Temperature adjusting device of cooling system of diesel engine

A technology of temperature adjustment device and cooling system, which is applied in the direction of engine cooling, coolant flow control, mechanical equipment, etc., and can solve the problems that affect the appearance of other parts, complicated pipeline layout, and large space occupation. Achieve the effects of reducing leakage hazards, reducing parts, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

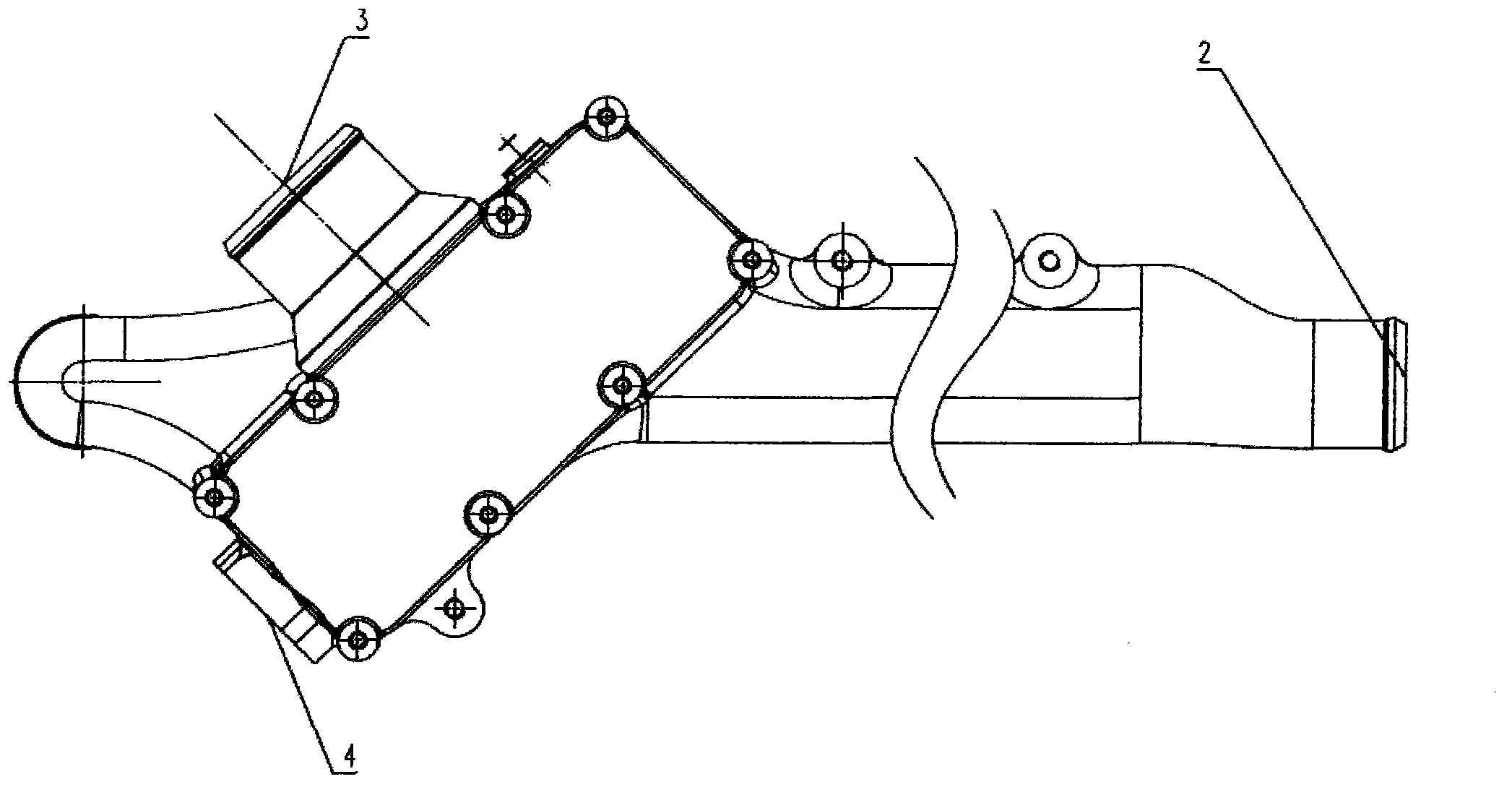

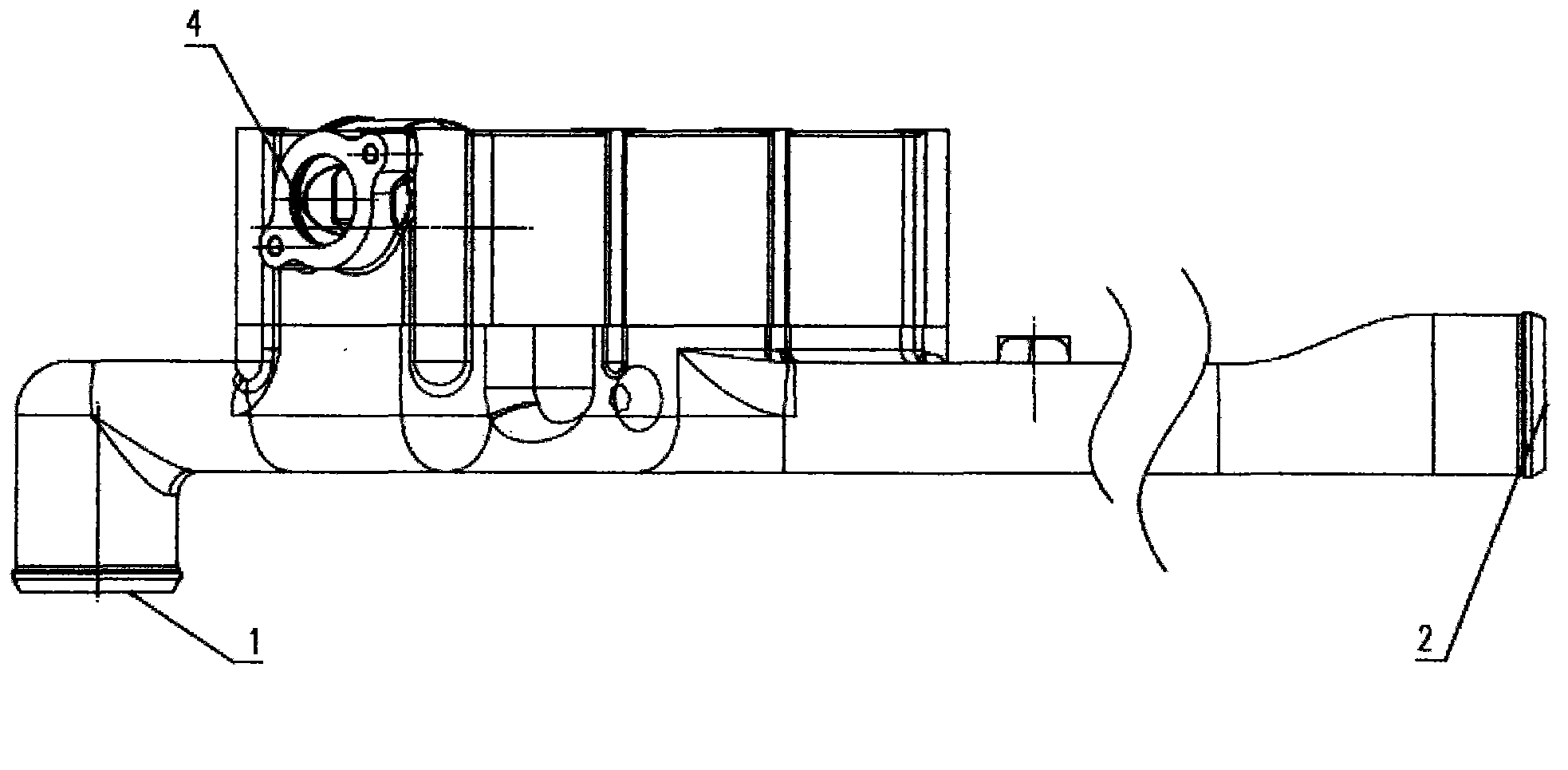

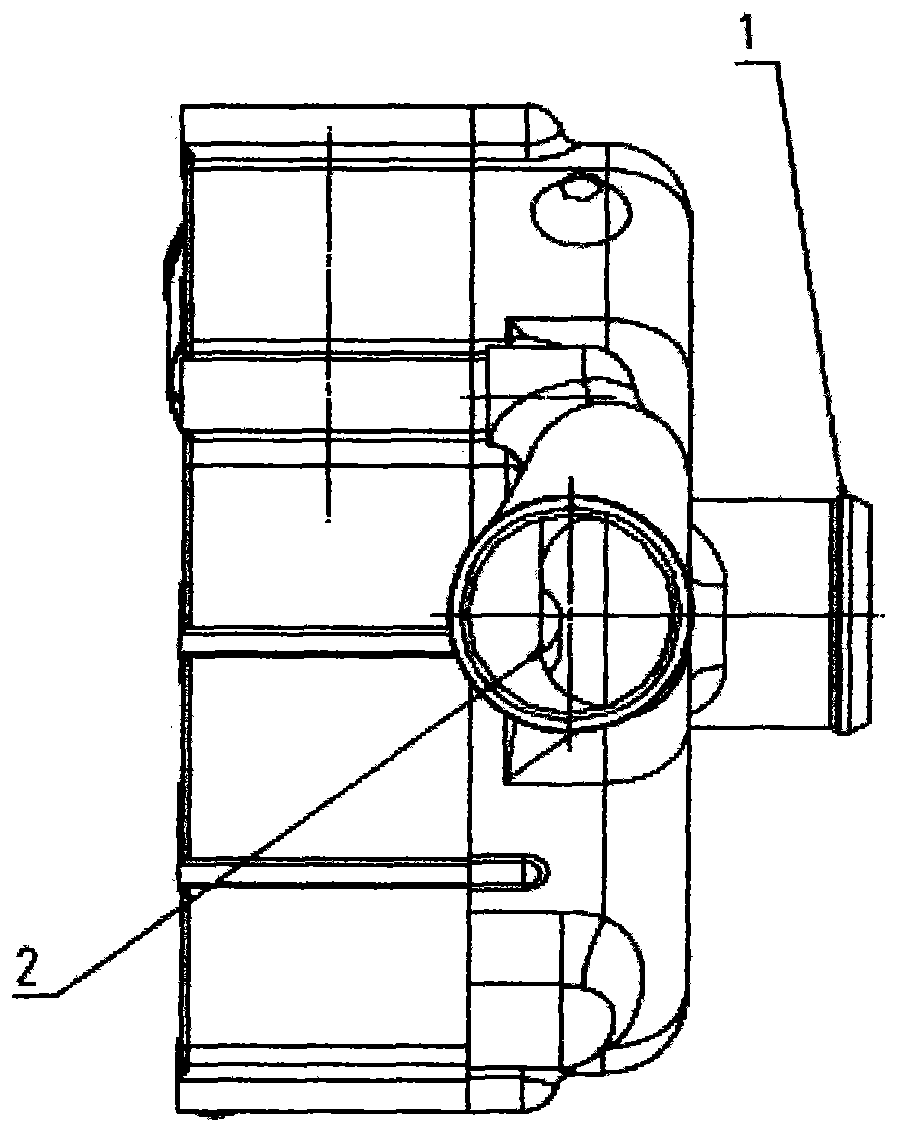

[0021] Embodiment 1, with reference to Figure 1 to Figure 7 , the diesel engine cooling water distribution body includes: the first water inlet (1) and the second water inlet (2) of the thermostat assembly are coolant inlets, the first water inlet (1), the second water inlet ( 