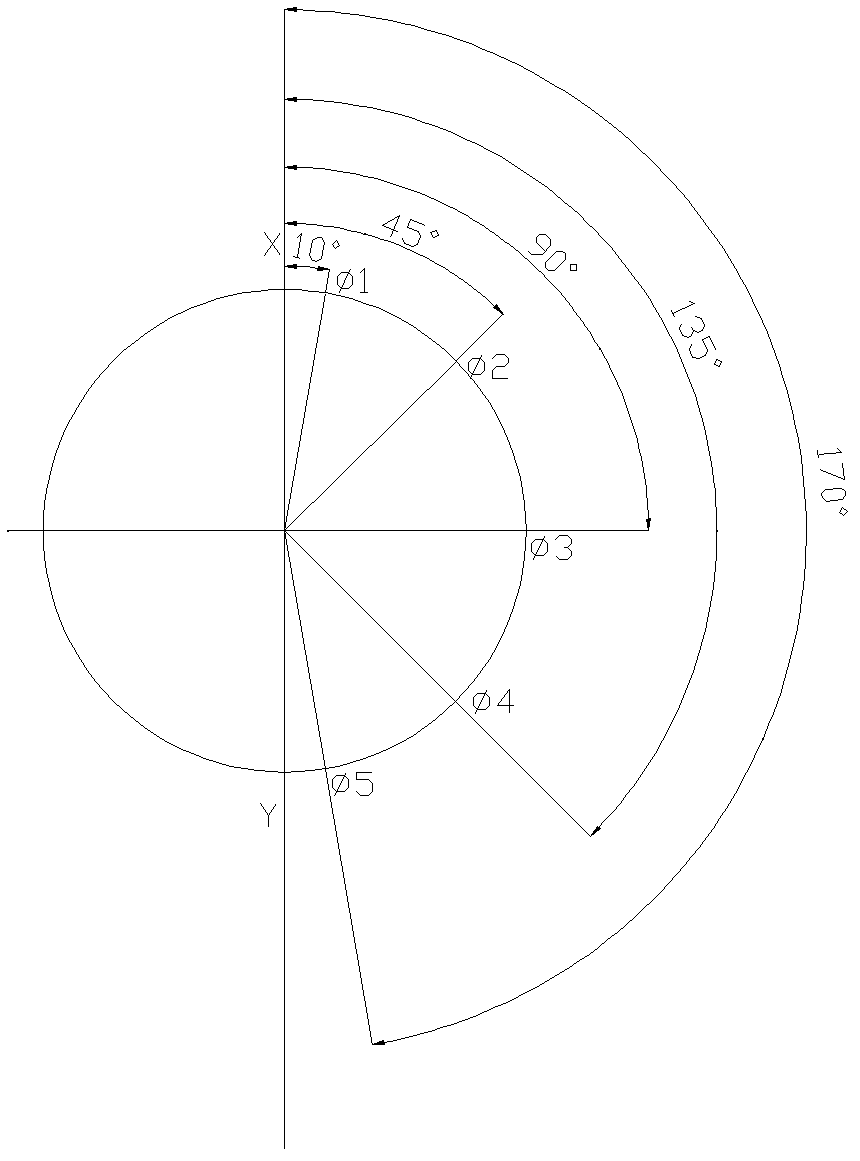

Method for manufacturing pre-deformation line diamond line saw through powder metallurgy

InactiveCN102218537AImprove gripExtended service lifeMetal sawing toolsStone-like material working toolsBLENDER/MIXERPre deformation

The invention provides a method for manufacturing a pre-deformation line diamond line saw through powder metallurgy, comprising the following steps: basic line manufacturing: selecting metal wires, stranding at least two metal wires into a line, and deforming the stranded line by a deformer to obtain a pre-deformation base line; powder preparation: weighing metal powder, a binder and diamond by mass percent, and adding the mixture into a blender mixer to evenly mixing; line blank manufacturing: putting the base line and powder into a mould, and taking the pre-deformation base line as a center to prepare a line blank by using a forming technology; and line saw manufacturing: putting the line blank to a sintering furnace for sintering, and cooling with the furnace to obtain the line saw. The manufacturing method provided by the invention has the advantages of simple process, low cost and high production efficiency. The produced line saw has excellent performance, high strength, good flexibility, high hold to diamonds, stable cutting performance, good chip discharging performance and long service life, and is not easy to crack.

Owner:长沙和谦新材料科技有限公司

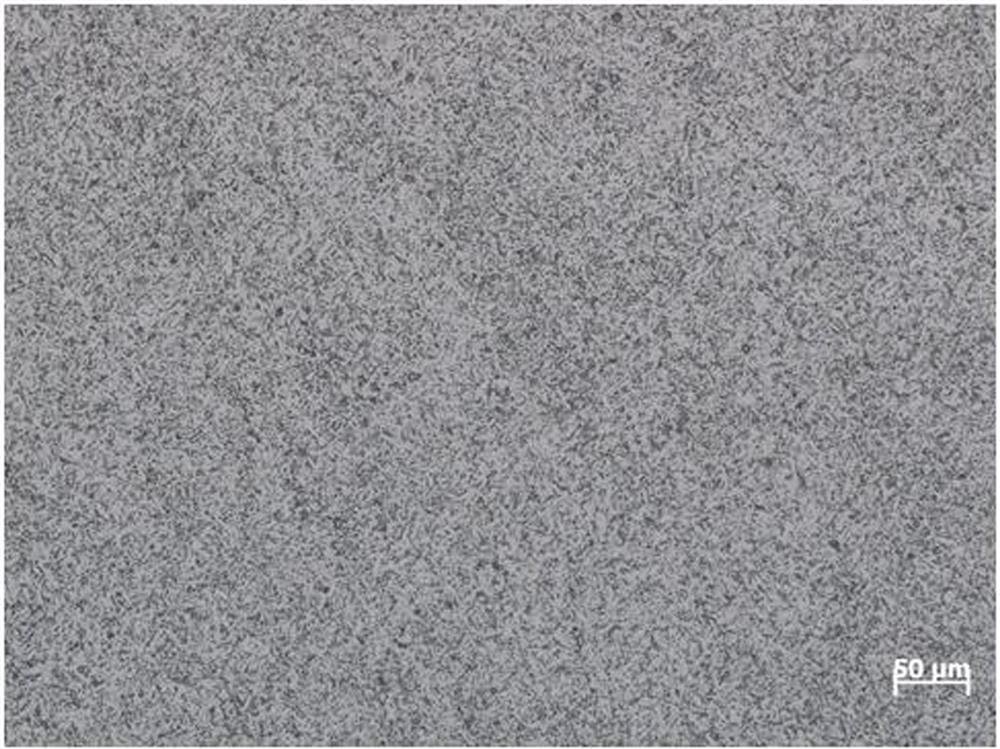

Preparation method of titanium alloy bar of universal resetting screw seat

ActiveCN111534715AEffective grain size refinementReduce residual stressWire straightening devicesTemperature control deviceOrthopedic departmentManufactured material

The invention belongs to the technical field of machining of medical titanium alloy materials and particularly relates to a preparation method of a titanium alloy bar of a universal resetting screw seat. The chemical ingredients of titanium alloy comprise, by mass percentage, 5.9%-6.4% of Al, 3.9%-4.4% of V, 0.15%-0.22% of Fe, 0.09%-0.13% of O, not larger than 0.05% of C, not larger than 0.005% ofH, not larger than 0.01% of N and the balance Ti. The preparation method comprises the steps that firstly, a round bar blank is obtained through the procedures of smelting, forging, and rolling; thena beta single-phase section homogenization annealing treatment process is adopted to obtain a homogeneous fine-grained acicular martensite structure, an electrifying straightening and hyperbolic straightening combined process is used for straightening, the electrifying straightening temperature is controlled to be less than 780 DEG C, and a balanced residual stress state is obtained; and finally,stress relief annealing and centerless grinding are conducted to obtain the finished bar. The preparation method of the titanium alloy bar of the universal resetting screw seat can produce a medicalTi-6Al-4V alloy bar basically free of stress, the Ti-6Al-4V alloy bar has excellent fatigue life, and a qualified raw material is provided for manufacturing of universal resetting screw seats of orthopedic medical instruments.

Owner:中科锐金山东钛业科技有限公司

Method for realizing stress corrosion resistance of stainless steel welding connector impacted by nanosecond-pulse laser

ActiveCN106834659ANo obvious mechanical forceFast processingFurnace typesHeat treatment furnacesWeld seamNanosecond pulse

The invention provides a method for realizing stress corrosion resistance of a stainless steel welding connector impacted by nanosecond-pulse laser. According to the method, a welding seam is impacted by adopting laser along an S shape, and an outer region of the welding seam is impacted along a direction parallel to the welding seam, so that pull stress of the welding connector is eliminated. By reasonably selecting power density, phase change does not occur and residual pull stress can be eliminated, so that a condition that the stress corrosion resistance performance of the welding connector is reduced is avoided. According to the method provided by the invention, the surface of a workpiece is impacted through the nanosecond-pulse laser, and no obvious mechanical force is used; a machining speed is rapid and automation is easy to realize; a complicated mold surface can be impacted.

Owner:AIR FORCE UNIV PLA

Variable bore ram

ActiveUS20050006087A1Preventing loss downholeEliminate tensile stressFluid removalSealing/packingEngineeringBlowout preventer

A ram type blowout preventer includes variable ram packers for sealing about tubulars of different outside diameters in the bore of the preventer housing or about a single tubular having a variable outside diameter. Each ram packer includes a body of elastomeric material formed about vertical ribs to conform to tubular having variable OD within a certain range.

