Method of Stress Corrosion Resistance of Stainless Steel Welded Joints by Nanosecond Pulse Laser Shock

A nanosecond pulse laser and laser shock technology, which is applied in the direction of furnaces, furnace types, heat treatment equipment, etc., can solve the problems of stress corrosion resistance degradation and other problems, and achieve the effect of easy automation, fast processing speed and automatic realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

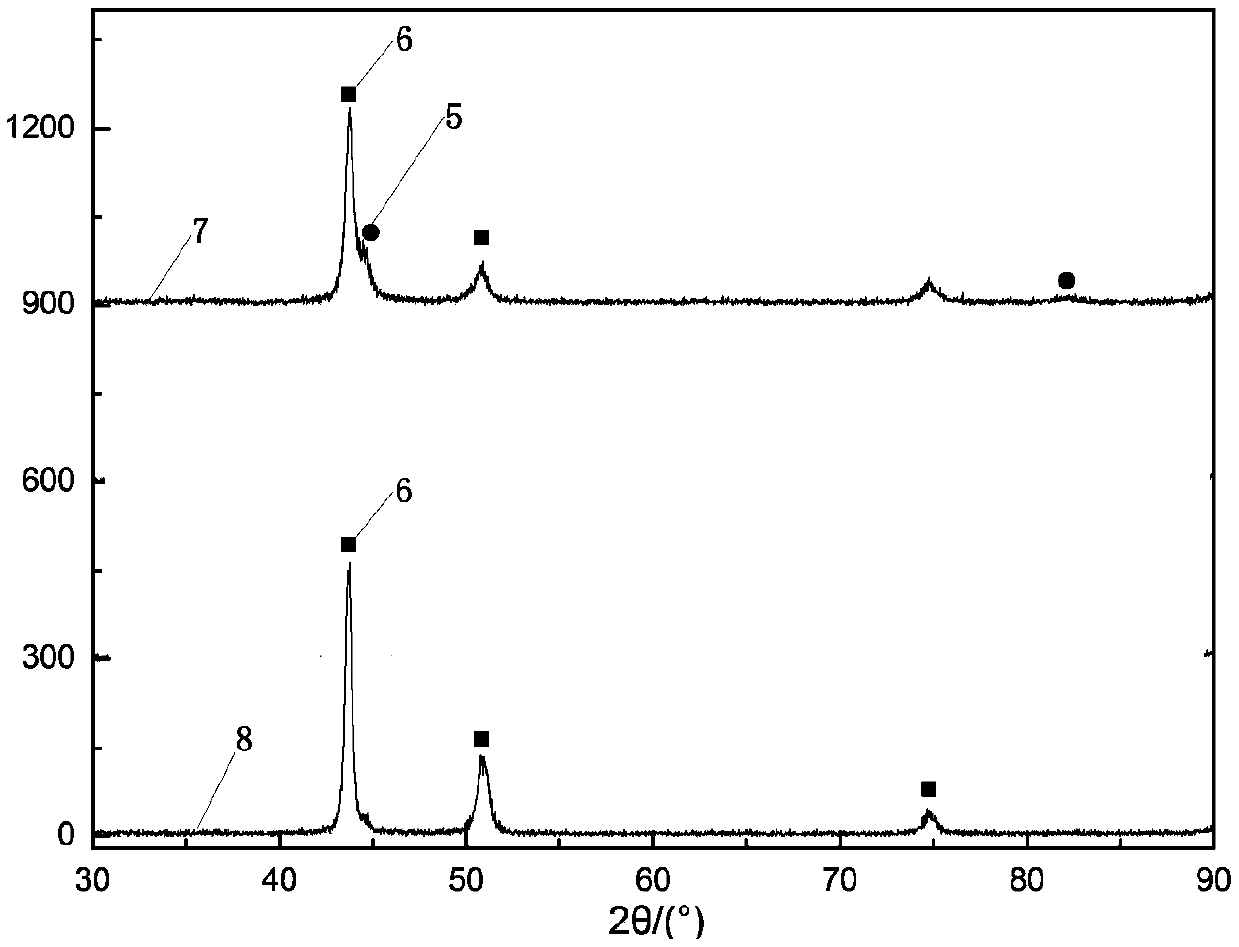

[0029] This embodiment is a process for resisting stress corrosion of stainless steel welded joints subjected to nanosecond pulse laser shock. The test pieces in this example are 316L stainless steel welded joints.

[0030] The specific steps are:

