Underground cut-off wall interlocking type drill hammer

A technology of underground anti-seepage wall and impact drill bit, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of difficult selection of anti-seepage treatment and small engineering tasks, and achieves a simple structure, great technical advantages and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

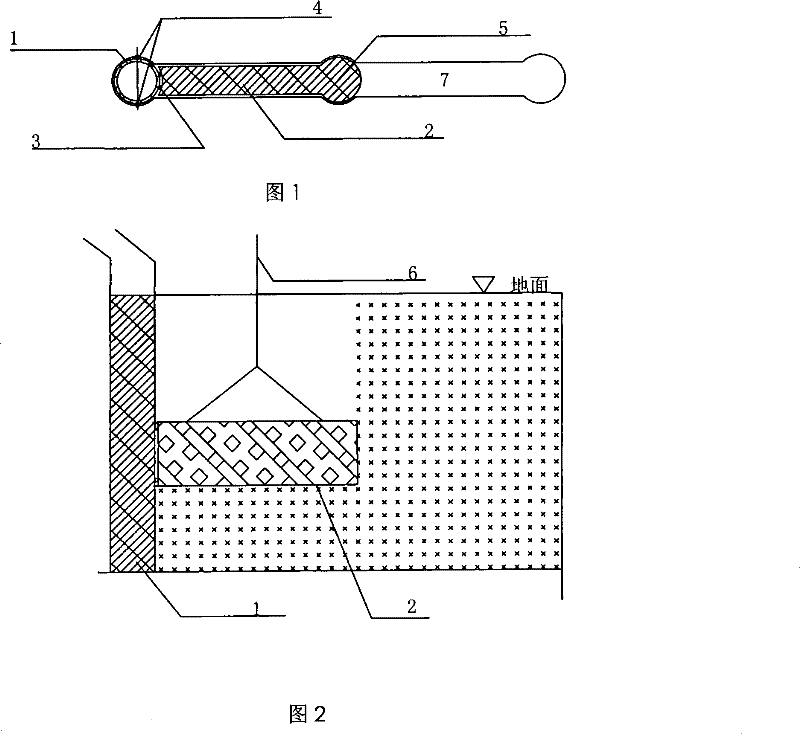

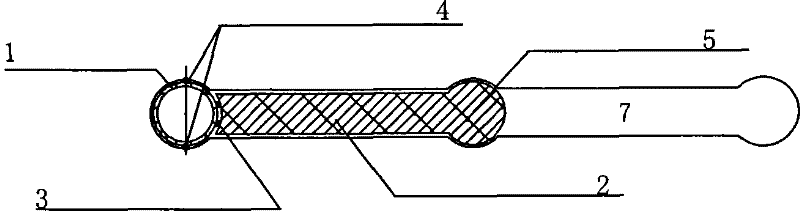

[0016] figure 1 , figure 2 Among them, the principle of the interlocking percussion drill bit for underground cut-off walls is that the plate percussion drill bit 2, under the action of the traction force 6, reciprocates impact on the formation along the guide rod 1, and the plate percussion drill bit 2 is supported by the sliding guide block 3 fixed on the guide rod 1. The direction constraint of , can only move in a straight line along the guide rod 1. Both sides of the guide rod 1 are provided with a water-filled expansion type side sealing device 4, which plays the role of isolating mud, and the hollow guide rod 1 is also a channel for slurry circulation. The cross-section expanding head 5 at the front end of the plate-type percussion drill 2 impacts the formation to form a hole consistent with the section of the guide rod 1, and the guide rod 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com