Fastener turnover box

A turnover box and fastener technology, used in external accessories, rigid containers, containers, etc., can solve the problems of turnover box movement, potential safety hazards, loss of identification function, etc., to improve the safety factor, not easy to oil pollution, convenient The effect of stacking transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

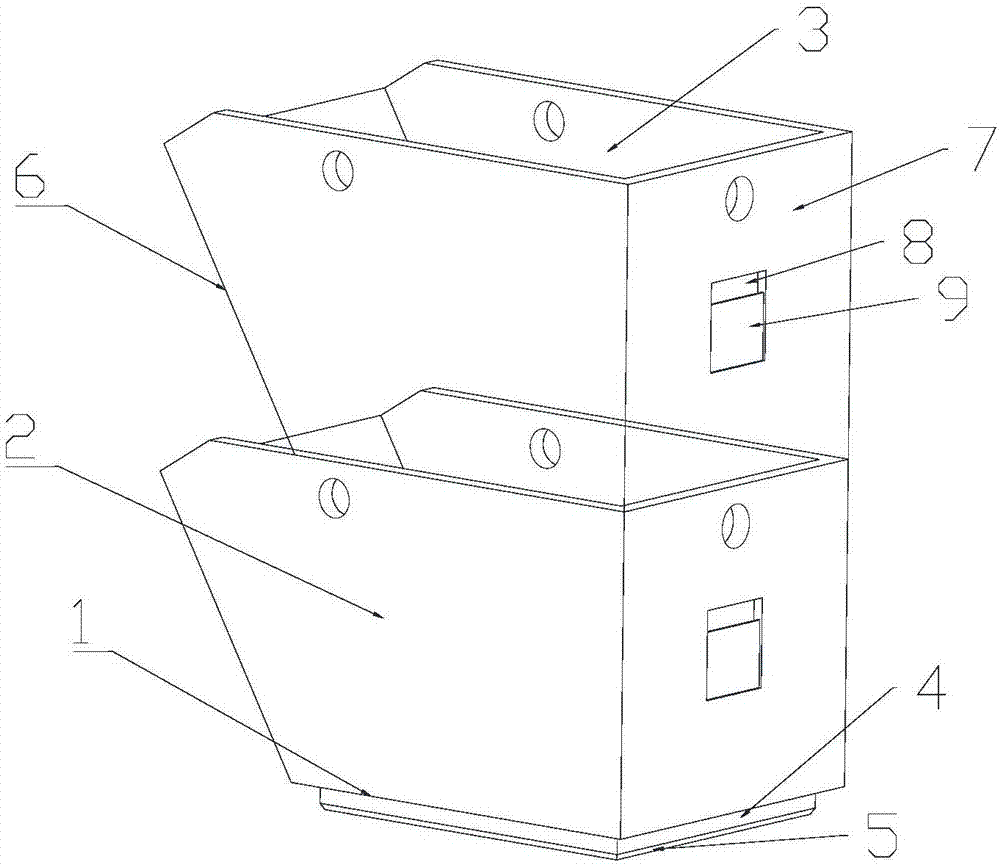

[0015] Such as figure 1 As shown, a turnover box for fasteners, the turnover box is a box with an opening 3 above it consisting of a bottom plate 1 and a number of side plates 2, and a limiting structure formed by a rectangular protrusion 4 under the bottom plate 1, The lower ends of the rectangular protrusions 4 contract inwardly to form a square truss 5 , which facilitates the insertion of the protrusions into the openings during stacking and serves as a guide. When two turnover boxes are stacked up and down, the limit structure of the upper turnover box can be snapped into the opening 3 of the lower turnover box, and the outer side of the bottom plate of the upper turnover box is placed on the side plate 2 of the lower turnover box . The bottom plate 1 is rectangular, and there are four side plates 2, three of which are perpendicular to the bottom plate 1, and the other side plate 6 is inclined outward at a certain angle. The side plate in the middle of the three side pla...

Embodiment 2

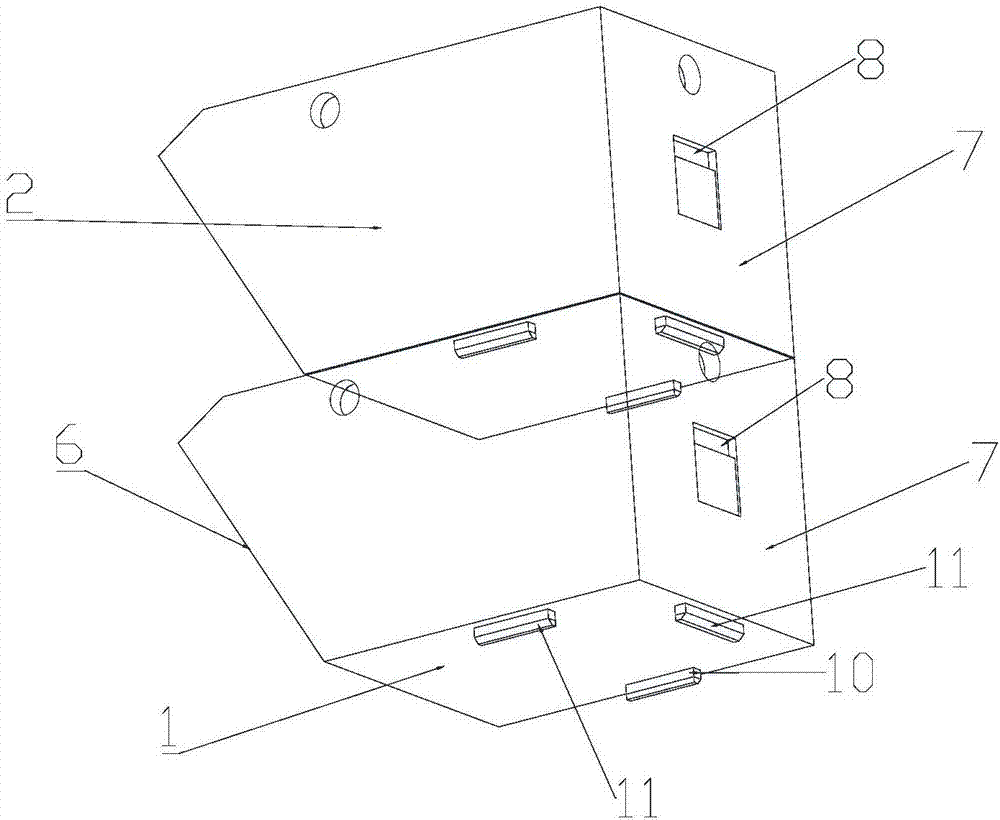

[0017] Such as figure 2 As shown, a turnover box for fasteners, the turnover box is a box body with an opening 3 above it consisting of a bottom plate 1 and a number of side plates 2, and a position-limiting structure consisting of three protrusions 10 below the bottom plate 1 When the two turnover boxes are stacked up and down, the three projections 10 all extend into the opening 3 of the lower turnover box and respectively resist the three side plates 2 of the lower turnover box, and the outer side of the upper turnover box bottom plate 1 is placed On the three side panels 2 of the turnover box of the lower floor.

[0018] The bottom plate 1 is rectangular, and there are four side plates 2, three of which are perpendicular to the bottom plate 1, and the other side plate 6 is inclined outward at a certain angle.

[0019] The lower ends of the three projections 10 have inwardly shrinking slopes 11 respectively, which facilitate the insertion of the projections 10 into the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com