A kind of preparation method of universal reset screw seat titanium alloy bar

A technology of titanium alloy and screw seat, which is applied in the field of preparation of universal reset screw seat titanium alloy bar, can solve the problems of universal reset screw seat bar expansion, shrinkage, and expansion, and achieve equipment and processing technology Simple, eliminates tensile stress and compressive stress, and meets the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

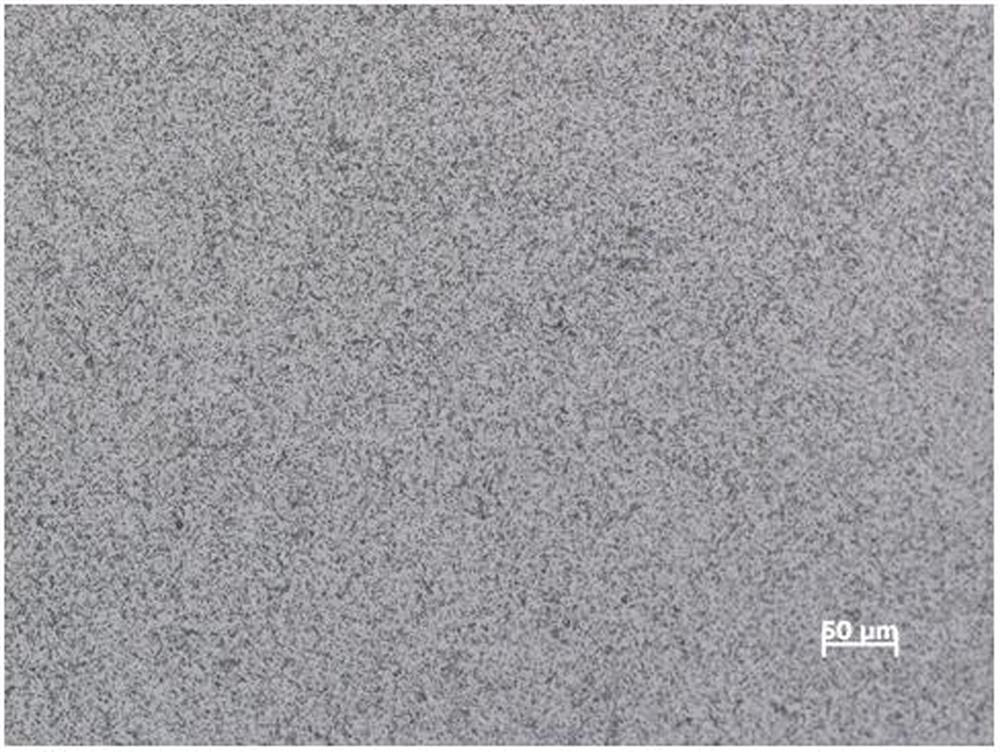

Embodiment 1

[0039] The composition design of the universal reset screw seat titanium alloy bar in this embodiment includes: 6.15% of Al element, 4.14% of V element, 0.17% of Fe element, 0.11% of O element, 0.013% of C element, and 0.0009% of H element %, N element 0.0092%, and the balance is Ti.

[0040] The preparation method of the universal reset screw seat titanium alloy bar is as follows:

[0041] Step 1. Use sponge titanium, metal Al, intermediate alloy AlV, metal Fe, compound TiO 2 According to the ingredients of titanium alloy, the vacuum self-consumption is used for three times of melting to obtain a titanium alloy ingot with stable and uniform composition;

[0042] Step 2: Carry out billet forging at 1100°C, and finish forging at 950°C. The holding time is controlled at 5 hours, and the deformation per time is controlled at 60%; The temperature is 40°C above the β-transition point of the titanium alloy, kept for 30 minutes, and water quenched to room temperature.

[0043] Ste...

