Reciprocation coating synchronous scraping steel strip roasting type cooker machine

A panci machine and reciprocating mechanism technology, which is applied in the field of sticky starch food extension and baking machinery, can solve the problems of poor density and fineness of thin slices, insufficient compactness of products, and affect the taste of products, so as to ensure uniformity, fineness, High production efficiency and dense texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

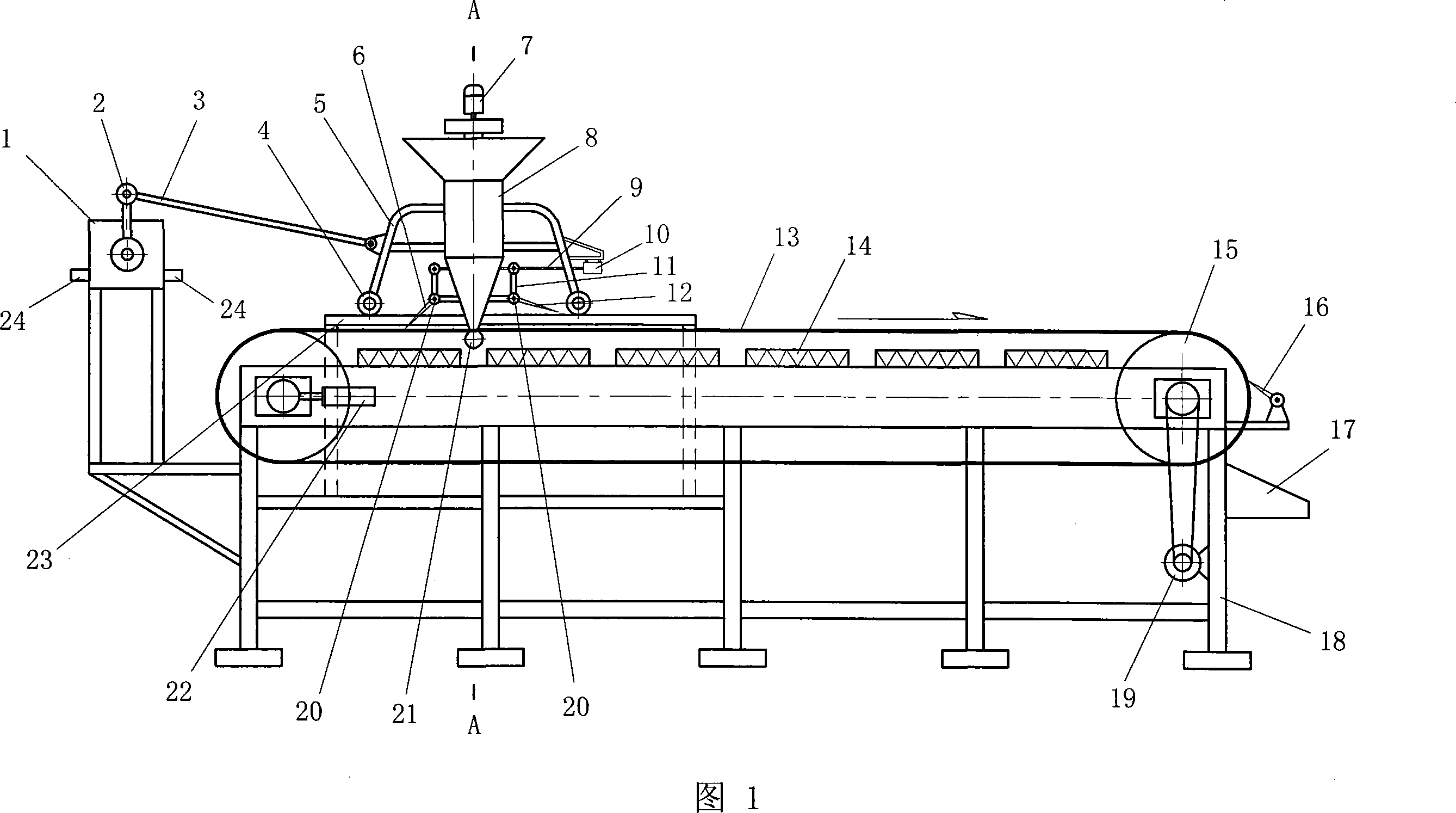

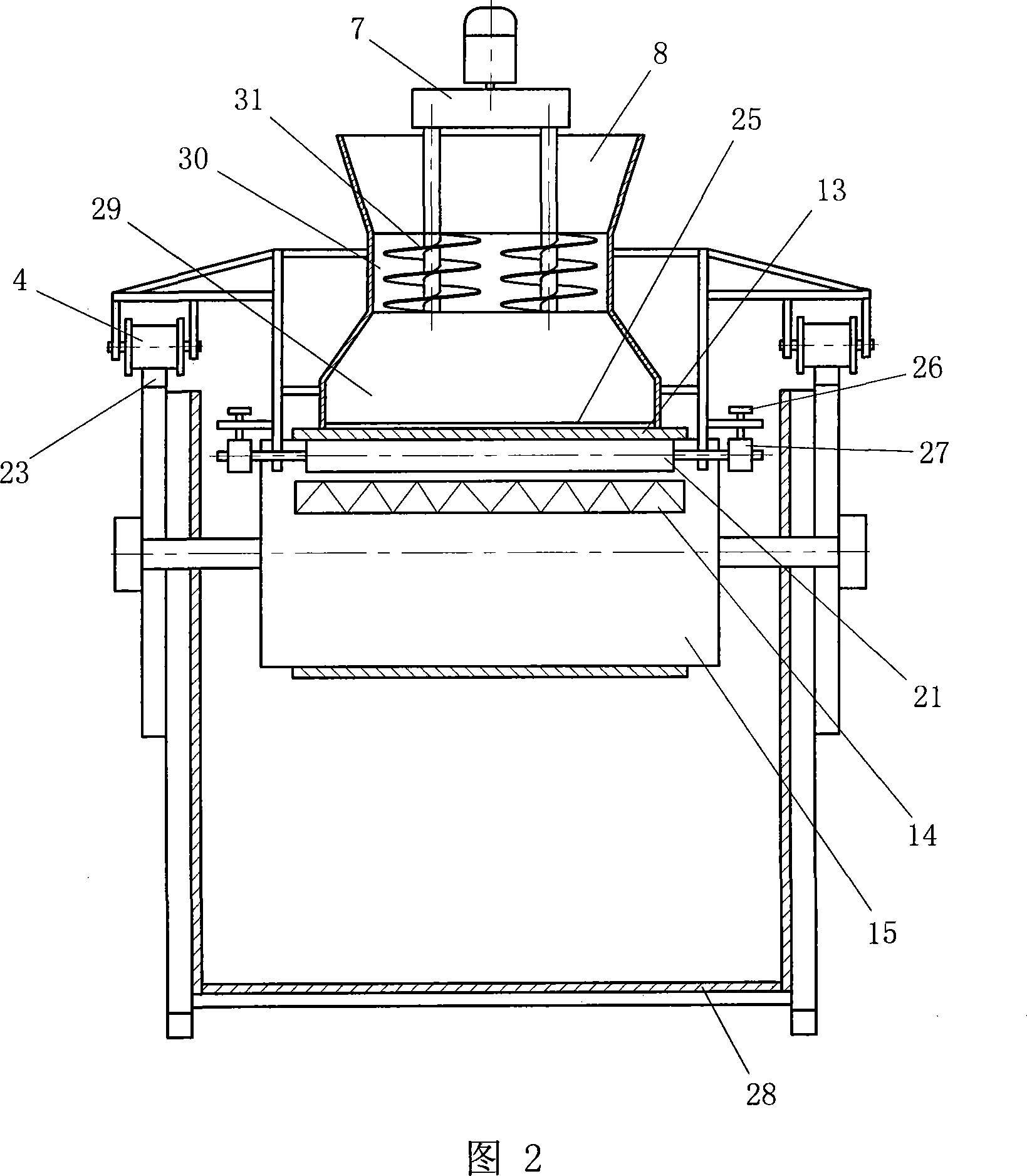

[0010] The present invention will be further described below with reference to the accompanying drawings.

[0011] Drive rollers 15 are respectively installed at both ends of the top of the elongated frame-shaped frame 18. Between the two drive rollers 15, there is a rotating stainless steel baking belt 13. The central axis of one of the drive rollers is connected with the reduction transmission mechanism 19, and the other A tensioner 22 is connected to the central axis of a drive roller; heaters 14 are evenly distributed between the upper and lower belts of the revolving baking belt 13, and heat preservation cover plates 28 are installed on both sides and the bottom surface of the revolving baking belt 13; Both sides of the revolving baking belt 13 are also provided with parallel guide rails 23, and the trolley 5 equipped with the feeding hopper 8 is connected to the guide rail 23 through its pulley 4. The middle part of the feeding hopper 8 is provided with a cylinder stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com