A plastic reflective sheet

A reflective sheet and integrated technology, applied in the field of reflective sheets, can solve the problems of complex forming process of thick reflective sheets and failure of secondary molding, etc., achieve good reflection effect, simple processing, and improve use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

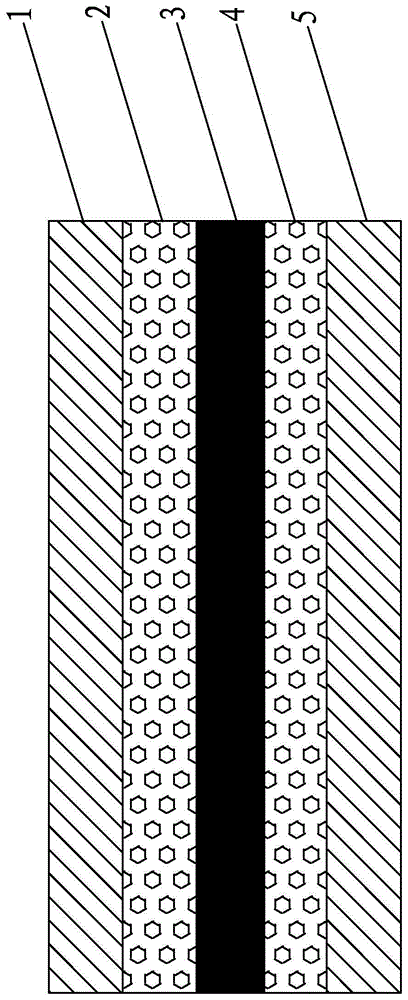

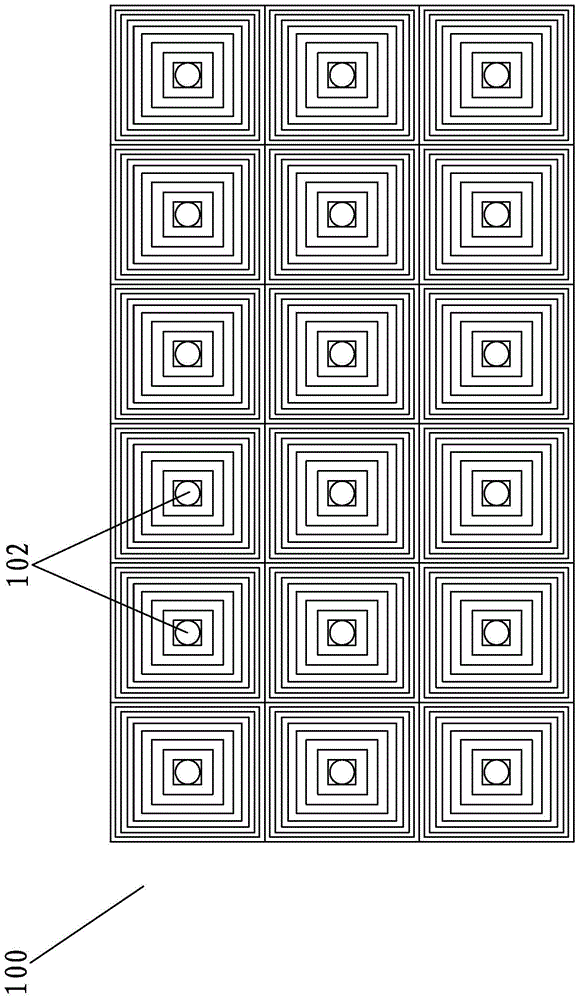

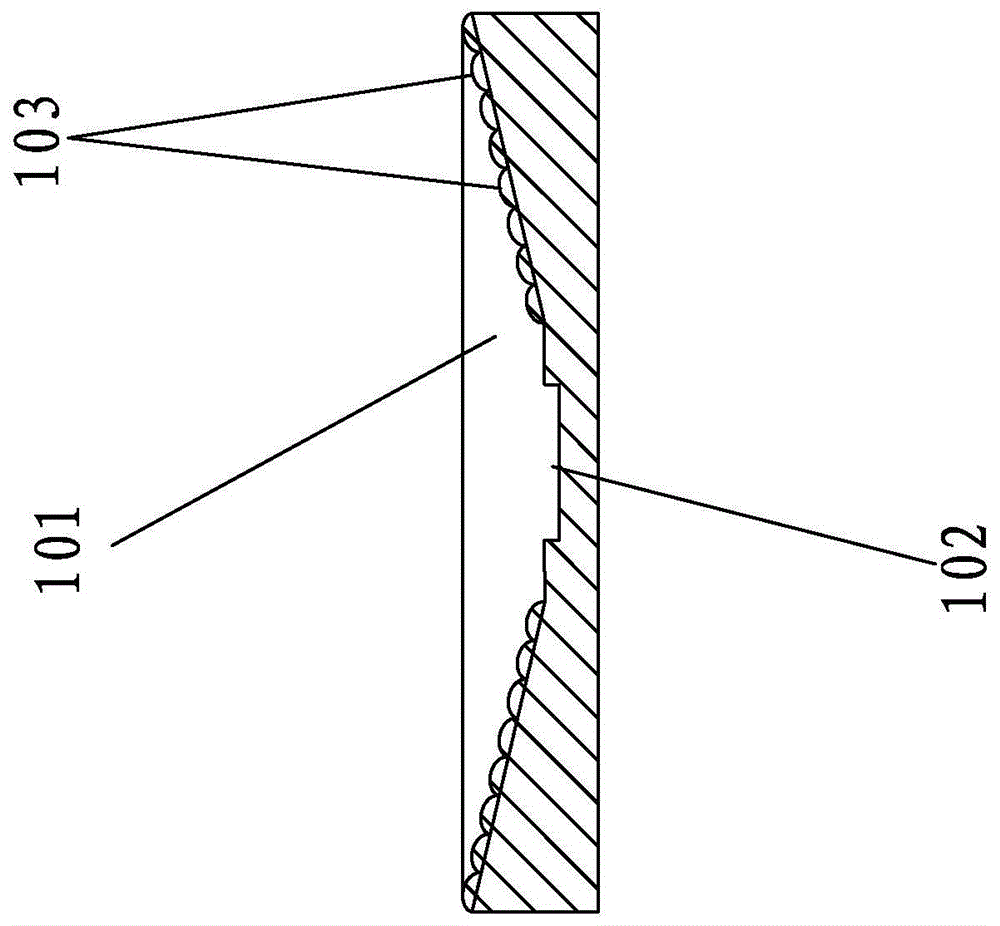

[0018] A kind of absorbable reflective sheet of the present invention, such as Figure 1-3 As shown, the reflection sheet 100 is composed of the first PMMA layer 1, the first PMMA foam layer 2, the PC layer 3, the second PMMA foam layer 4 and the second PMMA layer 5 from top to bottom, and the first PMMA Layer 1, the first PMMA foam layer 2, PC layer 3, the second PMMA foam layer 4 and the second PMMA layer 5 are integrally extruded into a sheet structure through an extrusion process, the first PMMA layer 1, the first PMMA foam layer The total thickness of the bubble layer 2, the PC layer 3, the second PMMA foam layer 4 and the second PMMA layer 5 is 0.25mm-0.85mm.

[0019] A kind of absorbable plastic reflection sheet of the present invention, because reflection sheet 100 is made of the first PMMA layer 1, the first PMMA foam layer 2, PC layer 3, the second PMMA foam layer 4 and the second PMMA from top to bottom Composed of layer 5, PMMA has countless tiny bubbles in it aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com