Owner:VARCO I P INC

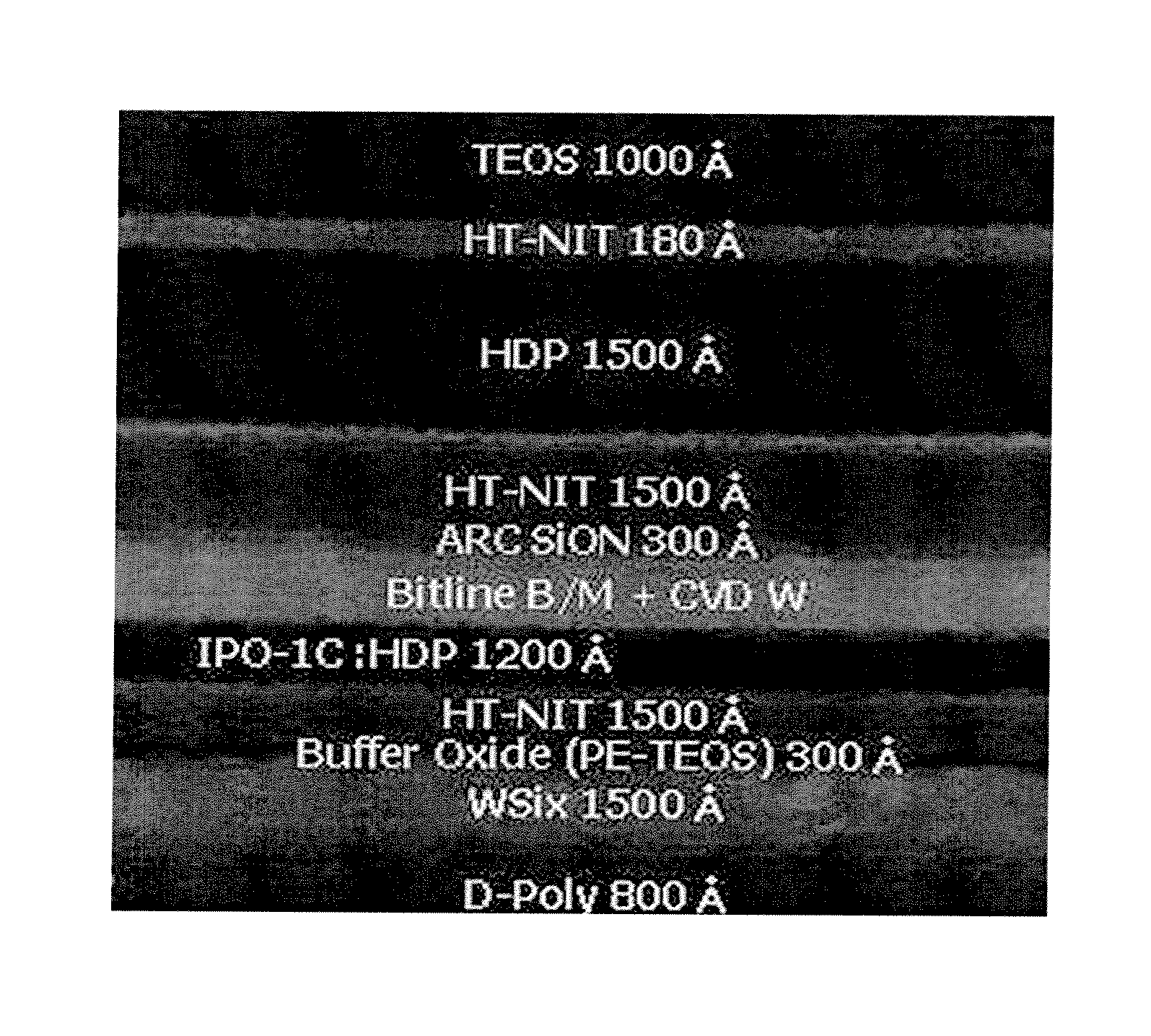

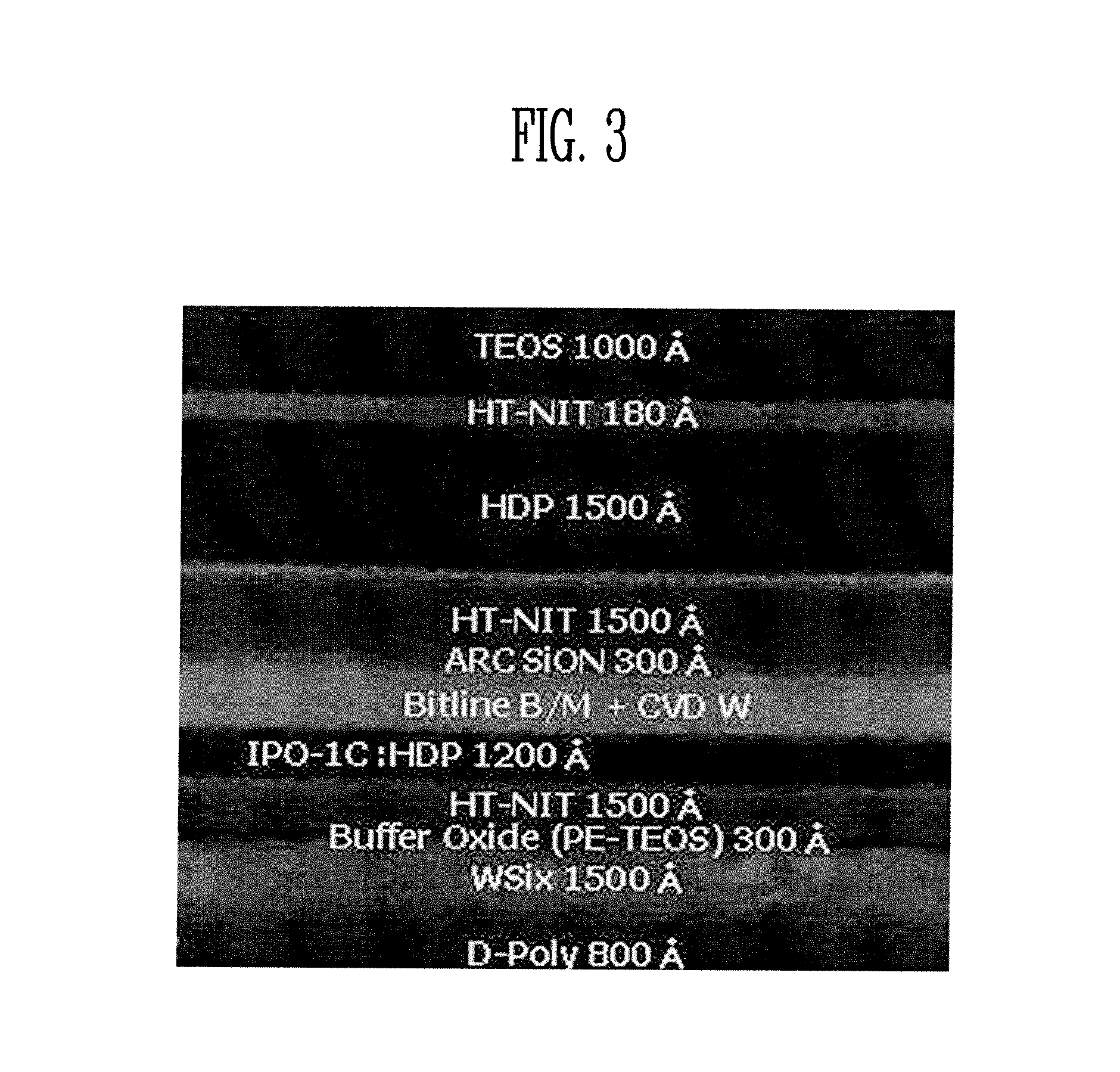

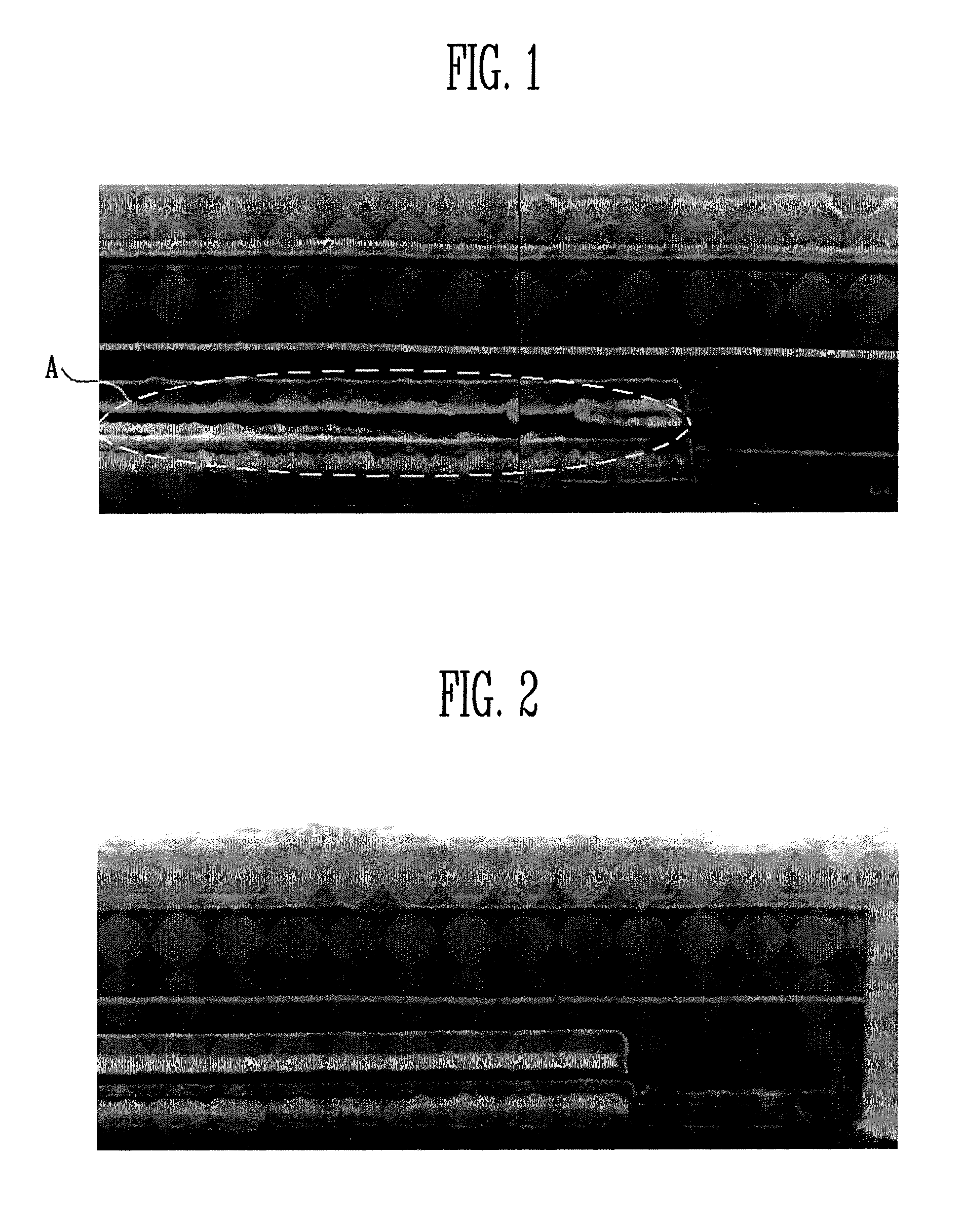

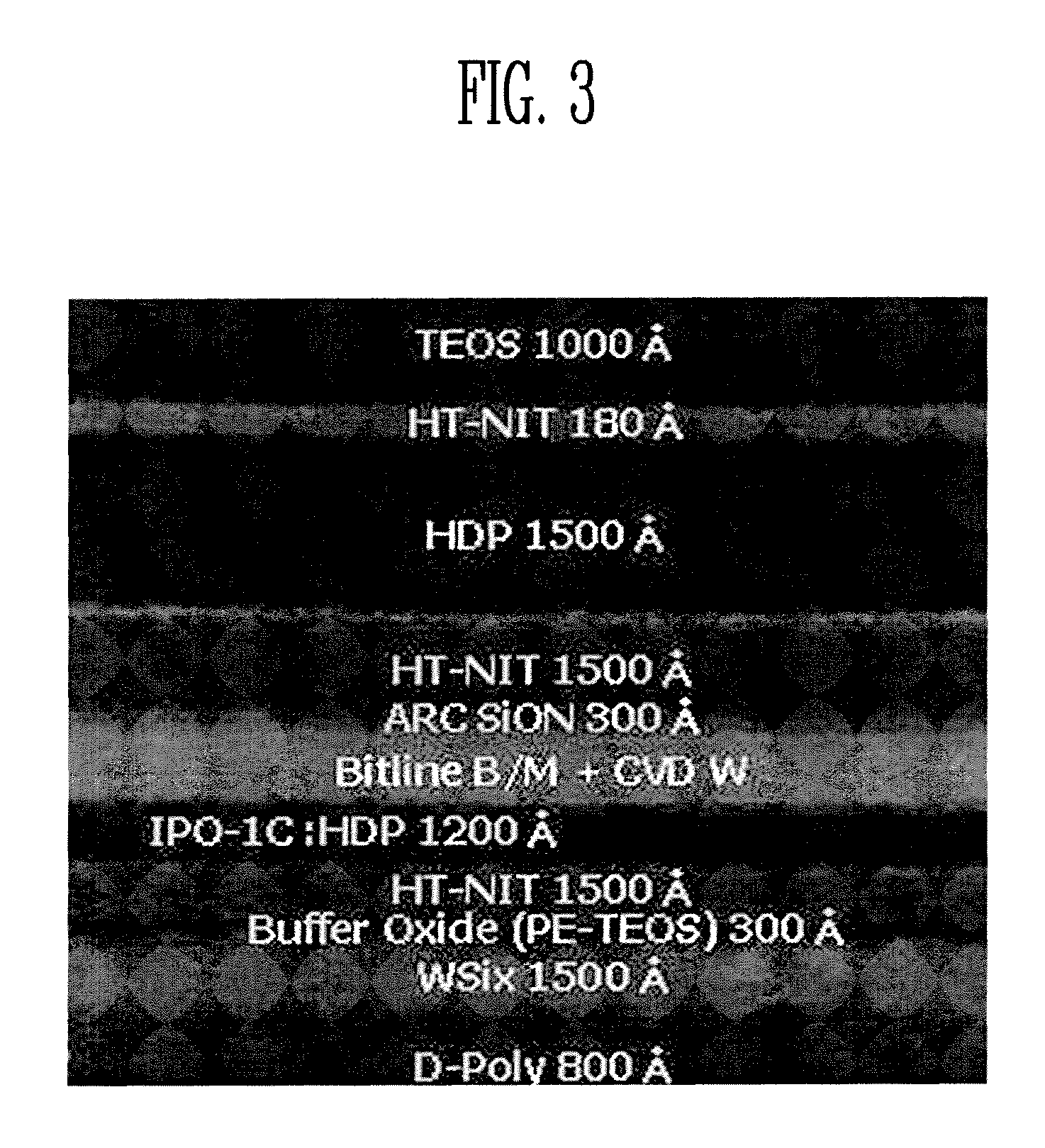

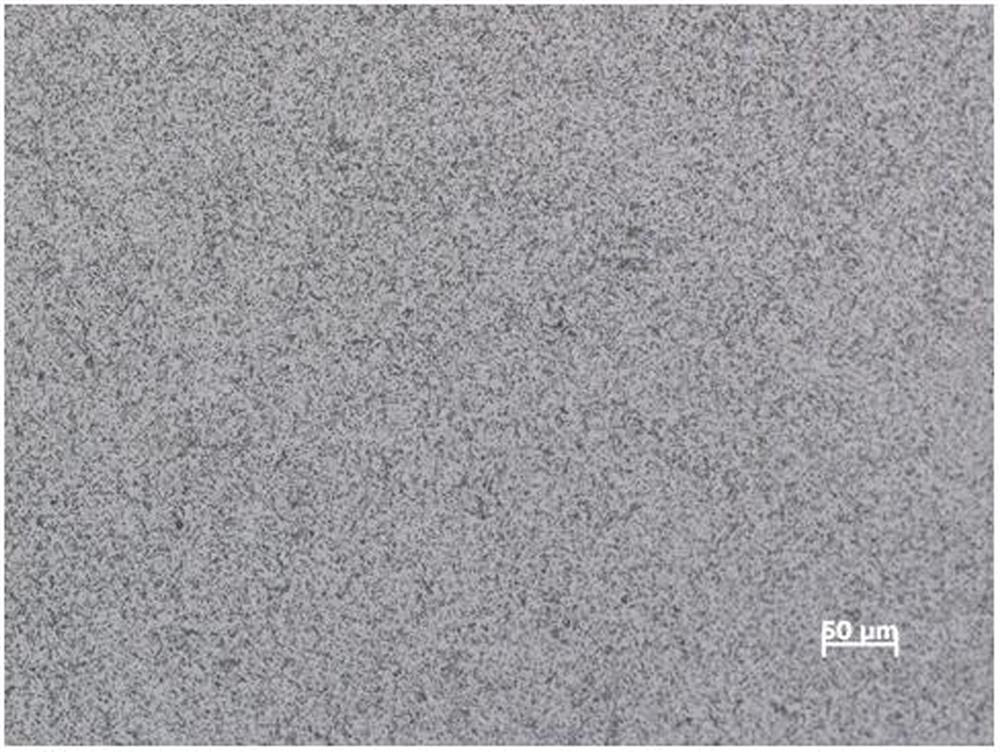

Method for Fabricating Semiconductor Device

ActiveUS20080081465A1Eliminate tensile stressReduce tensile stressSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorMaterials science

A method for fabricating a semiconductor device, in which a lifting phenomenon can be prevented from occurring in forming an amorphous carbon film on an etched layer having tensile stress. According to the invention, since a compression stress on the etched layer or the amorphous carbon film can be reduced or a compression stress film is formed between the etched layer or the amorphous carbon film to prevent a lifting phenomenon from occurring and thus another pattern can be formed to fabricate a highly integrated semiconductor device.

Owner:SK HYNIX INC

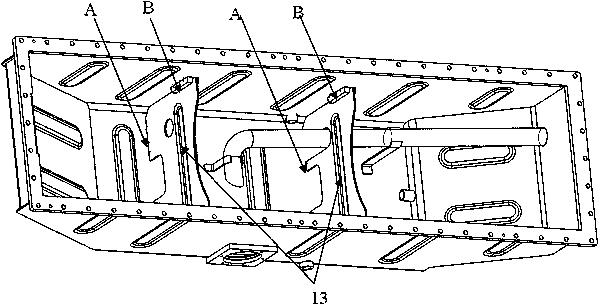

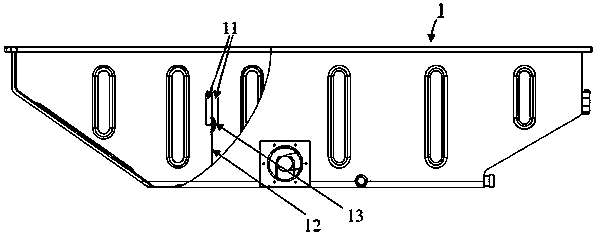

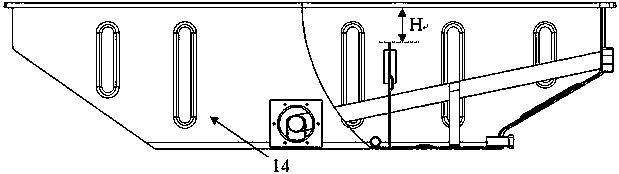

Oil baffle plate installation welding mode oil bottom case assembly

InactiveCN104775870AAvoid tearingEliminate tensile stressOilsumpsMachines/enginesEngineeringWeld seam

The invention discloses an oil baffle plate installation welding mode oil bottom case assembly. An oil baffle plate and a press block used for fixing the oil baffle plate are designed on the side surface of an oil bottom case body, a great distance from the top surface of the oil baffle plate to the flange surface of the oil bottom case body exits, the oil baffle plate is clamped by the press block and is not in contact with the wall surface of the oil bottom case body, and is in segmented welding connection with the bottom surface of the oil bottom case body, the oil baffle plate is transversely provided with a buffer reinforcing rib, an oil sucking disc supporter arranged on the oil baffle plate is in an arched door shape, and the oil baffle plate is not in contact with an oil sucking pipe. The oil baffle plate is clamped by the press block, the height of the oil baffle plate is reduced, the oil bottom case body adopts a segmented welding connecting mode, the tensile stress generated after the oil baffle plate and the side surface of the oil bottom case body are welded is fundamentally eliminated, and in addition, the force, caused by engine oil impact, transferred to an oil bottom case bottom surface welding seam is reduced, so that the reliability and the durability of the oil bottom case assembly are improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

