Labyrinth type axle head sealing device

A shaft end sealing and labyrinth technology, which is applied in the sealing of engines, clay preparation devices, cement mixing devices, etc., to increase resistance, prevent shaft end leakage and wear, and solve the problem of shaft end leakage and wear of stirring shafts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

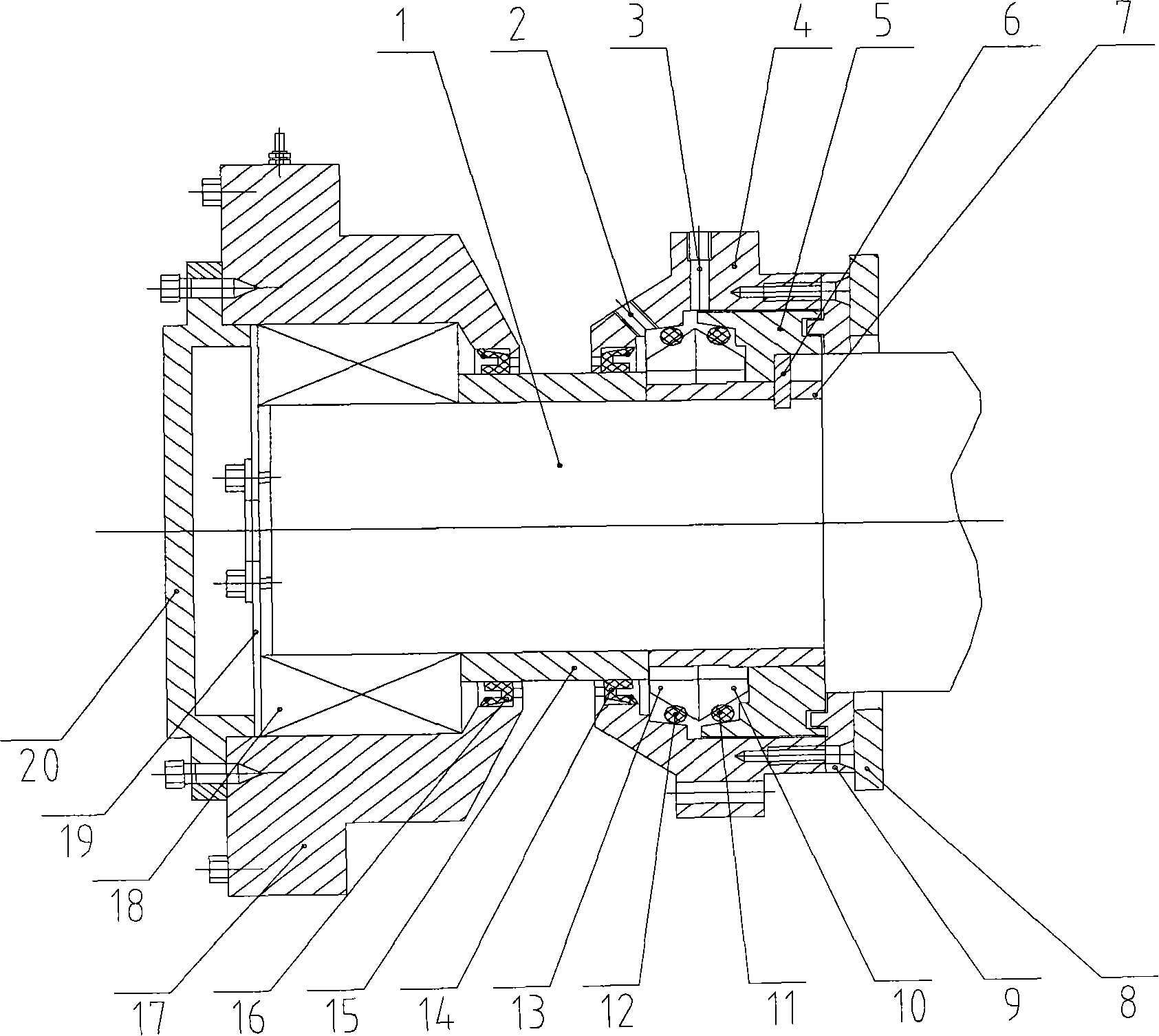

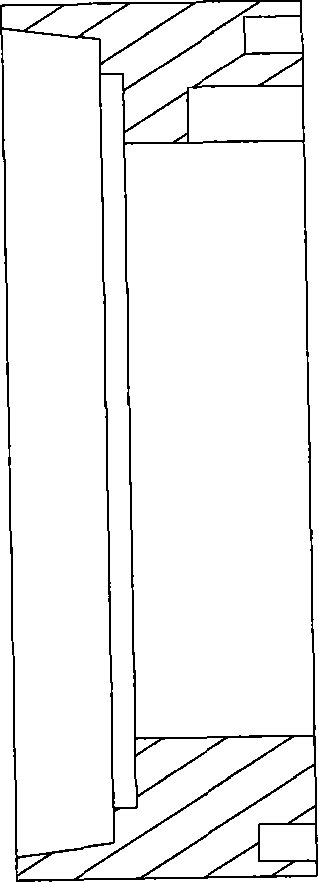

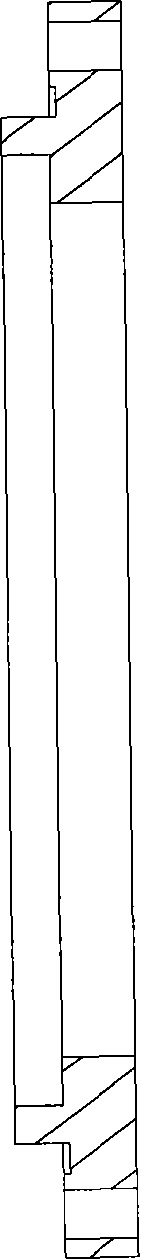

[0017] like figure 1 As shown, the labyrinth shaft end sealing device includes a stirring shaft 1, a first grease injection hole 2, a second grease injection hole 3, a fixed ring hub 4, a swivel hub 5, a positioning pin 6, a shaft sleeve 7, a protection Baffle plate 8, retaining ring 9, first floating seal ring 10, first "O" seal ring 11, second "O" seal ring 12, second floating seal ring 13, first skeleton oil seal 14, spacer 15. Second skeleton oil seal 16, bearing housing 17, supporting self-aligning bearing 18, bearing baffle 19, bearing end cover 20; protective baffle 8, retaining ring 9, fixed ring hub 4, and swivel hub 5 are sequentially connected or contacted ; The swivel hub 5 is connected with the shaft sleeve 7 and the stirring shaft 1 through the positioning pin 6, and the three rotate synchronously; There is a flange on the retaining ring 9, and the U-shaped ring groove of the swivel hub 5 matches the flange on the retaining ring 9, and the height and width of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com