Slope surface LED support and LED light source

A technology of LED brackets and LED light sources, which is applied in the direction of light sources, point light sources, and semiconductor devices of light-emitting elements, etc., can solve the problems of incomplete and effective formation of secondary reflections, suboptimal enhancement of light source brightness, and limited effects. Achieve the effect of saving material, benefiting heat dissipation, and increasing the light angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

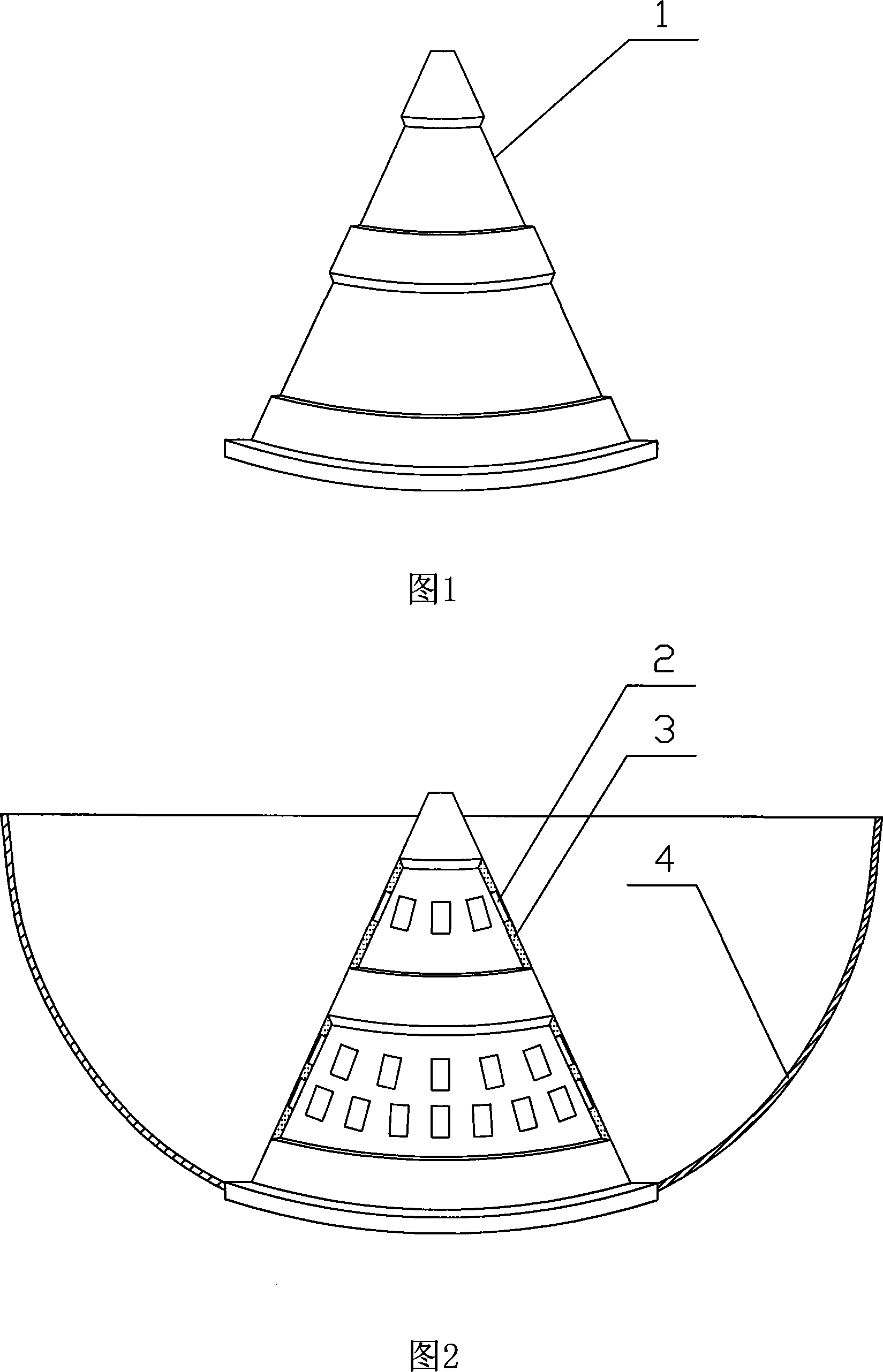

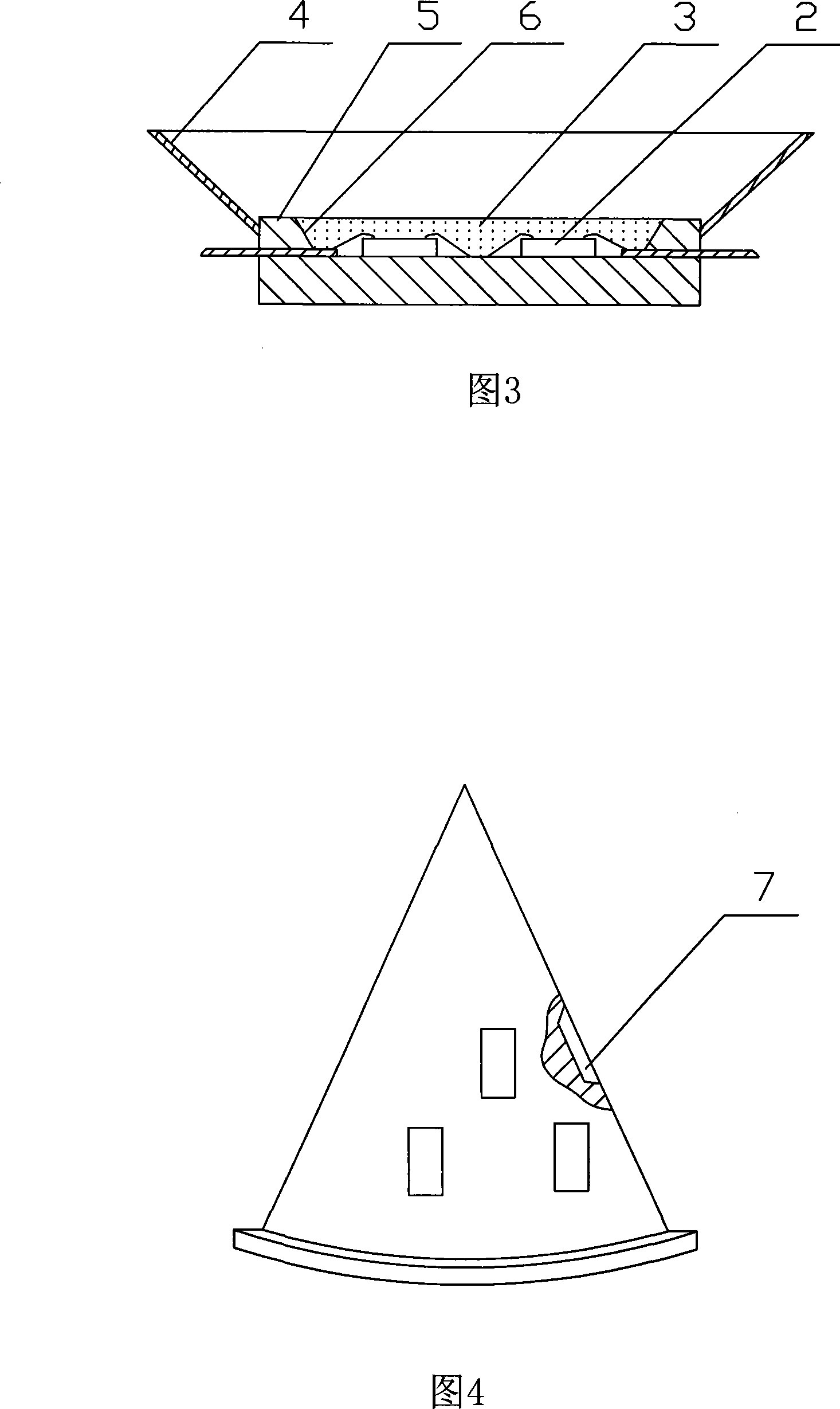

[0026] As shown in Figure 1, the bracket body of the slope LED bracket in the present invention is a headless cone, the cone is hollow, and two annular LED packaging channels 1 are arranged horizontally around the surface of the cone, and the bottom surface of the packaging channel 1 It is the LED package surface, and the channel wall of the package channel 1 is cambered to form the reflective surface of the LED; the entire LED bracket is made of metal material or metal-ceramic composite material, such as copper, aluminum, or such high thermal conductivity metal and ceramics Composite materials.

[0027] Fig. 2 is an LED light source with a sloped LED bracket of the present invention, and the bracket is the bracket with a conical slope described in the above example. The bottom seat of the bracket is connected with a reflective cup cover 4 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com