A cryogenic treatment method for cemented carbide for cold heading dies

A cryogenic treatment and cemented carbide technology, which is applied in the production process of cemented carbide cold heading dies, can solve the problems of unfavorable stress elimination and no tempering process, so as to eliminate tensile stress, improve comprehensive performance and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A cryogenic treatment method for a YG20 cold heading die with a cobalt content of 20%, the operation steps are: (1) putting the sintered cold heading die into a cryogenic treatment furnace; Liquid nitrogen, lowered to -80°C at a rate of -2°C / min, and kept for 1 hour; (3) lowered to -140°C at a rate of -1.5°C / min, kept for 2 hours; (4) kept at a rate of -1°C / min Lower it to -186°C, keep it warm for 4 hours, then cut off the power, and take it out after naturally heating up to room temperature; Raise the temperature to 100°C, keep it warm for 1 hour, then raise the temperature to 180°C at 1.5°C / min, keep it warm for 2 hours, then turn off the power, and let it cool down to room temperature naturally.

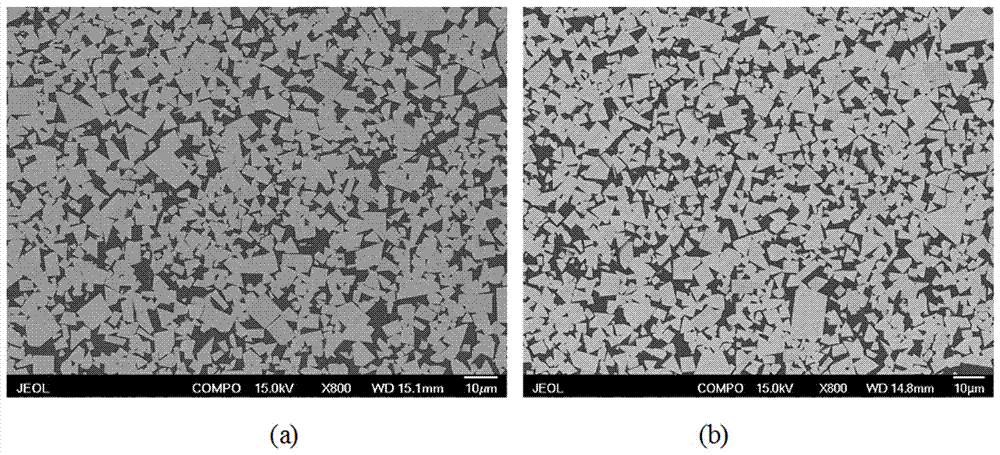

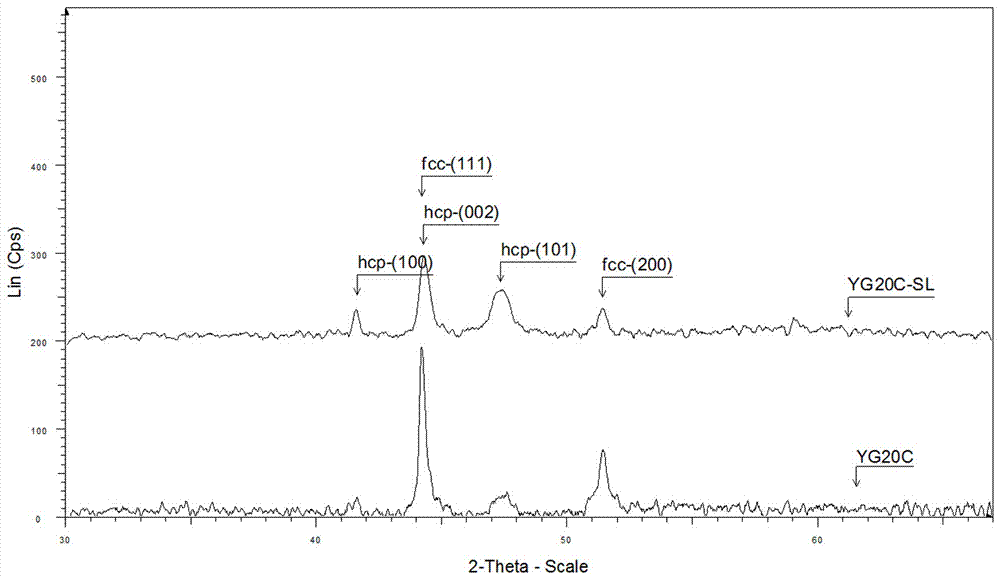

[0018] attached by figure 1 It can be seen that the microstructure of YG20 did not change significantly before and after cryogenic treatment. attached by figure 2 It can be seen that, compared with before cryogenic treatment, the face-centered cubic cobalt (fcc) in YG20...

Embodiment 2

[0021] A kind of cobalt content is the cryogenic treatment method of the MB50A cold heading mold of 22%, and its operation steps are: (1) the cold heading mold that sinters is put into the cryogenic treatment furnace; (2) open the cryogenic treatment furnace, pass into Liquid nitrogen, lowered to -75°C at a rate of -1.5°C / min, and kept for 2 hours; (3) lowered to -135°C at a rate of -1°C / min, kept for 4 hours; (4) kept at a rate of -1°C / min Lower it to -190°C, keep it warm for 5 hours, then turn off the power, and take it out after naturally heating up to room temperature; Raise the temperature to 95°C, keep it warm for 2 hours, then raise the temperature to 220°C at 1°C / min, keep it warm for 2 hours, then turn off the power and let it cool down to room temperature naturally.

[0022] Cold-heading Φ4.8 carbon steel screw straight rods with cold heading dies without cryogenic treatment and after cryogenic treatment, the results show that cryogenic treatment can increase the ser...

Embodiment 3

[0024] A kind of cobalt content is the cryogenic treatment method of MB65 cold heading die of 25%, and its operation steps are: (1) the cold heading die that sinters is put into cryogenic treatment furnace; (2) open cryogenic treatment furnace, pass into Liquid nitrogen, lowered to -85°C at a rate of -1°C / min, and kept for 2 hours; (3) lowered to -145°C at a rate of -0.5°C / min, kept for 4 hours; (4) kept at a rate of -0.5°C / min Lower it to -196°C, keep it warm for 6 hours, then cut off the power, and take it out after naturally heating up to room temperature; Raise the temperature to 105°C, keep it warm for 2 hours, then raise the temperature to 240°C at 0.5°C / min, keep it warm for 4 hours, then turn off the power and let it cool down to room temperature naturally.

[0025] The MB65 cold heading die without cryogenic treatment and after cryogenic treatment were cold-headed Φ8 stainless steel screw shrink rods, and the results showed that cryogenic treatment increased the servi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com