Cold forming process of solid stabilizing rod

A stabilizer bar, cold forming technology, applied in manufacturing tools, other manufacturing equipment/tools, furnace types, etc., can solve the problem of solid stabilizer bar not adapting to market development requirements, achieve short heating time, reduce surface decarburization, investment low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

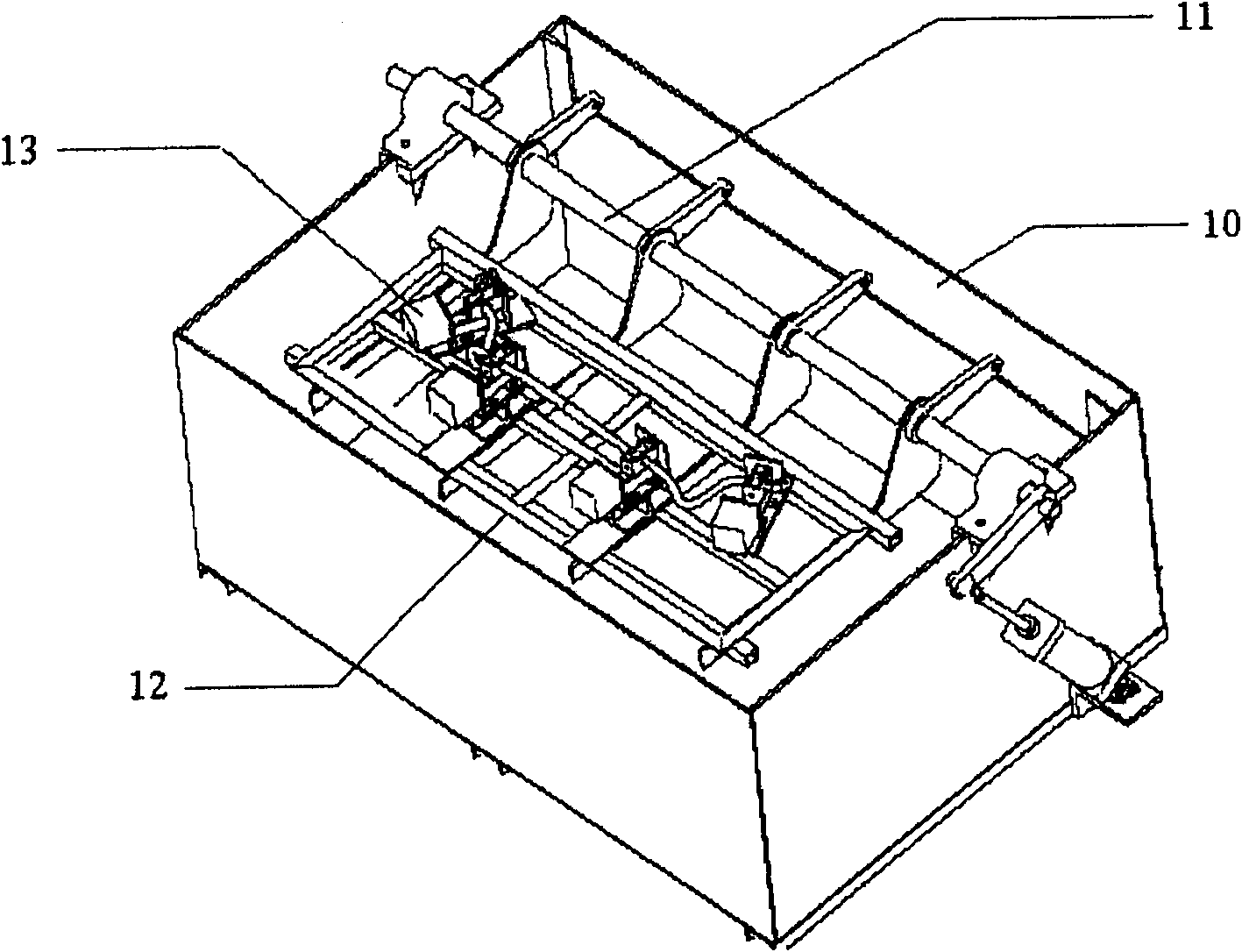

Image

Examples

Embodiment Construction

[0028] An embodiment of the solid stabilizing bar cold forming process of the present invention comprises the following steps: a) processing the end of the solid bar; b) bending the solid bar under normal temperature; c) forming the formed solid stabilizing bar heating; d) oil quenching of the solid stabilizer bar. Wherein the process of processing the end of the solid bar in step a) is the same as that in the thermoforming process. And in step b), the solid bar is bent into shape using a universal pipe bender.

[0029] In the heating step of step c), since the stabilizing rod has been formed before heating, and its shape is very complicated, it is not possible to adopt the method of heating with an intermediate frequency heating furnace in the thermoforming process. Therefore, in this embodiment, the electric heating method is adopted, that is, the two ends of the stabilizer bar are respectively placed on the two electrodes, and the two ends of the stabilizer bar are clamped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com