In-situ composite light steel supporting architecture heat preservation steam-partition building constitution and construction method

A composite, light steel technology, applied in the direction of building structure, construction, covering/lining, etc., can solve problems such as difficult to completely apply in place, difficult to meet steam insulation requirements, large lap gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

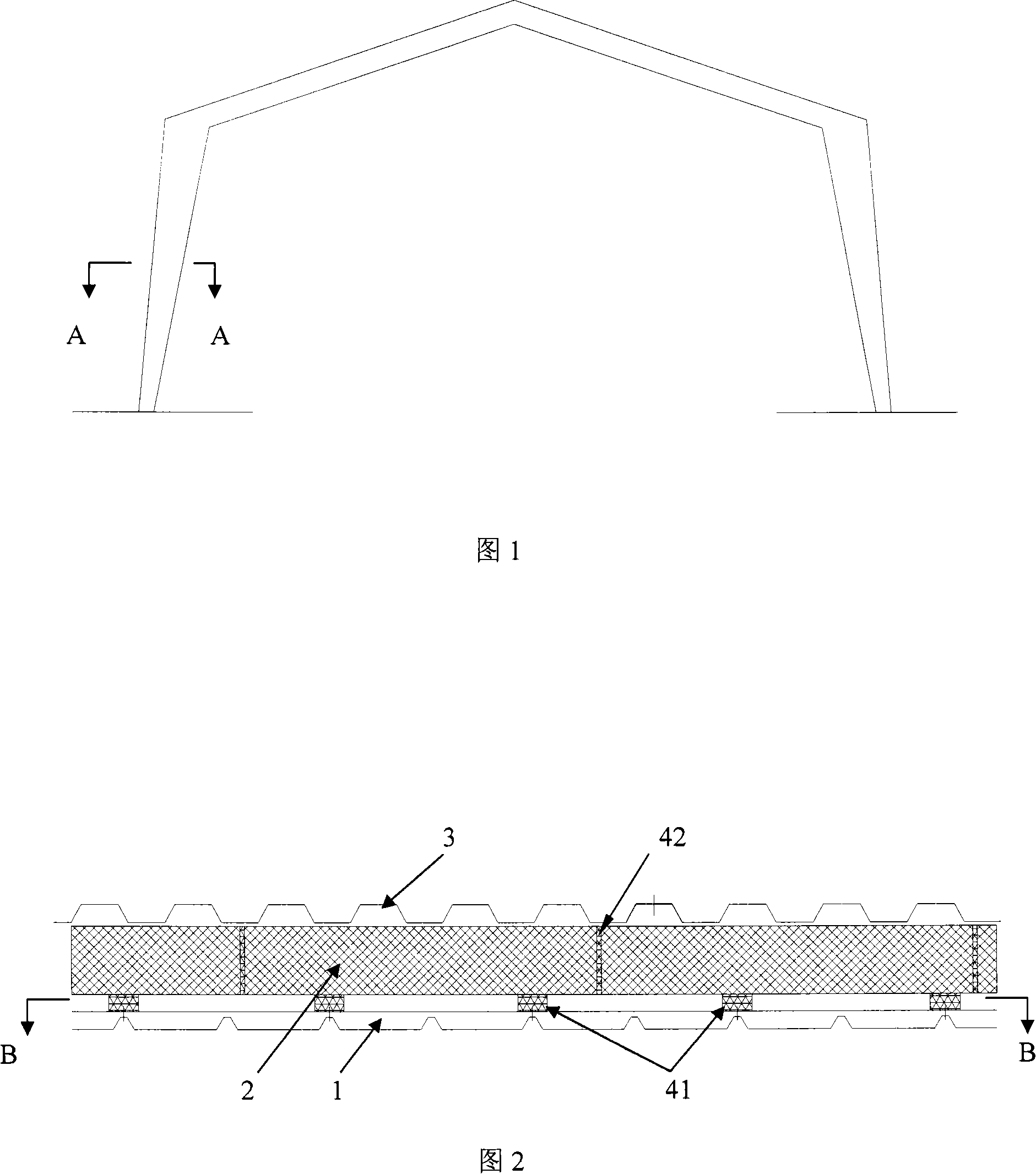

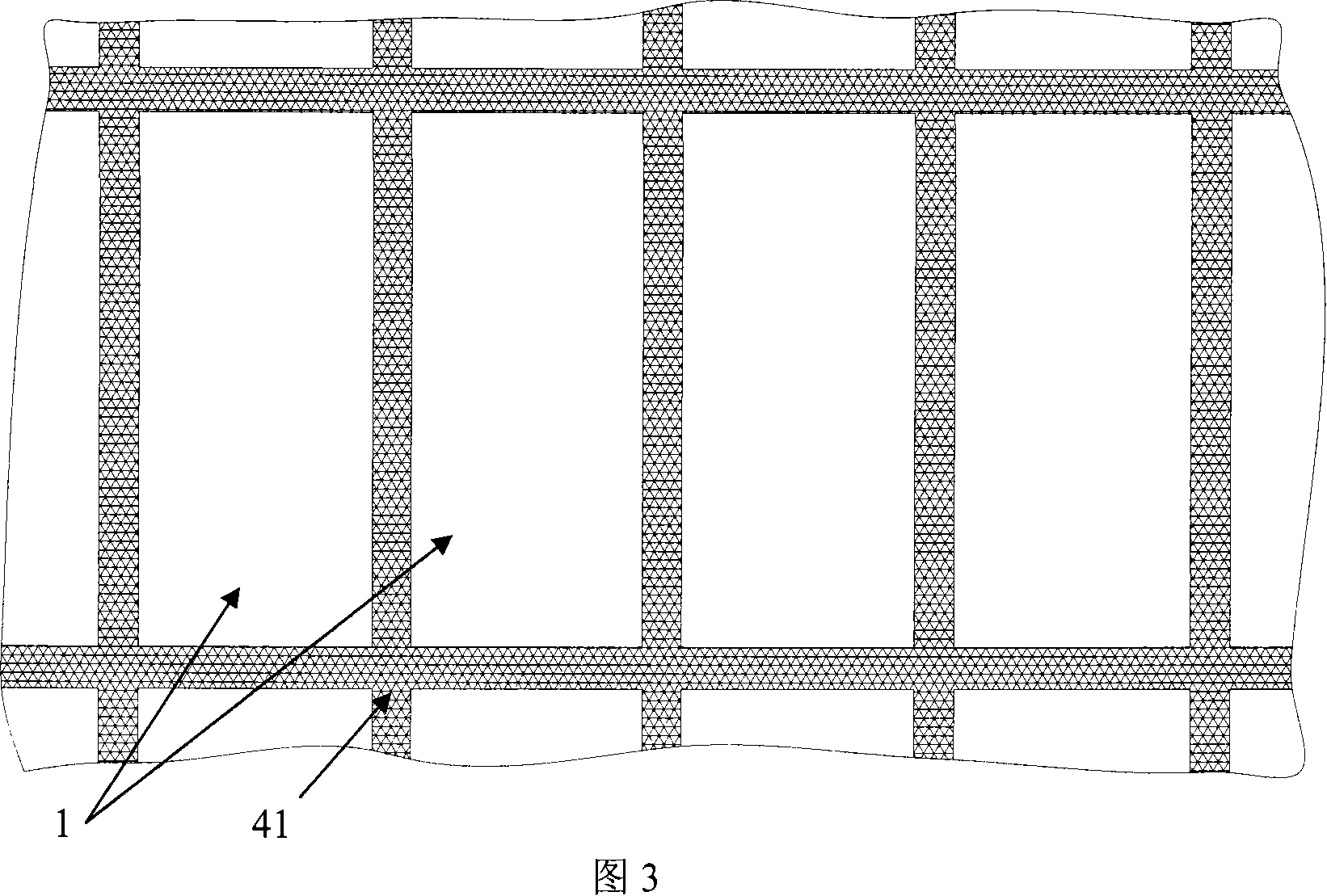

[0024] As shown in Figures 1 and 2, the on-site composite light steel maintenance system thermal insulation and steam insulation building structure of the present invention at least includes a plurality of overlapping lower (inner) floor plates 1, a plurality of insulating panels 2 and a plurality of overlapping The upper (outer) layer boards 3 are connected, wherein, there are joint gaps and connection gaps between any two adjacent lower (inner) layer boards 1, and between the lower (inner) layer boards and structural members. The foamed polyurethane layer 41 is sprayed, and the thermal insulation board 2 is arranged on the foamed polyurethane layer 41, and the joints between two adjacent thermal insulation boards 2, and between the thermal insulation board and the structural member are sealed by foaming polyurethane 42.

[0025] A foamed polyurethane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com