Blade for vertical shaft windmill and lift type vertical shaft windmill having the same

A vertical axis and blade technology, applied in the field of vertical axis windmill blades and lift type vertical axis windmills equipped with such blades, can solve the problems of the limit of friction surface durability, lack of specificity, and impracticality, etc., and achieve simple Structure, the effect of suppressing excessive rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

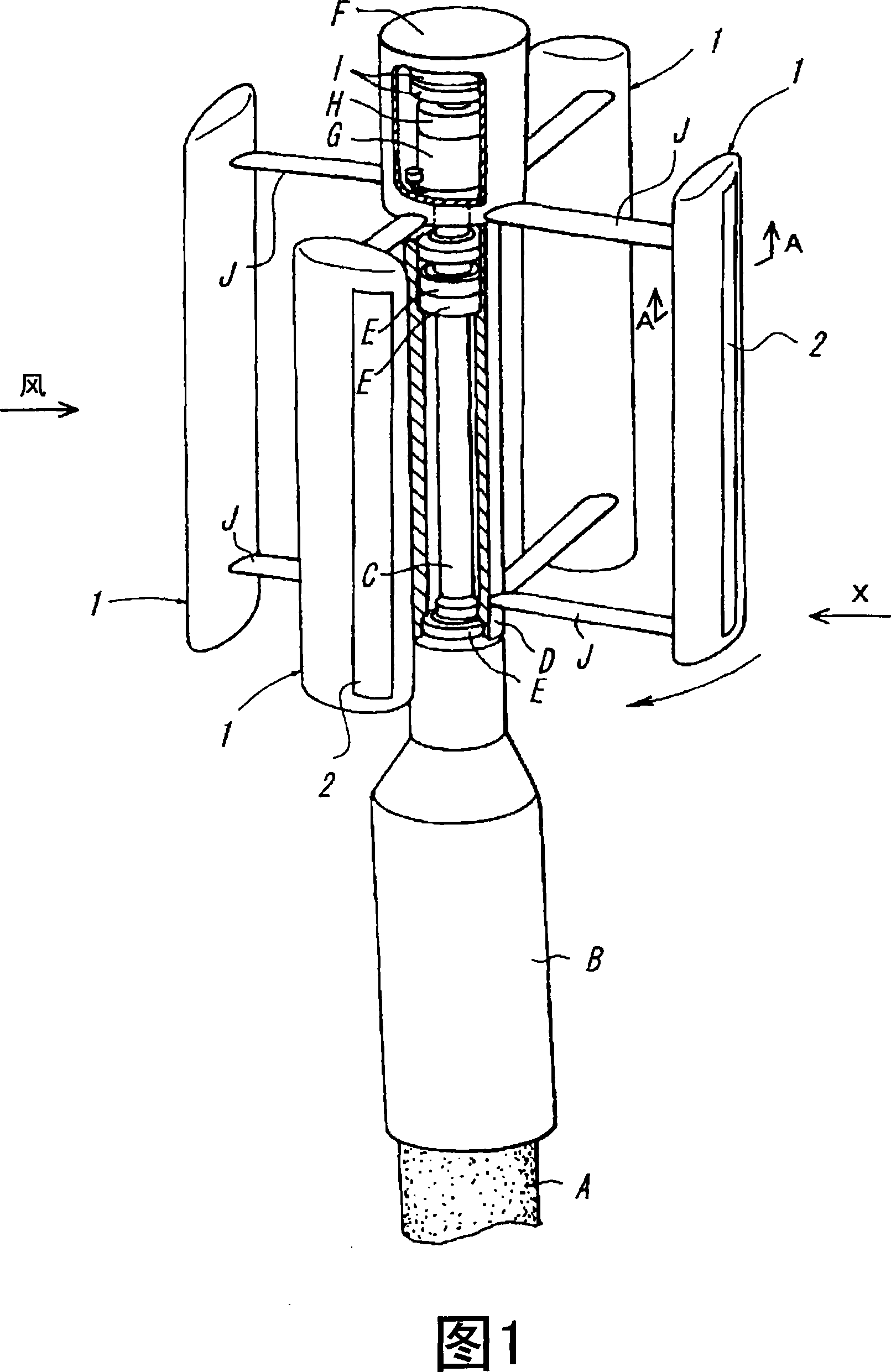

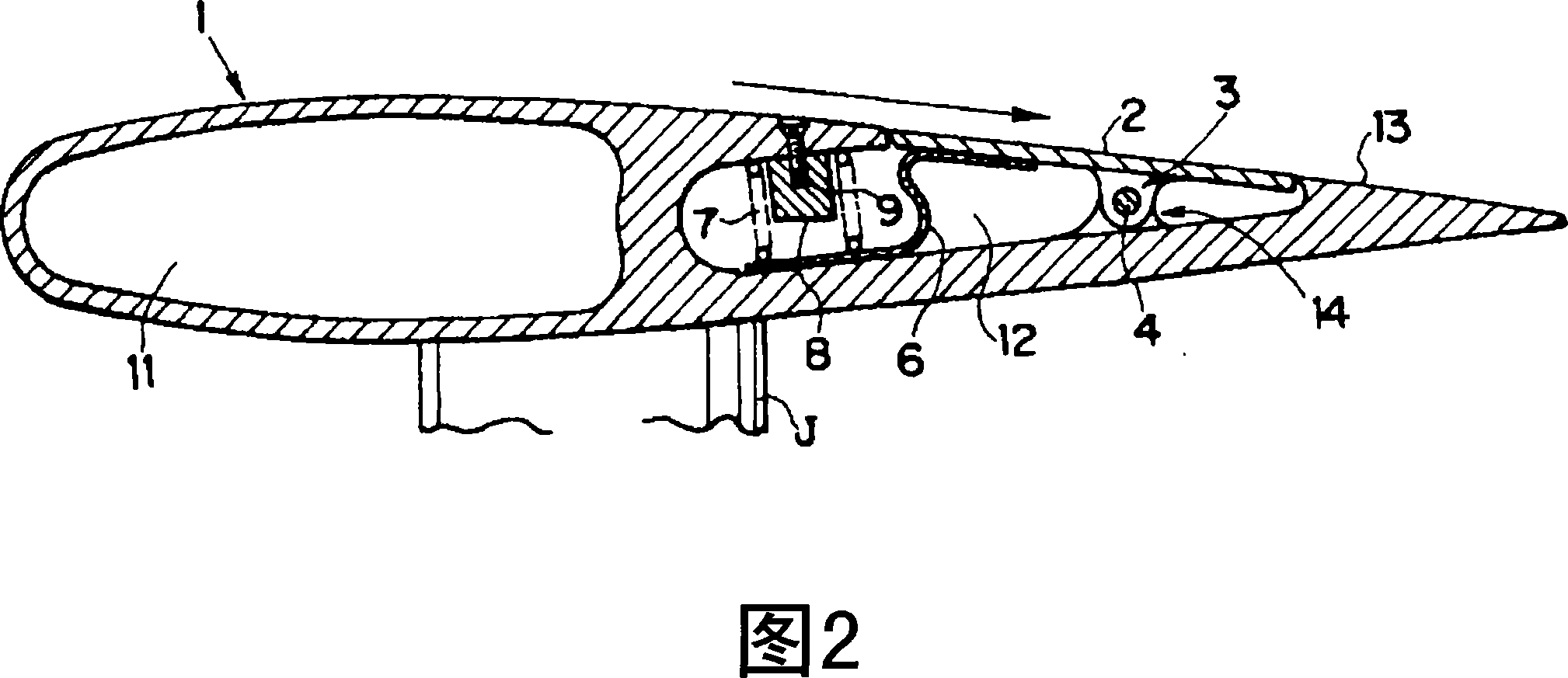

