Blowing and sucking machine

A technology of blower and main machine, applied in vacuum cleaners, vacuum cleaner equipment, applications, etc., can solve the problems of inconvenient operation and bulky blower, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

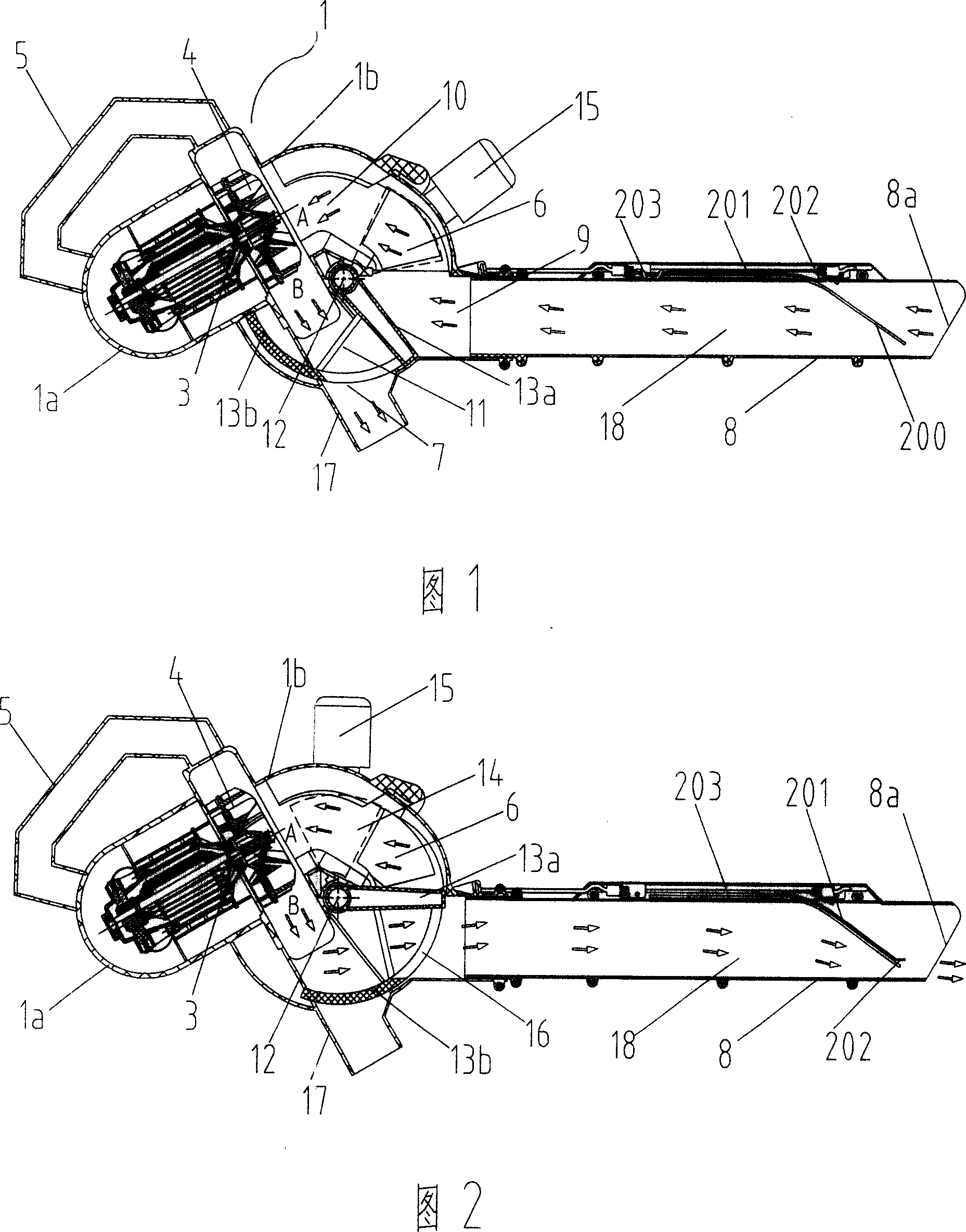

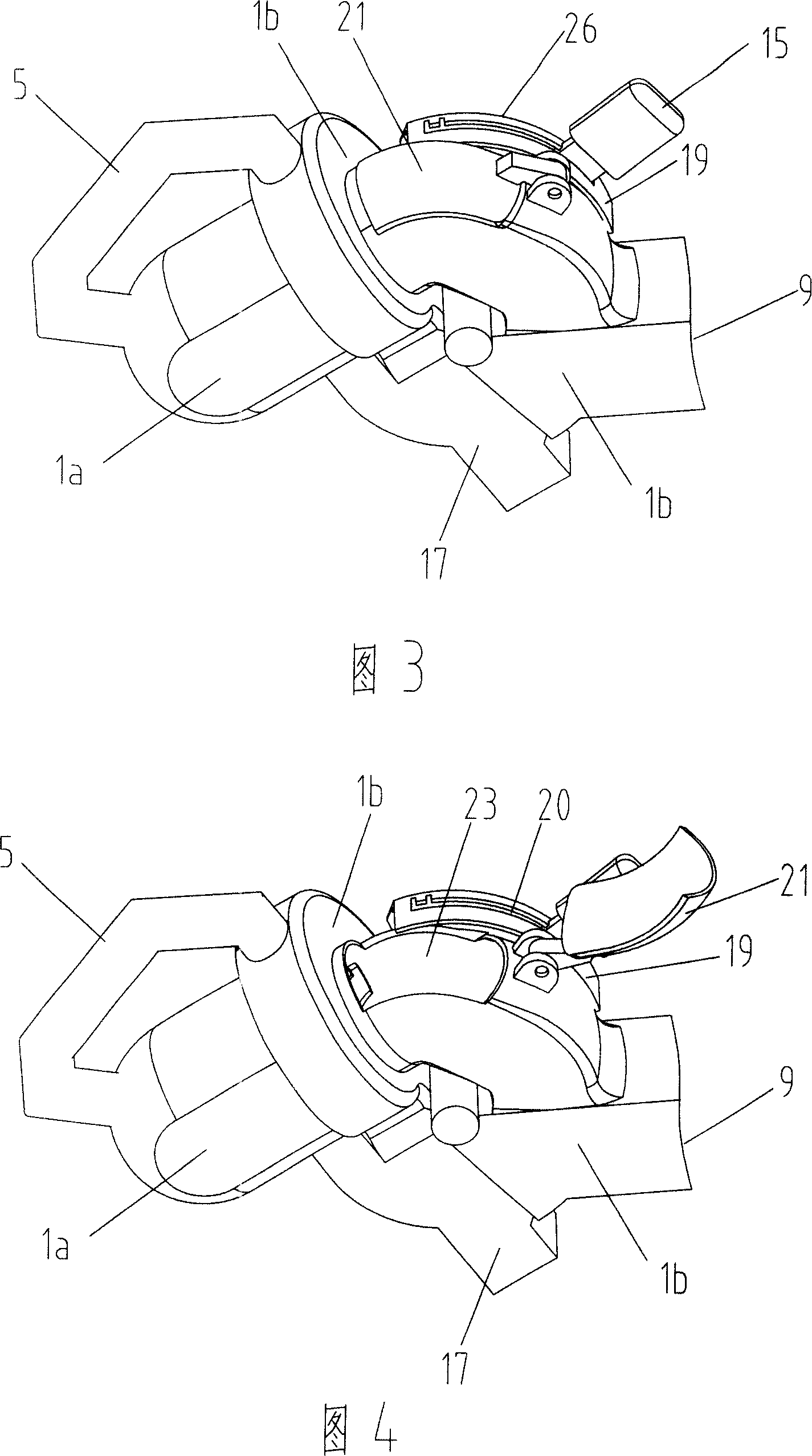

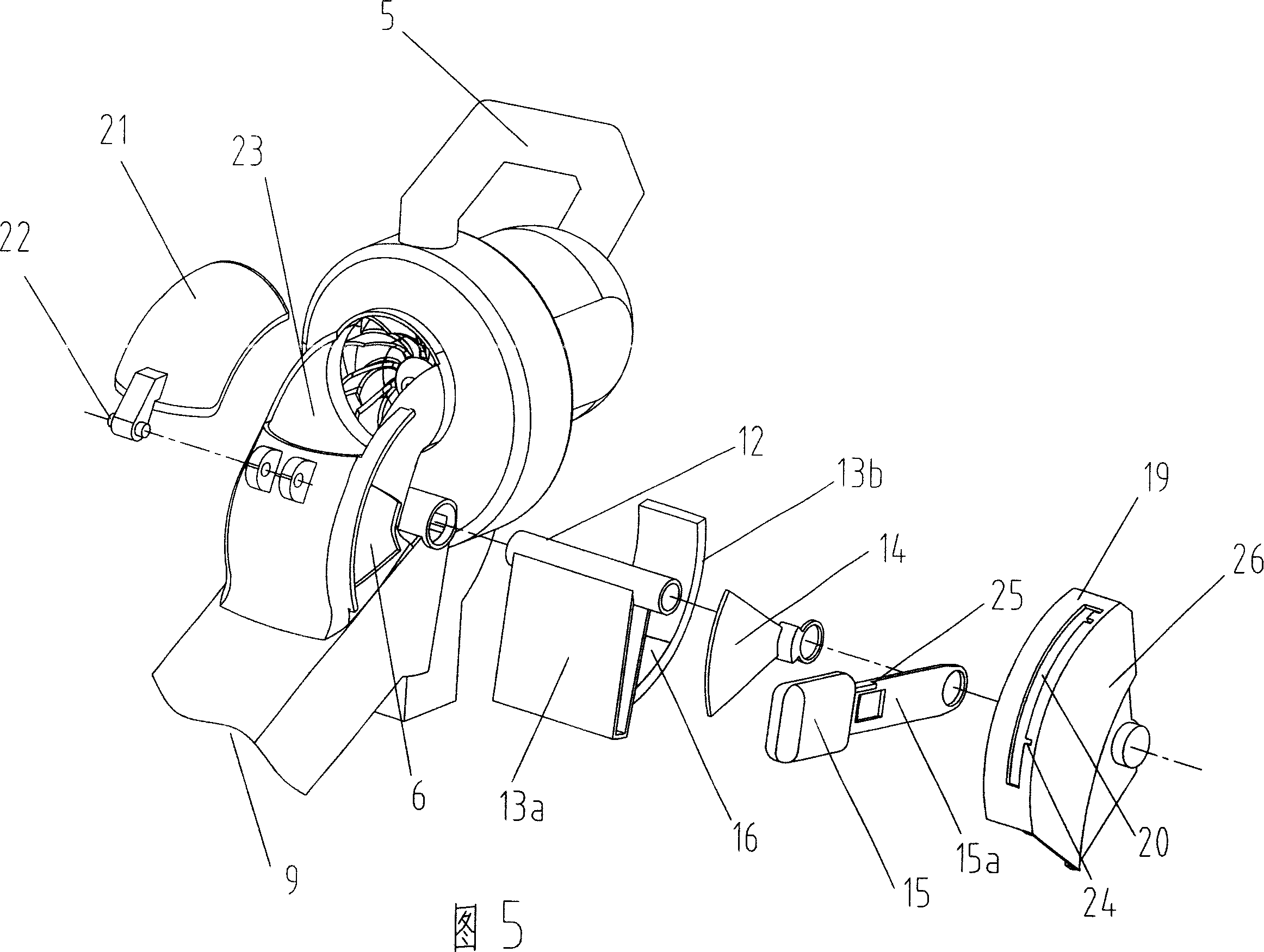

Method used

Image

Examples

Embodiment approach

[0061] Referring to Fig. 6, it is a second embodiment of the present invention, which has a similar structure to the above-mentioned first example, and the main casing 27 includes a casing 27a accommodating the motor 2' and a casing accommodating the fan 4' body 27b, the upper part of the housing 27b is provided with an air inlet 30, and the lower part of the housing 27b is correspondingly provided with a dust outlet 31, and a dust outlet pipe is detachably connected to the housing corresponding to the dust outlet 31 32. The dust outlet pipe 32 can be provided with a collection bag for dust collection, and the conversion mechanism 33 is provided in the cavity 10' formed by the casing 27b, and is used for switching between two different working positions of dust blowing and dust suction The housing 27b is also provided with a single-cavity port 9, and one end of the suction pipe 8' is releasably docked with the single-cavity port 9', and the other end of the suction pipe 8' is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com