Heating unit for bottom surface and conical surface of engine valve cap part and application method

An engine valve and heating device technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of inability to immediately heat and heat preservation to relieve stress, unstable effect, and influence on forging and pressing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

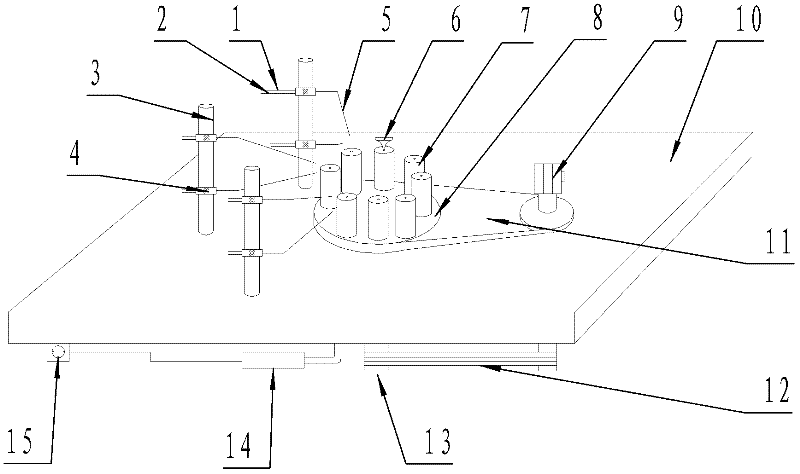

[0047] Embodiment 1, a heating device for the bottom surface and conical surface of an engine valve disc, is characterized in that it is mainly composed of a heater installed on the stand 10 and a valve fixing and rotating device,

[0048] Described heater is the oxyacetylene burner 5 that is fixed on the burner support,

[0049] The valve fixing and rotating device is composed of a sleeve 7 which is installed on the turntable 8 and can rotate with the turntable itself and rotates with the turntable, the sleeve self-rotation drive device and the turntable rotation drive device, and the valve 6 is inverted in the sleeve.

Embodiment 2

[0050] Embodiment 2, a heating device for the bottom surface and conical surface of the engine valve disc, is characterized in that it is mainly composed of a heater installed on the stand 10 and a valve fixing and rotating device,

[0051] Described heater is the oxyacetylene burner 5 that is fixed on the burner support,

[0052] The valve fixing and rotating device is composed of a sleeve 7 which is installed on the turntable 8 and can rotate with the turntable itself and rotates with the turntable, the sleeve self-rotation drive device and the turntable rotation drive device, and the valve 6 is inverted in the sleeve.

[0053] The heater includes three burner supports 9 standing on the stand, and two sets of oxyacetylene burners arranged up and down are fixed by burner fixing sleeves 4 on each support. Oxygen port 1 and acetylene gas port 2 are installed on the burner

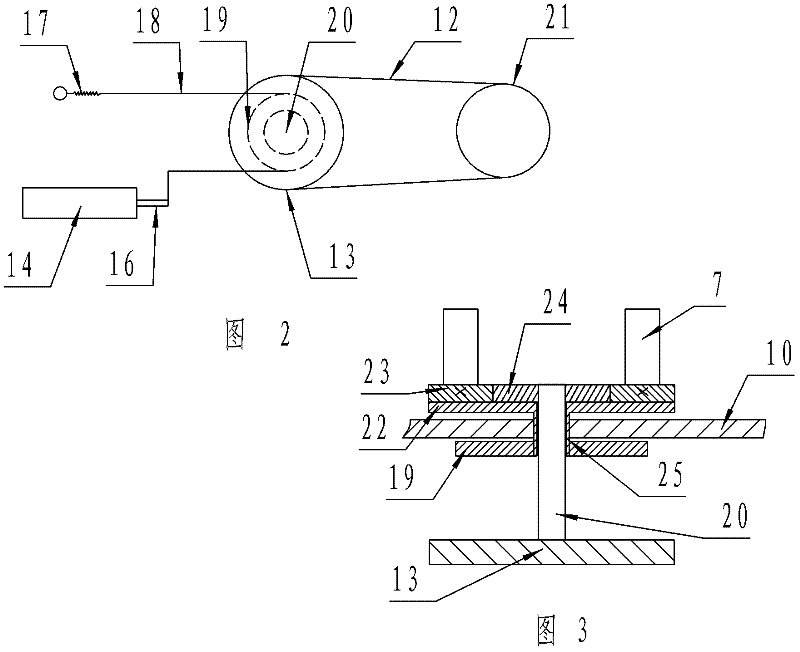

[0054]The sleeve self-rotating driving device includes a sleeve gear 23 fixed on the bottom of the sleev...

