Device for calcining gypsum in highland and method for calcining gypsum

A technology of calcining gypsum and calcining equipment, which is applied in the field of calcining gypsum equipment, can solve the problems of dead burning and raw burning of gypsum, and achieve the effect of preventing local dead burning and preventing raw burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

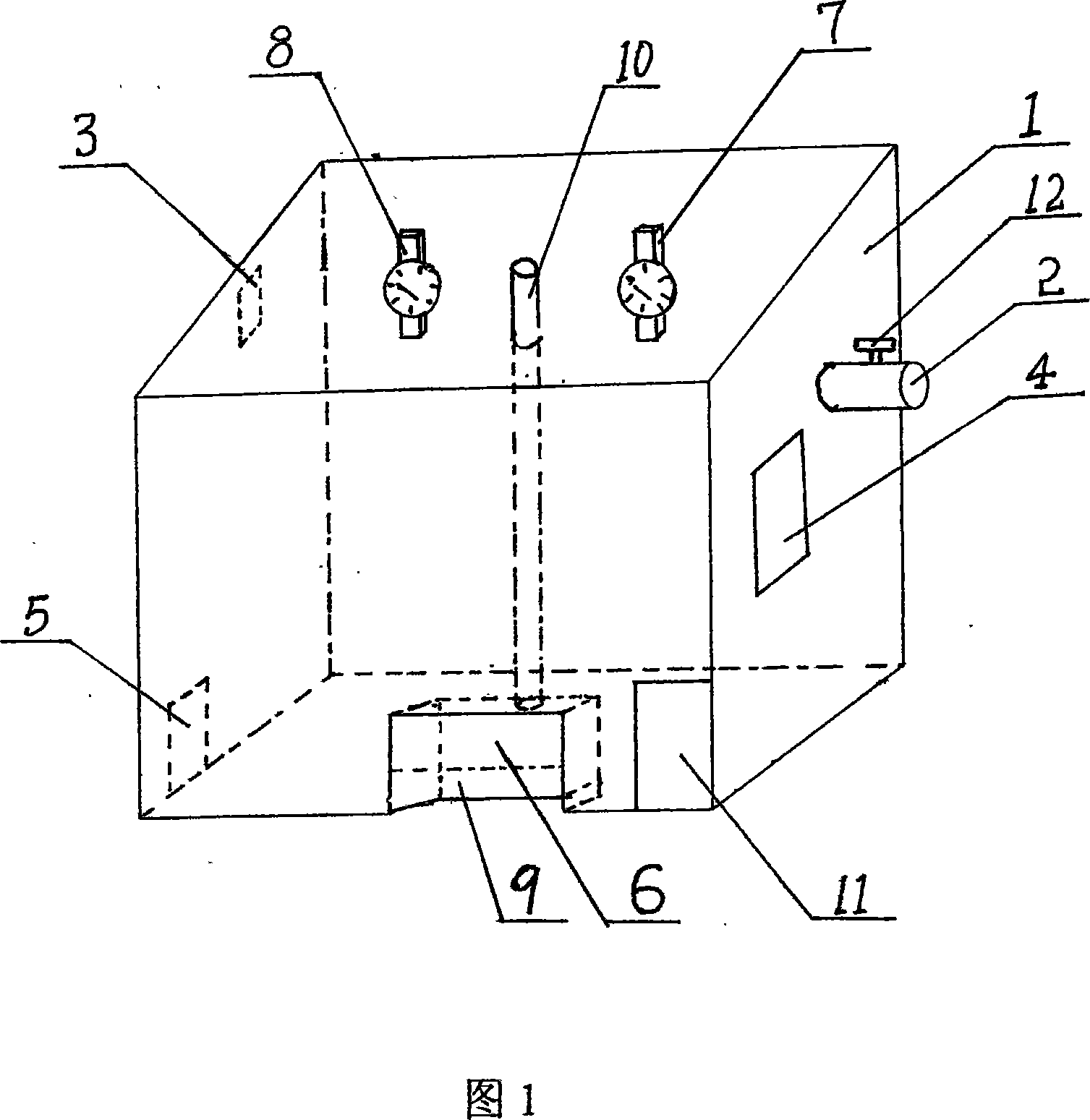

[0022] As shown in Figure 1, the calcined gypsum device on the plateau includes a closed space 1, and on the two sides opposite to the closed space 1, there are respectively provided with an air supply pipe 2 and an exhaust port 3 communicating with the inside of the closed space 1, and the air supply pipe 2 is provided with an adjustable on-off valve 12. A sealable feed inlet 4 and a sealable discharge outlet 5 are also provided on the side wall of the enclosed space 1 . The closed space 1 is also provided with a thermometer 7 and a barometer 8 , the thermometer 7 and the barometer 8 can measure the temperature and air pressure of the closed space 1 . The bottom in the confined space 1 is also provided with a coal heating device 6, the coal heating device 6 is provided with an air intake valve 9, which is used to let in air, so that the coal can be burned well, and the coal heating device 6 is also provided with a The connected exhaust flue 10 is used to discharge the exhaus...

Embodiment 2

[0029] Compared with Embodiment 1, the difference lies in that the calcining device 6 is a gas calcining device.

Embodiment 3

[0031] Compared with Example 1, the difference is that the calcining device 6 is an electric heating device, and the intake valve 9 and the gas flue 10 can be omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com