Automobile rear side window glass locking butt hinge

A technology for window glass and hinges, which is applied in door/window fittings, hinged panels, buildings, etc. It can solve the problems of relatively high strength requirements for hinge materials, decreased hinge strength, and glass falling, so as to prevent sliding deformation and improve Stability, the effect of increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

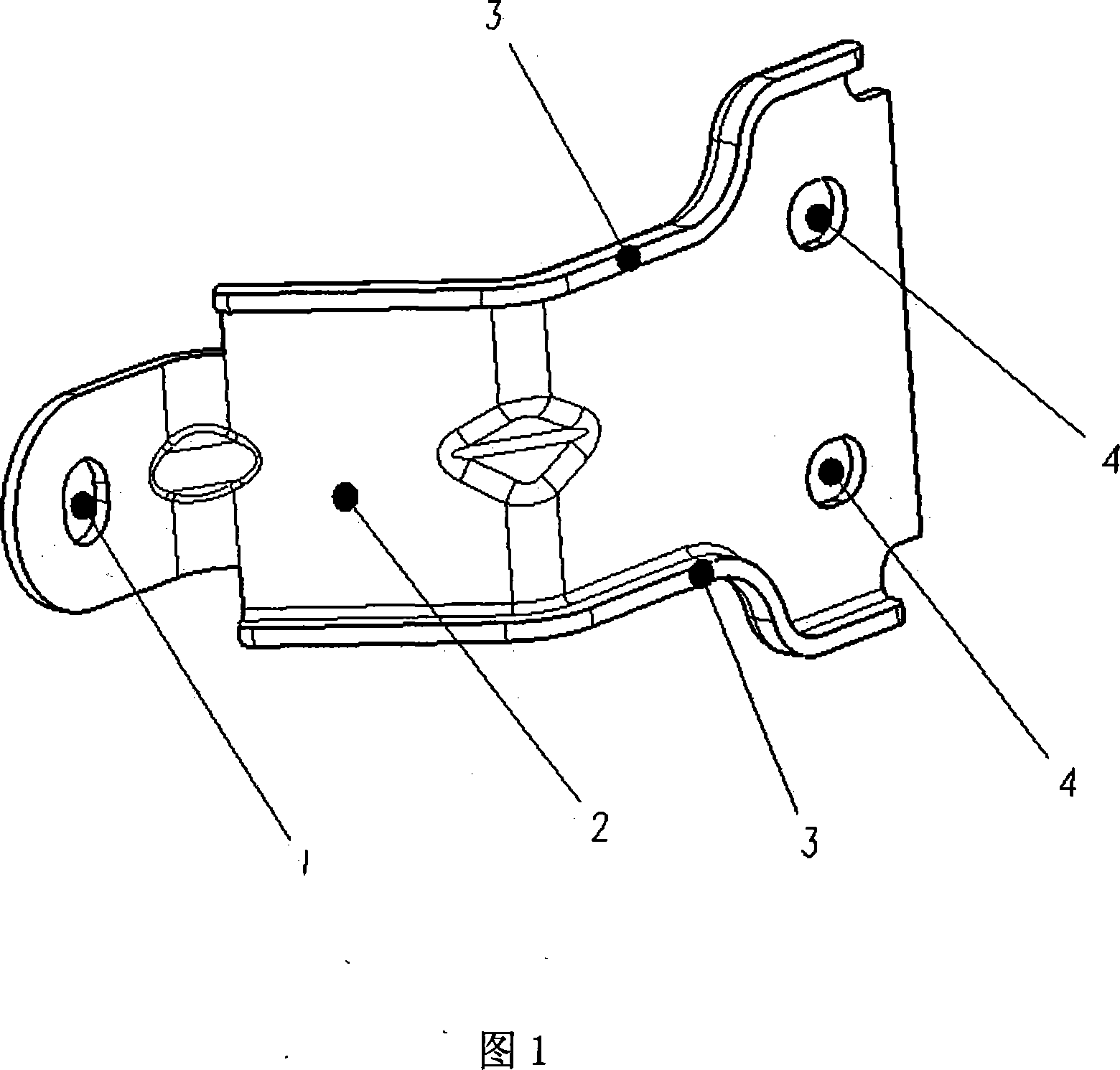

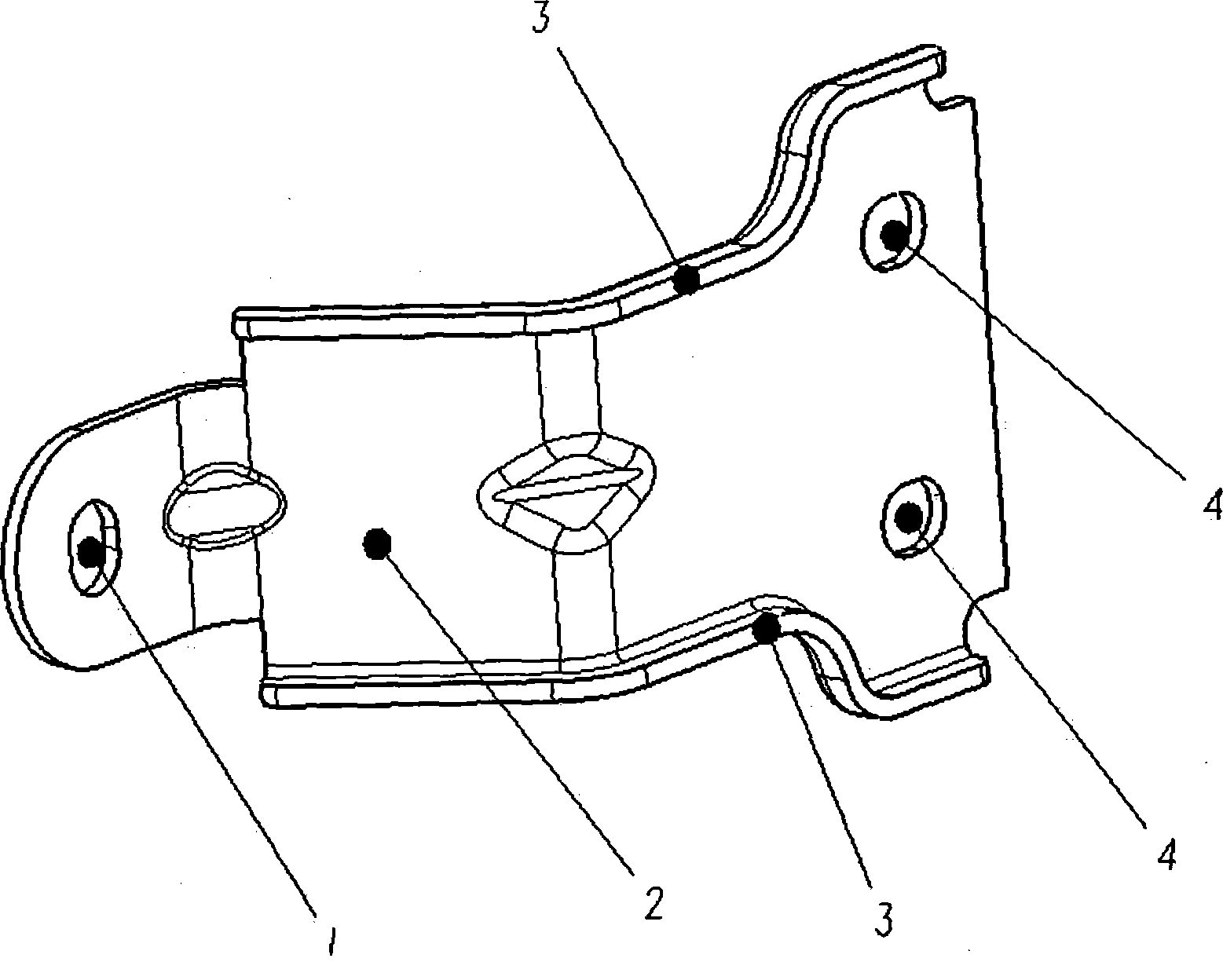

[0015] like figure 1 As shown, the rear side window glass locking hinge of the automobile is a single-piece type, and the hinge body 2 is provided with a glass connection installation hole 1 at the end connected with the side window glass, and the width of the end connected with the car body is increased, which is greater than that with the window glass. At one end of the connection, there are two car body connection installation holes arranged transversely with respect to the length direction of the hinge body, and flange structures 3 are arranged on the outer edges of both sides in the width direction of the hinge body 2 .

[0016] In assembly, it is consistent with the existing hinge installation method. First, the hinge body 2 is bolted to the glass through the glass connection installation hole 1, and then the glass and the locked hinge are locked on the vehicle body through the two vehicle body connection installation holes 4. Through such a design, the dropping of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com