Ultrasound wave dishware cleaner

A dishwashing machine and ultrasonic technology, applied in the field of washing machines, can solve the problems of uneconomical, automatic dishwashing without ultrasonic wave, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

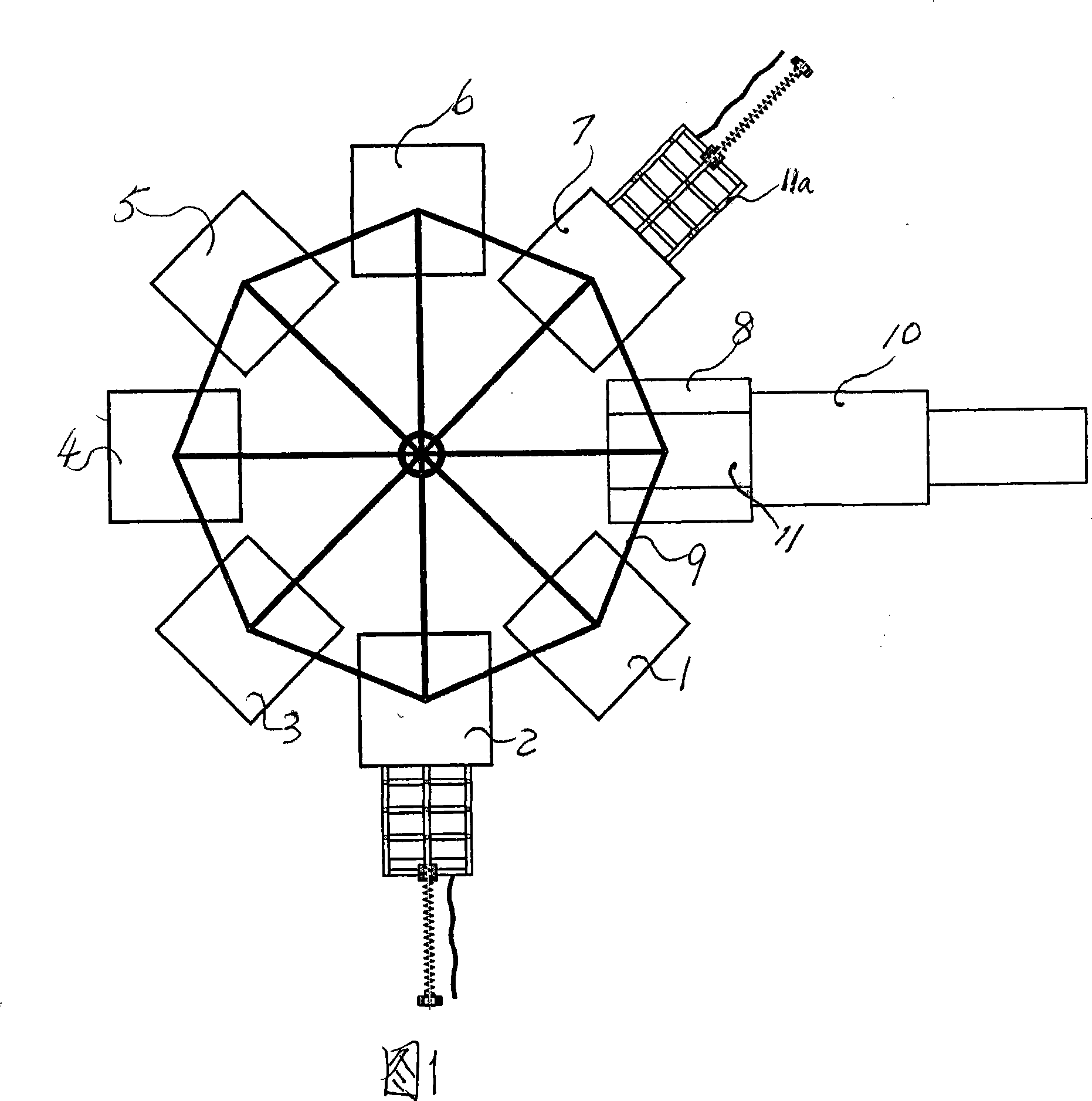

[0005] The present invention will be further described in conjunction with the above drawings. The cleaning machine is composed of eight stations: station 1 is a platform for placing tableware baskets, station 2 is a spray cleaning tank, station 3 is a heating tank, station 4 is a , 5 and 6 are three ultrasonic cleaning tanks, station 7 is the spray cleaning tank, station 8 is the position where the tableware basket is placed, this position is the end of the conveyor belt 11 of the drying tunnel 10, and the heating element set in the drying tunnel is far infrared The heating tube, the temperature in the drying tunnel is 270°C, and the running time of the conveyor belt 11 in the drying tunnel is 20-30 seconds, so that the water on the tableware is dried. The above 8 stations are evenly distributed on a circle (see Figure 1).

