Piston type hydraulic chuck

A hydraulic chuck, piston type technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problem of less moving parts, achieve uniform force, improve working environment, and improve sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

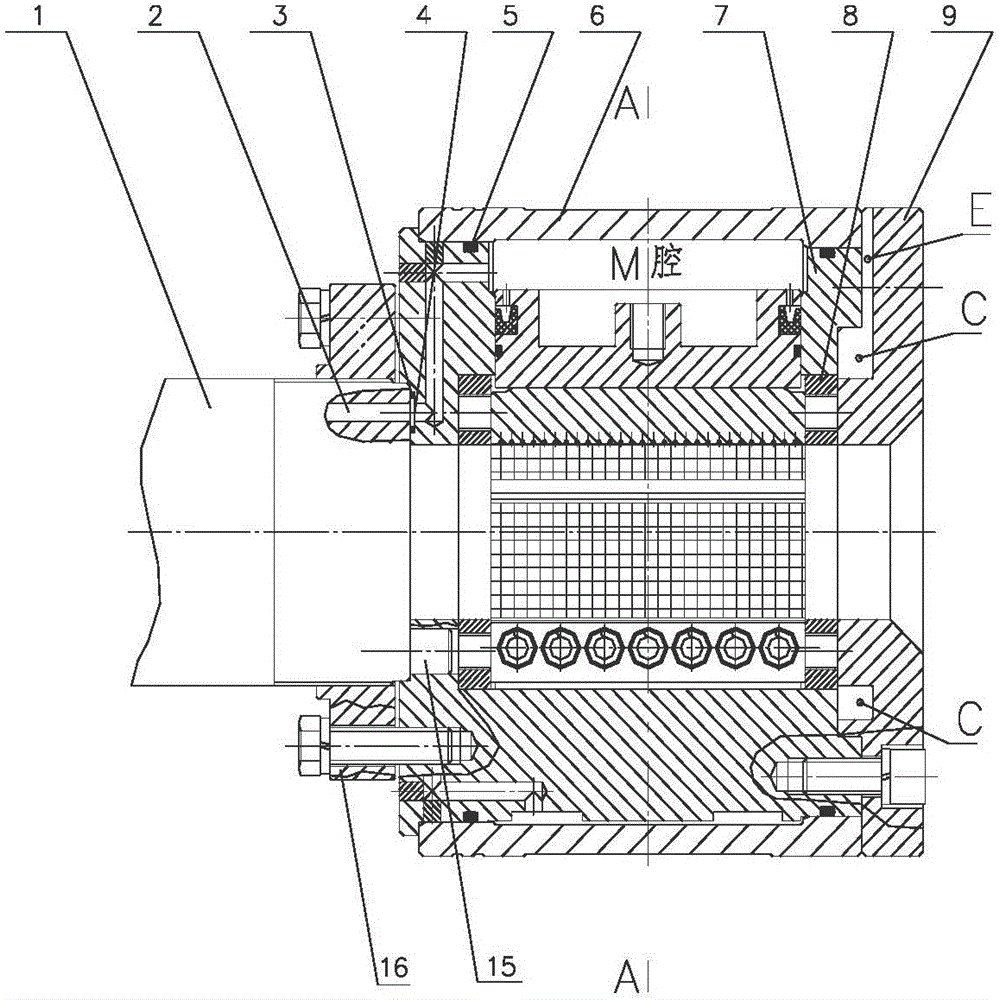

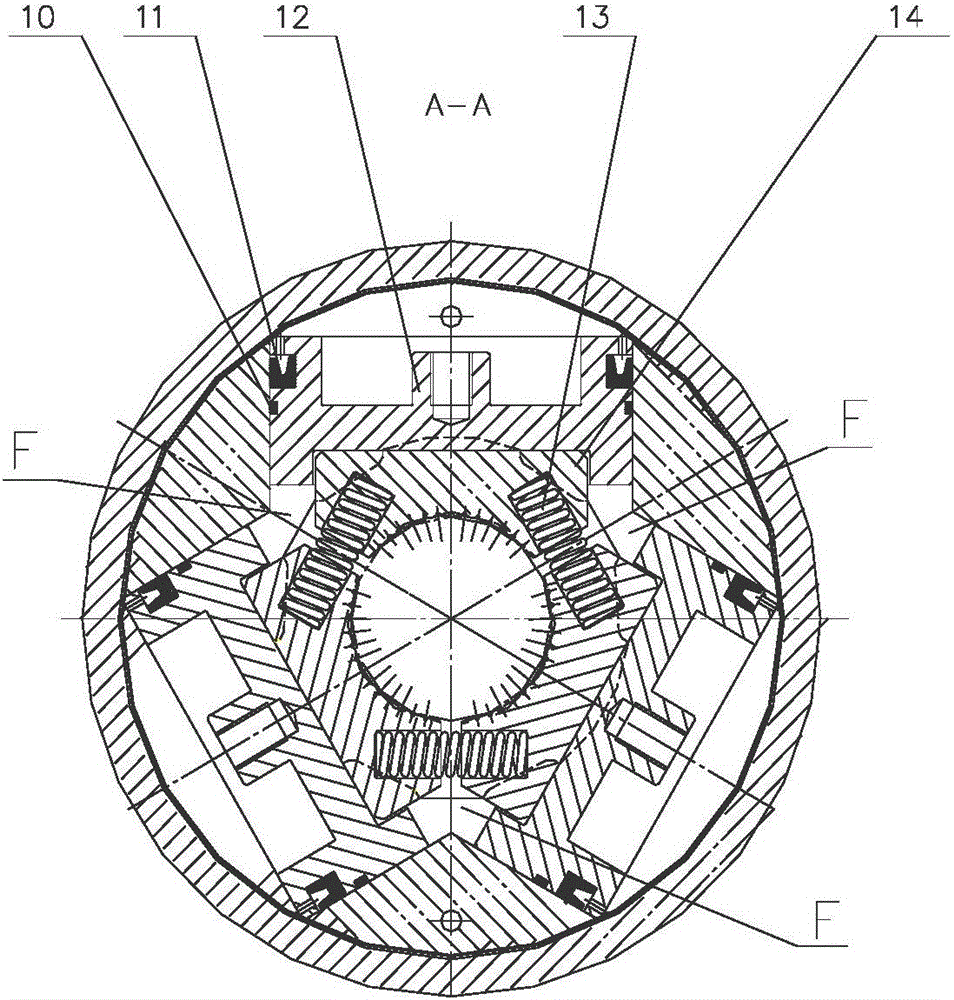

[0028] As shown in the figure, a piston-type hydraulic chuck includes a housing 6, one end of the housing 6 is provided with a chuck body 7, and the other end is provided with an end cover 9; the chuck body 7 is provided with a clamp for clamping the drill rod Clamping device, the clamping device comprises a plurality of slips 14 distributed along the circumferential direction of the chuck body 7, a plurality of pistons 12 for pressing the slips 14 and arranged between adjacent slips 14 for opening The spring group 13 of the slip 14, the piston 12 and the slip 14 are arranged in one-to-one correspondence, and a high-pressure oil chamber M is provided between the chuck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com