Suspension spring of high-speed locomotive steering frame and manufacturing method thereof

A technology for high-speed locomotives and bogies, applied in the manufacture of tools, low internal friction springs, furnace types, etc., can solve the problems that springs cannot meet the requirements of high-speed locomotives, and the production requirements are getting higher and higher, so as to achieve the optimization of elastic properties and the improvement of fatigue life , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

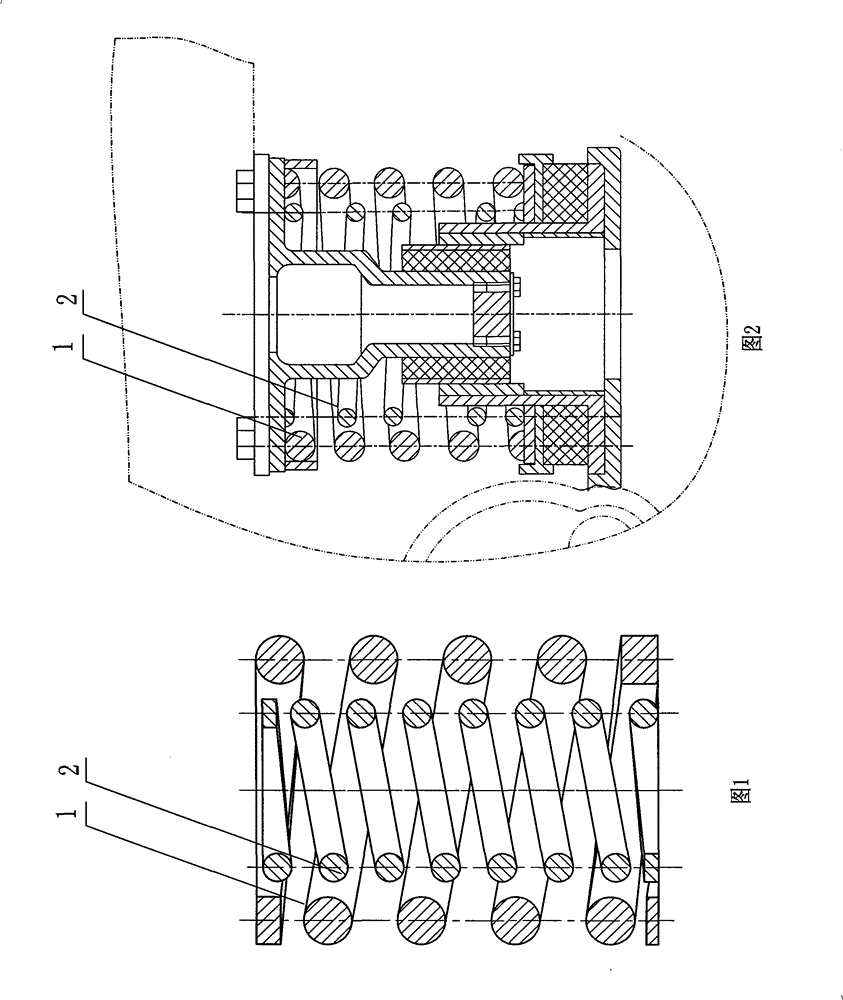

[0024] The material of the inner and outer springs is 52CrMoV4GT spring steel (produced by Shanghai Baosteel), whose comprehensive performance index is better than 52CrMoV. The outer spring and the inner spring, the inner spring is arranged in the outer spring tube, the helical direction of the outer spring is opposite to that of the inner spring, the two ends of the inner and outer springs are provided with flat support rings, and the ends of the springs are provided with garden arc chamfers.

[0025] A method for manufacturing a suspension spring of a high-speed locomotive bogie, comprising the following steps:

[0026] (1) The material of the inner and outer springs is peeled and polished spring steel, the steel grade (produced by Shanghai Baosteel) is 52CrMoV4GT spring steel, and its comprehensive performance index is better than 52CrMoV.

[0027] (2) Forging the end of the spring steel into flat shape (1), the initial forging temperature is 950-1050°C, and the final forgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com