Design method of single-tube electrolytic tank

A design method and electrolytic cell technology, which can be applied to electrolytic components, electrolytic processes, cells, etc., can solve the problems of a large number of fastening bolts, inconvenient installation, disassembly and maintenance, and complex combined structure, so as to achieve non-deformation and displacement, convenient assembly and disassembly, Good anti-knock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

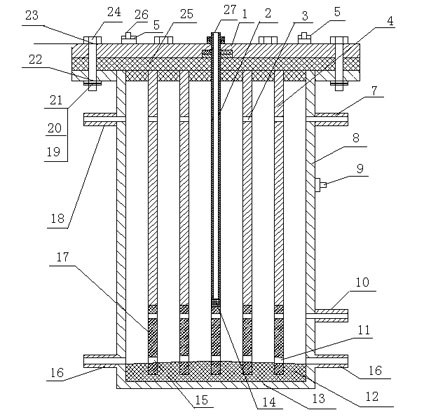

[0024] A design method for a single-tube electrolytic cell is composed of five tubular electrodes 4 with different tube diameters and arranged at equal intervals between a circular anode 2 and a tubular cathode 8; It is a single-tube tank body whose diameter is larger than that of other tubular electrodes 4 and circular anode 2, and the circular anode 2 is arranged at the center of the tank body; the circular anode 2 is tubular or cylindrical.

Embodiment 2

[0026] A design method for a single-tube electrolytic cell is composed of a circular anode 2 and a tubular cathode 8 with two tubular electrodes 4 with different diameters and equally spaced sets of tubular electrodes 4 arranged sequentially; the tubular cathode 8 It is a single-tube tank whose diameter is larger than that of other tubular electrodes 4 and circular anode 2, and the circular anode 2 is arranged in the center of the tank; the circular anode 2 is tubular (or cylindrical) . The circular anode 2 is made of low-carbon steel pipe (or low-carbon steel column), and its surface is plated with a nickel layer; the tubular cathode 8 and the tubular electrode 4 are both made of low-carbon steel pipe, and their steel pipe surfaces are blasted deal with.

Embodiment 3

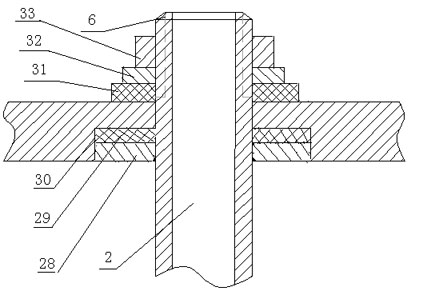

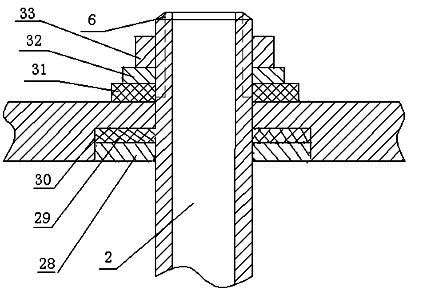

[0028] A design method for a single-tube electrolytic cell is composed of a circular anode 2 and a tubular cathode 8, and eight tubular electrodes 4 with different tube diameters and arranged at equal intervals are sequentially nested; the tubular cathode 8 It is a single-tube tank whose diameter is larger than that of other tubular electrodes 4 and circular anode 2, and the circular anode 2 is arranged in the center of the tank; the circular anode 2 is tubular (or cylindrical) . The upper end of the tubular electrode 4 is provided with an end plate insulating rubber pad 25 with an annular groove, and the lower end is provided with an insulating rubber pad 12 with an annular groove. The tubular electrode 4 is embedded in the end plate insulating rubber pad 25 and the insulating rubber pad with an annular groove. In the annular groove of pad 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com