Gluing edge-folding machine blank beating-pressing engaged propelling mechanism

A technology of a propulsion mechanism and a folding machine, which is applied to shoe uppers, clothing, footwear, etc., can solve the problems of inability to translate and fold the uppers, unclear vision, and difficult manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

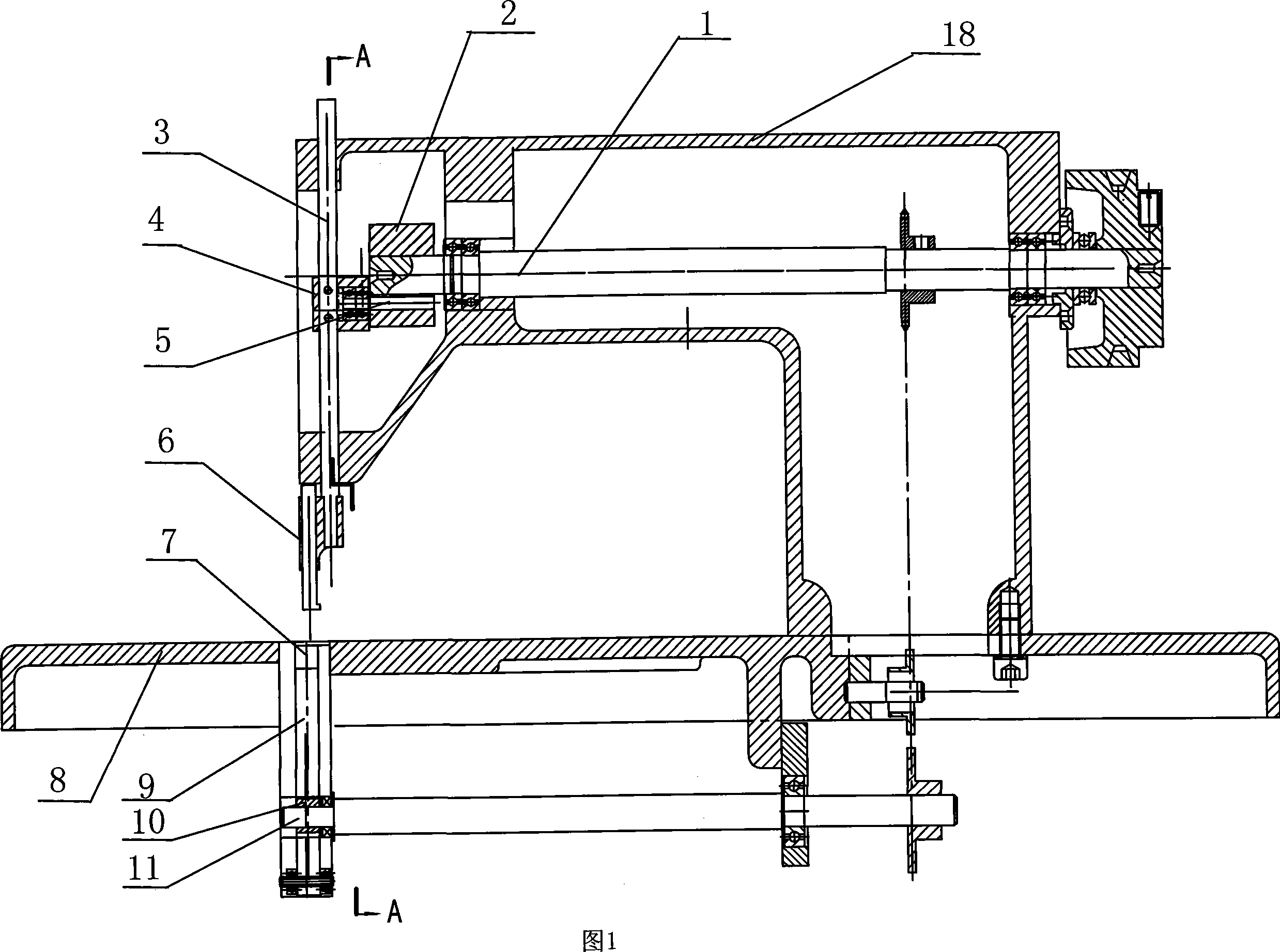

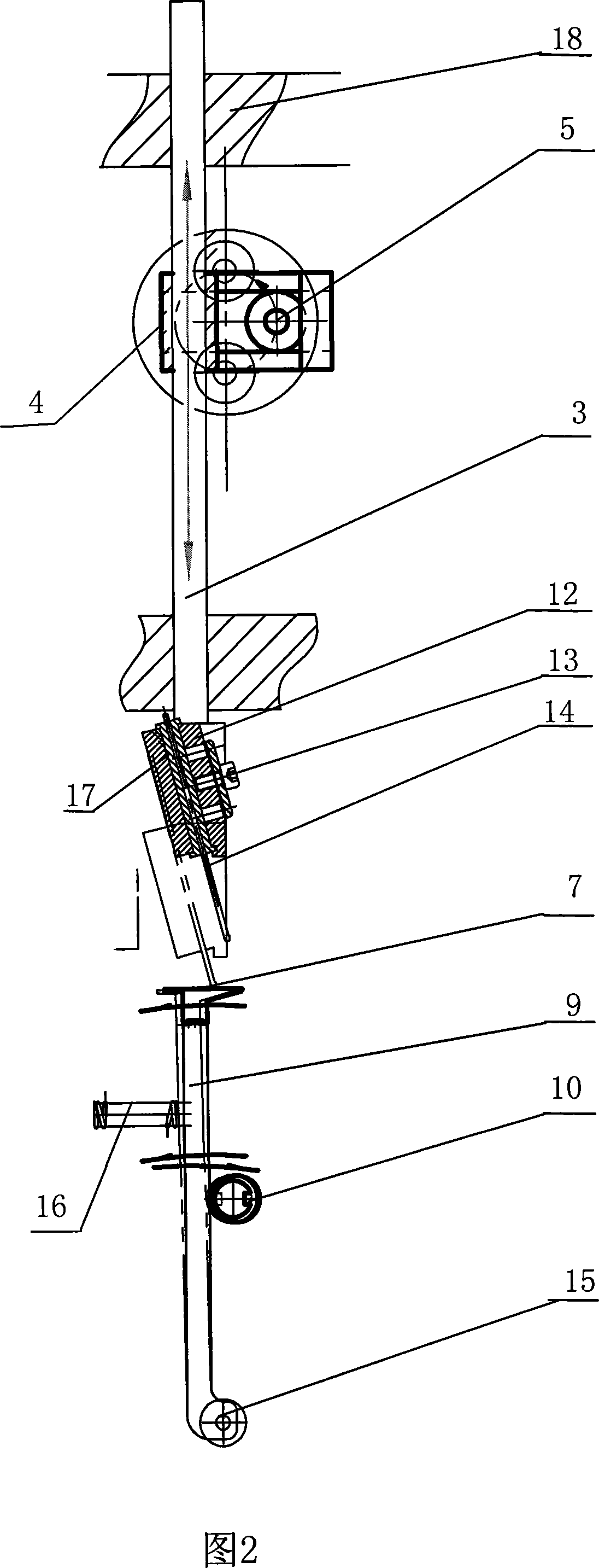

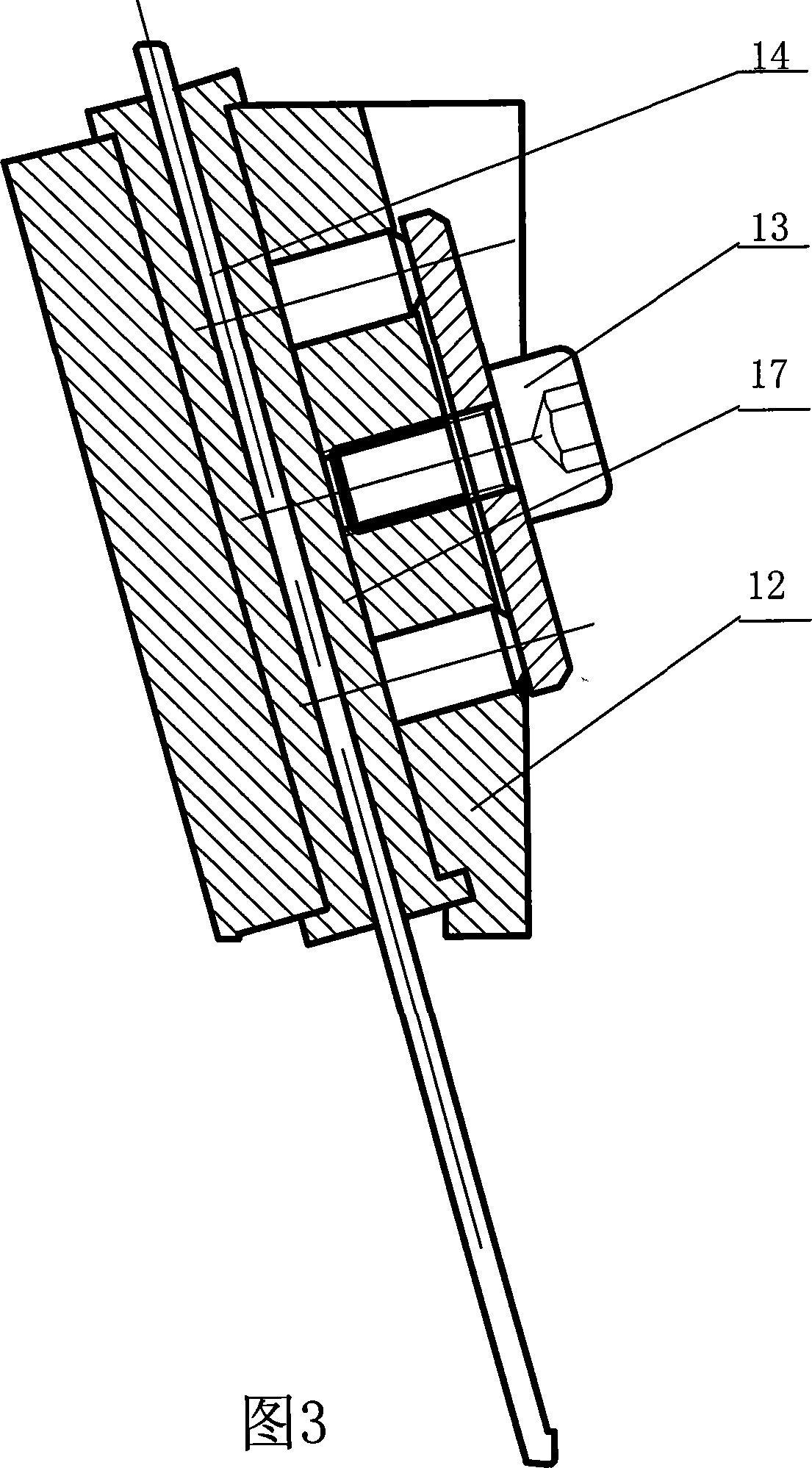

[0010] As shown in Fig. 1-Fig. 3, present embodiment comprises nose frame 18, working machine platform 8, upper propulsion mechanism, lower propulsion mechanism, and upper propulsion mechanism is located on the nose frame 18, and lower propulsion mechanism is located at working machine. On stage 8. in:

[0011] The upper propulsion mechanism includes an upper main shaft 1, a crank wheel 2, a shift fork 5, a connecting block 4, a transmission rod 3, and a telescopic long-arm hammerhead 6. The outer end of the upper main shaft 1 is connected to the crank wheel 2, and the crank wheel 2 is eccentric to the shift fork 5. connection, the shift fork 5 is slidingly connected with the connecting block 4, the connecting block 4 is fixedly connected with the transmission rod 3, the transmission rod 3 is connected with the axial movement of the head frame 18, and the lower end of the transmission rod 3 is connected with the telescopic long-arm hammer head 6, so The telescopic long-arm ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com