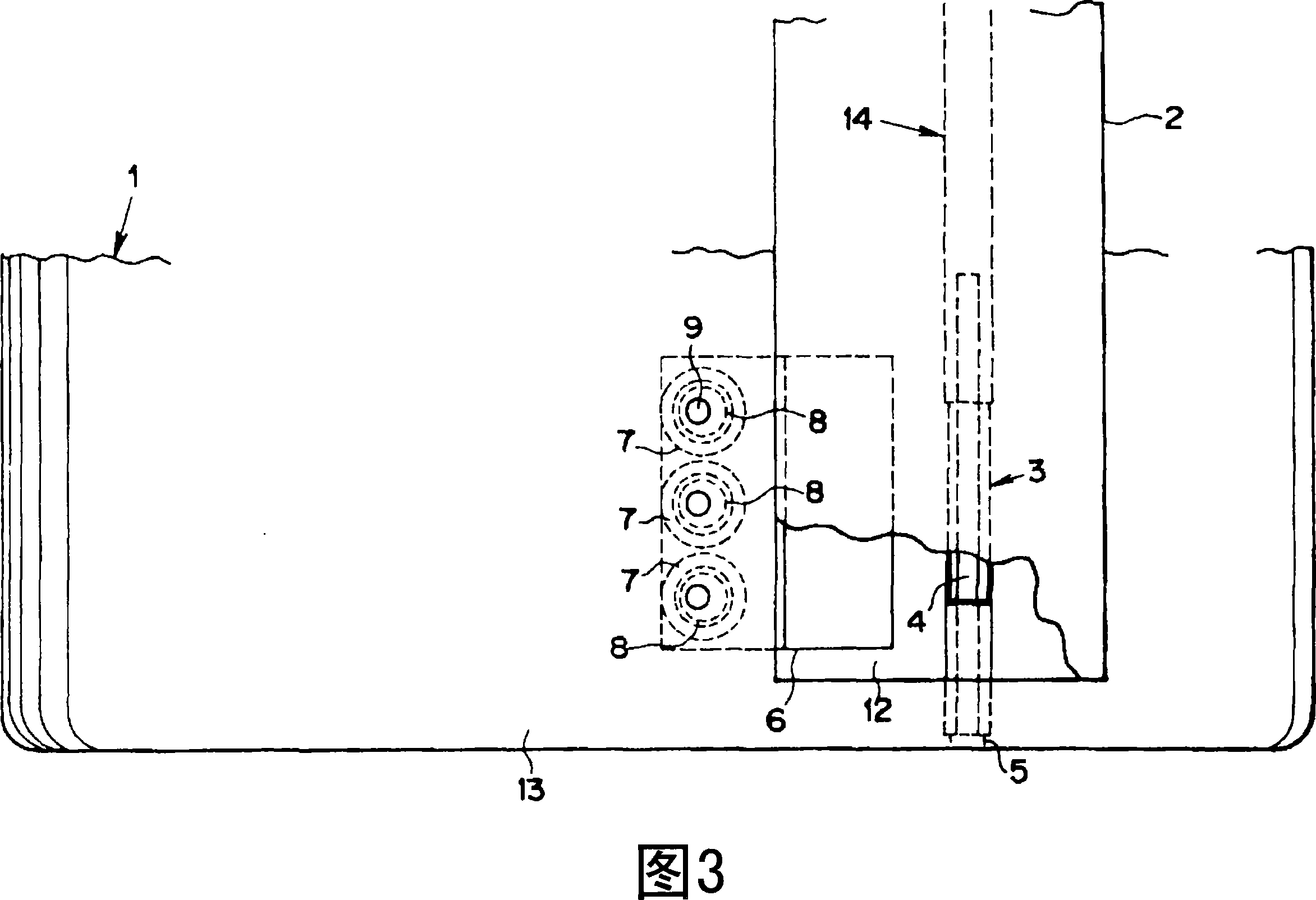

[0037] The best mode for implementing the blade for a vertical axis windmill of the present invention will be described with reference to the drawings. Fig. 1 is a partially cutaway perspective view of a straight airfoil type vertical axis wind turbine using blades for a vertical axis wind turbine according to the present invention. Fig. 2 is an A-A cross-sectional view of the best mode for carrying out the blade for a vertical axis windmill of the present invention.

[0038] As shown in Fig. 1, the linear airfoil type vertical axis windmill has a cylindrical mounting part B mounted on a column-shaped installation platform A such as a utility pole, and a cylindrical mounting part B fixed to the mounting part B and arranged vertically on the axis. A round bar-shaped fixed shaft C, a bearing E mounted on the outer circumference of the fixed shaft C, a cylindrical outer ring sleeve D mounted on the outer circumference of the bearing E and capable of rotating around the fixed shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com