Rotating anode x-ray tube assembly

A technology of rotating anodes and ray tubes, which is applied to X-ray tubes, X-ray tube parts, X-ray tube electrodes, etc., and can solve problems such as shortening the life of the collector ring mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

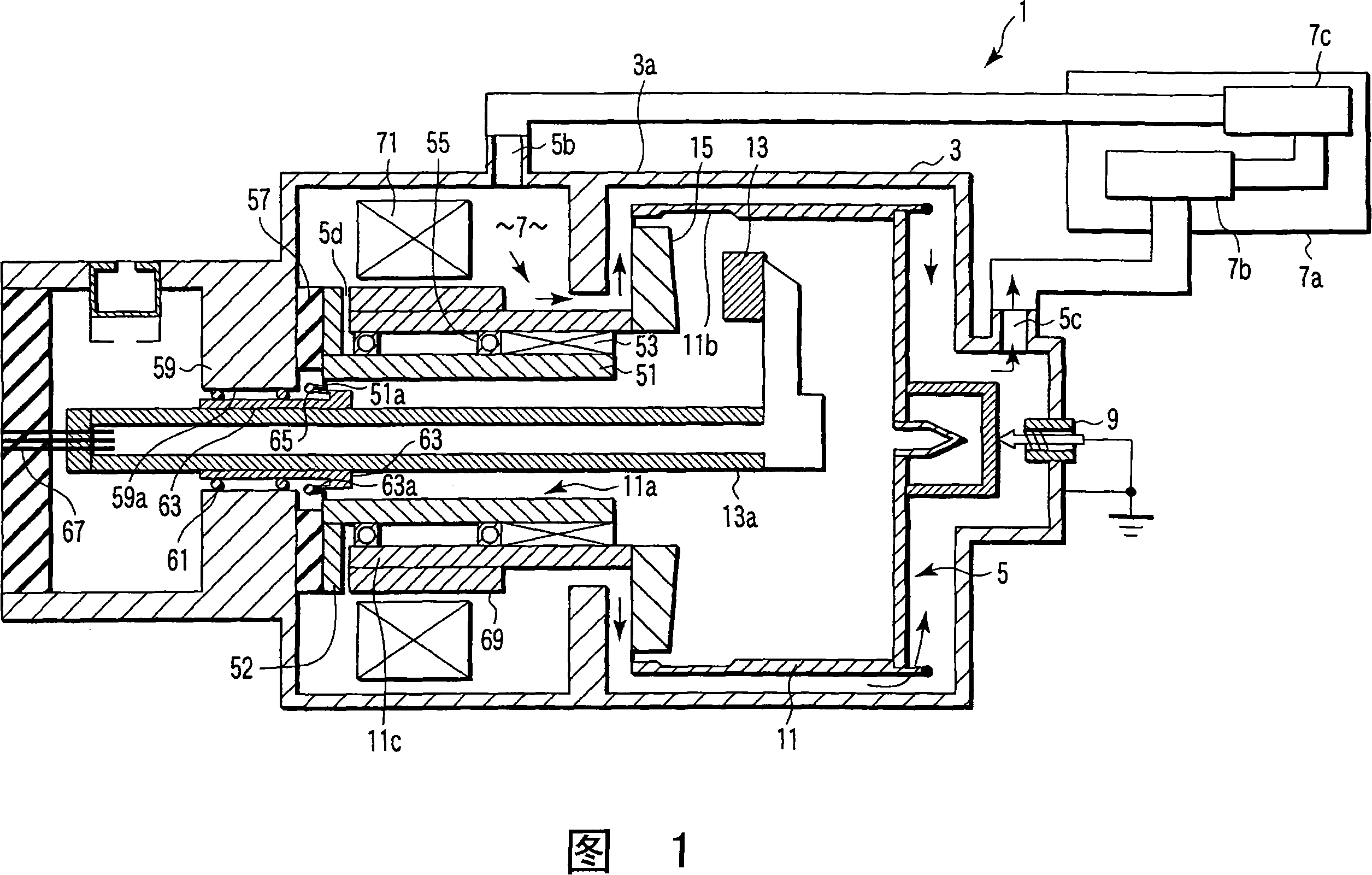

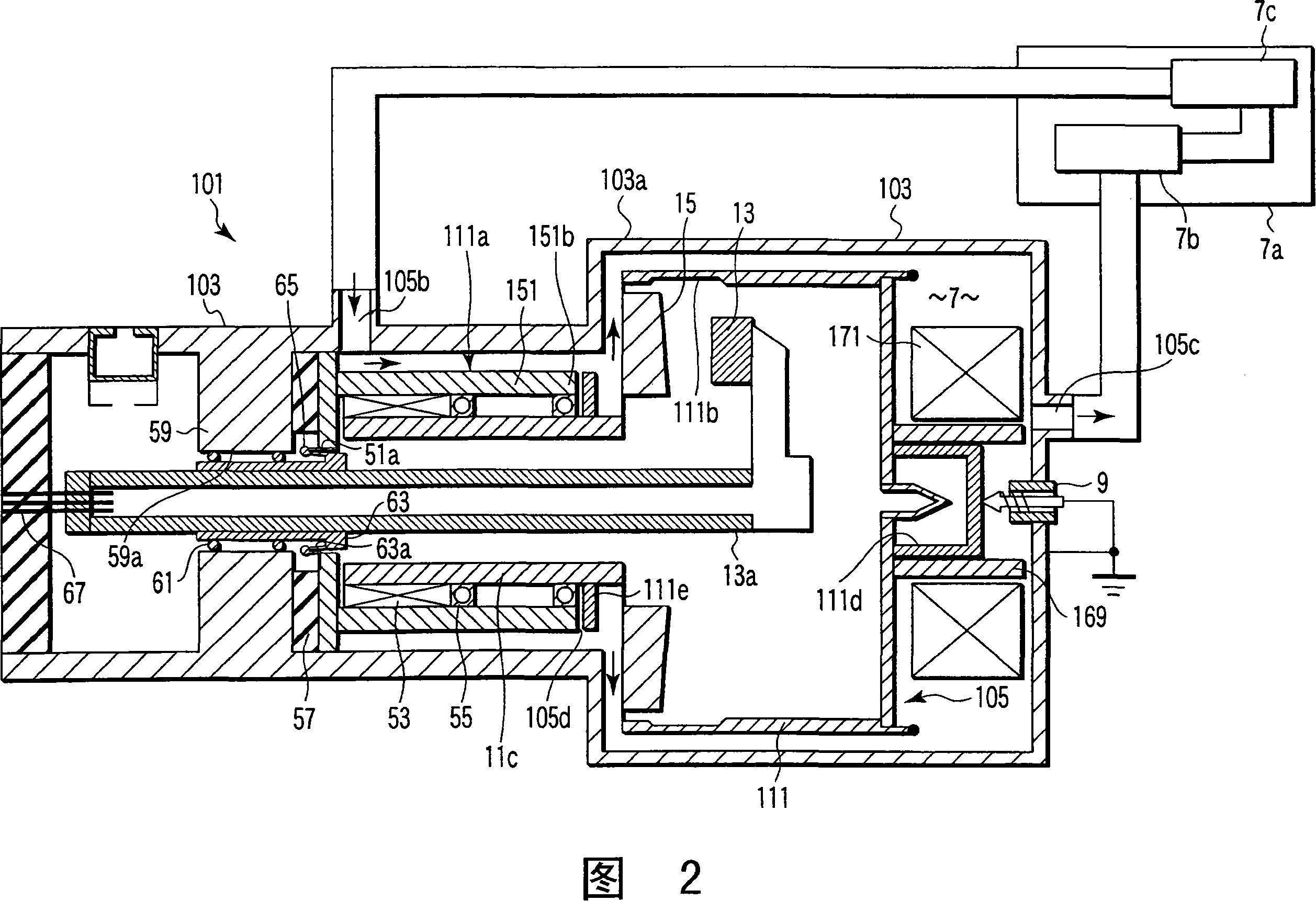

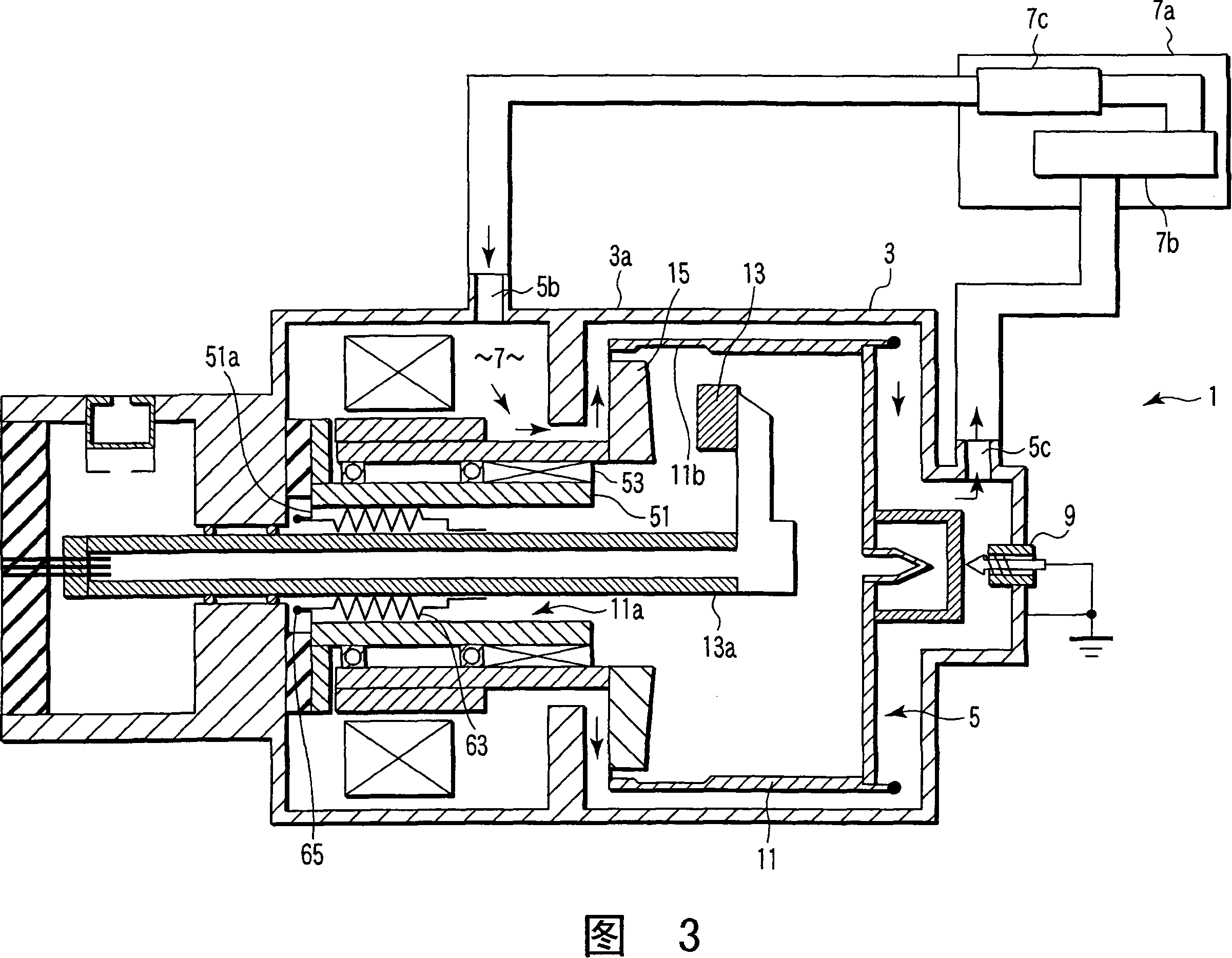

[0052] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0053] As shown in FIG. 1 , the X-ray tube assembly 1 is configured, for example, as an X-ray imaging diagnostic device and a non-destructive tester. The X-ray tube assembly 1 emits X-rays toward a target, ie, a test target. The X-ray tube assembly 1 has a housing 3 and an X-ray tube body (rotating anode X-ray tube) 5 . The X-ray tube body 5 is accommodated in the housing 3, and emits X-rays with a predetermined intensity in a predetermined direction.

[0054] The X-ray tube body 5 is accommodated at a predetermined position of the housing 3 by means of a coolant 7 . The coolant 7 is mainly composed of, for example, water, and is a non-oil cooling liquid (water-based cooling medium) having an electrical conductivity smaller than a predetermined value. A cooling medium having a conductivity of less than 1 mS / m is used as the coolant 7 to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com