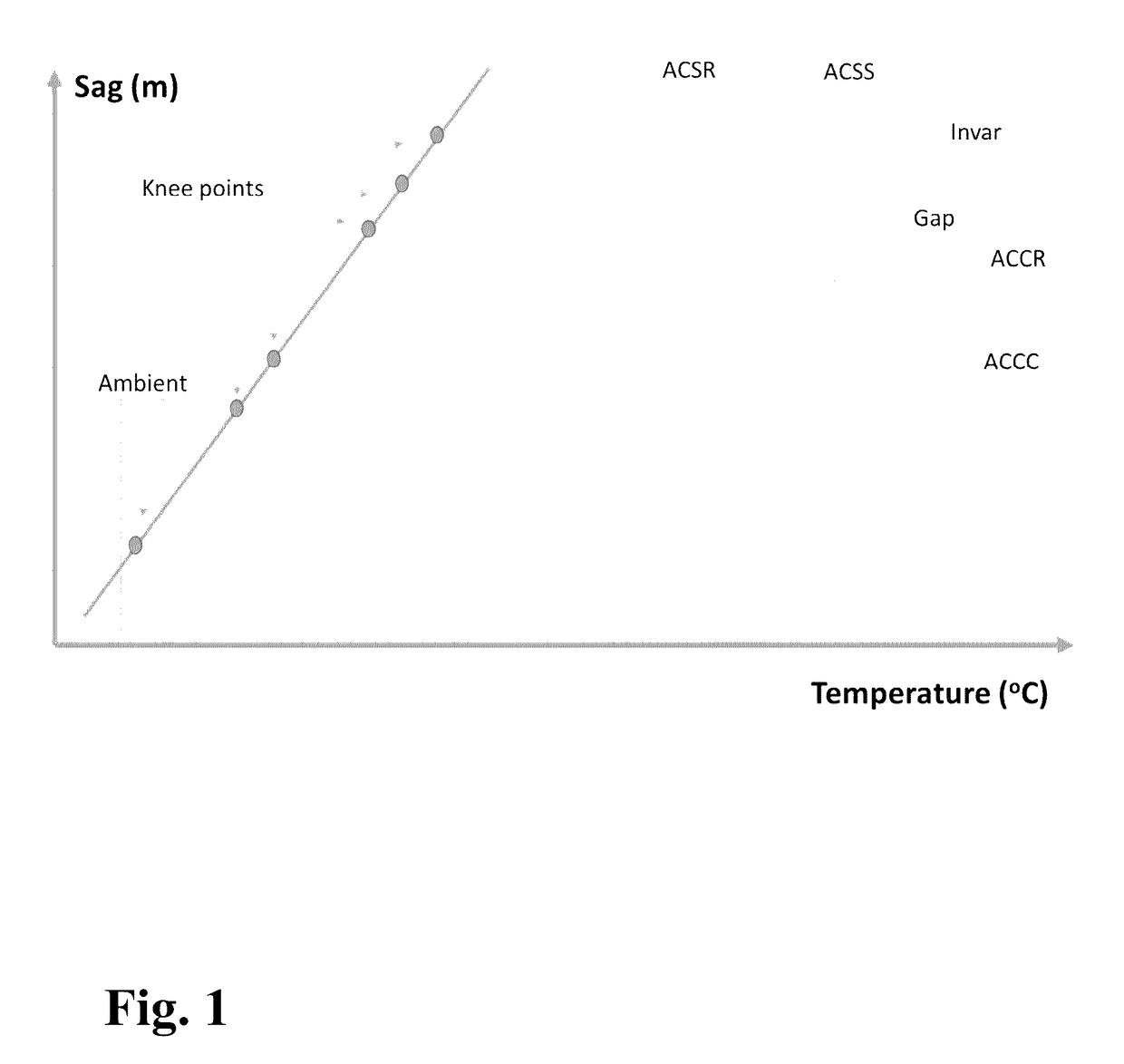

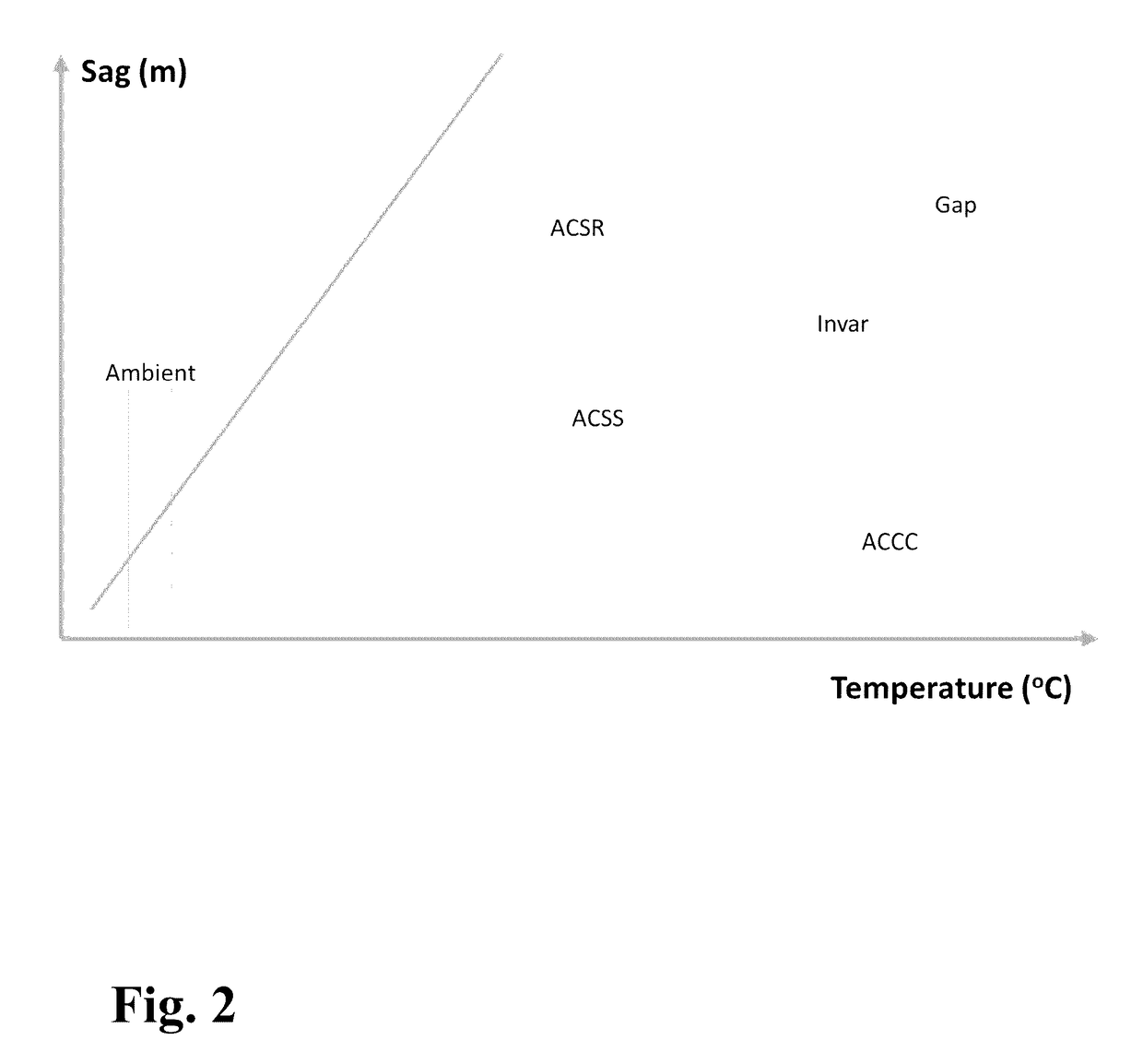

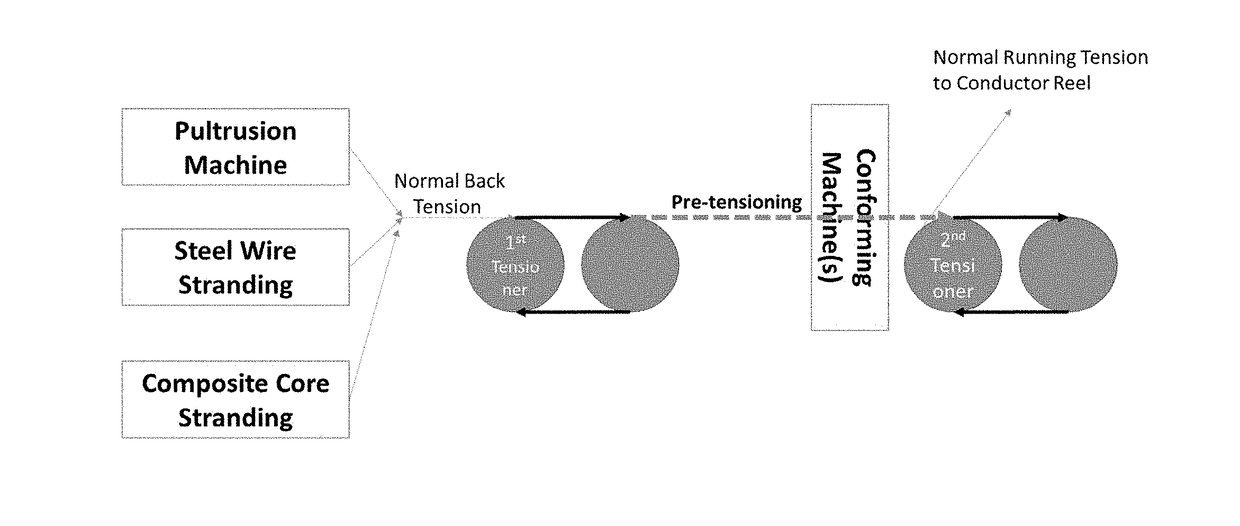

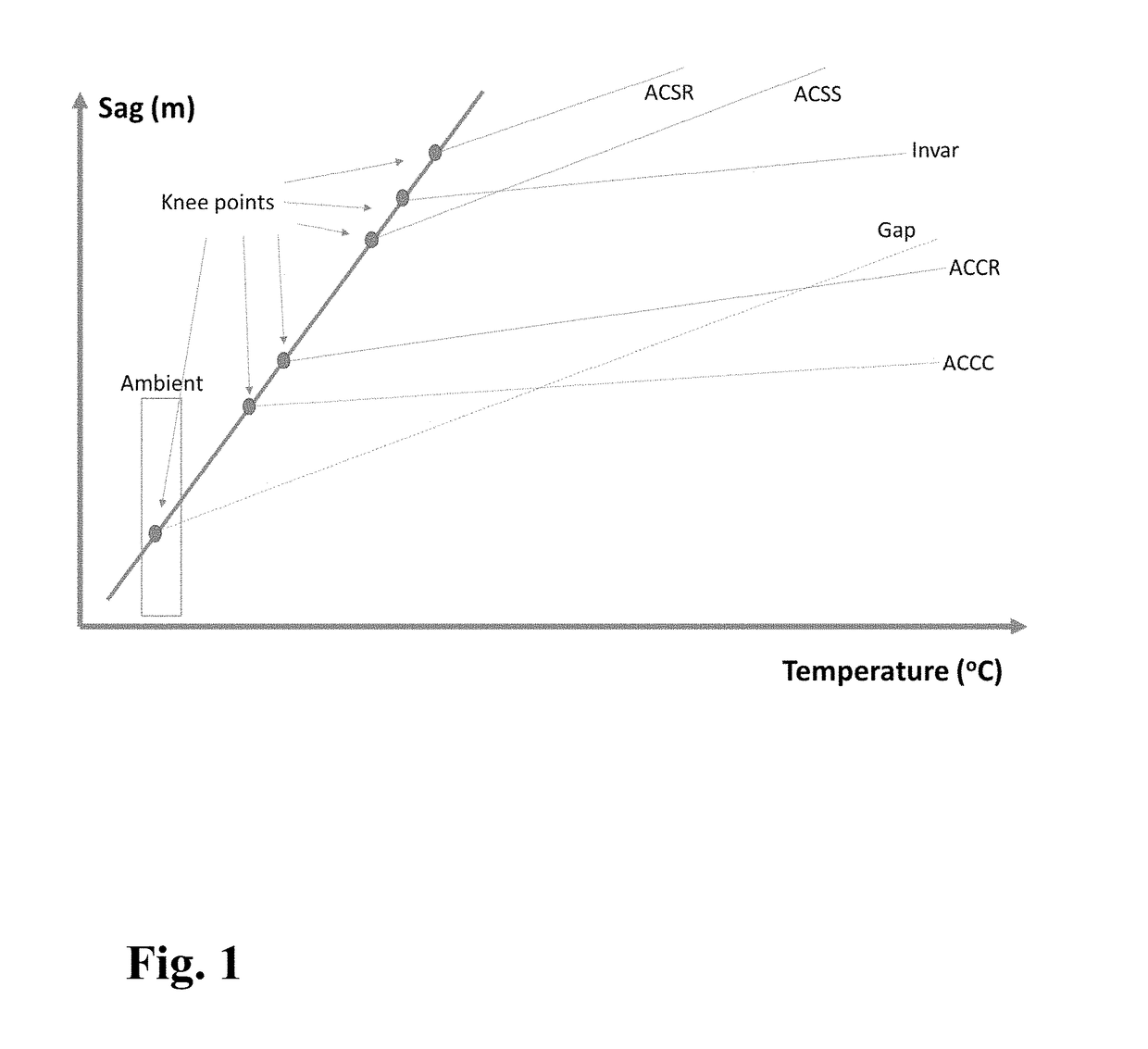

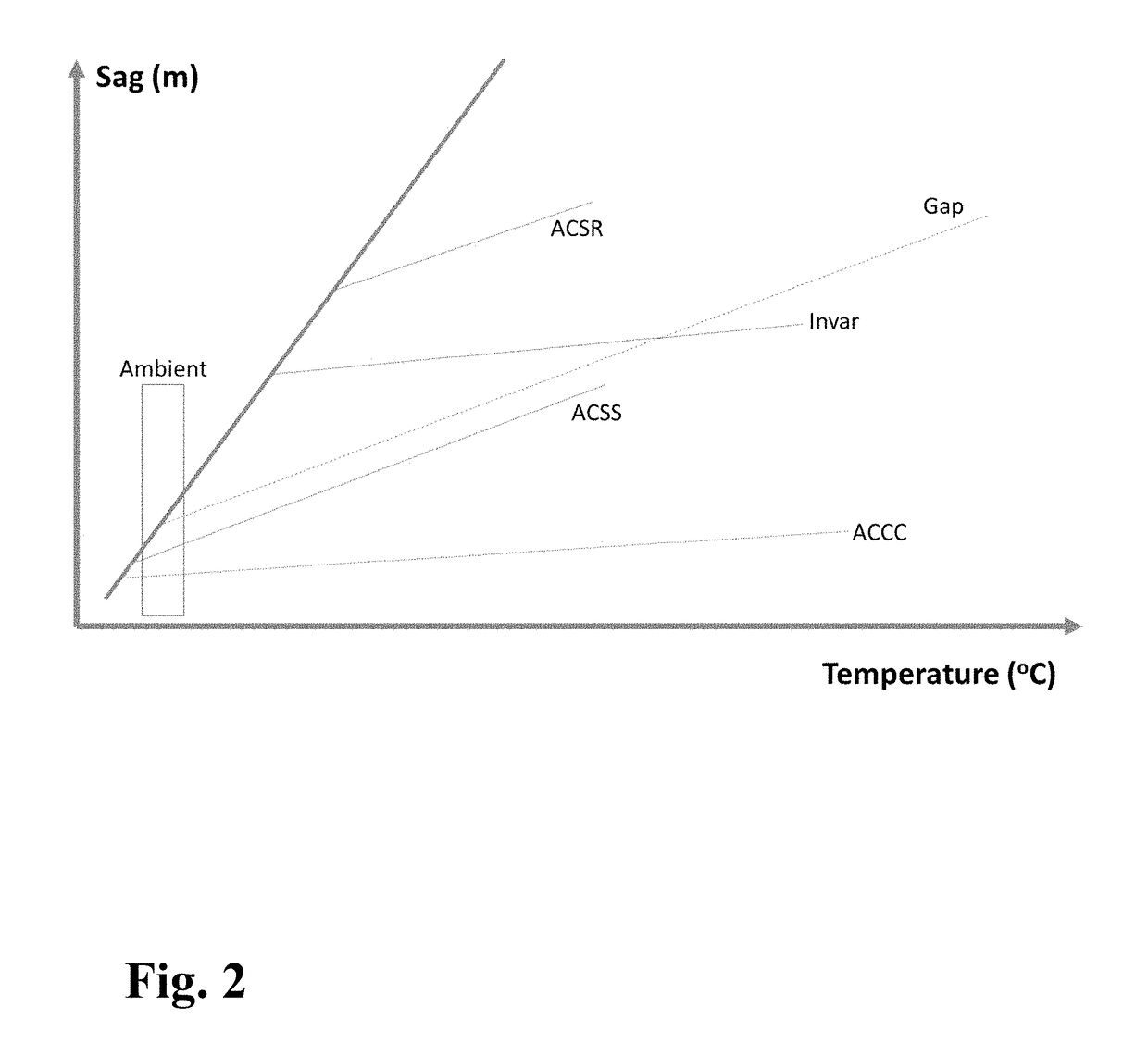

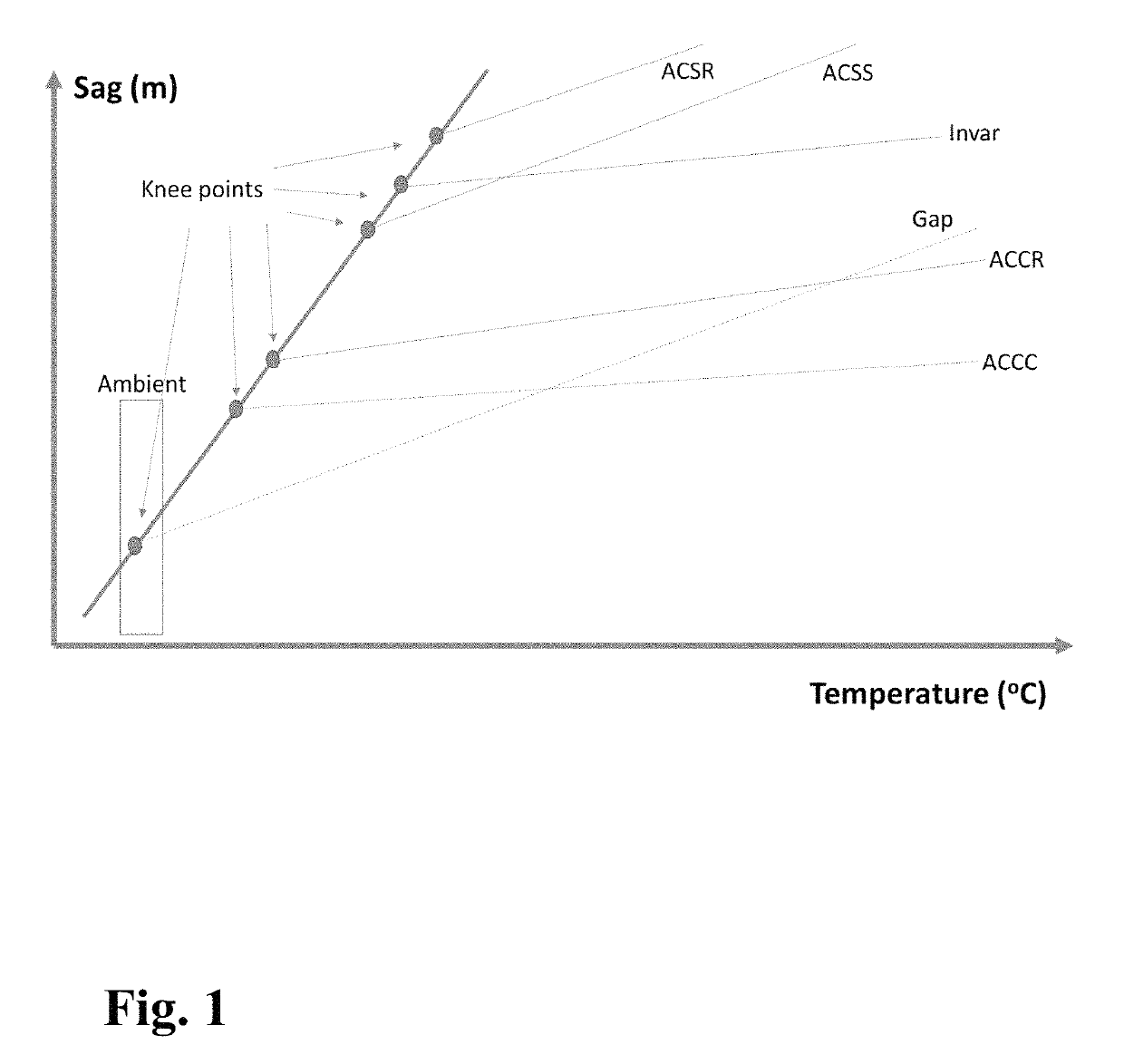

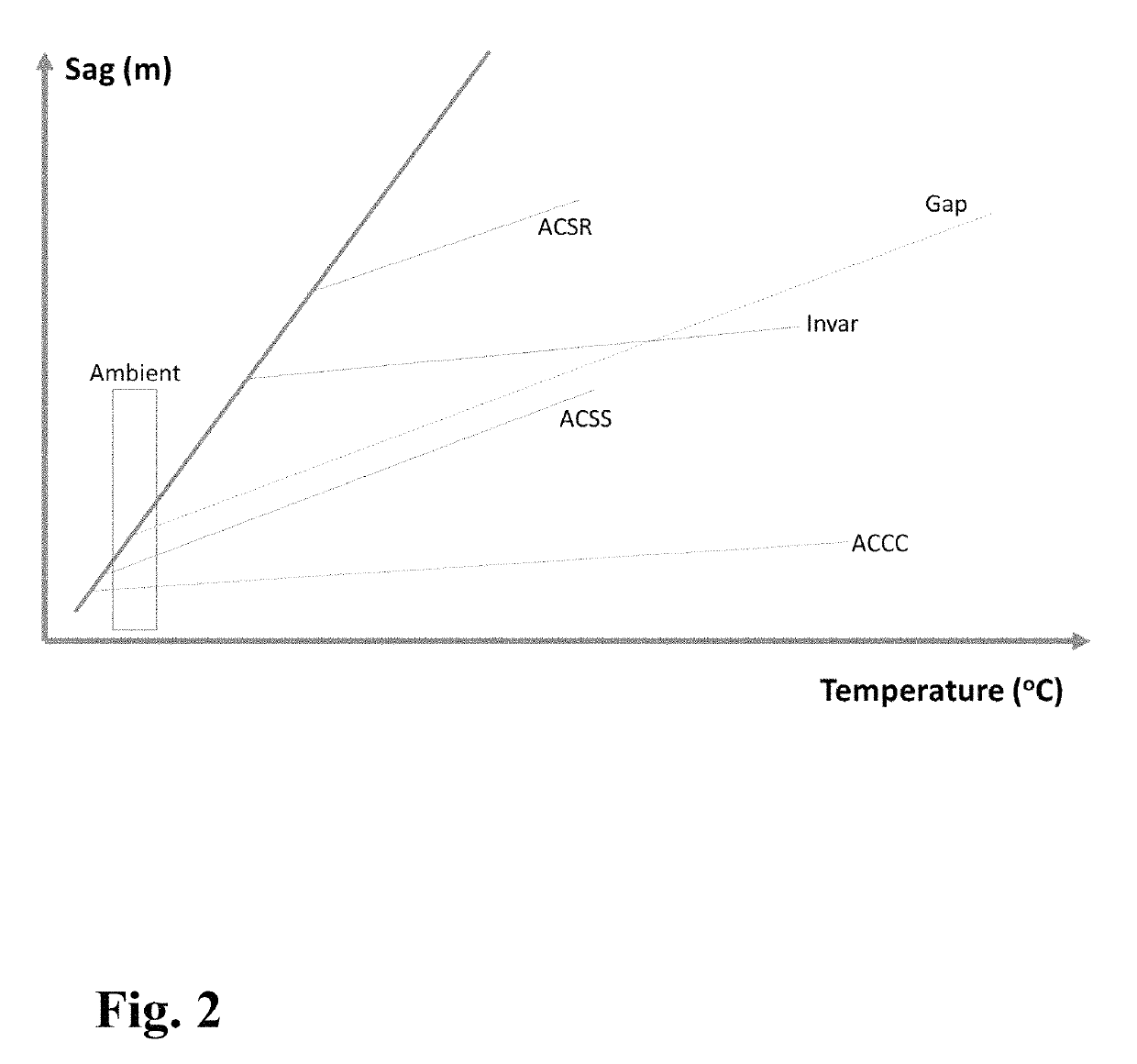

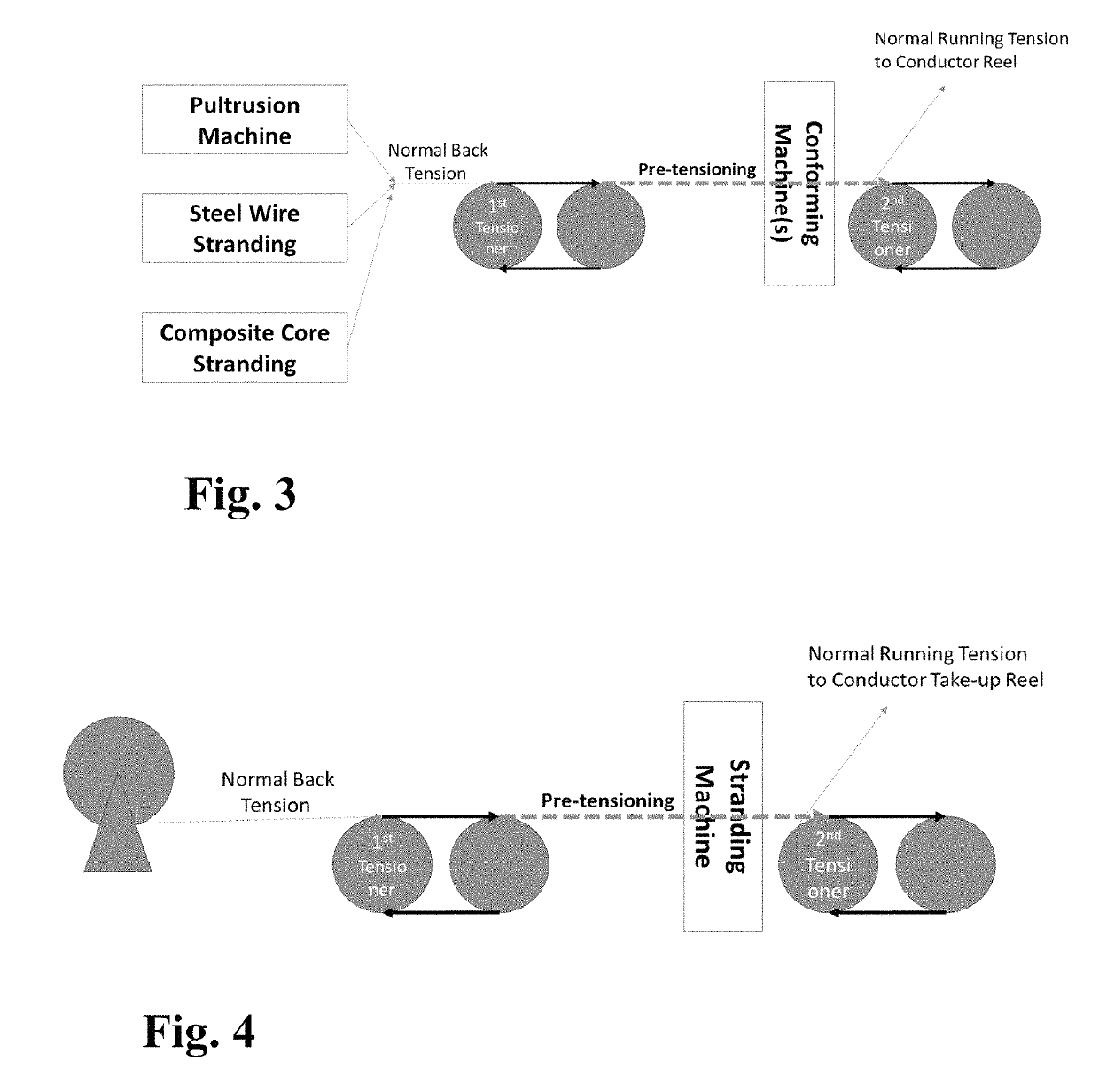

Energy efficient conductors with reduced thermal knee points and the method of manufacture thereof

ActiveUS9633766B2IntegrityReduce impactNon-insulated conductorsPlastic/resin/waxes insulatorsElectricityPre stress

The present invention relates to electrical conductors for electrical transmission and distribution with pre-stress conditioning of the strength member so that the conductive materials of aluminum, aluminum alloys, copper, copper alloys, or copper micro-alloys are mostly tension free or under compressive stress in the conductor, while the strength member is under tensile stress prior to conductor stringing, resulting in a lower thermal knee point in the conductor.

Owner:TS CONDUCTOR CORP

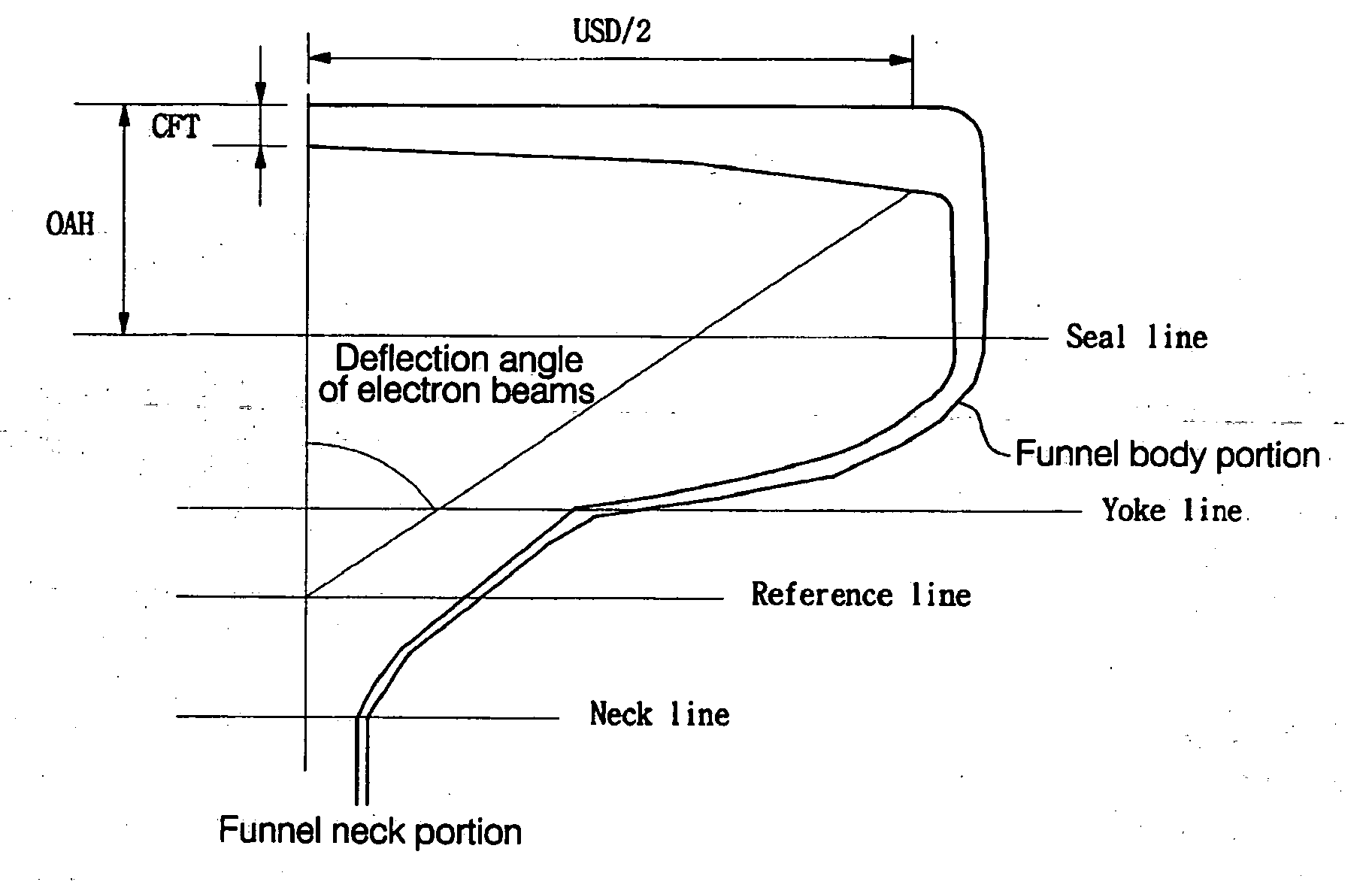

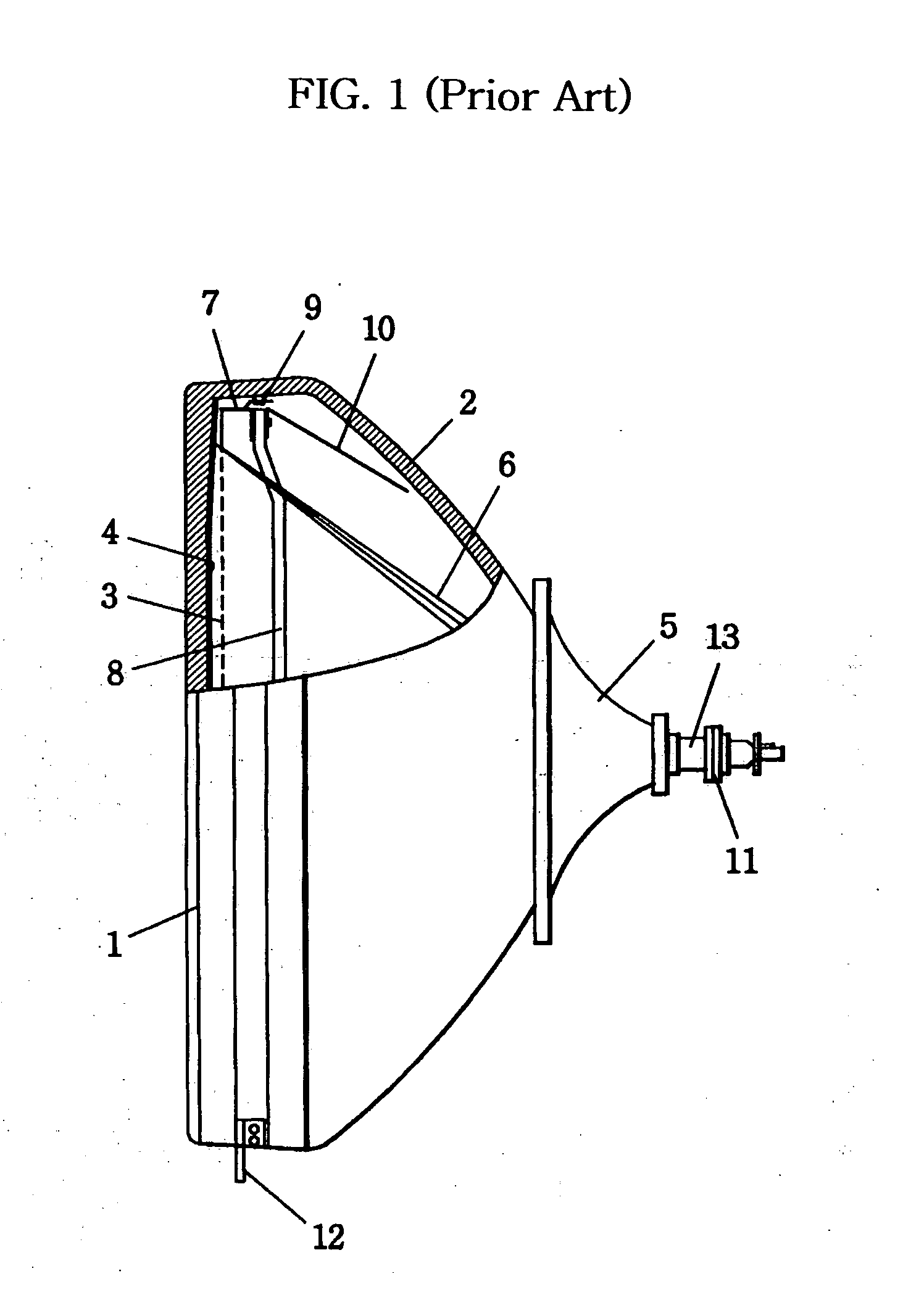

Color cathode ray tube

InactiveUS20050134165A1Simple structureReduce weightCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersManufacturing cost reductionX-ray

Disclosed herein is a color cathode ray tube which optimizes the structure of a glass panel and funnel to achieve weight reduction thereof. In the color cathode ray tube, a curvature radius of an outer surface of the panel is in a range of 5000 mm to 100000 mm, and the panel is configured to satisfy an expression: 1.0≦(OAH*CFT) / USD≦1.5, where, OAH is a distance from the outer surface of the panel to a sealing surface between the panel and the funnel, USD is a diagonal length of an effective screen of the panel, and CFT is a thickness of a central region of the panel. The cathode ray tube of the present invention has the effects of reducing manufacturing costs through weight reduction thereof, of lowering the degree of breakage during a heat treatment step included in a manufacturing process of the cathode ray tube, resulting in an improved yield, and of effectively intercepting X-rays generated during operation thereof.

