LED and its making method

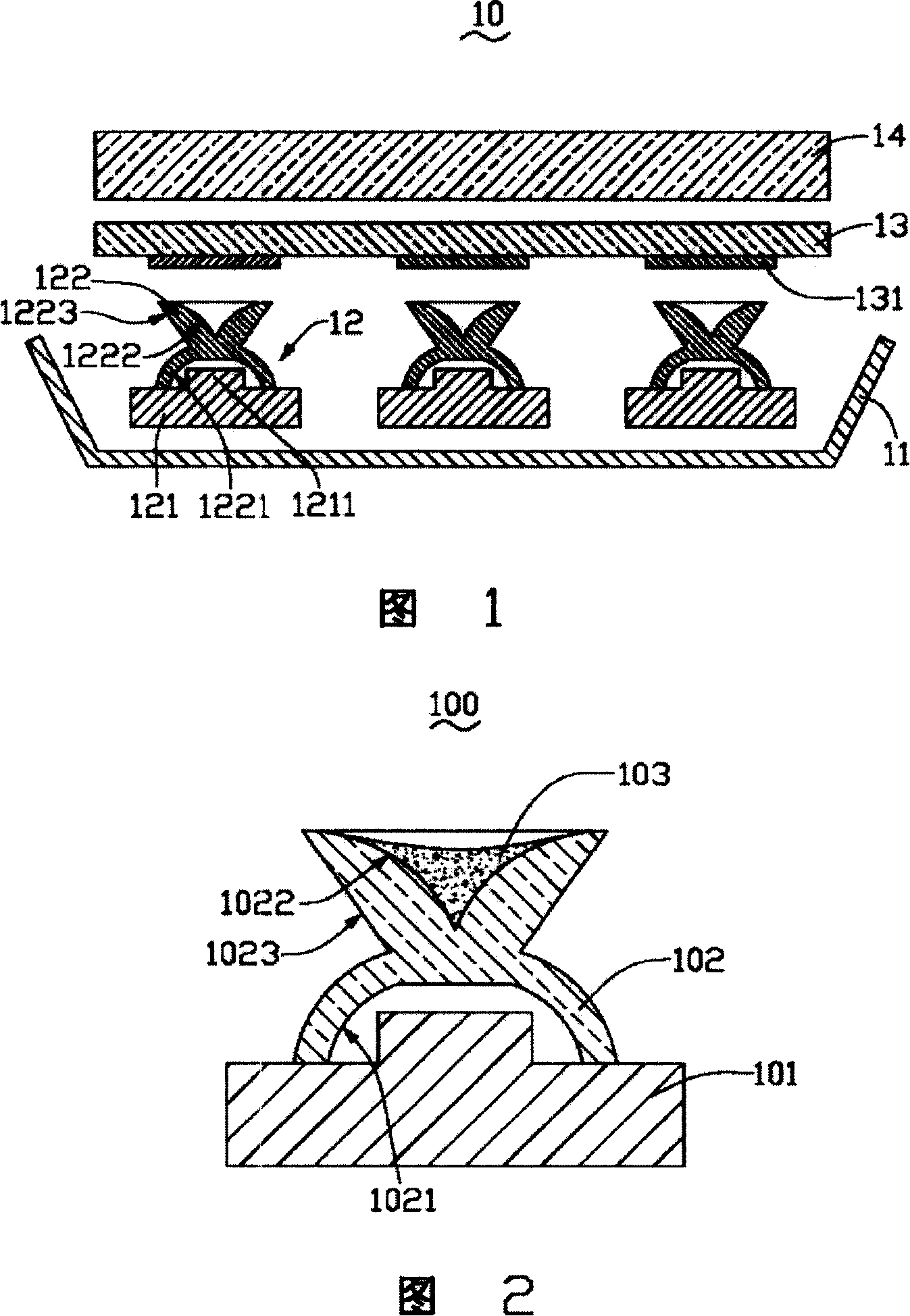

A technology of light-emitting diodes and light-emitting elements, which is applied to optics, condenser lenses, optical elements, etc., can solve problems such as affecting the light-emitting effect of the backlight module 10, yellowing, and affecting the quality of the backlight module 10.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The light-emitting diode and its preparation method will be further described in detail below with reference to the accompanying drawings and embodiments.