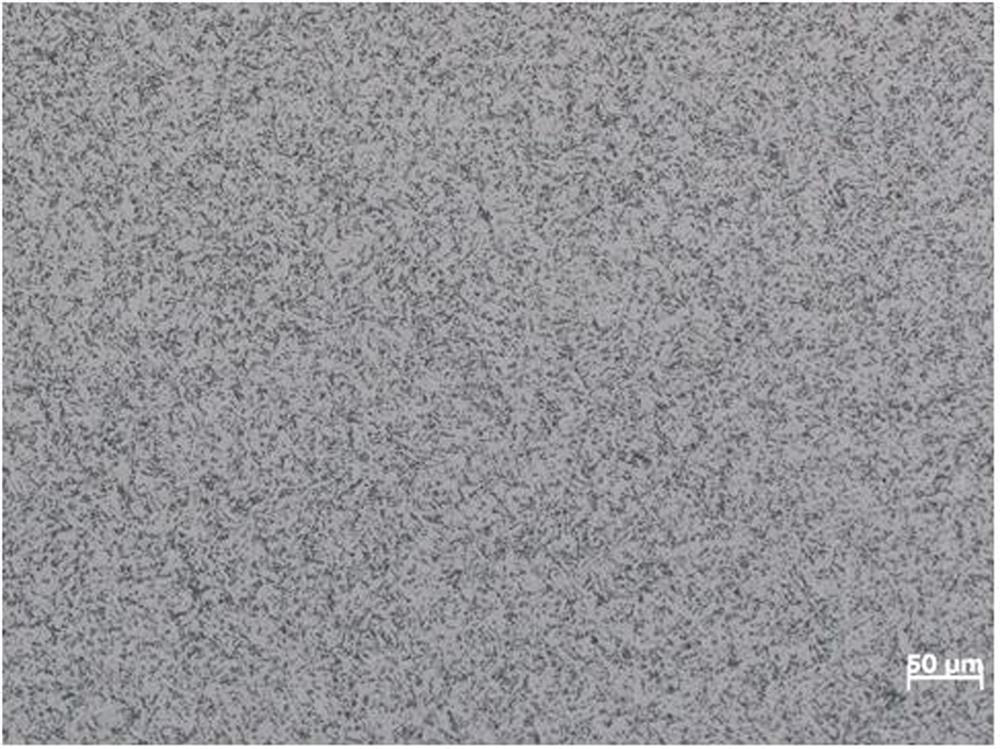

Embodiment 2

[0056] The composition design of the universal reset screw seat titanium alloy bar in this embodiment includes: 6.35% of Al element, 4.3% of V element, 0.20% of Fe element, 0.13% of O element, 0.019% of C element, and 0.0005% of H element %, N element 0.0078%, and the balance is Ti.

[0057] The preparation method of the universal reset screw seat titanium alloy bar is as follows:

[0058] Step 1. Use sponge titanium, metal Al, intermediate alloy AlV, metal Fe, compound TiO 2 According to the ingredients of titanium alloy, the vacuum self-consumption is used for three times of melting to obtain a titanium alloy ingot with stable and uniform composition;

[0059] Step 2: Carry out blank forging at 1050°C, and finish forging at 900°C. The holding time is controlled at 2 hours, and the deformation per time is controlled at 40%; The temperature is 30°C above the β transformation point of the titanium alloy, kept for 60 minutes, and water quenched to room temperature.

[0060] S...

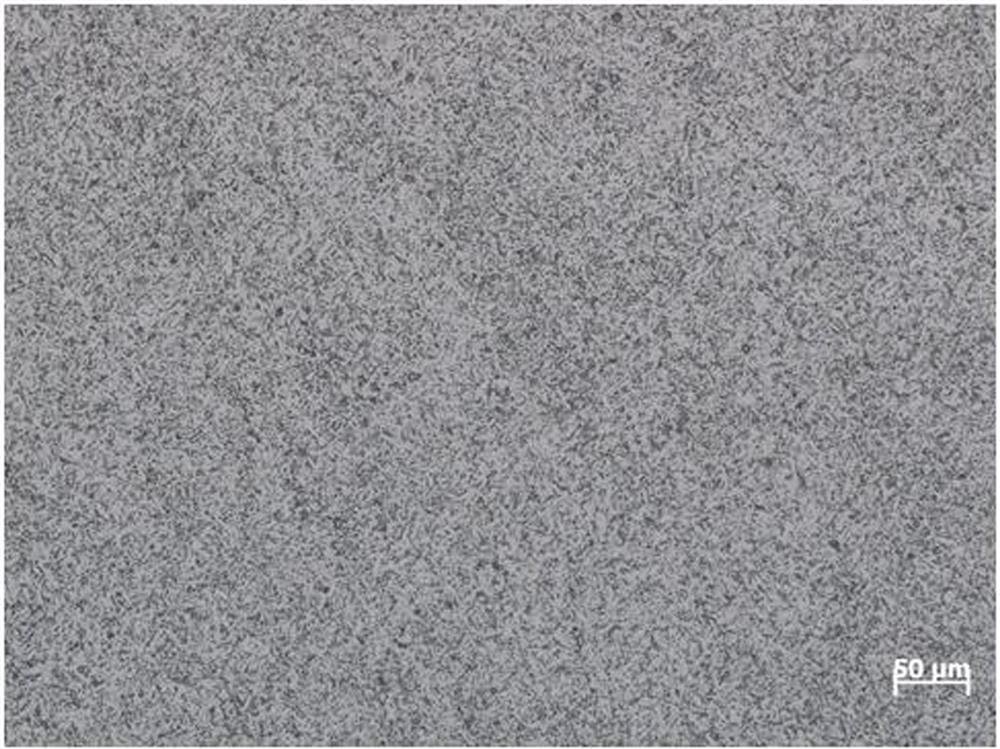

Embodiment 3

[0073] The composition design of the universal reset screw seat titanium alloy bar in this embodiment includes: 5.9% of Al element, 4.0% of V element, 0.16% of Fe element, 0.096% of O element, 0.037% of C element, and 0.001% of H element %, N element 0.0096%, and the balance is Ti.

[0074] The preparation method of the universal reset screw seat titanium alloy bar is as follows:

[0075] Step 1. Use sponge titanium, metal Al, intermediate alloy AlV, metal Fe, compound TiO 2 According to the ingredients of titanium alloy, the vacuum self-consumption is used for three times of melting to obtain a titanium alloy ingot with stable and uniform composition;

[0076] Step 2: Carry out billet forging at 1150°C, and finish forging at 1000°C. The holding time is controlled at 6 hours, and the deformation per time is controlled at 80%; The temperature is 50°C above the β transformation point of the titanium alloy, kept for 10 minutes, and water quenched to room temperature.

[0077] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com