Owner:LG PHILIPS DISPLAY KOREA CO LTD

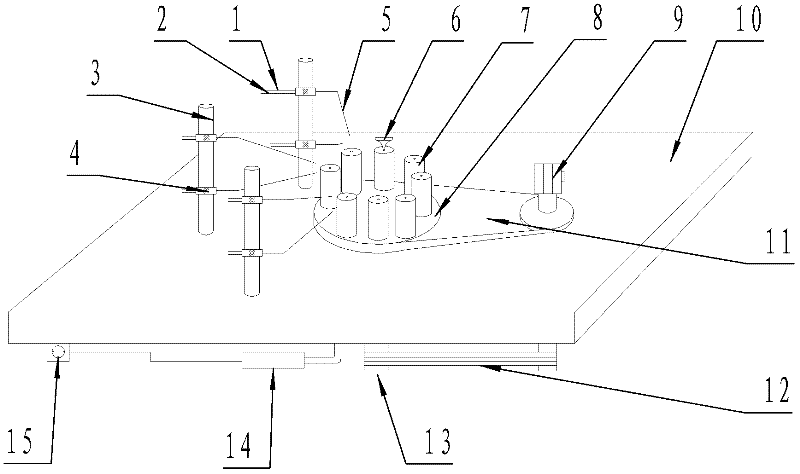

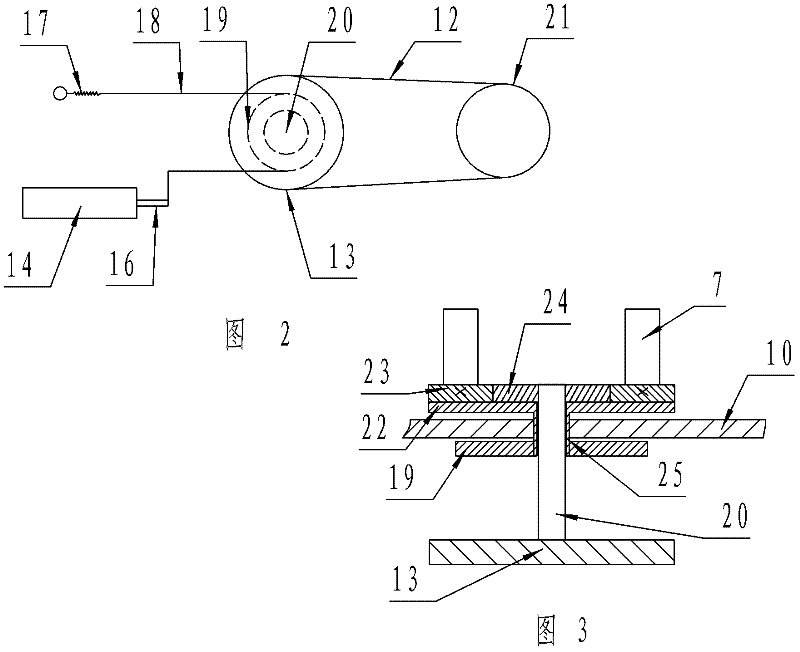

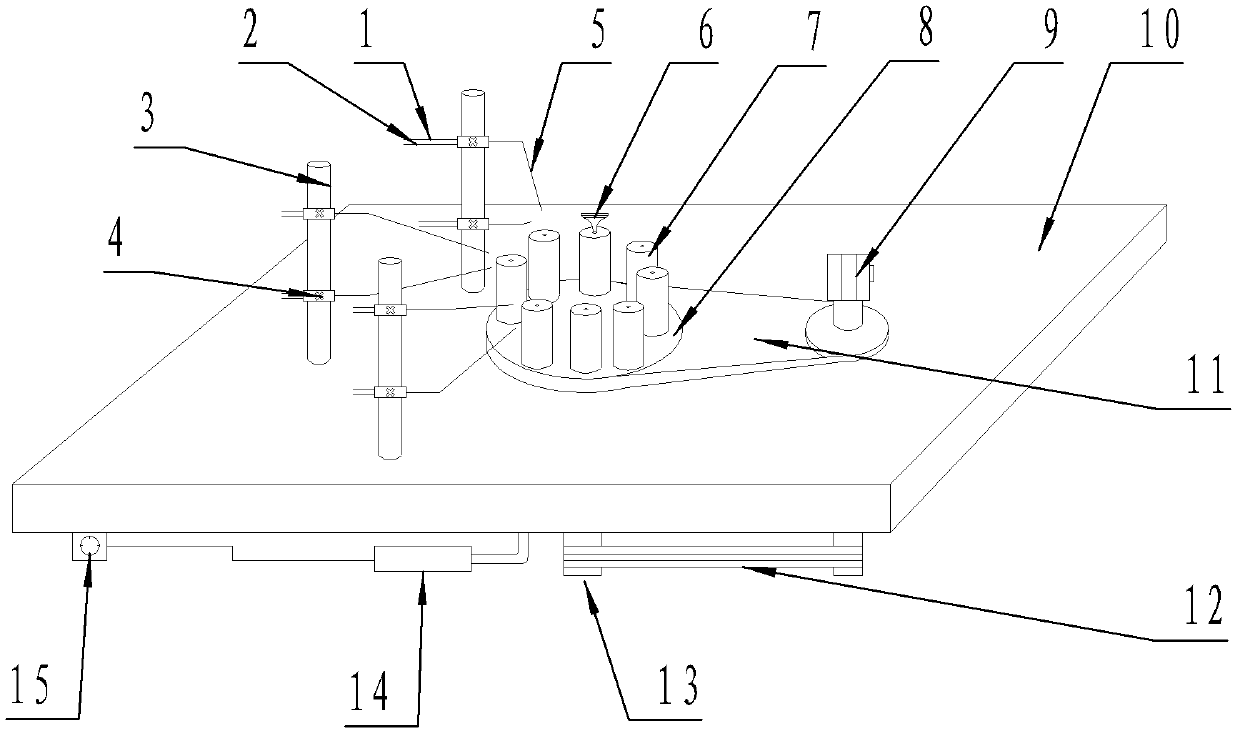

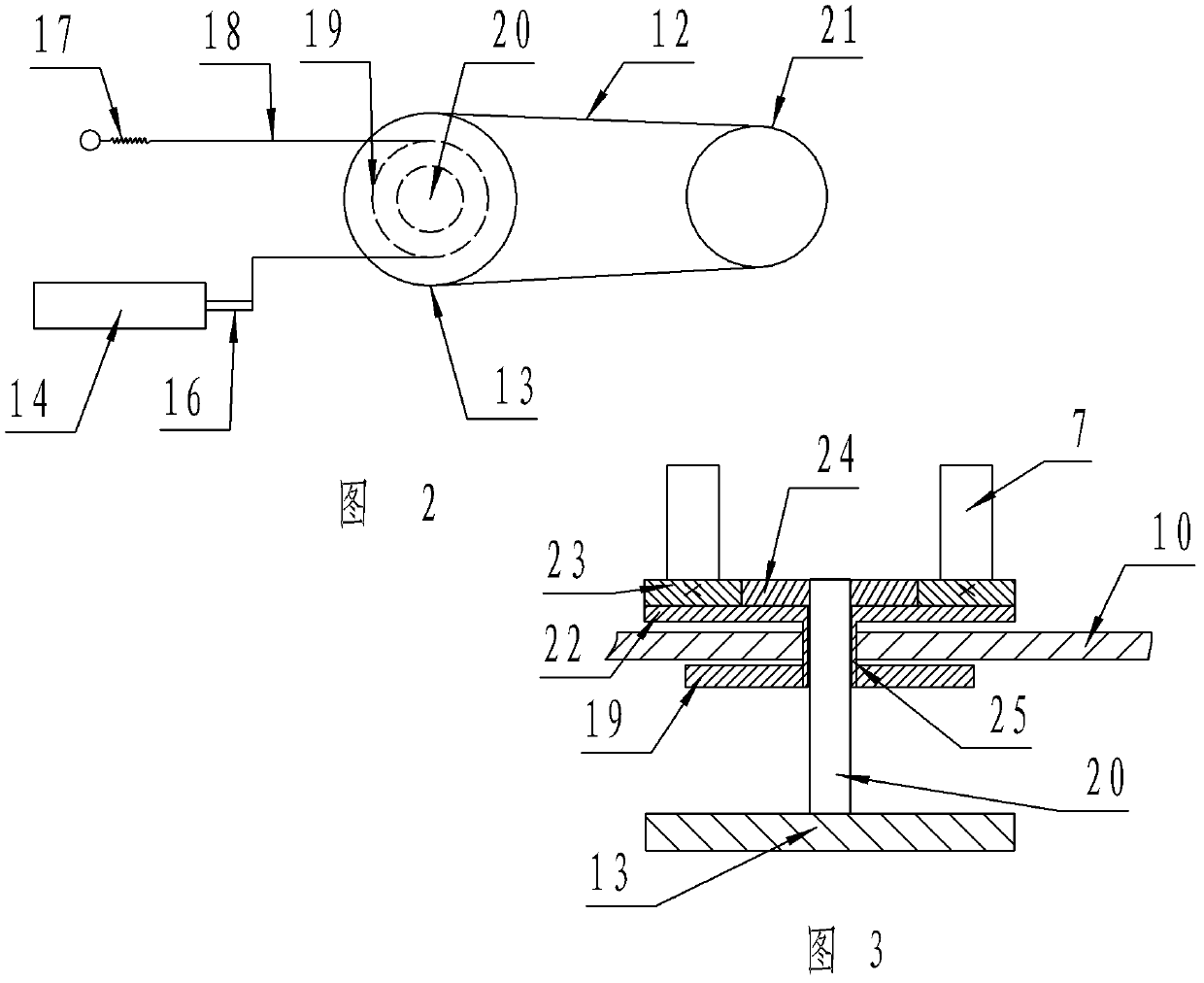

Heating unit for bottom surface and conical surface of engine valve cap part and application method

ActiveCN102392109AImprove the heating effectEliminate tensile stressFurnace typesHeat treatment furnacesHeating timeEngineering

The invention discloses a heating unit for a bottom surface and a conical surface of an engine valve cap part and an application method, belongs to a heat treating device, and particularly relates to a heating source taking oxyacetylene flame as a heat source. The heating unit is characterized by mainly comprising a heater arranged on a rack and a valve fastening and a rotating device, wherein the heater is an oxyacetylene burner nozzle fixed on a burner nozzle support; and the valve fastening and the rotating device is composed of a sleeve which is arranged on a turnplate and can automatically rotate and rotate along with the turnplate, a sleeve self-rotating driving device and a turnplate rotating driving device. The heating unit provided by the invention has the beneficial effects that the heating unit can rapidly and conveniently heat the bottom surface and the conical surface subjected to overlaying, of the valve cap part and conveniently control heating time and temperature, the volume of equipment is small so as facilitate connection with a next step process, and the equipment is conveniently used for eliminating tension stress generated by overlaying of the valve.

Owner:济南沃德汽车零部件有限公司

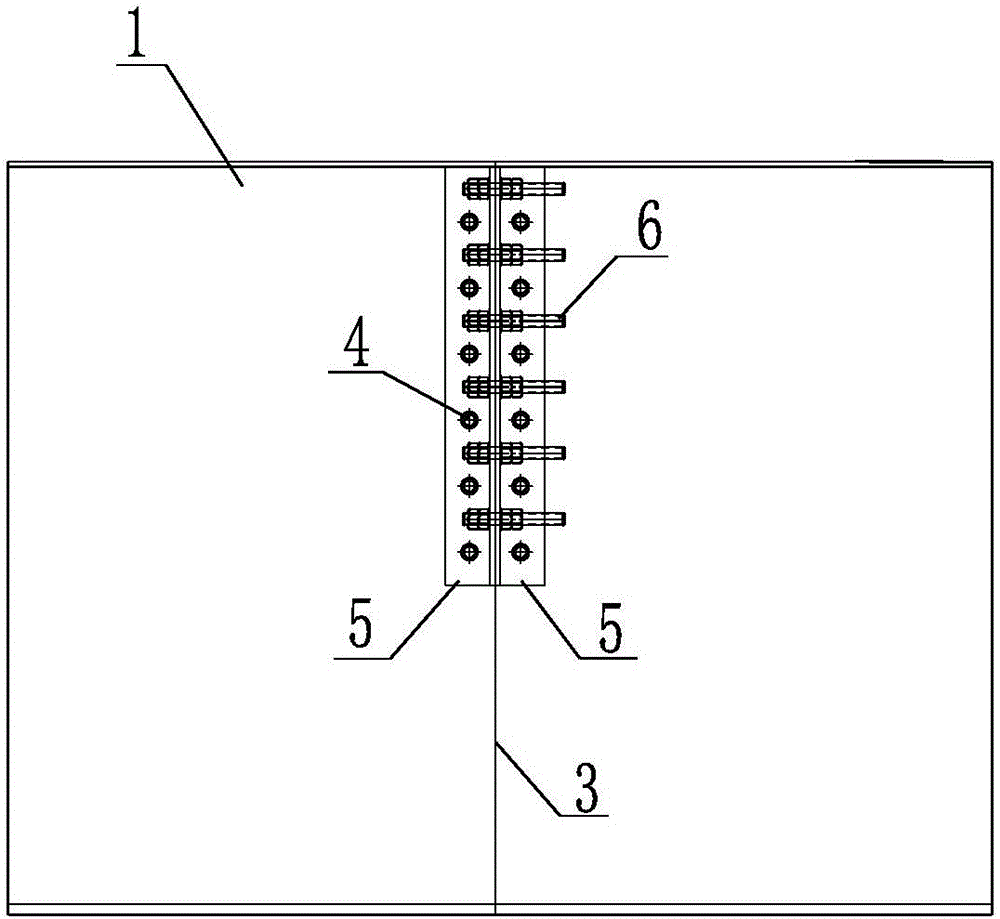

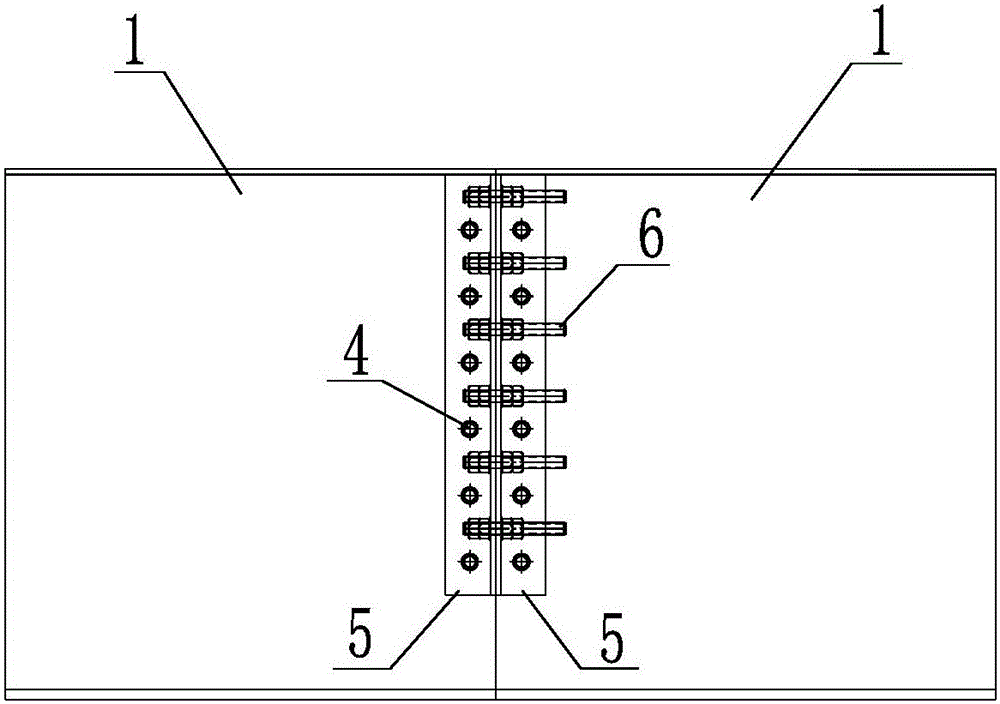

Steel beam segment, continuous combined beam bridge and construction method of continuous combined beam bridge

ActiveCN105951574AStrong tensile capacityHigh compressive capacity of concreteBridge structural detailsBridge erection/assemblyWork performanceSurface plate

The invention relates to the field of beam bridge construction and discloses a steel beam segment. The steel beam segment comprises a left part and a right part. A gap formed in an opposite-pulling manner is formed between the left part and the right part. The left part and the right part are connected in a welded manner. A continuous combined beam bridge comprises two abutment piers and at least one middle pier located between the two abutment piers. The pier top of the middle pier is provided with the steel beam segment. Multiple combined beam segments are arranged on the two sides of the steel beam segment. A construction method of the continuous combined beam bridge includes the following steps that firstly, the steel beam segment formed by splicing the left part and the right part is provided, the left part and the right part of the steel beam segment are connected through bolts, and the bolts are tensioned; secondly, the combined beam segments are installed on the two sides of the steel beam segment till a steel beam is closed; and thirdly, the bolts on the steel beam segments are loosened gradually, and the left part and the right part of the steel beam segment are welded. By the adoption of the steel beam segment, the continuous combined beam bridge, and the construction method of the continuous combined beam bridge, the working performance of a concrete bridge panel can be greatly improved.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Energy Efficient Conductors With Reduced Thermal Knee Points And The Method Of Manufacture Thereof

ActiveUS20170178764A1Preserve integrityPreserve propertyNon-insulated conductorsApparatus for heat treatmentElectricityPre stress

The present invention relates to electrical conductors for electrical transmission and distribution with pre-stress conditioning of the strength member so that the conductive materials of aluminum, aluminum alloys, copper, copper alloys, or copper micro-alloys are mostly tension free or under compressive stress in the conductor, while the strength member is under tensile stress prior to conductor stringing, resulting in a lower thermal knee point in the conductor.

Owner:TS CONDUCTOR CORP

L-shaped extrusion device for producing ultra-fine crystal block body material

Owner:TAIYUAN UNIV OF TECH

Heating unit for bottom surface and conical surface of engine valve cap part and application method

ActiveCN102392109BImprove the heating effectEliminate tensile stressFurnace typesHeat treatment furnacesHeating timeEngineering

The invention discloses a heating unit for a bottom surface and a conical surface of an engine valve cap part and an application method, belongs to a heat treating device, and particularly relates to a heating source taking oxyacetylene flame as a heat source. The heating unit is characterized by mainly comprising a heater arranged on a rack and a valve fastening and a rotating device, wherein the heater is an oxyacetylene burner nozzle fixed on a burner nozzle support; and the valve fastening and the rotating device is composed of a sleeve which is arranged on a turnplate and can automatically rotate and rotate along with the turnplate, a sleeve self-rotating driving device and a turnplate rotating driving device. The heating unit provided by the invention has the beneficial effects that the heating unit can rapidly and conveniently heat the bottom surface and the conical surface subjected to overlaying, of the valve cap part and conveniently control heating time and temperature, the volume of equipment is small so as facilitate connection with a next step process, and the equipment is conveniently used for eliminating tension stress generated by overlaying of the valve.

Owner:济南沃德汽车零部件有限公司

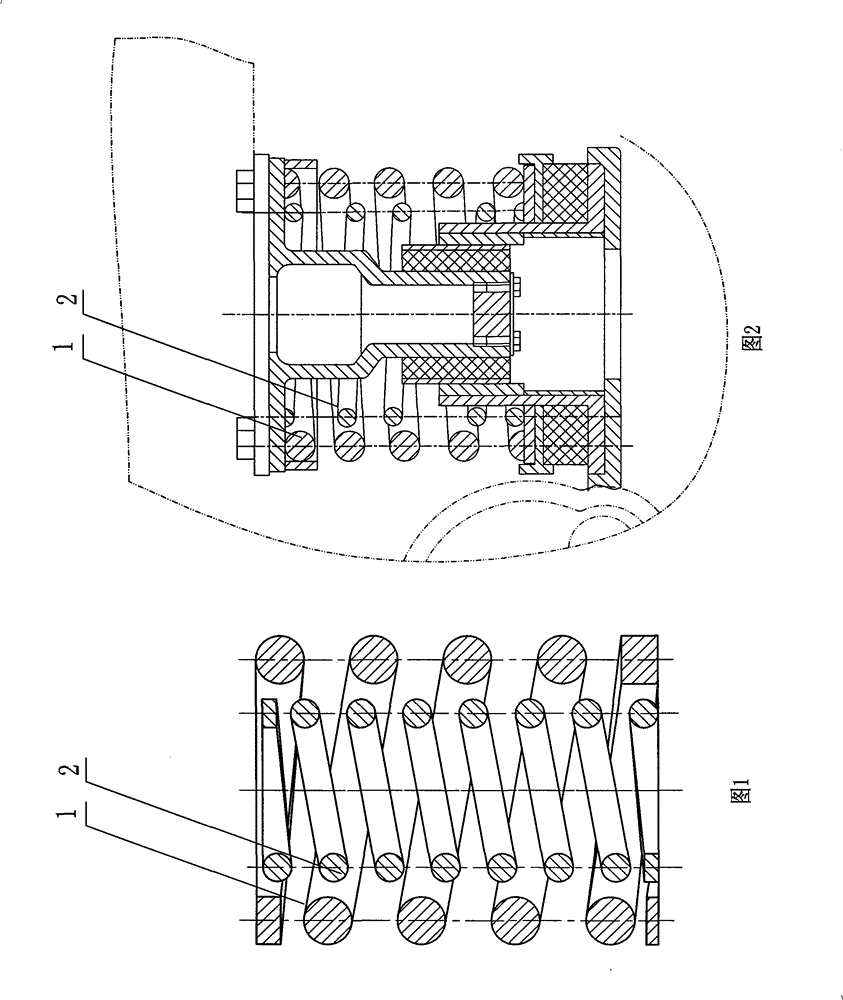

Suspension spring of high-speed locomotive steering frame and manufacturing method thereof

ActiveCN101504049BImproves elastic decay resistanceReduce surface decarburizationFurnace typesHeat treatment furnacesBogieHigh intensity

The invention relates to a suspension spring of an express locomotive steering frame and a manufacturing method thereof. The suspension spring consists of an inner spring and an outer spring, the inner spring is arranged in an outer spring tube, the spiral directions of the outer spring and the inner spring are opposite, the trademark of spring steels adopted by the inner spring and the outer spring is 52CrMoVGT, and the comprehensive performance index of the spring steels is superior to that of 52CrMoV. The manufacturing method for the suspension spring comprises the main steps: selecting materials, making flat ends, polishing and heating, winding, strengthening and shot blasting treatment, spraying paint and the like. The manufacturing method adopts the 52CrMoV4GT spring steels of a high-strength material to improve the elasticity fade resisting performance of the spring, namely, improve the capabilities of resisting relaxation and creep deformation of the spring. The materials are subjected to fault detection before winding, and subjected to transverse wave ultrasonic inspection for the first time. A spring product is subjected to magnetic particle inspection before leaving a factory so as to effectively ensure the using reliability. The spring is subjected to shot blast clear-up and shot blast reinforcement so as to improve the pressure stress of the surface, eliminate thetension stress of an inner ring and greatly improve the fatigue endurance of the spring.