Embodiment 3

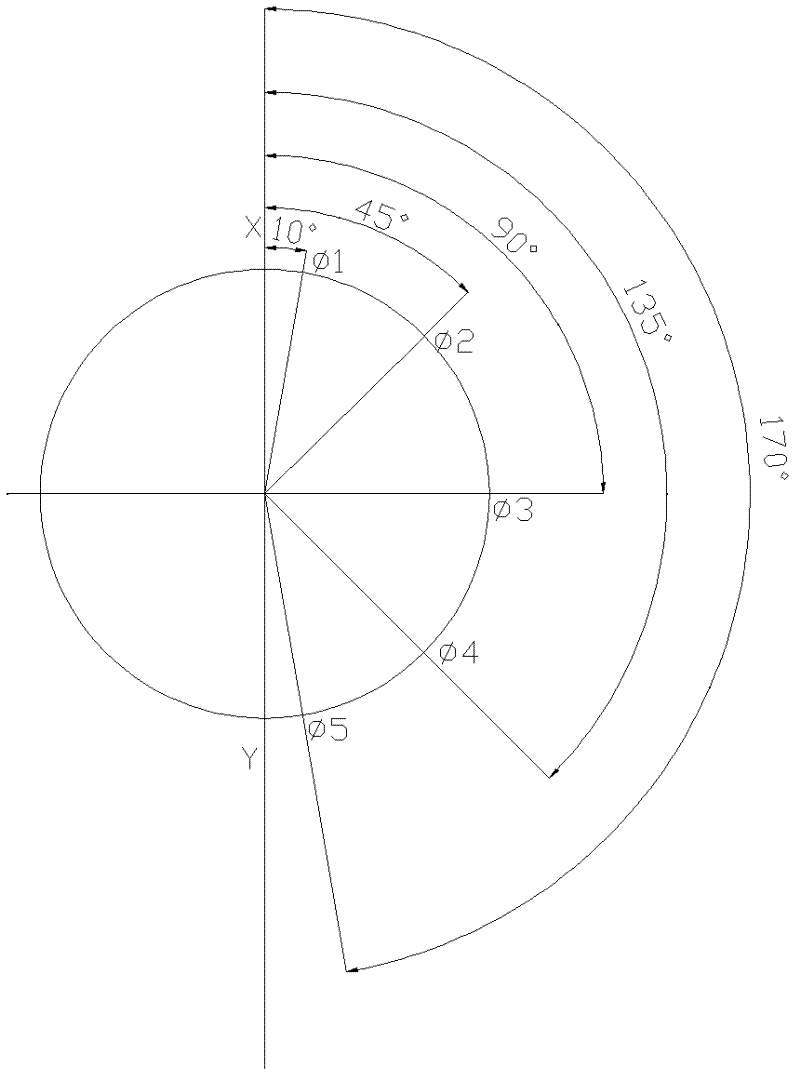

[0056] Embodiment 3, using the method of the present invention to eliminate the tensile stress of the valve disc cone surface and form positive pressure, mainly includes the following steps,

[0057] (1) Make the oxyacetylene flame burn stably, and the power supply of the device work stably;

[0058] (2) Insert the engine valve into the valve sleeve, the sleeve rotates continuously driven by the servo motor, and the valve rotates continuously driven by the sleeve;

[0059] (3) Make the oxyacetylene flame heat the bottom surface and the conical surface of the valve at the same time, the valve is heated rapidly, and the temperature is measured with an infrared thermometer. When the stress relief temperature reaches 900-1000°C, turn the turntable to move the valve out of the heating zone;

[0060] (4) The turntable rotates regularly under the action of the cylinder controlled by the time relay,

[0061] (5) When the valve is heated to the stress-relief temperature, the conical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com