Method for optimizing nozzle of a internal combustion engine

A technology of internal combustion engines and nozzles, applied in multi-objective optimization, fuel injection devices, mechanical equipment, etc., can solve problems such as failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

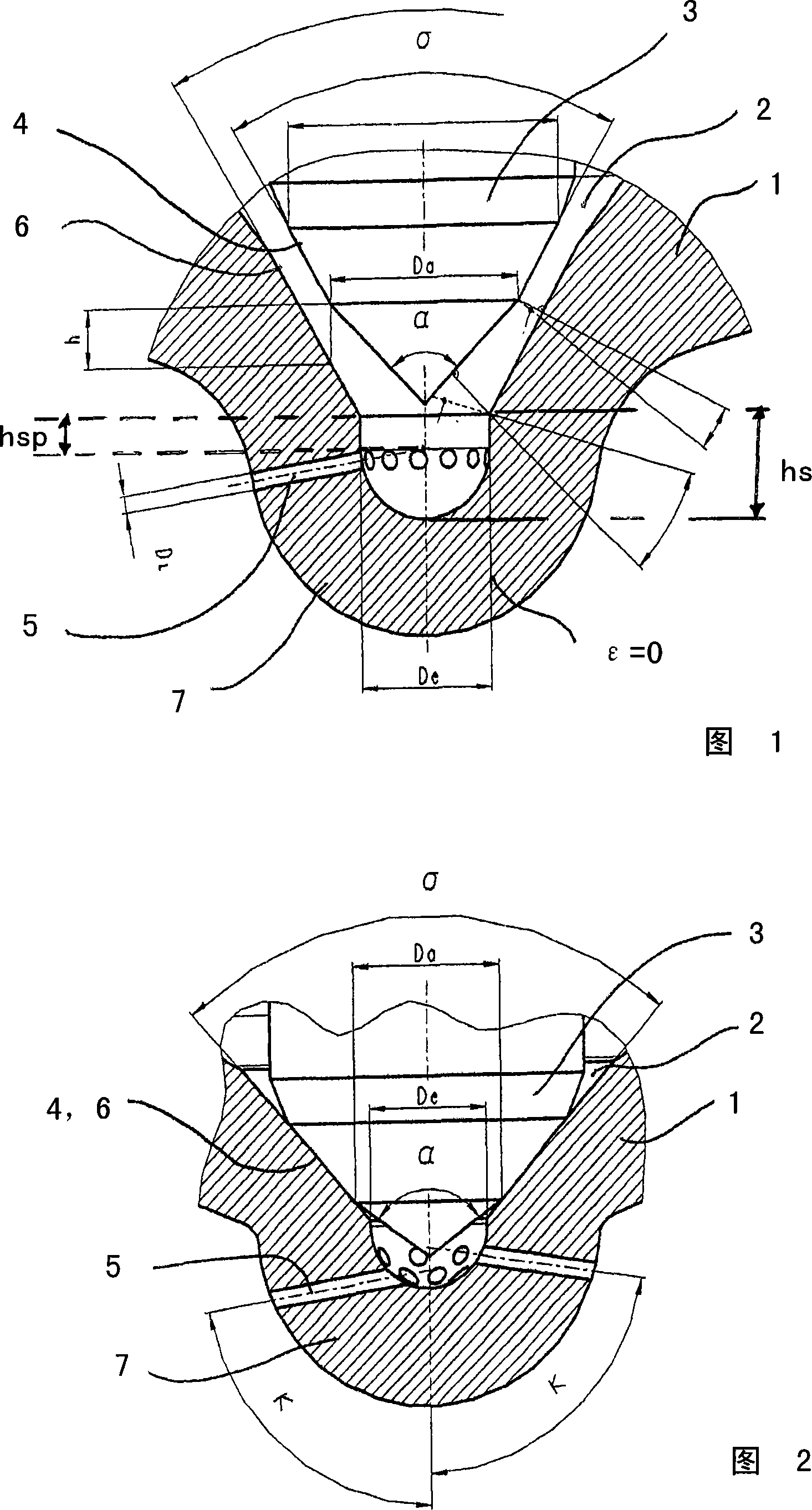

[0025] The invention relates to a method for optimizing a nozzle of an internal combustion engine comprising a nozzle body 1 and a nozzle needle 3 which can be moved axially against a closing force in a bore 2 of the nozzle body 1, wherein the nozzle needle 3 is on the combustion chamber side thereof There is a valve sealing surface 4 on the end face of the nozzle needle, in order to control the flow cross-section to at least one nozzle opening 5 introduced into the combustion chamber of the internal combustion engine, the nozzle needle cooperates with the valve seat surface 6 of the nozzle body 1 with the valve sealing surface, wherein for the nozzle For the geometrical modeling, a mathematical method in the form of particle swarm optimization (PSO) is used and referenced in the structural design of the nozzle as a criterion for the best attainment, using arbitrarily chosen individual parameters.

[0026] In a particularly preferred manner, the described optimization using PSO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com