Owner:YANGZHOU SPRING

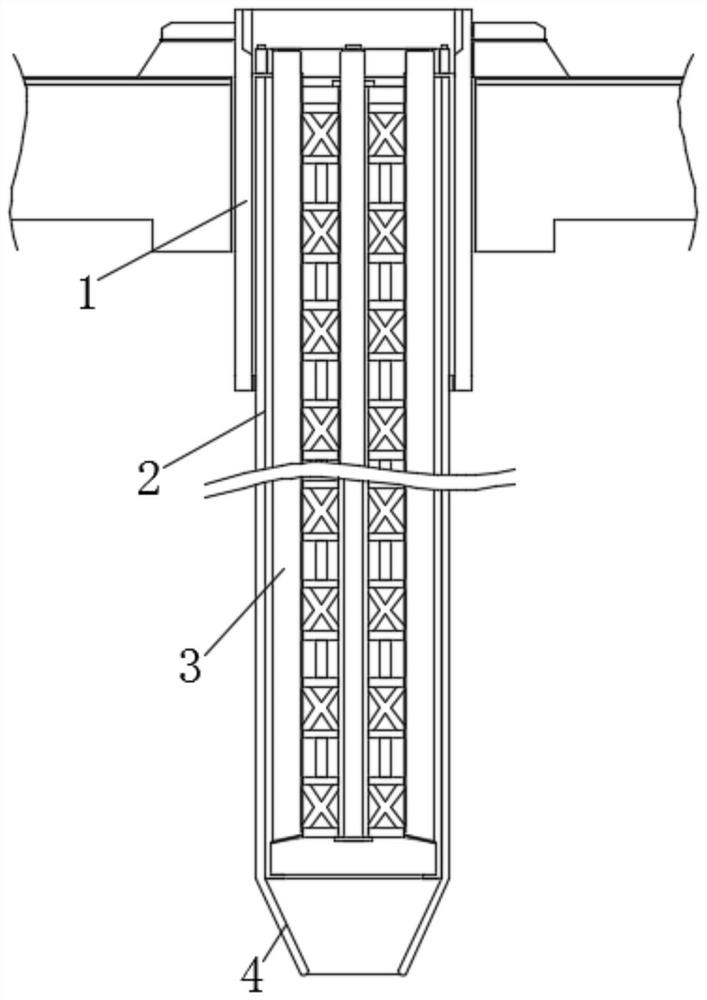

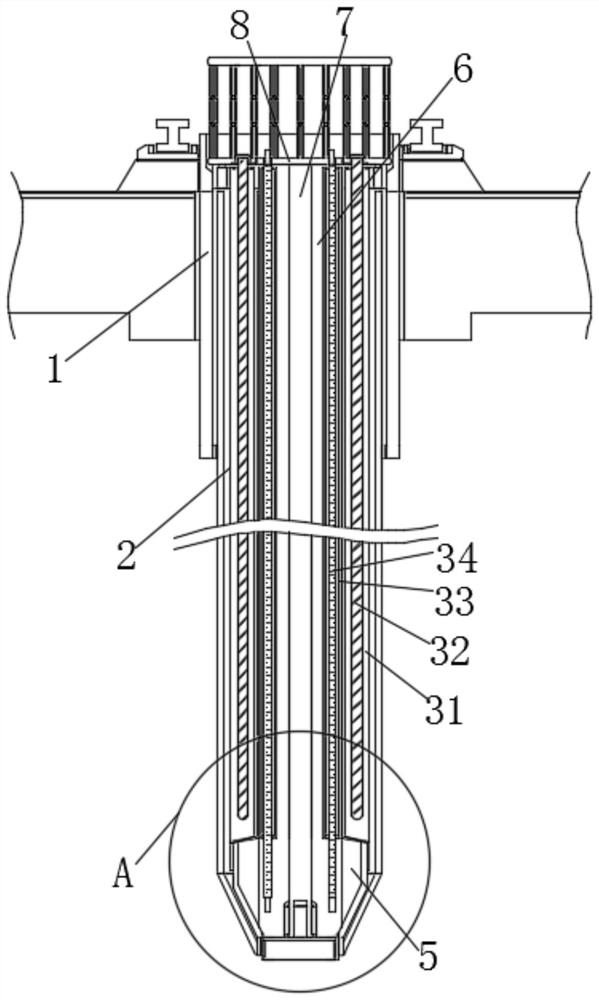

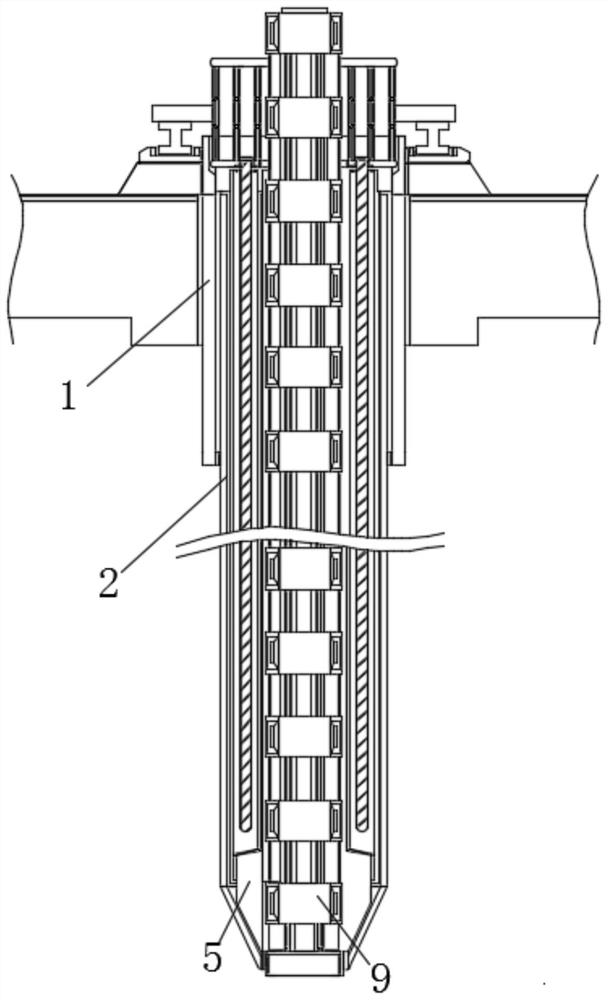

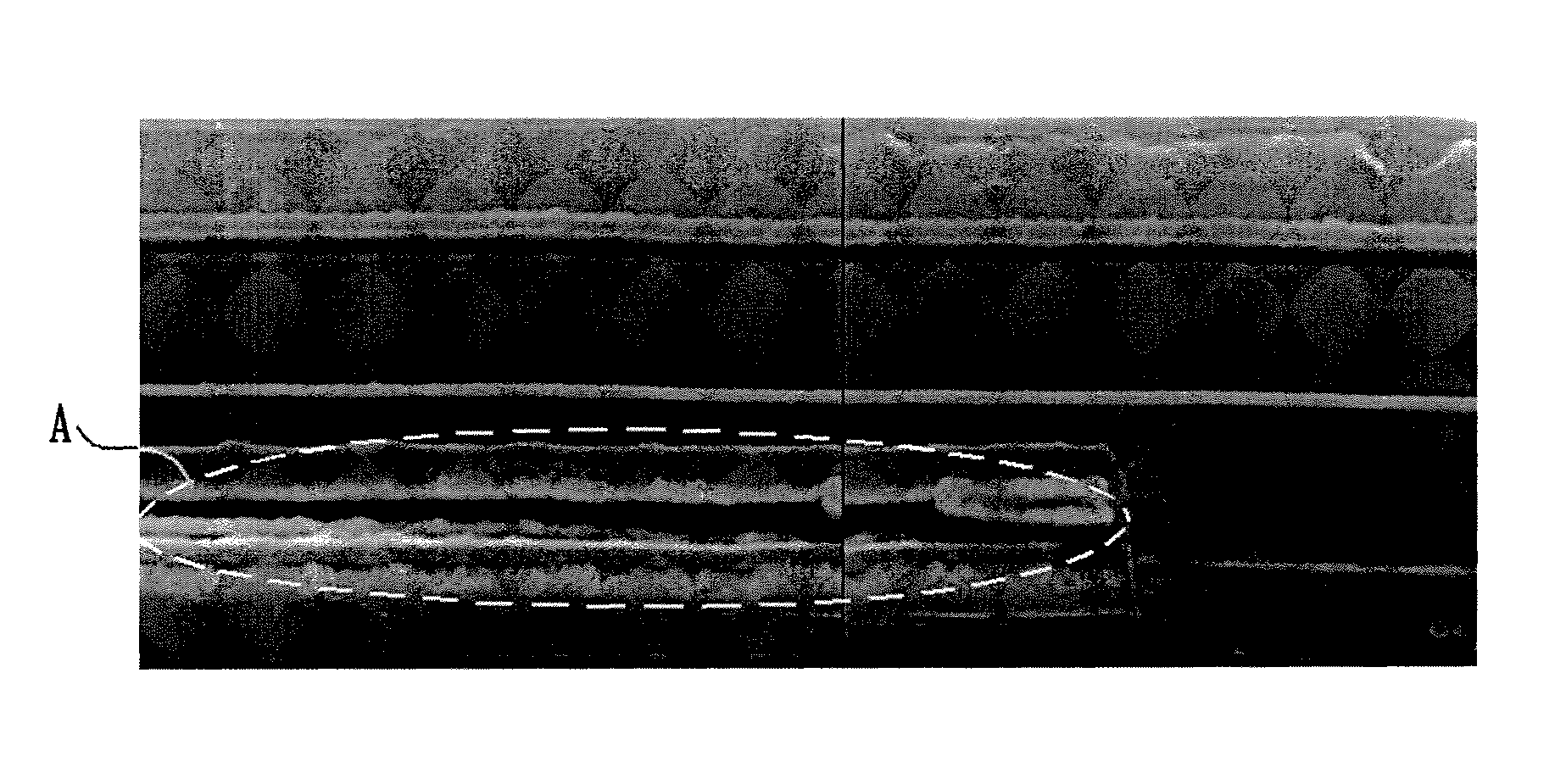

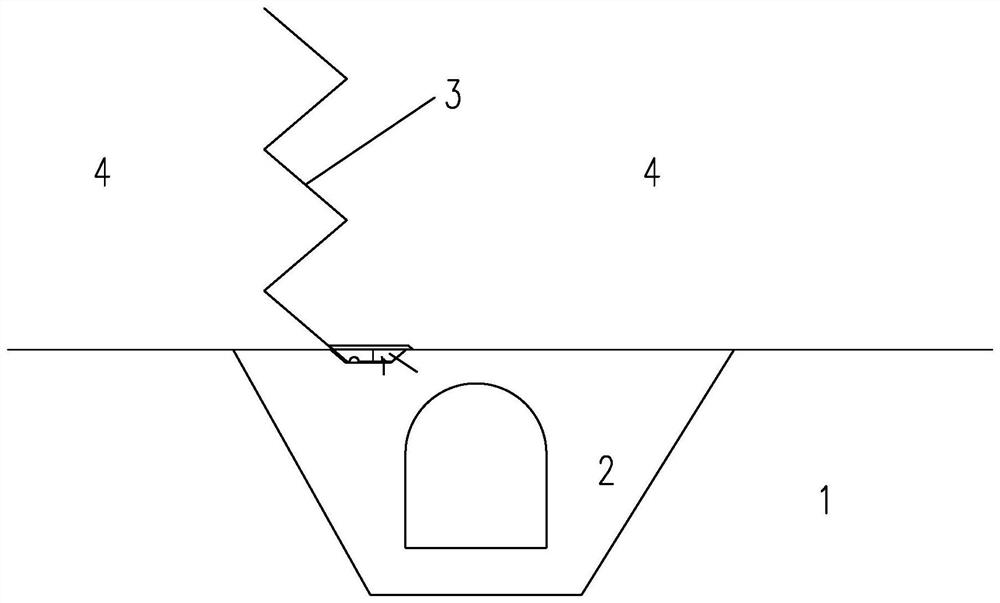

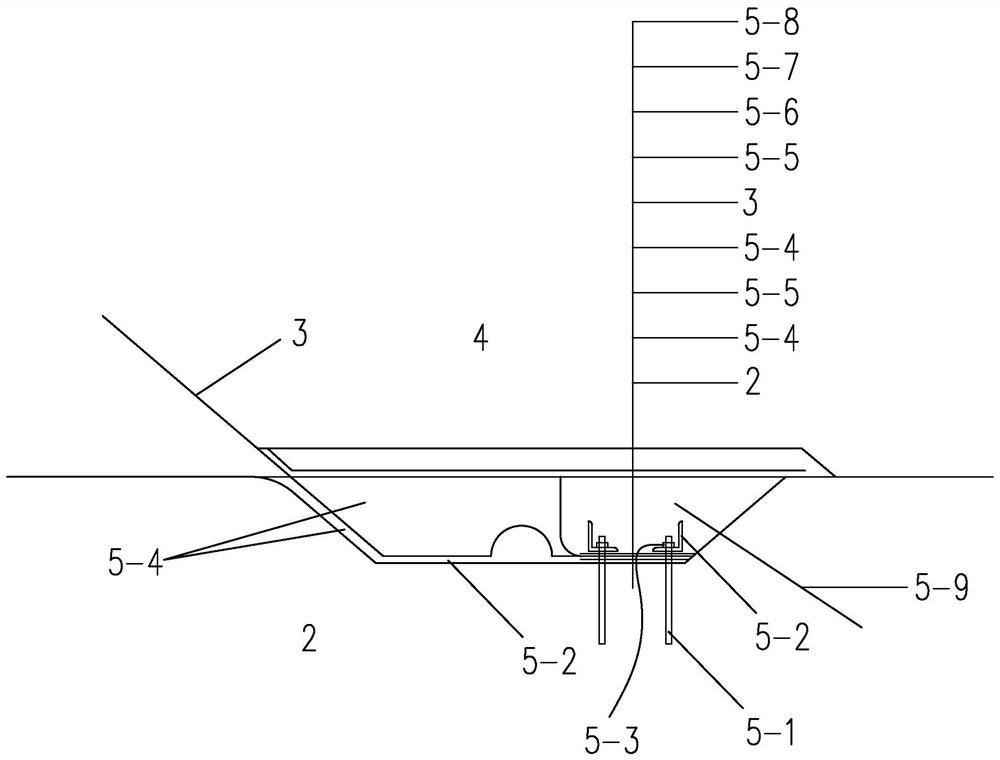

Prestressed post-inserted composite anchor cable uplift pile and on-site loading equipment thereof

The prestressed post-inserted composite anchor cable uplift pile comprises a pile casing, an outer steel bar frame is inserted into the inner side of the pile casing, a cone-shaped body with a guide device is arranged at the bottom of the outer steel bar frame, an inner steel bar cage is inserted into the inner side of the outer steel bar frame, and the inner steel bar cage is arranged in the outer steel bar frame. A hollow pipe is fixedly connected to the axis of the bottom of the interior of the inner reinforcement cage, a concrete pouring channel is formed in the center of the interior of the hollow pipe, and through openings are evenly formed in the bottom of the outer side of the concrete pouring channel. Through the structural cooperation of the pile casing, the outer steel bar frame, the inner steel bar cage and the latticed column, the structural system of the uplift pile is made to be well arranged during installation work, a positioning guide structure between the structures can be formed through structural traction of the guide mechanism, it is guaranteed that vertical installation of the uplift pile body is more accurate and centered, and the construction efficiency is improved. The phenomena of inclination and position deviation of the post-inserted uplift pile are reduced, and meanwhile the tensile stress of the uplift pile body in the working state is eliminated.

Owner:CHINA ACAD OF BUILDING RES +1

Method for fabricating semiconductor device

ActiveUS7897504B2Eliminate tensile stressReduce tensile stressSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorMaterials science

A method for fabricating a semiconductor device, in which a lifting phenomenon can be prevented from occurring in forming an amorphous carbon film on an etched layer having tensile stress. According to the invention, since a compression stress on the etched layer or the amorphous carbon film can be reduced or a compression stress film is formed between the etched layer or the amorphous carbon film to prevent a lifting phenomenon from occurring and thus another pattern can be formed to fabricate a highly integrated semiconductor device.

Owner:SK HYNIX INC

A kind of preparation method of universal reset screw seat titanium alloy bar

ActiveCN111534715BGuaranteed uniformityEnsure consistencyWire straightening devicesTemperature control deviceOrthopedic departmentStress relief

The invention belongs to the technical field of processing titanium alloy materials for medical use, and in particular relates to a method for preparing titanium alloy rods for universal reset screw seats. The chemical composition and mass percentage of titanium alloy are: Al 5.9-6.4%, V 3.9-4.4%, Fe 0.15-0.22%, O 0.09-0.13%, C≤0.05%, H≤0.005%, N≤0.01%, and the rest The amount is Ti; firstly, the round bar blank is obtained through smelting, forging, and rolling processes; then, the uniform annealing process in the β single-phase region is adopted to obtain uniform fine-grained acicular martensite structure, and electric straightening and hyperbolic straightening are adopted. Straightening is carried out by direct composite process, and the electrified straightening temperature is controlled below 780°C to obtain a balanced residual stress state; finally, stress relief annealing and centerless grinding are carried out to prepare finished rods. The invention can produce substantially stress-free medical Ti-6Al-4V alloy rods, has excellent fatigue life, and provides qualified raw materials for manufacturing orthopedic medical device universal reset screw seats.

