Automatic weighing charging type packer

An automatic weighing and packing machine technology, applied in the field of packing machines, can solve the problems of affecting work efficiency, inconvenient transportation and stacking, large randomness, etc., and achieve the effect of convenient transportation and stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

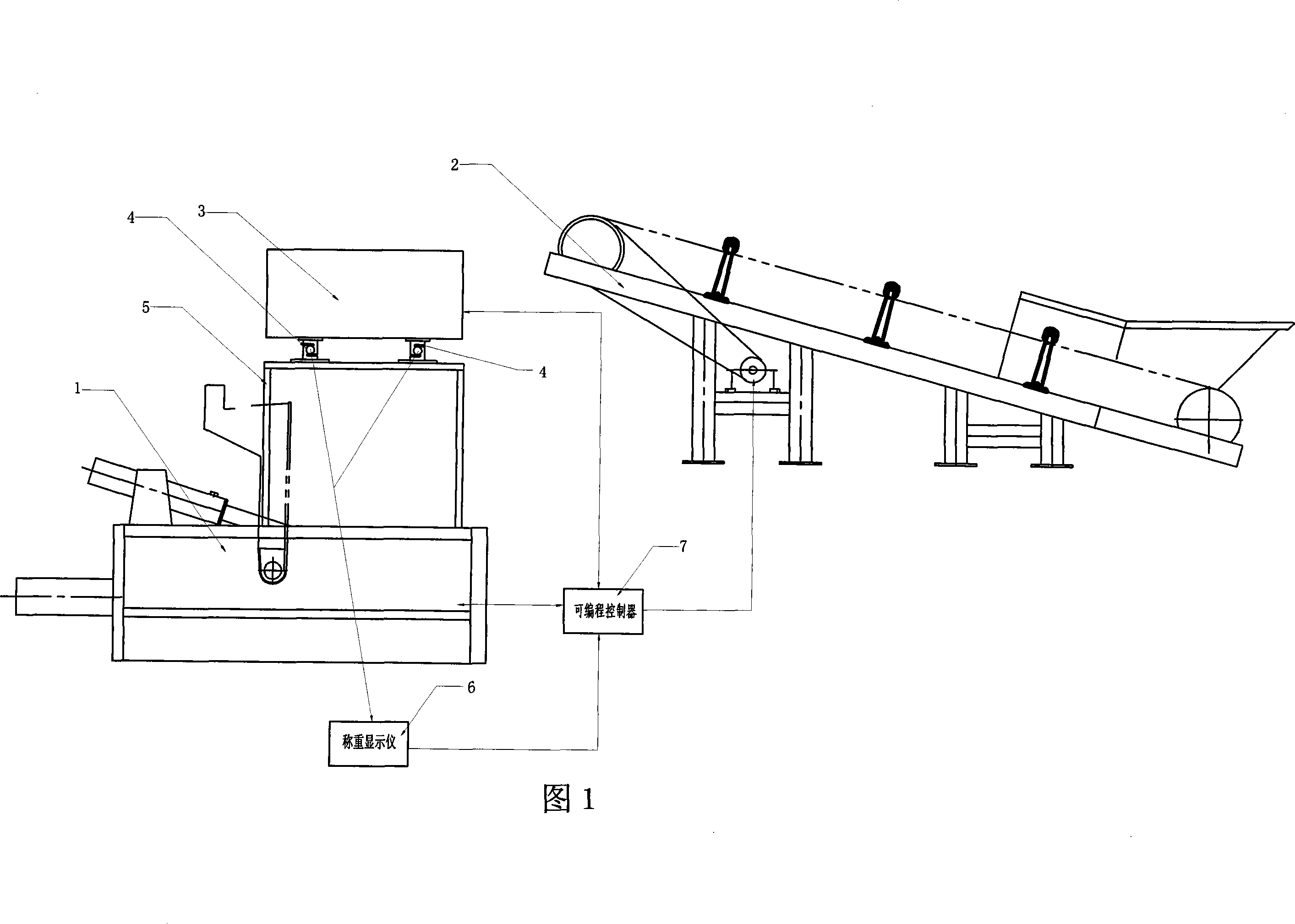

[0008] As shown in Figure 1, a kind of automatic weighing feeding type baler includes a baler 1 and a material conveyor 2, and is characterized in that it also includes a hopper 3, a frame 5, a load cell 4, a programmable control device 7 and weighing display instrument 6, the feeding hopper 3 is installed above the compression chamber of the baler 1 through the frame 5, and a load cell 4 is installed between the frame 5 and the feeding hopper 3, and the load cell 4 and the weighing The weighing display instrument 6 is connected, the weighing display instrument 6 is connected with the programmable controller 7, and the programmable controller 7 is respectively connected to control the feeding hopper 3, the material conveyor 2 and the packing machine 1.

