Axial turbine

An axial-flow turbine and stage technology, which is applied in mechanical equipment, non-variable-capacity pumps, engine components, etc., can solve the problems of disrupting the mainstream of steam and reducing the output of the stage, so as to prevent the decline of the stage output and improve the turbine stage. The effect of class efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

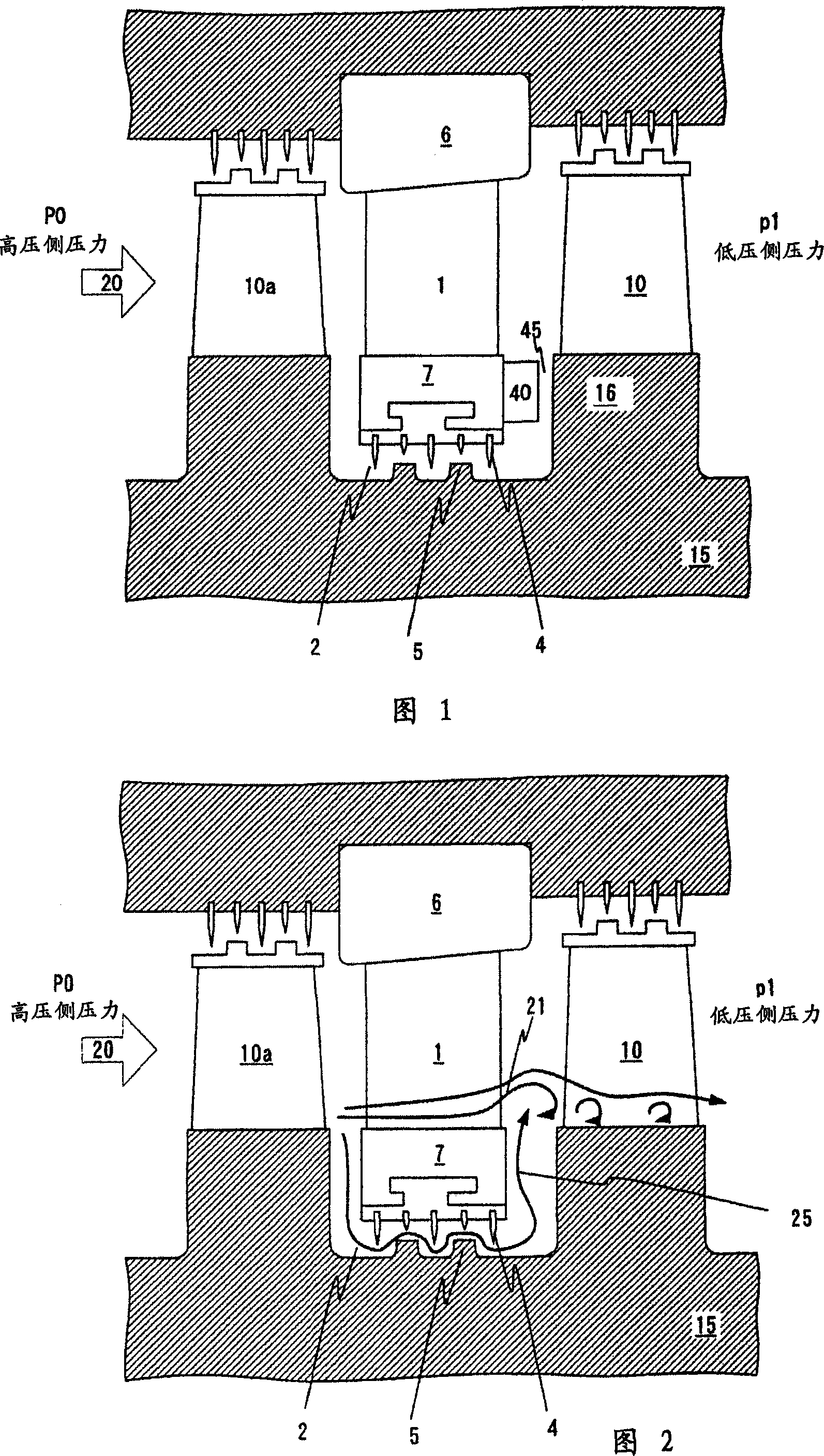

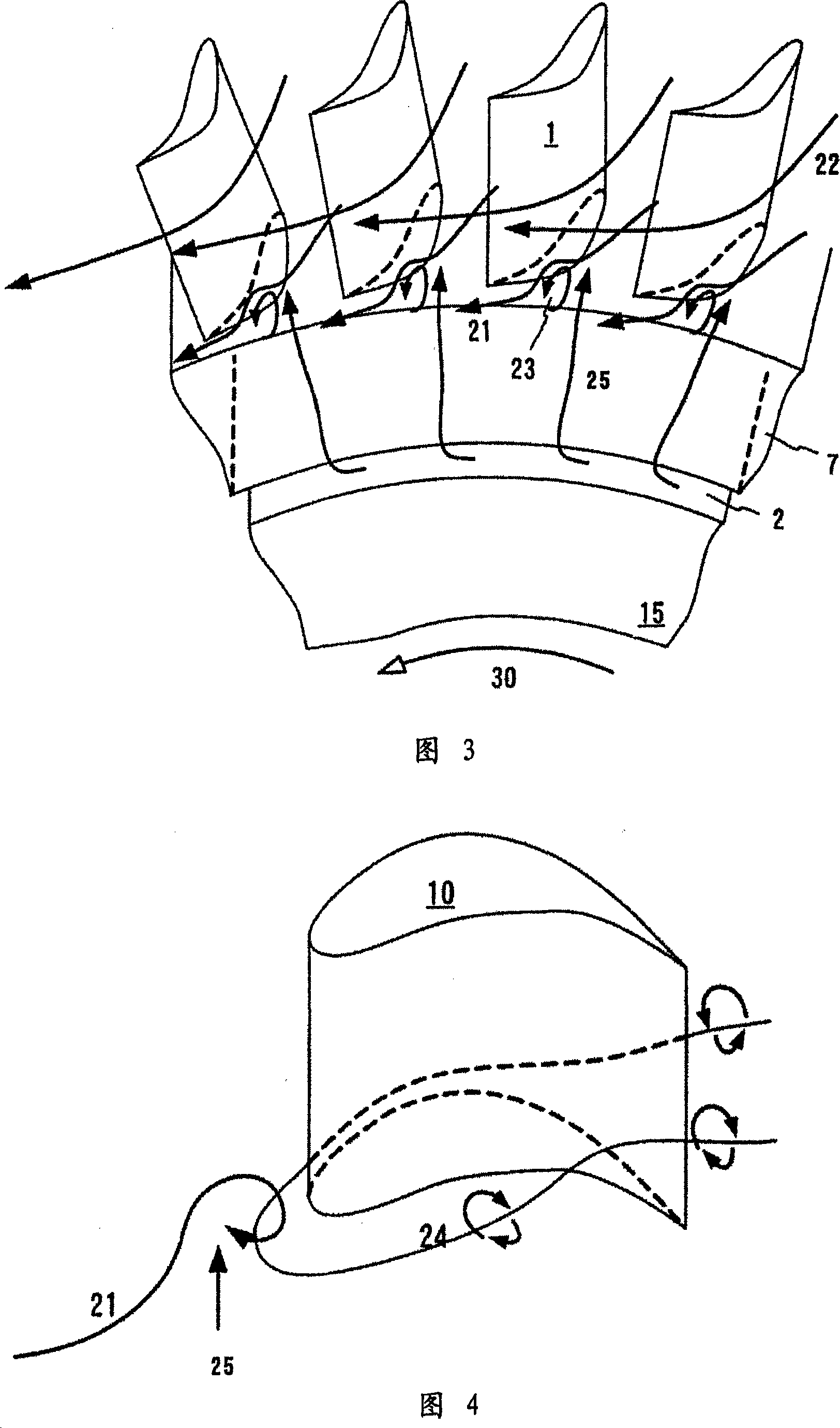

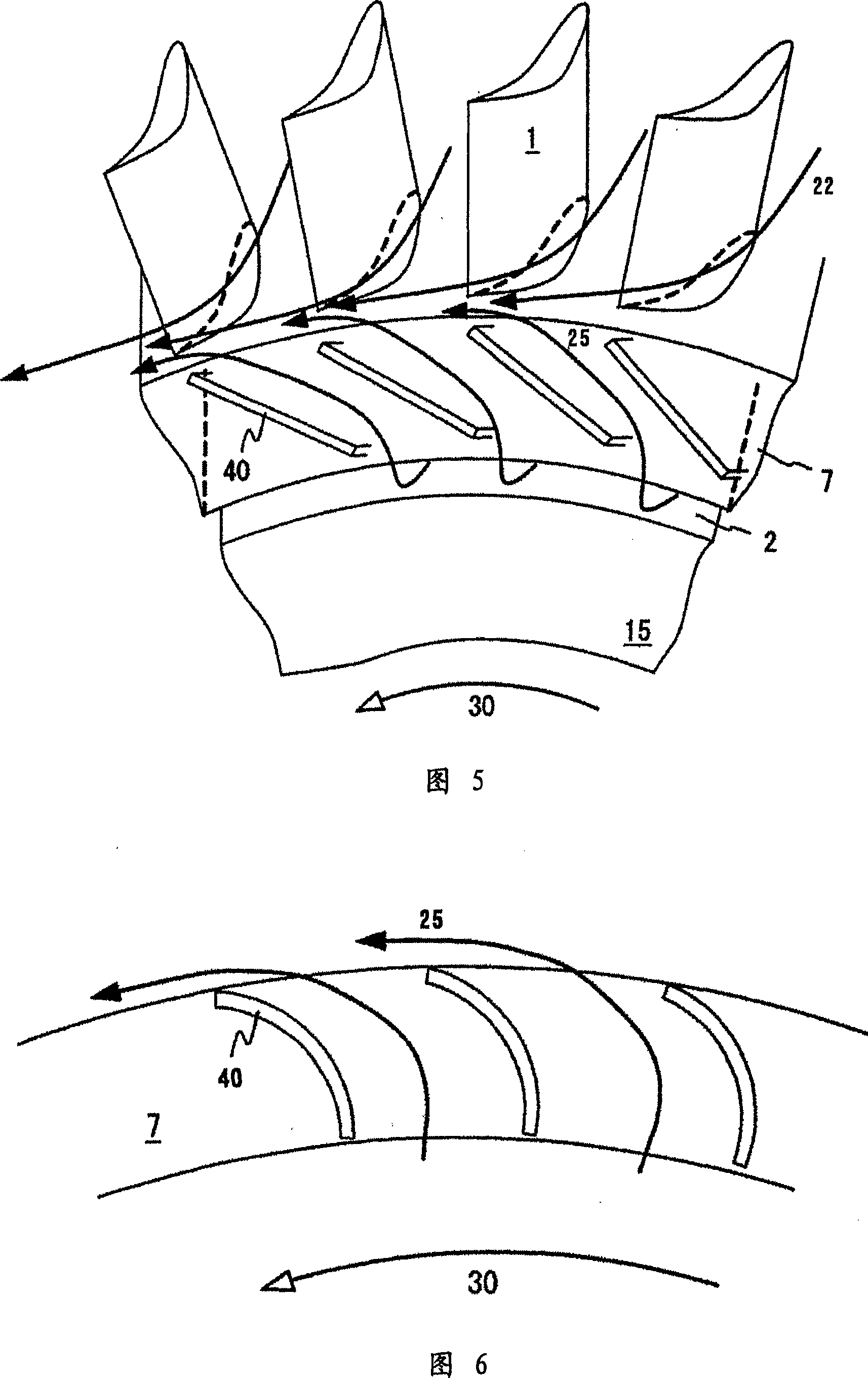

[0020] One embodiment of the axial turbine stage of the present invention will be described with reference to the drawings.

[0021] Figure 1 shows a cross-sectional view of a turbine stage of the invention. As shown in Fig. 1, the turbine stage is arranged between the high-pressure part P0 and the low-pressure part P1, and consists of the stator blades 1 fixed on the outer peripheral side diaphragm 6 and the inner peripheral side diaphragm 7 and the rotating rotor 15. The moving blade 10 constitutes. In the case of a turbine having a multi-stage turbine stage, the rotor blades 10a of other stages are provided on the upstream side of the stator blades 1 .

[0022] The flow (steam main flow) 20 is caused by the pressure difference P0-P1, and the flow 20 is accelerated by the stator blade 1 and is deflected in the circumferential direction. The flow having a velocity component in the circumferential direction through the stator blade 1 imparts kinetic energy to the rotor blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com