Sander

A grinding machine and main body technology, which is applied in the direction of grinding frame, grinding machine, grinding machine parts, etc., can solve the problems of no dust cover, dust entry, restricted shape, etc., and achieve cost increase and high dust resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

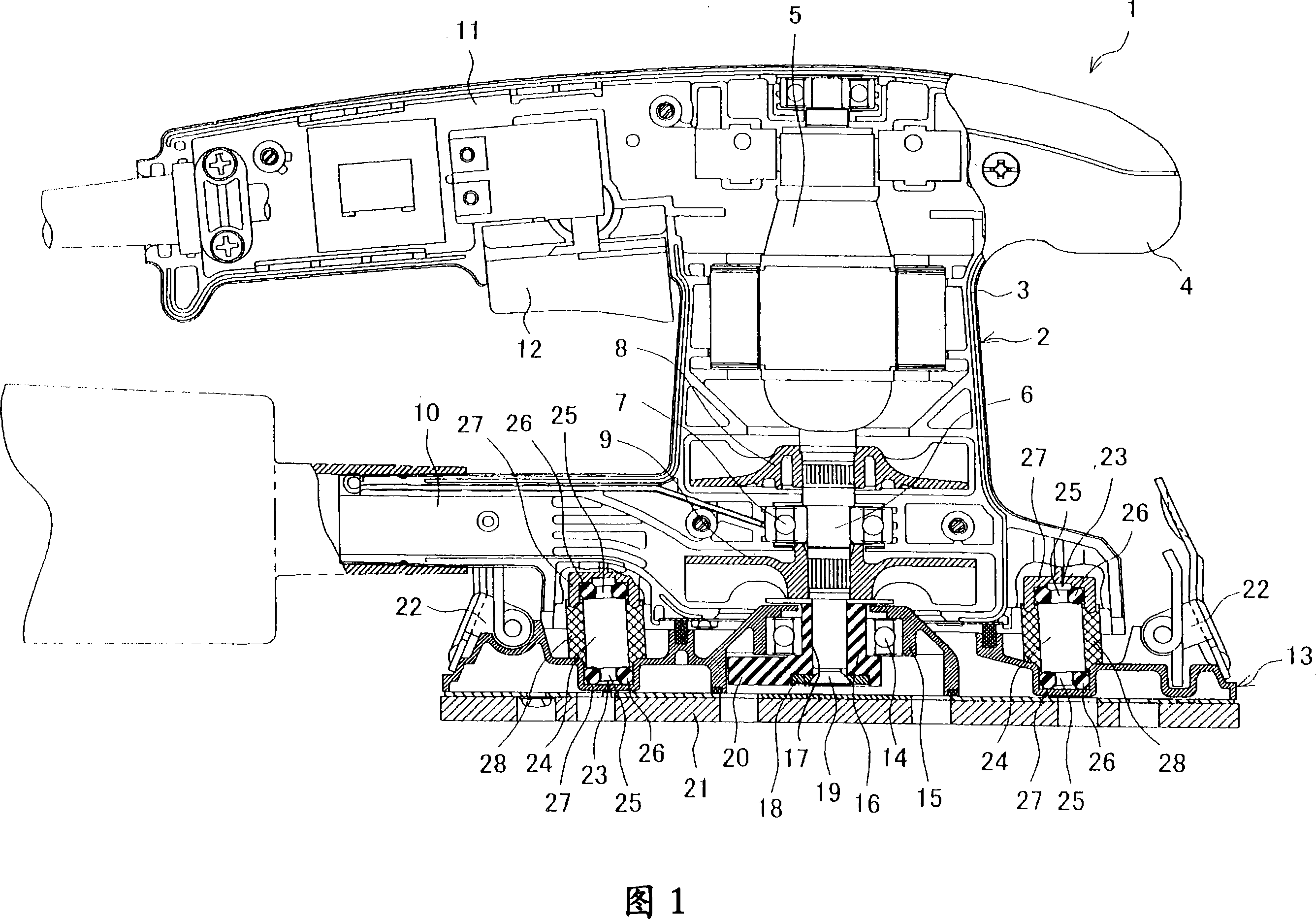

[0013] FIG. 1 is a vertical cross-sectional view of a finishing grinder as an example of grinders. The finishing grinder 1 has a main body 2 and a base 13 located therebelow. The main body 2 is formed by longitudinal two-piece covers 3 and 4, and accommodates a motor 5 facing downward. An output shaft 6 rotatably supported by a ball bearing 7 projects downward of the main body 2. A fan 8 for cooling the motor 5 is fixed to the output shaft 6 at a position above the ball bearing 7 so that the fan plane is perpendicular to the output shaft 6 . At the lower position of the ball bearing 7, the dust collection fan 9 is fixed on the output shaft 6 in a state where the fan plane is perpendicular to the output shaft 6. The dust collection fan 9 sucks dust from the bottom of the main body 2 and sends it to the main body 2 side dust collection nozzles 10. Reference numeral 11 denotes a handle extending from the upper part of the main body 2, and reference numeral 12 denotes a trigger. ...

