Two-phase twenty-pole radial stator and rotor combined magnetic field electric motor

A combined magnetic field and stator technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit stationary parts, magnetic circuit rotating parts, etc., can solve the problem of magnetically concentrated transverse magnetic fields that are not suitable for small diameters Motor and other problems, to simplify the stator structure and manufacturing process, improve the air gap flux density, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

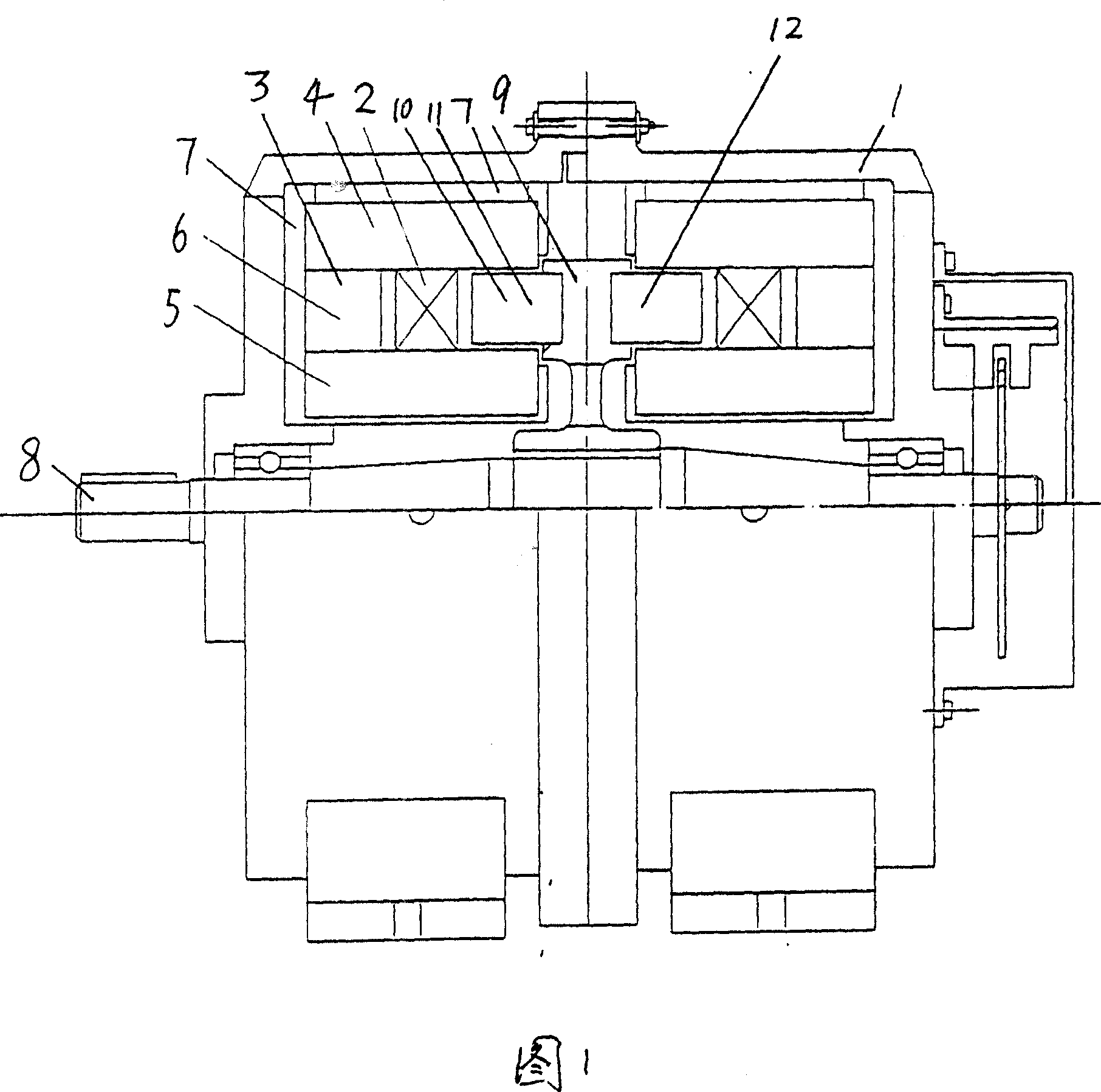

[0007] Embodiment: A two-phase 20-pole radial stator and rotor combined field motor, each group of stators 3 consists of outer stator core 4, inner stator core 5 and transition core 6 riveted by stacked rivets of iron core punching sheets A horizontally concave stator 3 is formed, the outer stator core 4 and the inner stator core 5 are staggered by a pole pitch along the axial cross section, the two-phase stator 3 is relatively staggered by half the pole pitch, the outer stator core 4 and the inner stator core The length and height of the sub-iron core 5 are the same. The stator 3 is limited by the end plate 7 on the housing 1 in the four directions of up, down, left, and right, and is fixed in the housing 1 by bolts. There are rotor spokes 9 on the rotating shaft 8, and the rotor spokes 9 has a rotor excitation ring 12 formed by alternating permanent magnet poles 10 and rotor cores 11, and adjacent permanent magnets 10 magnetic poles on the rotor excitation ring 12 are opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com