Electric iron rack

A technology of electric soldering iron and iron frame, which is applied in the direction of soldering iron, electrical components assembly printed circuit, auxiliary device, etc., which can solve the problems of easily hurting people or other objects, time-consuming, and should not be scrubbed on wet sponges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

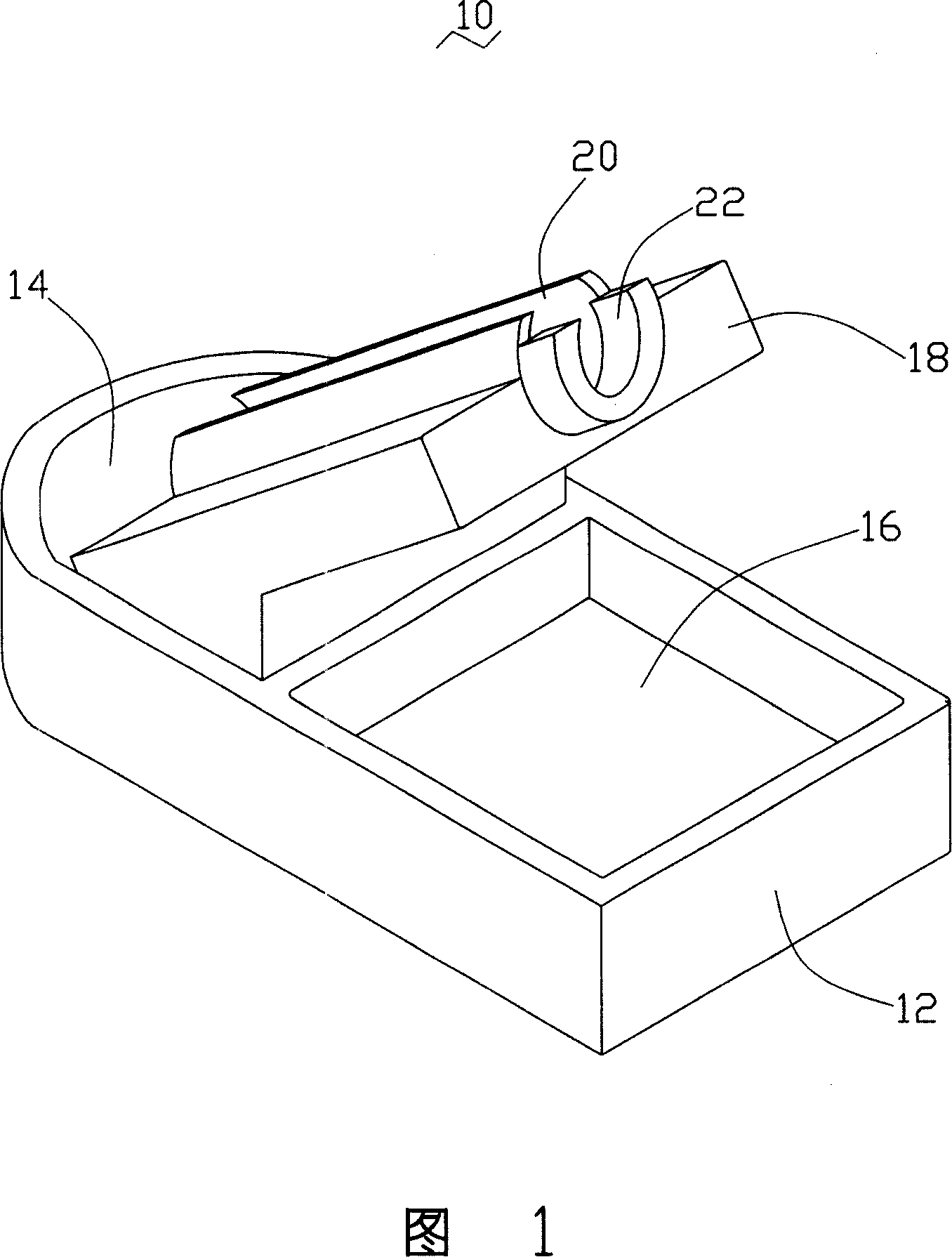

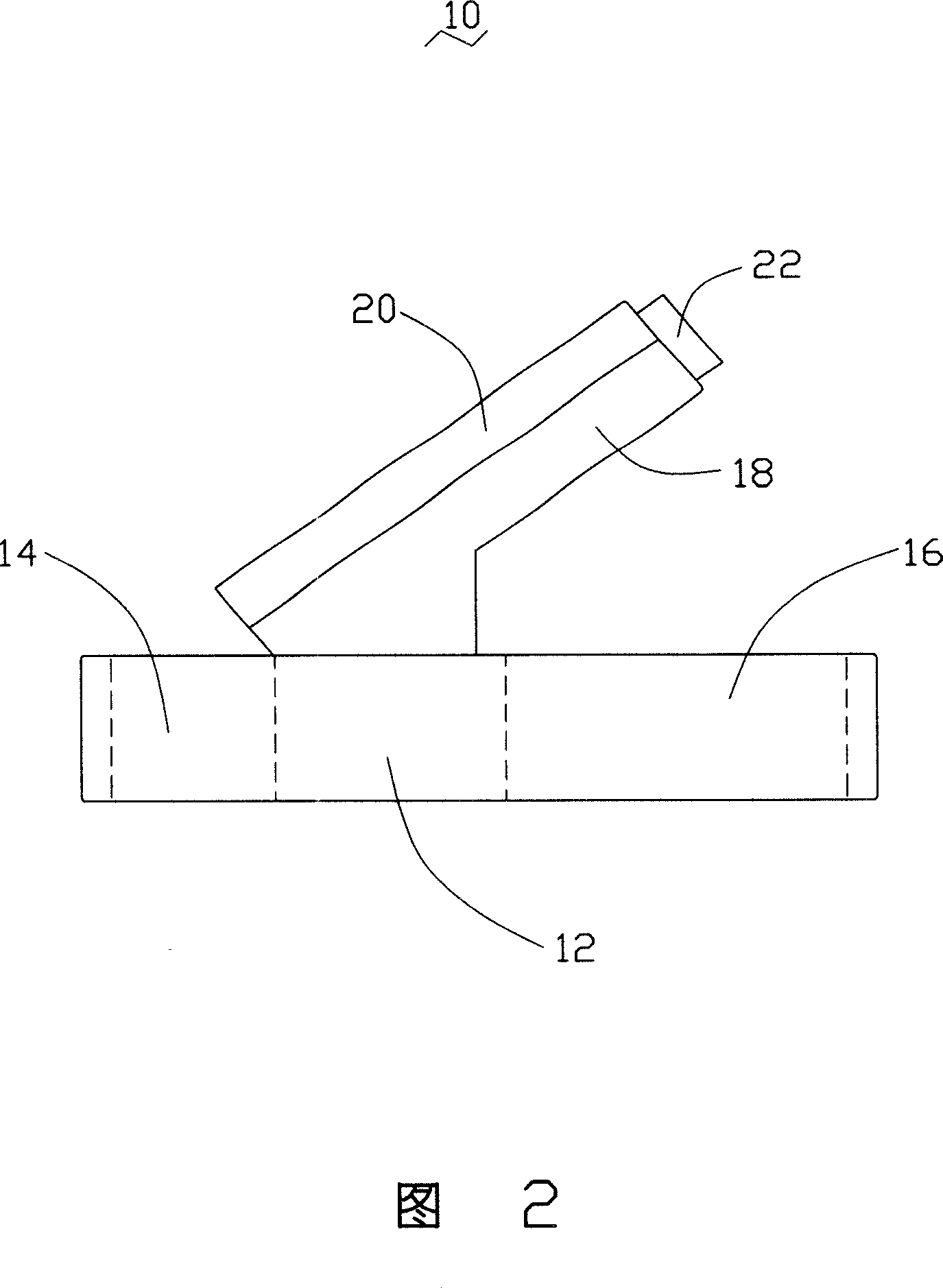

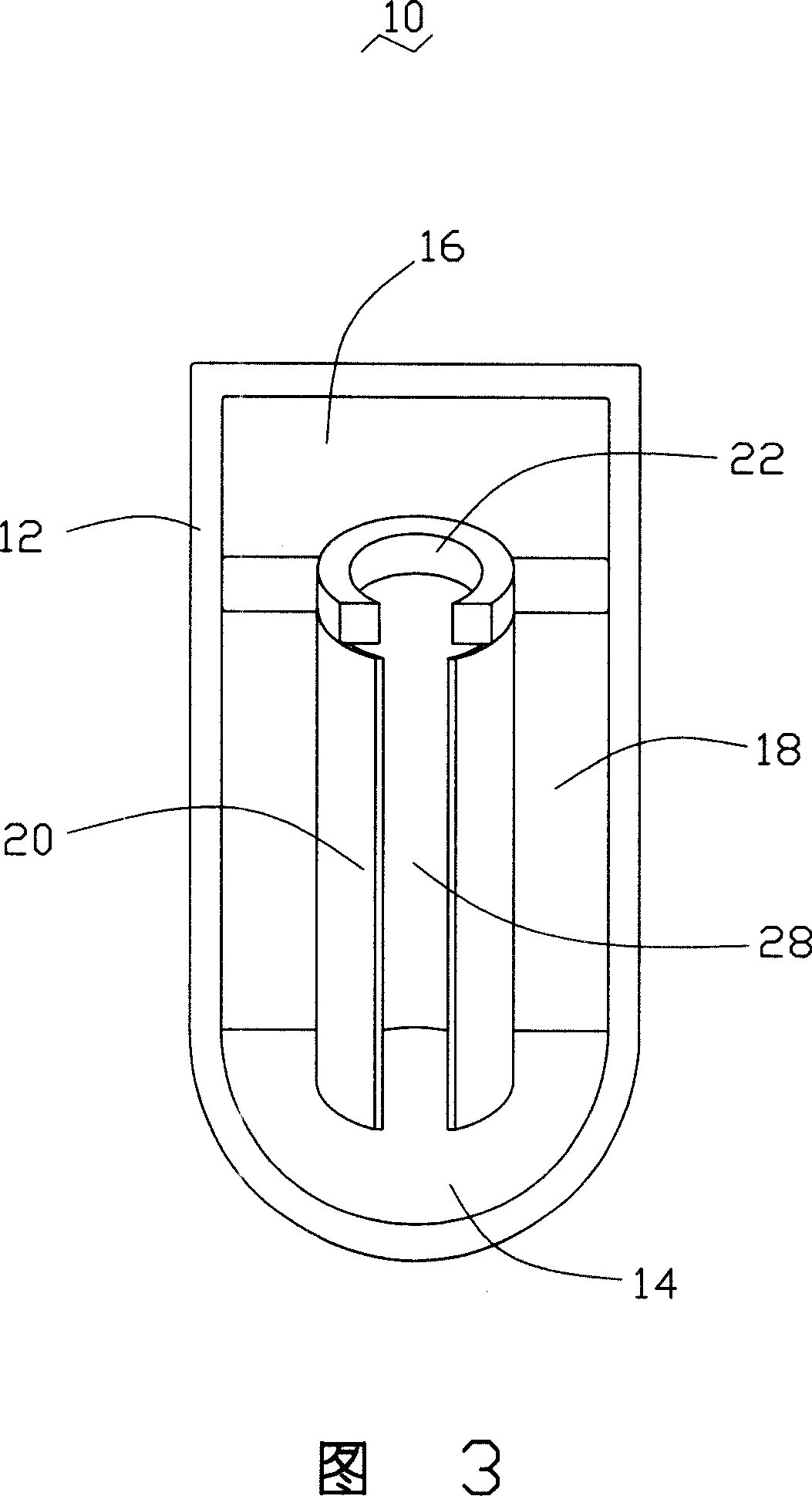

[0010] Please refer to Fig. 1 and Fig. 4, which is a preferred embodiment of the electric soldering iron stand 10 of the present invention, including a base 12, a support frame 18 is formed on the base 12, and a support frame 18 is formed on the base 12, and a The storage groove 14 and an accommodating groove 16 .

[0011] Please refer to FIG. 1 to FIG. 3 , the support frame 18 is arranged in an inclined shape, one end is formed on the base 12 , and the other end is a free end. The support frame 18 is provided with a cylindrical casing 20 along its length direction, and a strip-shaped opening 28 is defined on the top surface of the cylindrical casing 20 , the length of the opening 28 is equal to the length of the support frame 18 . The free end of the support frame 18 is also provided with a U-shaped protrusion 22 , and the height of the left and right sides of the U-shaped protrusion 22 is higher than the thickness of the support frame 18 . The storage groove 14 is placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com