2) These two ports are connected in the form of intubation, flowing from the first water inlet (1) and the second water inlet (2) to the first base (5) of the thermostat seat, and after the thermostat is opened, it passes through The large circulation channel (7) of the device base flows to the water outlet (4) of the small circulation channel and is connected with the engine cooling water tank; The circulation channel (8) flows to the water outlet (3) of the large circulation channel; the diameter and position of the large circulation channel (7) of the device base and the small circulation channel (8) of the device base are adjusted through CFD optimization analysis to ensure the flow to the left and ...

Embodiment 2

[0022] Embodiment 2, with reference to Figure 1 to Figure 7 , the coolant in the thermostat assembly enters the first water inlet (1) and the second water inlet (2) are connected by clamps, which are easy to adjust and easy to install. The water outlet (3) of the large circulation channel is arranged in the middle of the thermostat seat to facilitate connection with the cooling water tank. The water outlet (4) of the small circulation channel is arranged on one side of the thermostat seat, and the end face is provided with an O-ring sealing groove, which is reliable in sealing and can prevent leakage of coolant. The above disclosure is only a specific embodiment of the present invention, however, the present invention is not limited thereto, and any changes conceivable by those skilled in the art shall fall within the protection scope of the present invention. The coolant from the left and right cylinders of the engine from the cooling water pipe, if the temperature of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com