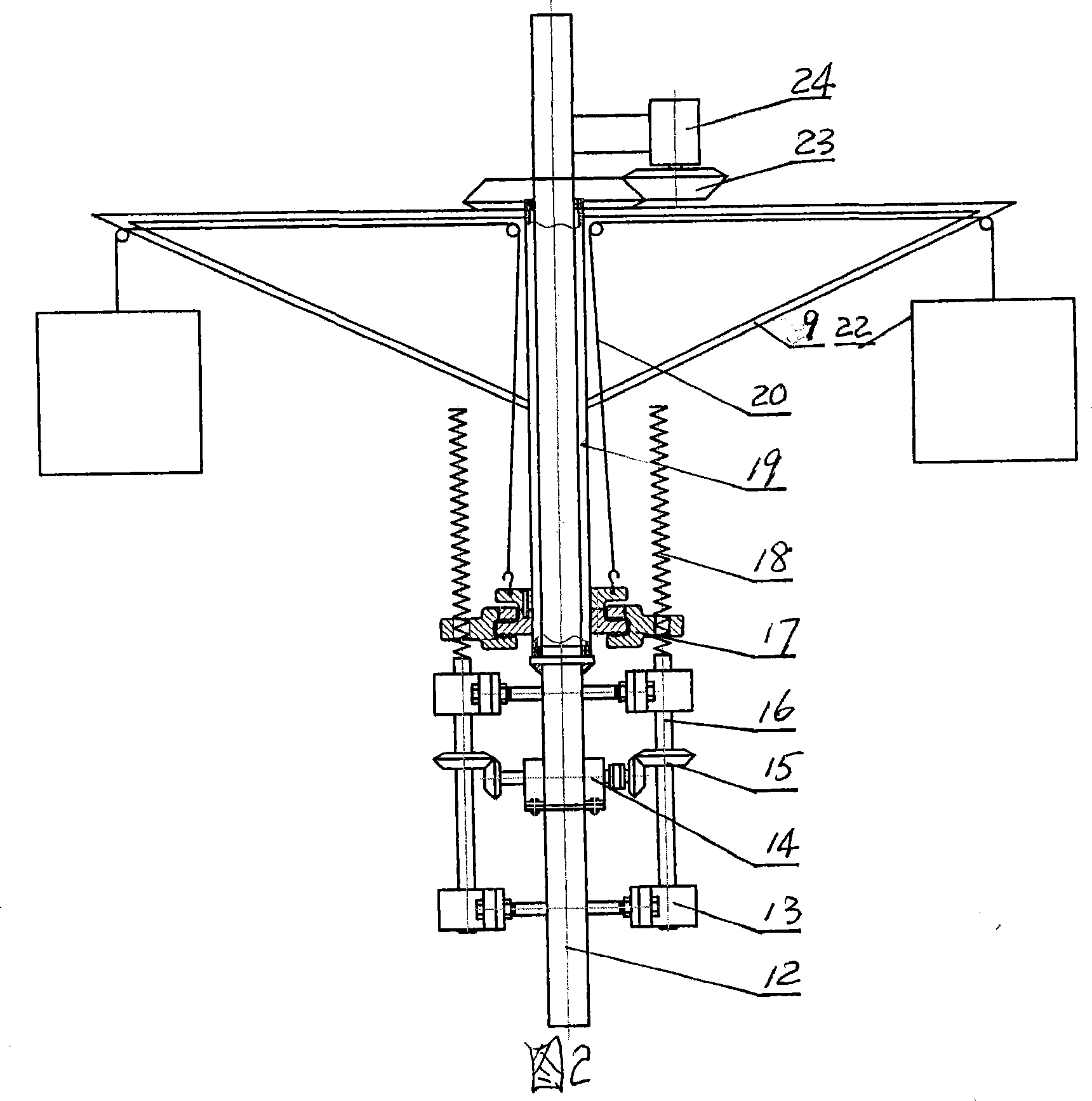

[0006] The lifting, lowering and rotating mechanism of the present invention is that the double-speed lifting motor 14 is fixedly connected to the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com