Embodiment approach 2

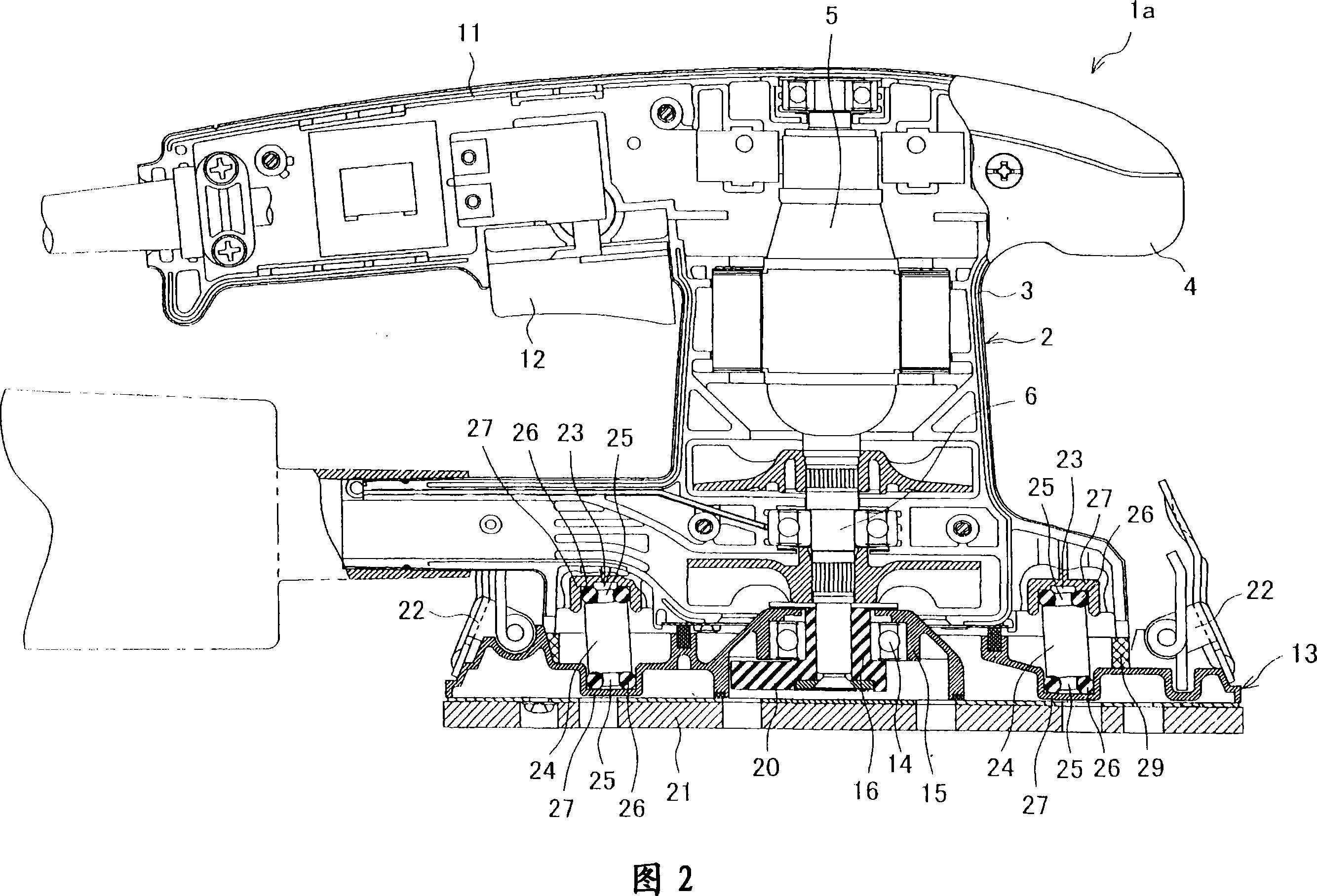

[0024] Next, other embodiments of the present invention will be described. Components having the same configuration as those in Embodiment 1 are denoted by the same reference numerals, and repeated explanations are omitted.

[0025] In the finishing sander 1a shown in FIG. 2 , the sponge sleeve 29 is not mounted on each leg 23 but stuck between the main body 2 and the base 13 and surrounds the entire area where the legs 23 , 23 are provided. That is, the sponge sleeve 29 is formed as a cylindrical body along the outer shape of the lower part of the main body 2, and is slightly longer than the vertical distance between the main body 2 and the base 13 in the axial direction, and its upper end is in pressure contact with the lower part of the main body 2. The upper and lower ends of the surface are in pressure contact with the upper surface of the base 13 at positions inside the clamping member 22 and are in close contact, thereby sealing the entire area where the legs 23 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com