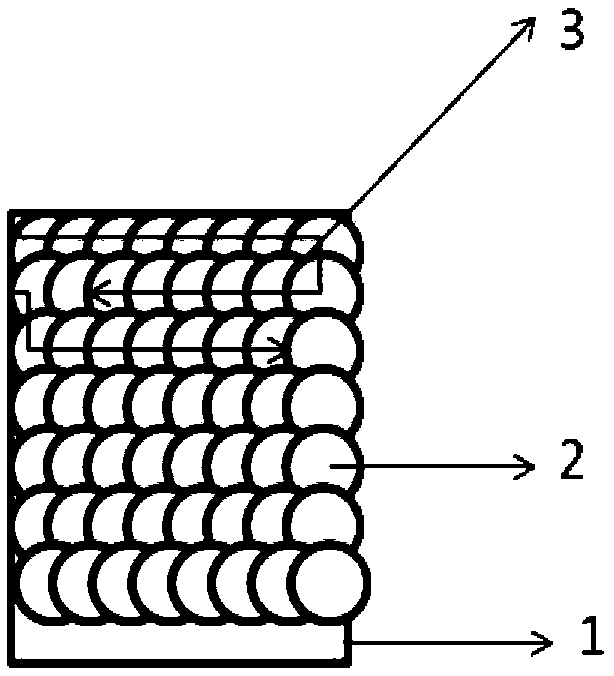

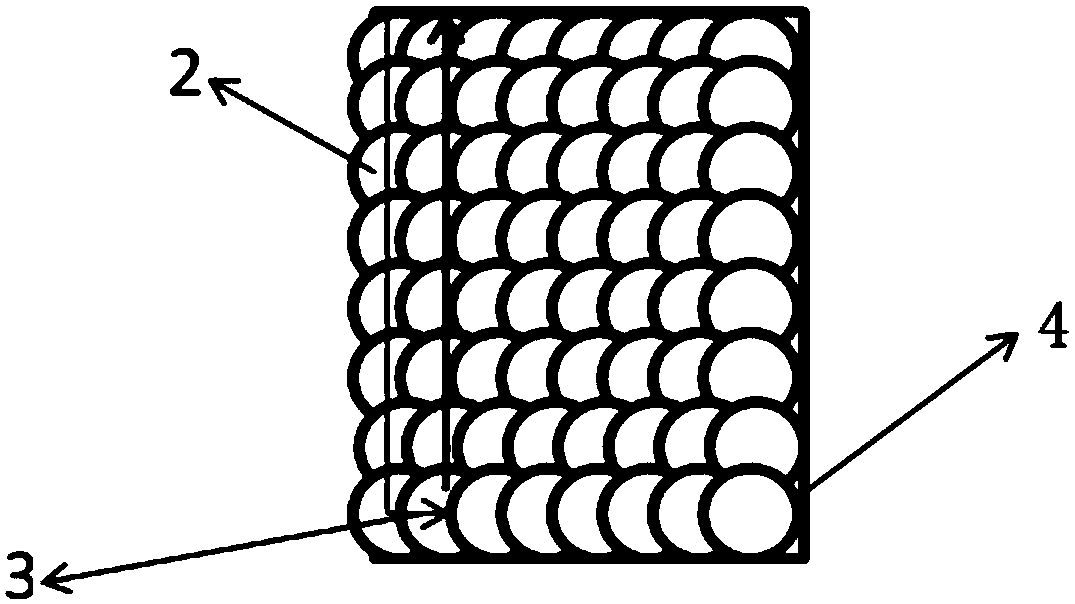

[0031] Step 1, Paste the absorbing protective layer. Aluminum foil with a thickness of 0.05mm to 0.1mm is used as the absorbing protective layer. Paste the aluminum foil on the surface of the weld seam of the test piece and in the area of 7mm on both sides of the weld seam, the thickness of the aluminum platinum is ≤0.1mm.

[0032] In this embodiment, the sticking thickness of the absorbing protective layer is 0.05 mm.

[0033] Step 2, forming a constraint layer. A deionized water layer with a thickness of 1 mm to 2 mm is formed on the surface of the absorbing protective layer as a constrained layer by conventional methods and maintained.

[0034] Step 3, laser shock weld. The weld seam is impacted with a nanosecond pulsed ...

Embodiment 2

[0047] This embodiment is a process for resisting stress corrosion of stainless steel welded joints subjected to nanosecond pulse laser shock. The test pieces in this example are 304 stainless steel welded joints.

[0048] The specific steps are:

[0049] The specific steps are:

[0050] Step 1, Paste the absorbing protective layer. Aluminum foil with a thickness of 0.05mm to 0.1mm is used as the absorbing protective layer. Paste the aluminum foil on the surface of the weld seam of the test piece and in the area of 6mm on both sides of the weld seam, the thickness of the aluminum platinum is ≤0.1mm.

[0051] In this embodiment, the sticking thickness of the absorbing protective layer is 0.1 mm.

[0052] Step 2, forming a constraint layer. A deionized water layer with a thickness of 1 mm to 2 mm is formed on the surface of the absorbing protective layer as a constrained layer by conventional methods and maintained.

[0053] Step 3, laser shock weld. The weld seam is im...

Embodiment 3

[0066] This embodiment is a process for resisting stress corrosion of stainless steel welded joints subjected to nanosecond pulse laser shock. The test pieces in this example are 304 stainless steel welded joints.

[0067] The specific steps are:

[0068] The specific steps are:

[0069] Step 1, Paste the absorbing protective layer. Aluminum foil with a thickness of 0.05mm to 0.1mm is used as the absorbing protective layer. Paste the aluminum foil on the surface of the weld seam of the test piece and in the area of 7mm on both sides of the weld seam, the thickness of the aluminum platinum is ≤0.1mm.

[0070] In this embodiment, the sticking thickness of the absorbing protective layer is 0.08mm.

[0071] Step 2, forming a constraint layer. A deionized water layer with a thickness of 1 mm to 2 mm is formed on the surface of the absorbing protective layer as a constrained layer by conventional methods and maintained.

[0072] Step 3, laser shock weld. The weld seam is im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com