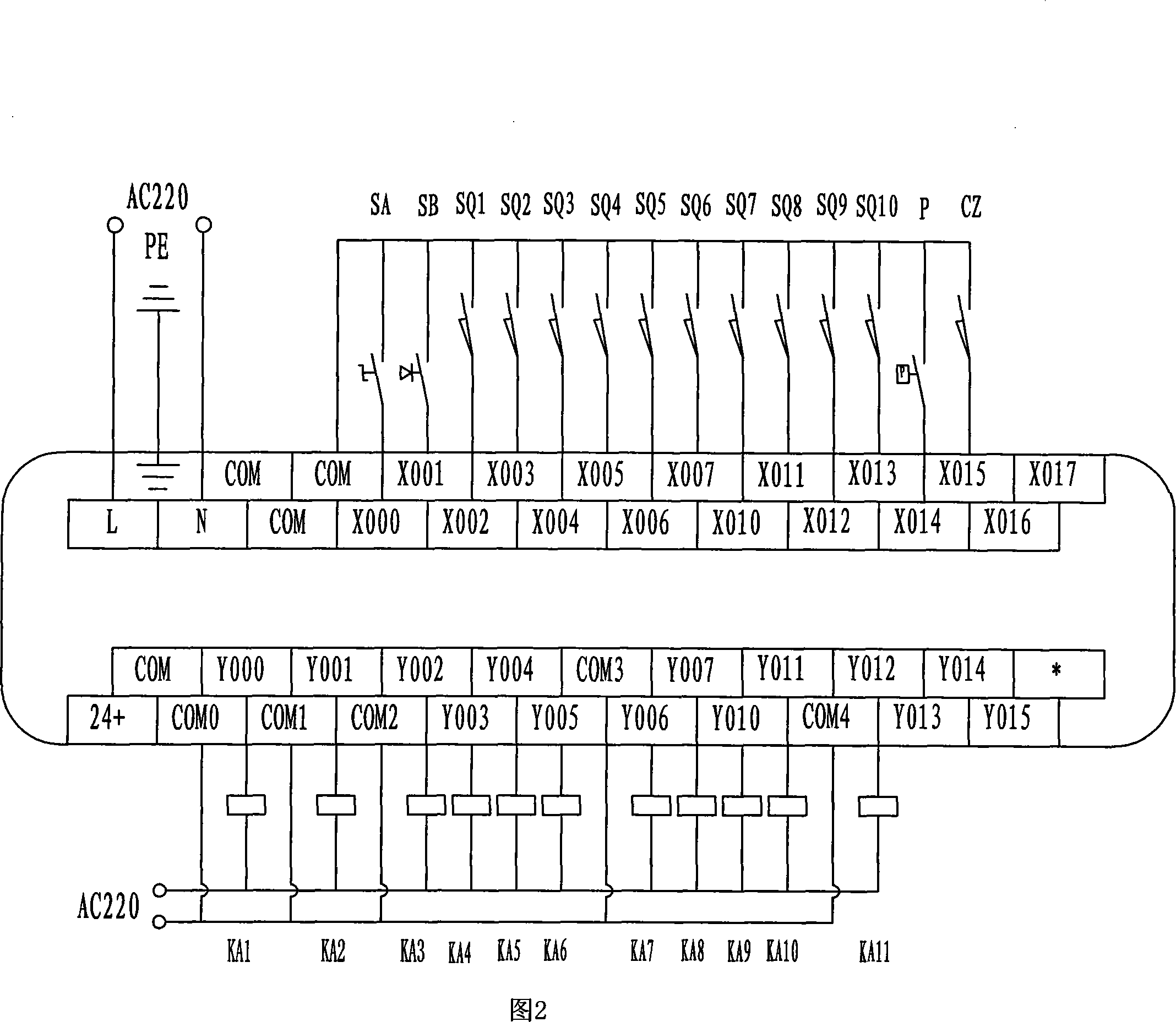

[0009] As shown in Figure 2, the circuit connection of the input terminal of the programmable controller 7 is: the input contacts X000~X007, X010~X015 of the programmable controller are respectively connected to the automatic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com