Owner:中科锐金山东钛业科技有限公司

Method of Stress Corrosion Resistance of Stainless Steel Welded Joints by Nanosecond Pulse Laser Shock

ActiveCN106834659BReduced stress corrosion resistanceAccelerated corrosionFurnace typesHeat treatment furnacesNanosecond pulseWeld seam

The invention provides a method for realizing stress corrosion resistance of a stainless steel welding connector impacted by nanosecond-pulse laser. According to the method, a welding seam is impacted by adopting laser along an S shape, and an outer region of the welding seam is impacted along a direction parallel to the welding seam, so that pull stress of the welding connector is eliminated. By reasonably selecting power density, phase change does not occur and residual pull stress can be eliminated, so that a condition that the stress corrosion resistance performance of the welding connector is reduced is avoided. According to the method provided by the invention, the surface of a workpiece is impacted through the nanosecond-pulse laser, and no obvious mechanical force is used; a machining speed is rapid and automation is easy to realize; a complicated mold surface can be impacted.

Owner:AIR FORCE UNIV PLA

Double-defense-line flexible anchoring structure of dam body core wall geomembrane and foundation concrete structure

PendingCN112502102AEliminate tensile stressImprove operational safetyEarth-fill damsRock-fill damsGeomembraneStructural engineering

The invention relates to a double-defense-line flexible anchoring structure of a dam body core wall geomembrane and a foundation concrete structure. According to the double-defense-line flexible anchoring structure of the dam body core wall geomembrane and the foundation concrete structure, a geomembrane in a dam body can be fixed to foundation concrete below the geomembrane. According to the technical scheme of the double-defense-line flexible anchoring structure, an anchoring groove is formed in the top face of the foundation concrete, the interior of the anchoring groove is divided into a plastic deformation area located on the upstream side and formed by filling plastic filler and an anchoring mechanism located on the downstream side, and the geomembrane penetrates through the plasticdeformation area to be fixed to the downstream side in the plastic deformation area through the anchoring mechanism. The double-defense-line flexible anchoring structure is suitable for engineering adopting the geomembrane as the middle anti-seepage core wall of the dam body.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

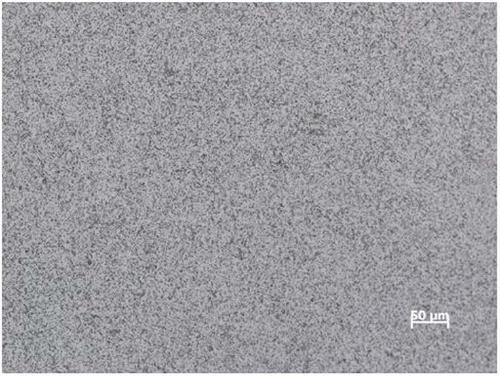

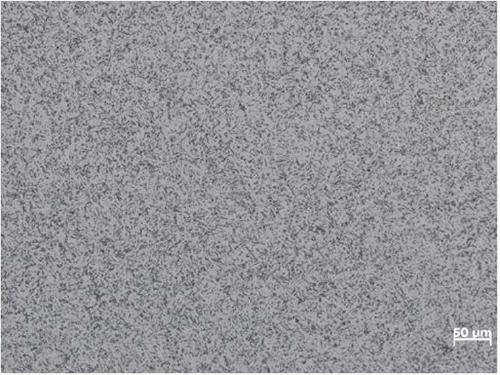

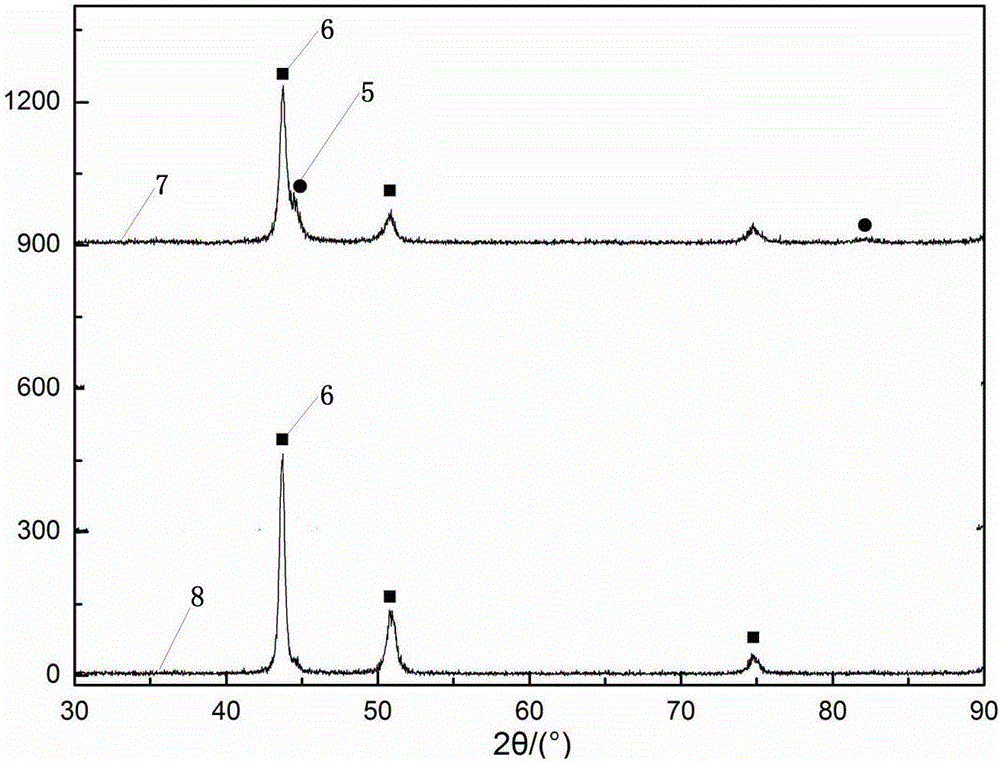

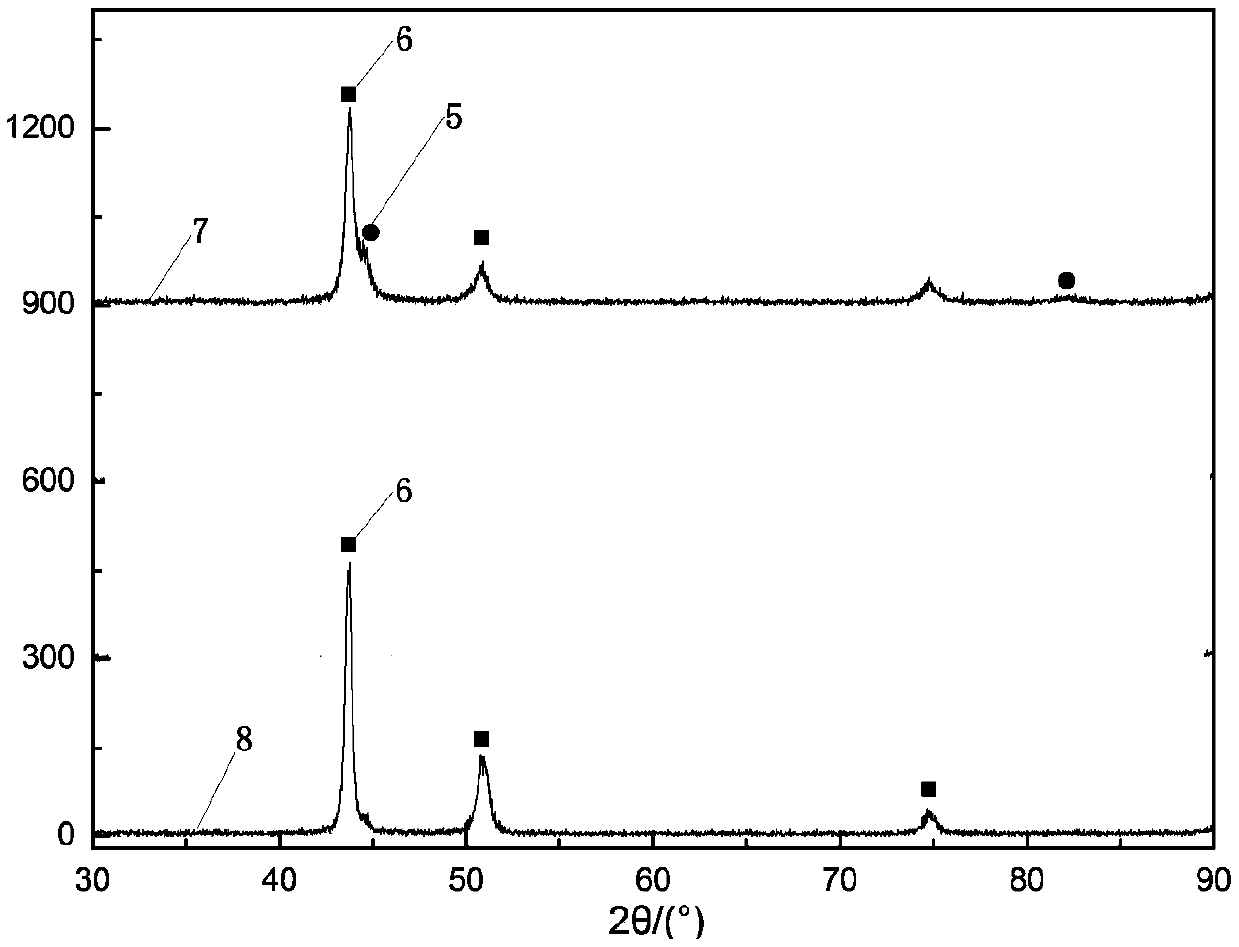

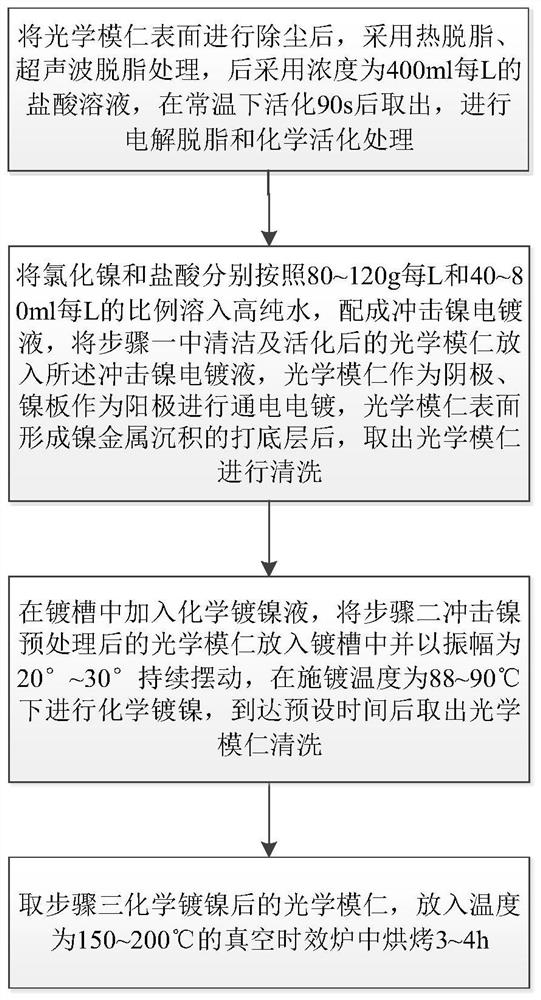

A kind of optical mold core nickel plating process

ActiveCN109518235BAvoid Bubble ProblemsIncreasing the thicknessLiquid/solution decomposition chemical coatingSuperimposed coating processCorrosion resistantHeat treated

The invention discloses a nickel plating process for an optical mold core, which comprises the following operation steps: cleaning and activation, impact nickel pretreatment, chemical nickel plating and heat treatment. The optical mold core is pretreated by multiple degreasing and activation to avoid the impact of impurities on the surface of the optical mold core on the nickel layer; the surface of the optical mold core is pretreated by impact nickel plating to prevent the chromium contained in the optical mold core material The influence of corrosion-resistant metals such as molybdenum and molybdenum on nickel plating can improve the bonding force between the nickel layer and the substrate; the use of a special electroless nickel plating solution makes the uniformity of the grains formed by the nickel layer and the deposition rate of the coating more ideal, and the obtained High-thickness nickel layer; finally, heat treatment is used to eliminate the compressive stress and tensile stress of the nickel layer, and further make hydrogen gas escape, so as to obtain a high-quality nickel layer without cracking and peeling.

Owner:JIANGXI PHENIX OPTICS TECH CO LTD

A composite manufacturing technology of ceramic and titanium alloy assisted by frequency conversion ultrasonic

The invention relates to a technical method for composite casting of ceramic and a titanium alloy through assistance of variable-frequency ultrasonic waves. The method aims to solve the problem that the ceramic is fragile, and can reduce the stress of the ceramic and avoid cracking of the ceramic. An ultrasonic solidification technology can enable molten titanium alloy to be well combined with a ceramic matrix, the variable-frequency ultrasonic waves assist in the casting process, so that segregation of the titanium alloy in the solidification process is reduced in the casting process, a finegrained area is enlarged, and formation of developed dendritic crystals is reduced; and the ceramic matrix is coated with the molten titanium alloy, so that the crack resistance of the ceramic material is improved. The molten titanium alloy is prepared by adopting a non-consumable vacuum smelting furnace, wherein a titanium alloy bar is made into consumable electrodes, electric arc heat is generated through discharge between the electrodes under the vacuum condition, and the titanium alloy bar is rapidly heated to a high temperature and then melted to obtain the molten titanium alloy. In the casting and cooling process of the molten titanium alloy, due to solidification and shrinkage of the molten titanium alloy, a pressure stress is applied to the surface of the ceramic matrix, and therefore cracks cannot be easily generated in the using process of the ceramic, and the material integrating the advantages of the ceramic and the titanium alloy is obtained.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

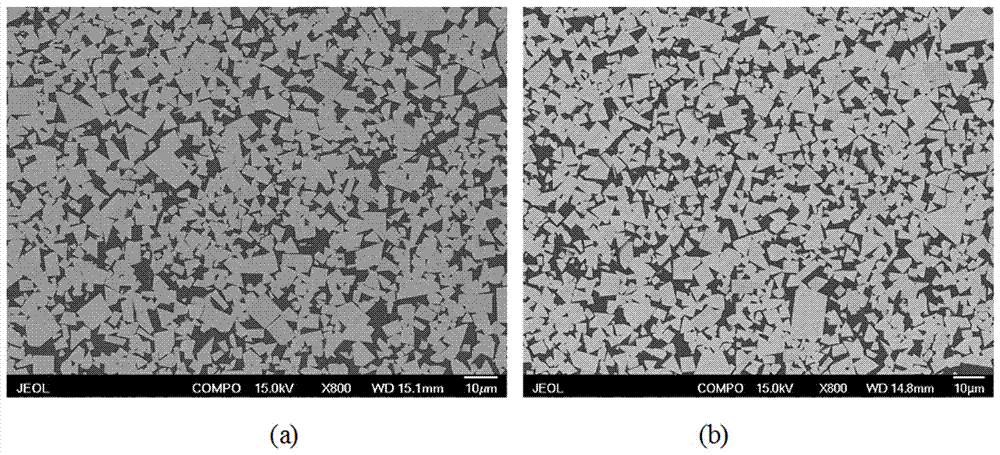

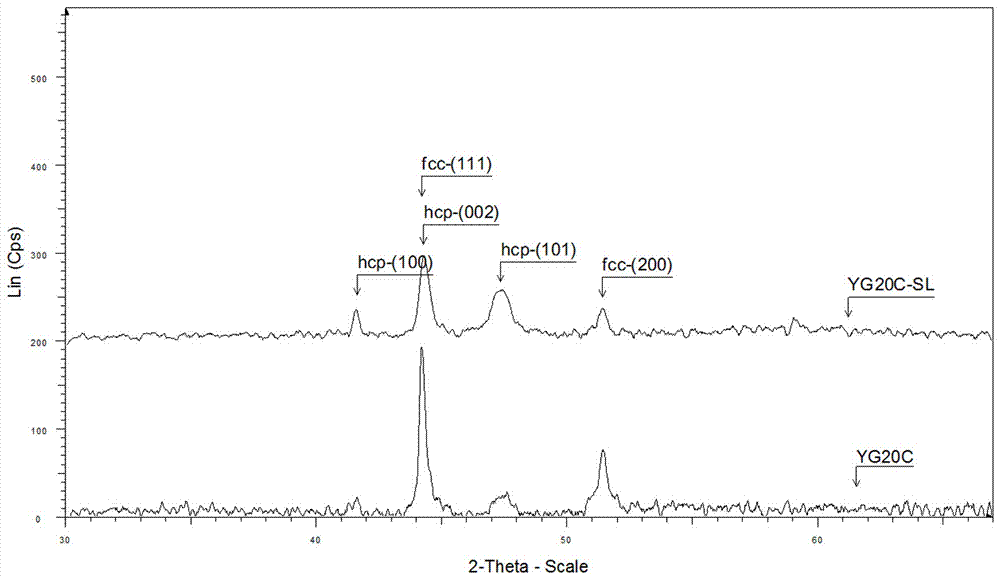

A cryogenic treatment method for cemented carbide for cold heading dies

The invention relates to a subzero treatment method of a hard alloy for a cold heading mold. Subzero treatment and tempering treatment are performed in sequence for the sintered hard alloy for the cold heading mold; the subzero treatment comprises the following three stages of cooling and insulation treatment after cooling: the temperature is firstly reduced to -75 to -85 DEG C, then is reduced to -135 to -145 DEG C, and is finally reduced to -186 to -196 DEG C; and the tempering treatment comprises the following two stages of heating and insulation treatment after heating: the temperature is firstly heated up to 95-105 DEG C, and then is heated up to 180-240 DEG C. The method enables part face-centered cubic (fcc) cobalt in the alloy to be converted to hexagonal close-packed (hcp) cobalt, improves the wear resistance and the comprehensive performance of the alloy, eliminates the tensile stress in the alloy, and prolongs the service life.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Method of manufacturing an energy efficient electrical conductor

ActiveUS10304586B2Preserve integrityPreserve propertyLine/current collector detailsNon-insulated conductorsElectricityPre stress

The present invention relates to electrical conductors for electrical transmission and distribution with pre-stress conditioning of the strength member so that the conductive materials of aluminum, aluminum alloys, copper, copper alloys, or copper micro-alloys are mostly tension free or under compressive stress in the conductor, while the strength member is under tensile stress prior to conductor stringing, resulting in a lower thermal knee point in the conductor.