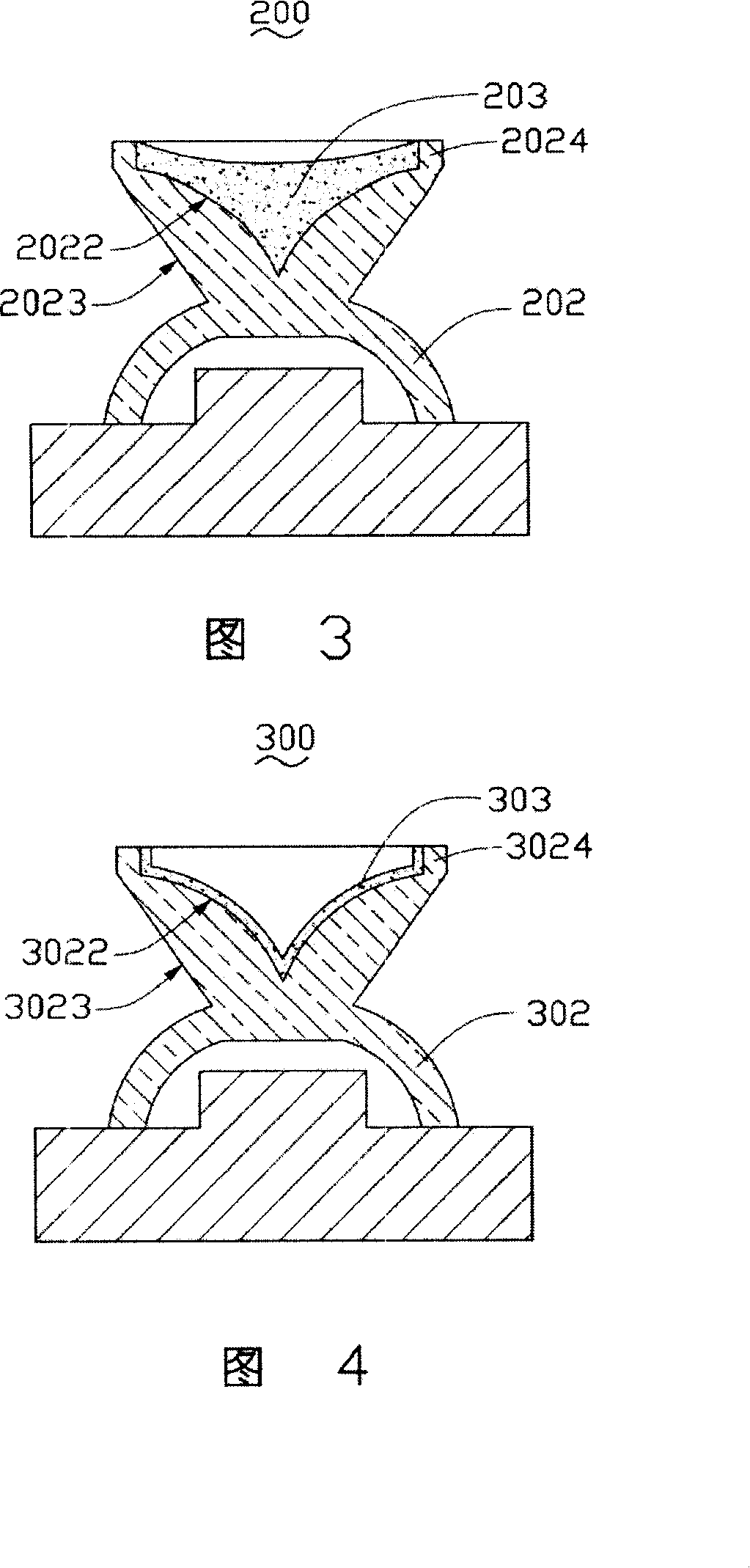

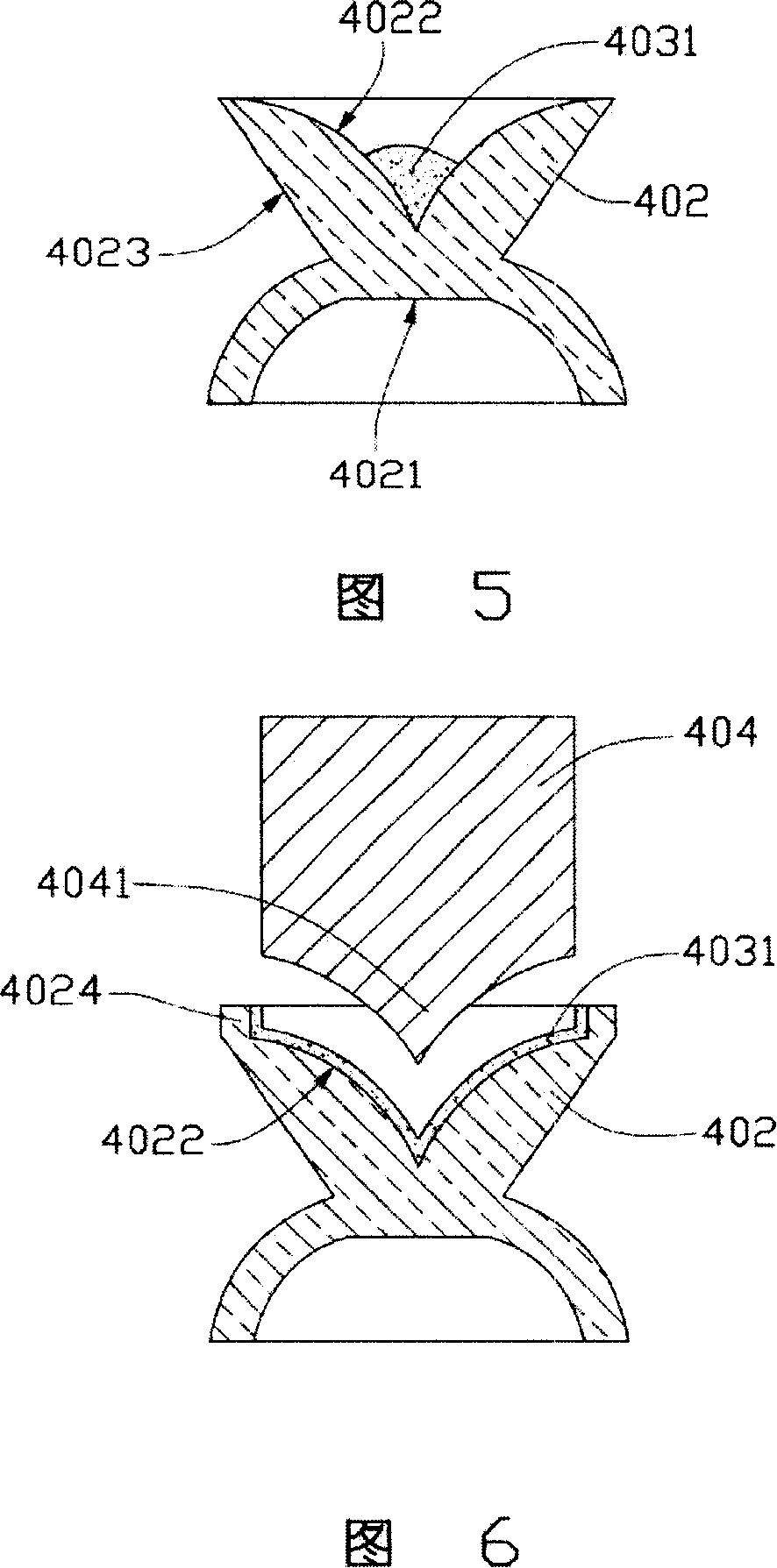

[0018] Please refer to FIG. 2 , which is a schematic cross-sectional view of a preferred embodiment 1 of the light emitting diode of the present invention. The light emitting diode 100 includes a semiconductor light emitting element 101 , a light guide prism 102 and an aluminum paste coating 103 . The light guide prism 102 includes a light incident surface 1021 opposite to the semiconductor light emitting element 101 , a top surface 1022 opposite to the light incident surface 1021 , and a light exit surface 1023 outside the light guide prism 102 and connected to the top surface 1022 . The aluminum paste paint coating 103 is formed on the top surface 1022, which includes a transparent resin substrate and a plurality of aluminum scales dispersed on the transparent resin substrate.

[0019] According to different ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com