Method for manufacturing mirror scanning array antenna

An array antenna and manufacturing method technology, applied to antennas, antenna arrays, electrical components, etc., can solve the problems of complex design of parabolic reflectors, large rotation space and servo power, and large RF insertion loss, and achieve flexible beam sidelobe characteristics. , Low sidelobe characteristics, low servo power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

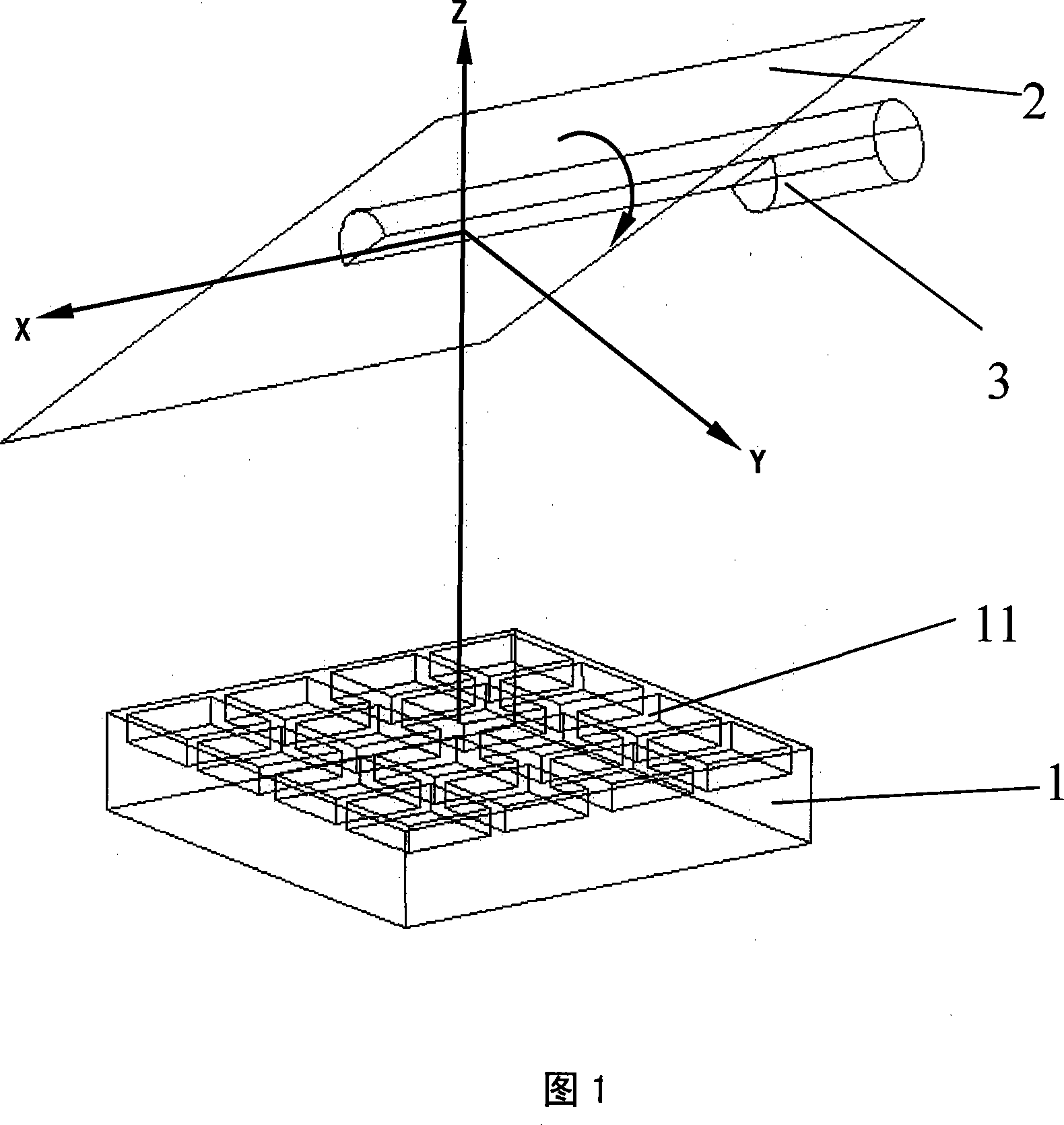

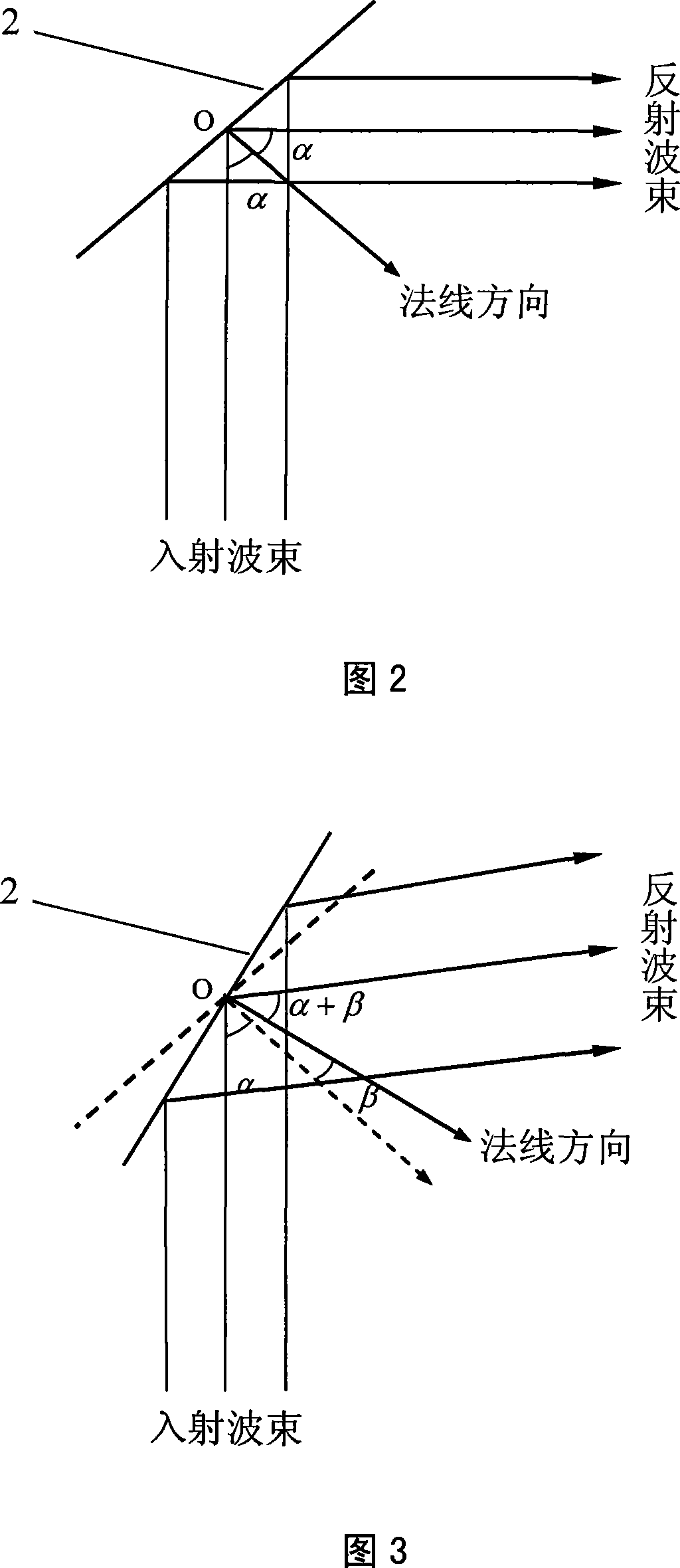

[0024] Referring to Fig. 1 to Fig. 3, the present invention adopts array antenna feeding, and realizes beam scanning technology by rotating the antenna reflecting surface, including steps:

[0025] ①The array antenna 1 is designed according to the working frequency, and the array antenna 1 is designed with M×N array units 11 according to the requirements of the antenna gain. M or N is a natural number greater than 1, and the array antenna 1 is installed on the On the antenna platform, the radiation beam is directed to the reflecting mirror 2 . The array structure of the array antenna 1 of the present invention is a rectangular array, or a circular array, or a tapered distribution array, or a rectangular array with unequal spacing, or a tapered distribution array with unequal spacing. The units of the array unit 11 of the present invention are configured as microstrip antennas, or antennas in the form of waveguide, or slot antennas, or horn antennas, or antennas in the form of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com