Owner:TS CONDUCTOR CORP

Method for manufacturing pre-deformation line diamond line saw through powder metallurgy

InactiveCN102218537BWon't breakEliminate residual tensile stressMetal sawing toolsStone-like material working toolsPre deformationMetal filament

Owner:长沙和谦新材料科技有限公司

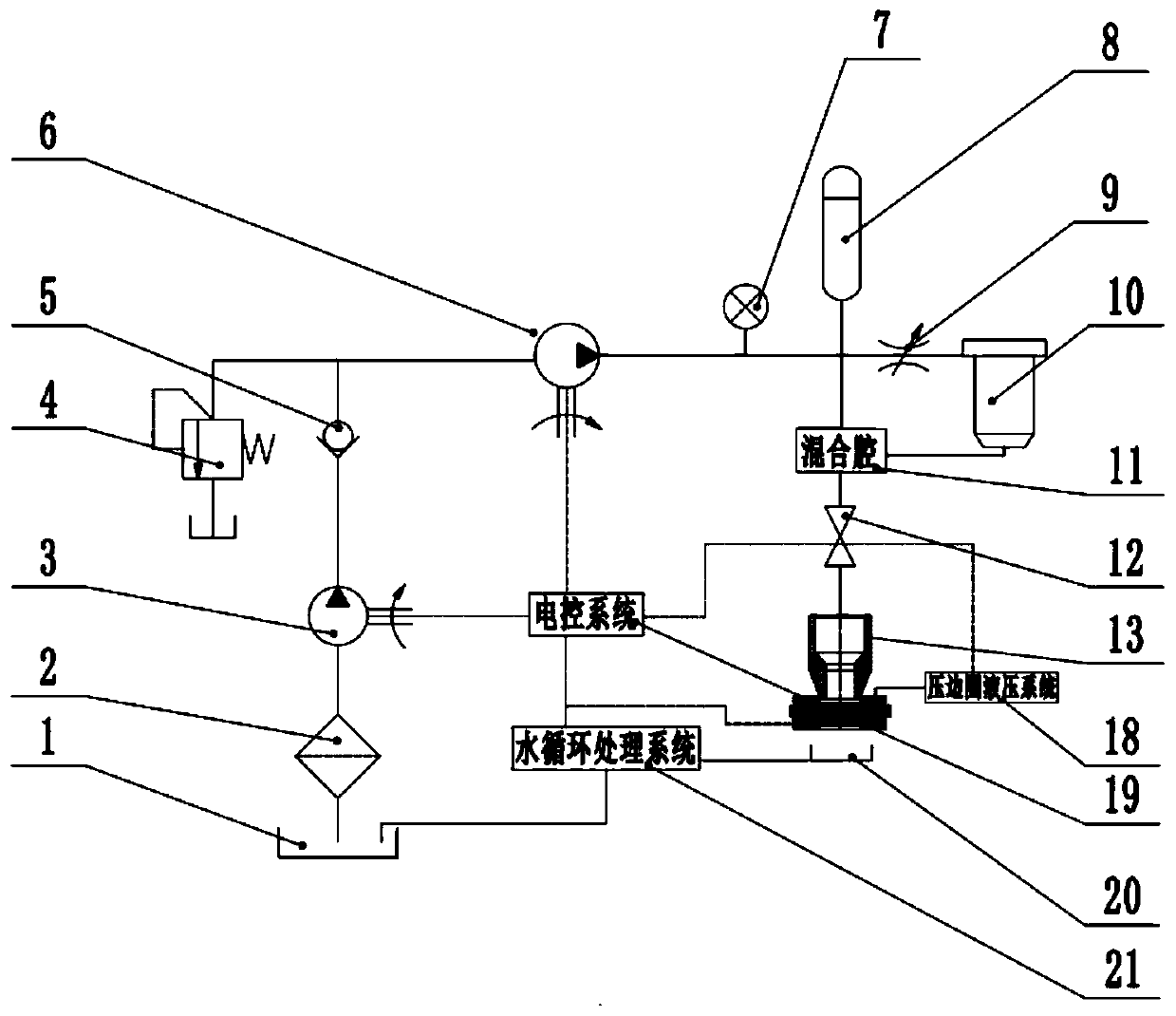

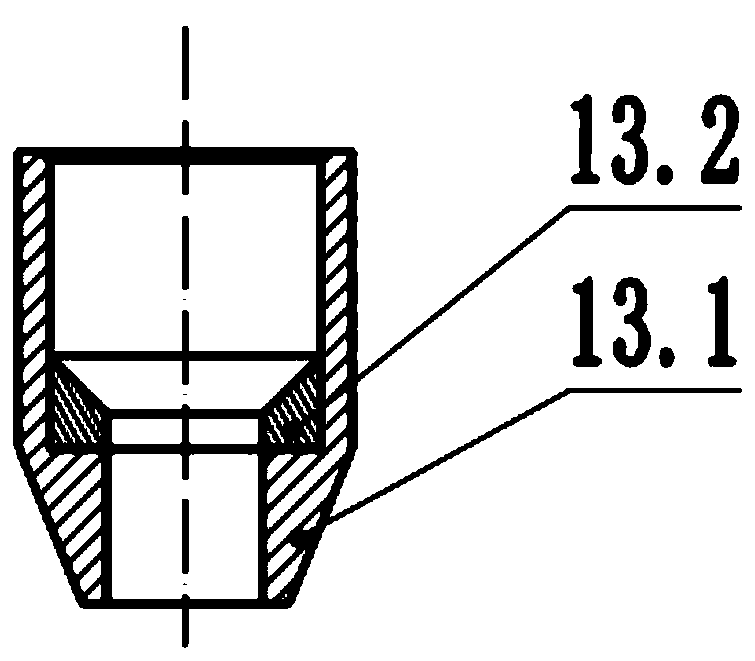

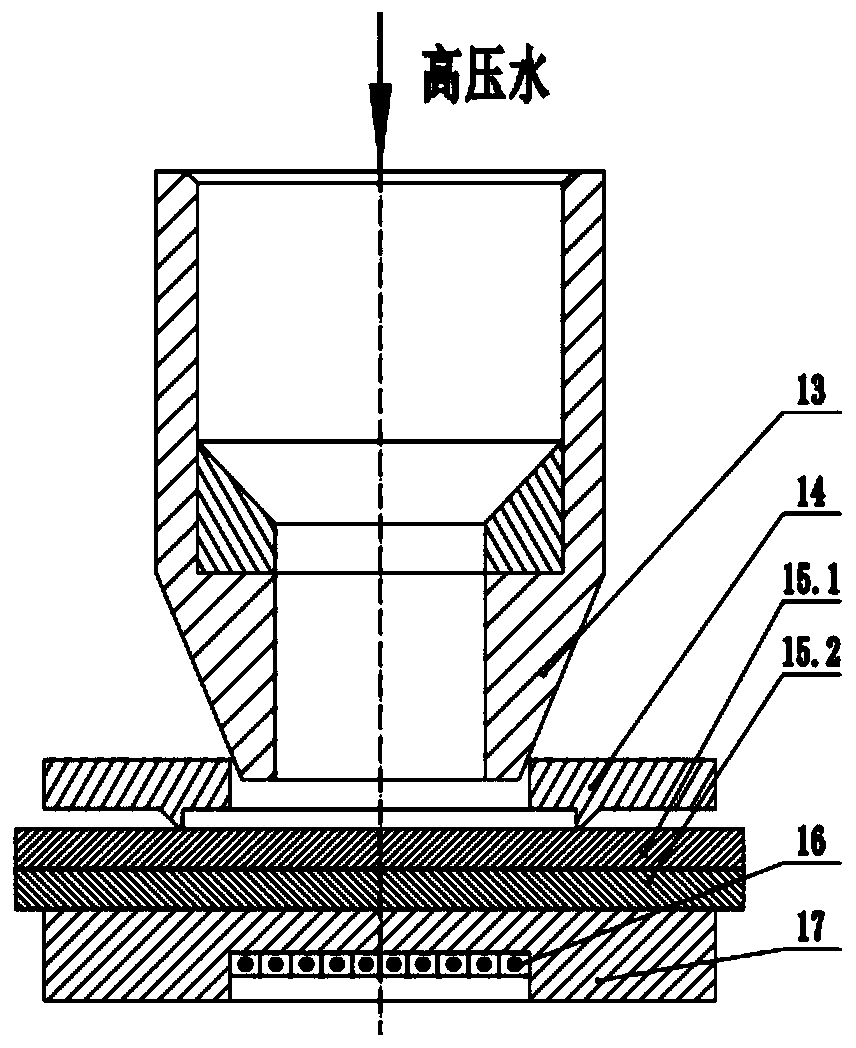

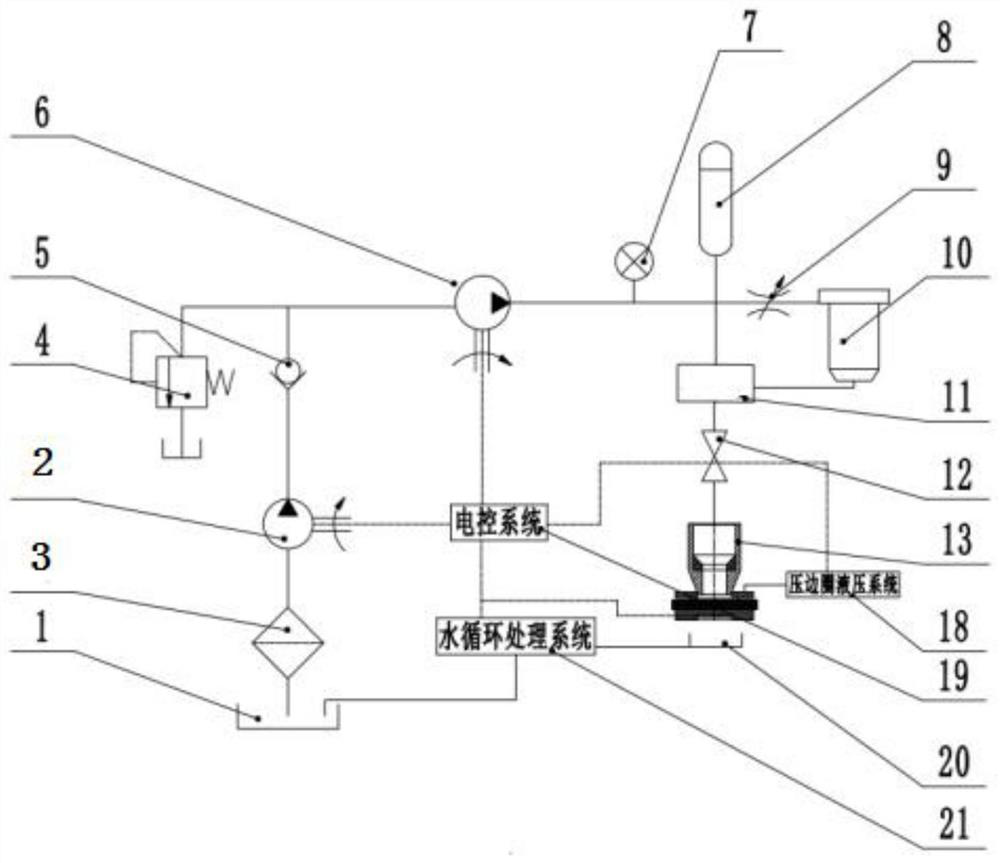

Integrated anti-extrusion connecting system and method thereof for water knife forming, strengthening and quenching

The invention provides an integrated anti-extrusion connecting system and a method thereof for water-knife forming, strengthening and quenching. The system comprises a connecting device, a water-knifepower system, an electric control system and a water circulation treatment system, wherein the connecting device comprises a spray head and a connecting tool; the water-knife power system comprises awater tank, a filter, a low-pressure water pump, a check valve, a high-pressure water pump, an energy accumulator, a throttle valve, a hard particle tank, a mixing cavity and a stop valve, and the stop valve is located above the spray head; the electric control system is electrically connected with the high-pressure water pump, the low-pressure water pump, electromagnetic coils and a blank holderhydraulic system; and one end of the water circulation treatment system is connected with the water tank of the water-knife power system, and the other end of the water circulation treatment system is connected with a water collector. The system is used for connecting multi-layer plates, forming, quenching and strengthening are integrated, the production efficiency is high, the connection reliability is high, and the connection position has the advantages of compact metal structure, high strength, strong wear resistance, high hardness and the like.

Owner:CENT SOUTH UNIV

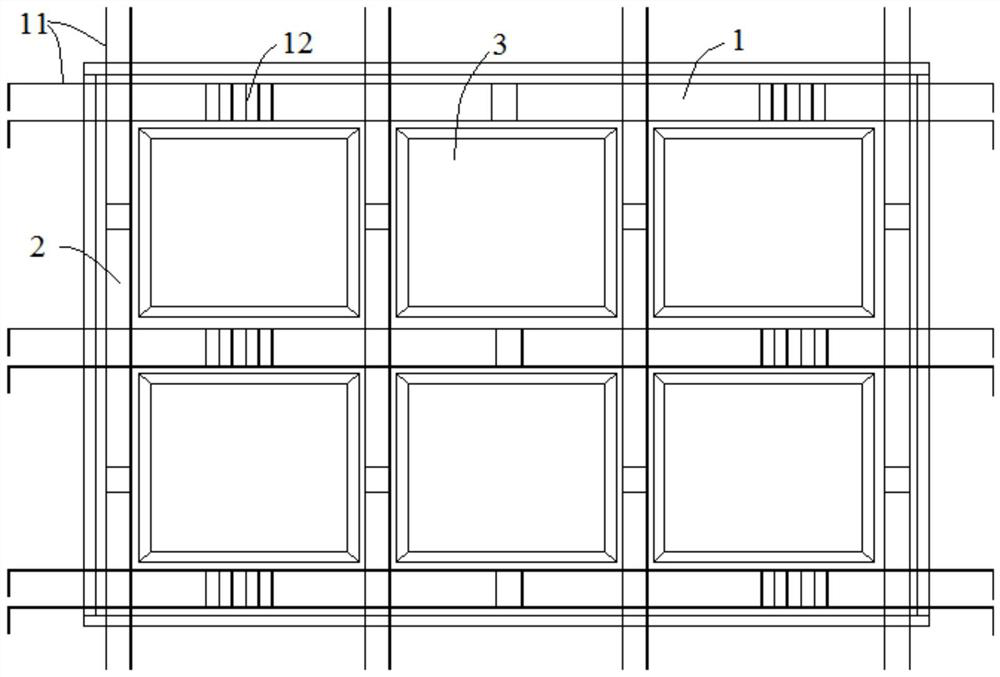

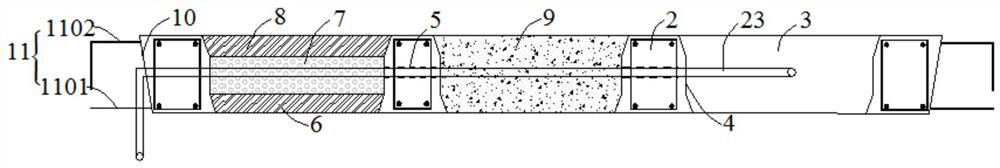

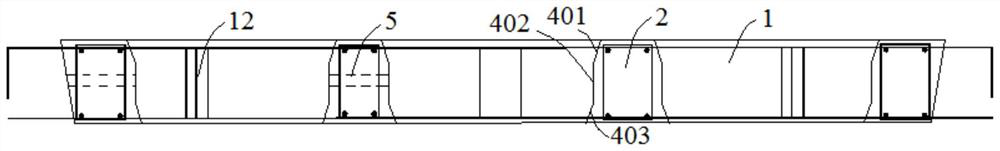

A prefabricated and assembled lattice composite floor slab and its construction method

ActiveCN112878562BLight weightMeet the bearing capacity requirementsFloorsSound proofingFloor slabThermal insulation

The invention discloses a prefabricated and assembled lattice type composite floor slab and a construction method thereof, belonging to the technical field of prefabricated and assembled buildings. The prefabricated assembled lattice type composite floor is assembled by a plurality of prefabricated slab units. Intercostal grid; the sides of the rib beams that constitute the intercostal grid are provided with upper, middle, and lower planes, and the lower parts of the upper and lower planes extend toward the intercostal grid to form inclined surfaces. The surface is connected with the surface of the upper and lower regions, and the intercostal cells are correspondingly filled with intercostal cell filling materials. Adopting the technical scheme of the present invention can effectively satisfy its heat insulation and sound insulation performance on the basis of ensuring the bearing capacity of the floor slab, and at the same time can better control the thickness of the floor slab. Continuous performance improvement conditions, strong practicability.

Owner:CHINA MCC17 GRP

Water jet forming enhanced quenching integrated reverse extrusion connection system and method

The invention provides an integrated anti-extrusion connecting system and a method thereof for water-knife forming, strengthening and quenching. The system comprises a connecting device, a water-knifepower system, an electric control system and a water circulation treatment system, wherein the connecting device comprises a spray head and a connecting tool; the water-knife power system comprises awater tank, a filter, a low-pressure water pump, a check valve, a high-pressure water pump, an energy accumulator, a throttle valve, a hard particle tank, a mixing cavity and a stop valve, and the stop valve is located above the spray head; the electric control system is electrically connected with the high-pressure water pump, the low-pressure water pump, electromagnetic coils and a blank holderhydraulic system; and one end of the water circulation treatment system is connected with the water tank of the water-knife power system, and the other end of the water circulation treatment system is connected with a water collector. The system is used for connecting multi-layer plates, forming, quenching and strengthening are integrated, the production efficiency is high, the connection reliability is high, and the connection position has the advantages of compact metal structure, high strength, strong wear resistance, high hardness and the like.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com