Transformer conducting bar and winding leads connection structure

A winding lead wire and connection structure technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of increased sealing difficulty, transformer oil leakage, etc., and achieve the effects of simple wiring, reduced leakage, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

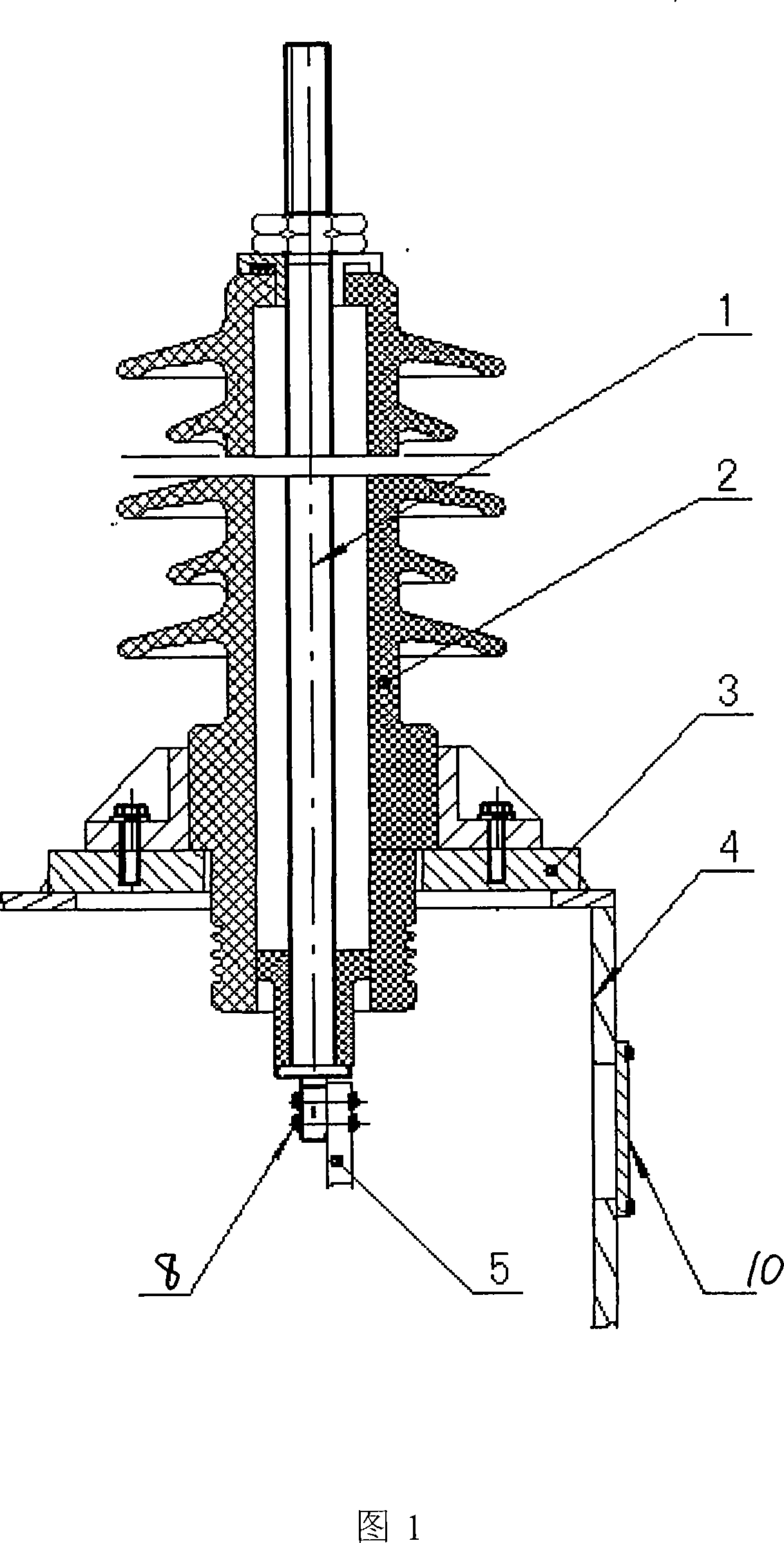

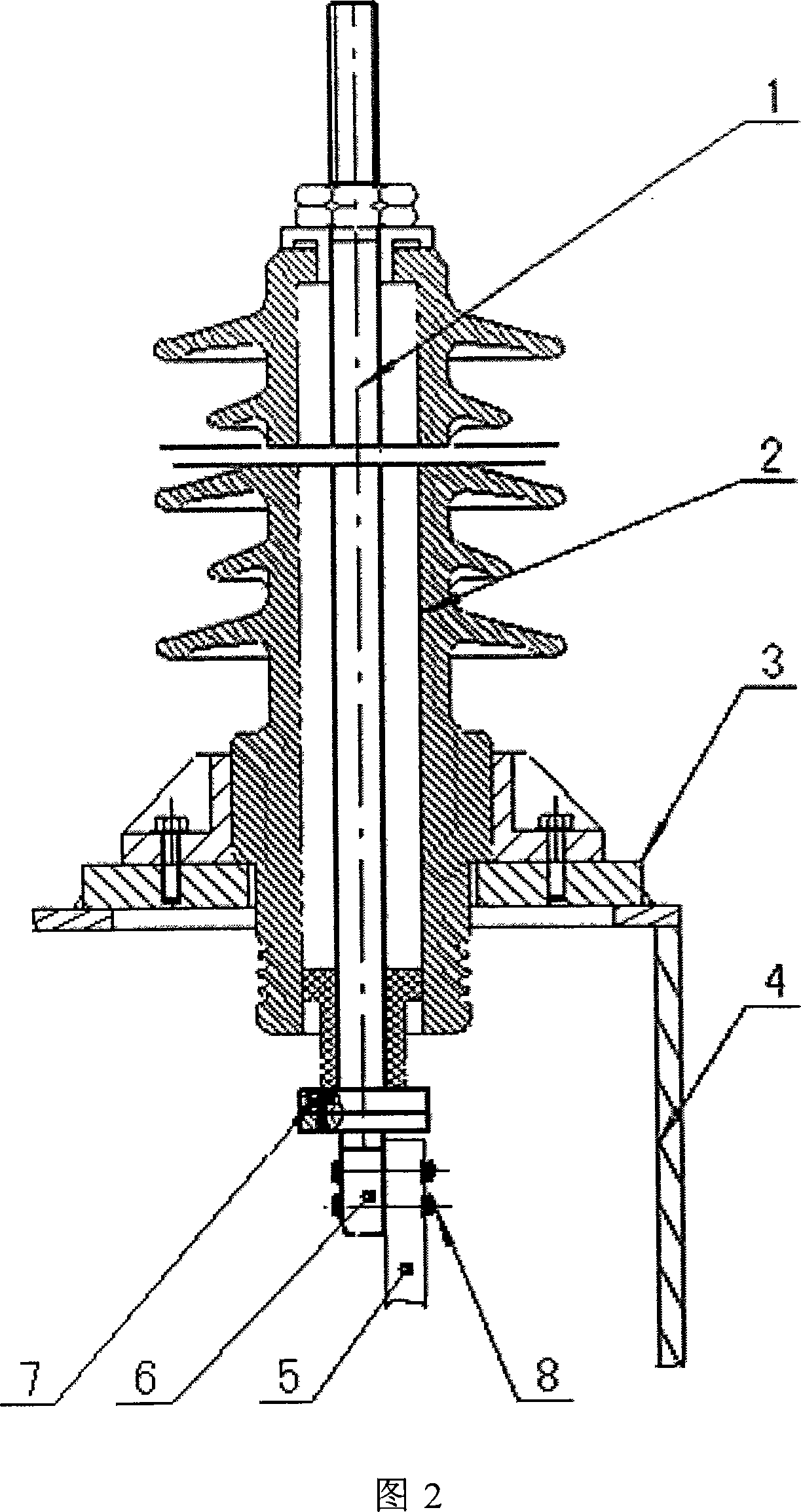

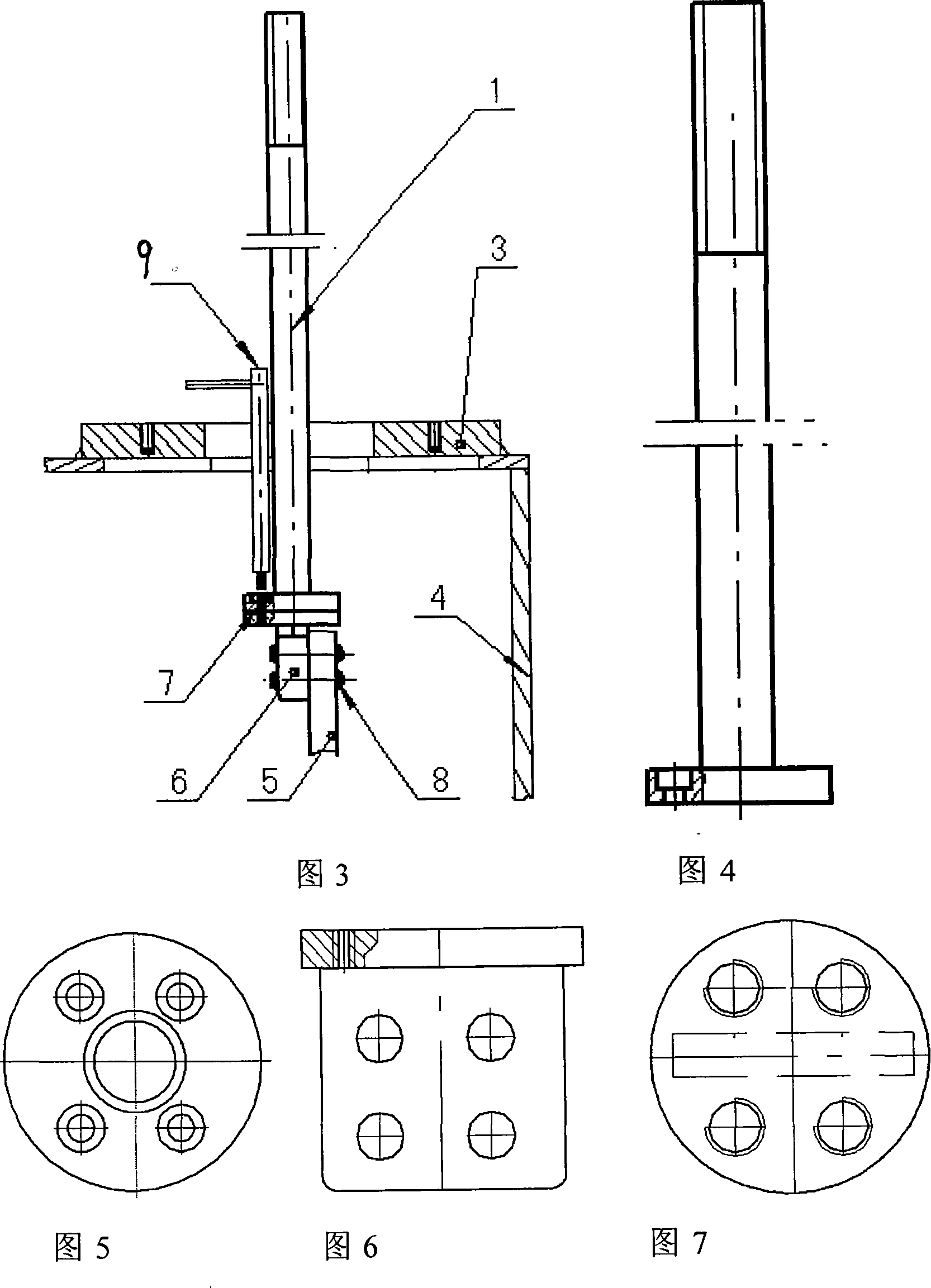

[0010] Accompanying drawing 2-7 is a kind of specific embodiment of the present invention.

[0011] The connection structure of the transformer conductive rod and the winding lead wire of the present invention includes a lead wire connection plate 6 connected between the conductive rod 1 and the winding lead wire 5. The lead wire connection plate is composed of two mutually perpendicular flanges fixed as one. The conductive rod The lower end of 1 is provided with the flange corresponding to lead wiring board. For ease of use, one of the two flanges of the lead wiring board 6 is circular and the other is square, and one end of the square flange is connected to the middle of the circular flange. The flange at the lower end of the conductive rod is a circular flange.

[0012] In the connection structure of the transformer conductive rod and the winding lead wire of the present invention, when the winding is in place in the lower box body, the ends of the winding lead wire 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com