Box-type steel corrugated plate structure pipeline or container corner connecting structure

A corner connection and corrugated plate technology, which is applied to underwater structures, sewer piping systems, infrastructure engineering, etc. The effect of good performance, simplified production process and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

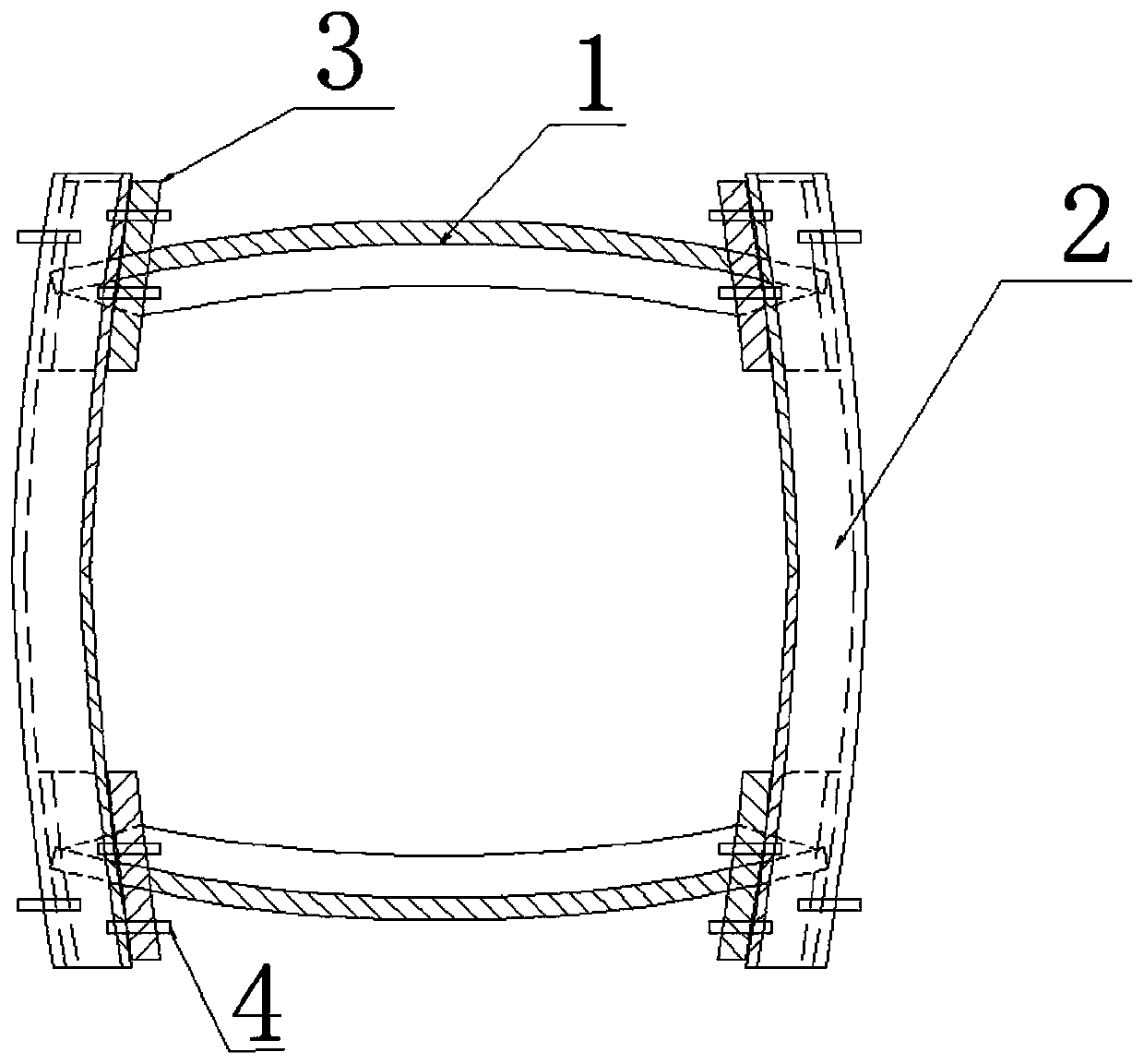

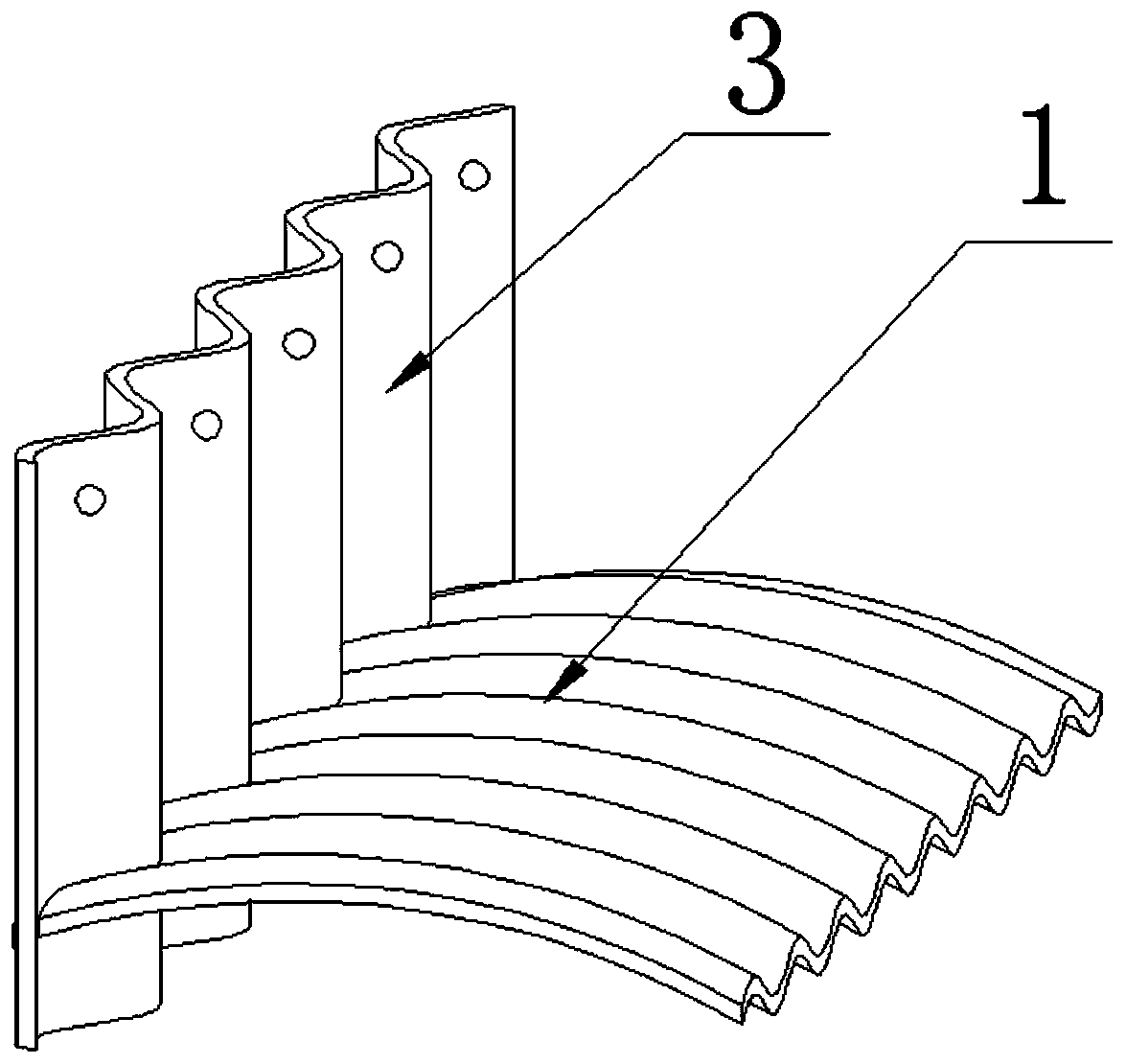

[0022] Such as figure 1 and figure 2 As shown, the present invention includes a pipeline or container assembled from four corrugated steel wall panels 2 up and down, left and right, and the board surfaces of every two adjacent corrugated steel wall panels 2 intersect at a certain angle, and the intersection line is a straight line, and the corrugated steel panels The corrugated pattern of the steel plate wallboard 2 is perpendicular to the intersecting line, wherein at least one corrugated steel plate wallboard 2 is composed of a first corrugated steel plate 1 and a second corrugated steel plate 3, such as figure 1 shown. The directions of the corrugated lines of the first corrugated steel plate 1 and the second corrugated steel plate 3 are both perpendicular to the intersection line. The end surface of the first corrugated steel plate 1 perpendicular to the direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com